Equal-high segmenting combined numerical controlling milling manufacture method of complex shaped parts

A CNC milling and high-segmentation technology, which is applied in the direction of program control, computer control, general control system, etc., can solve problems such as difficulty in meeting processing requirements and precision, affecting processing efficiency, and inability to cut, so as to achieve convenient consignment combination, improve work efficiency, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

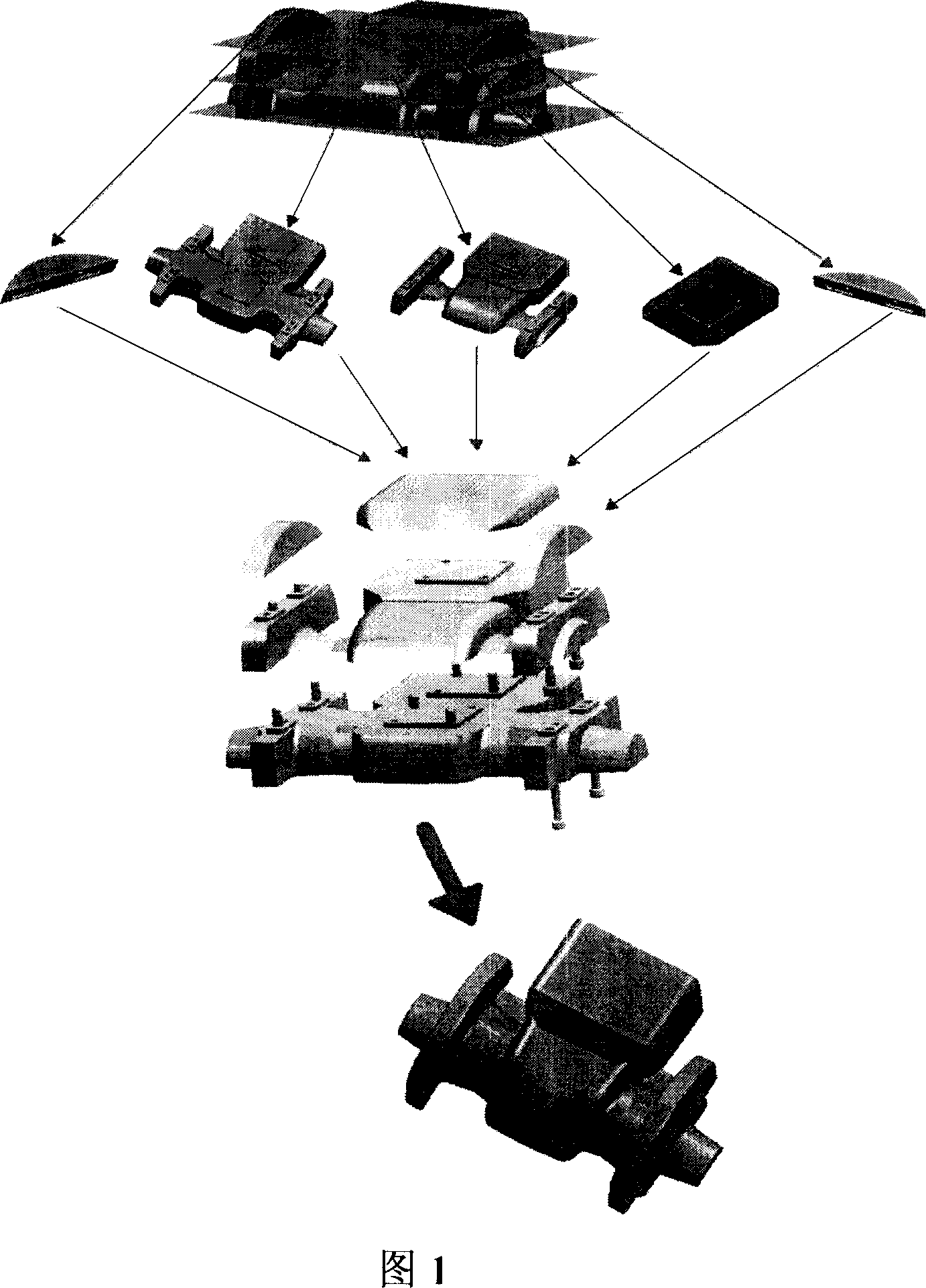

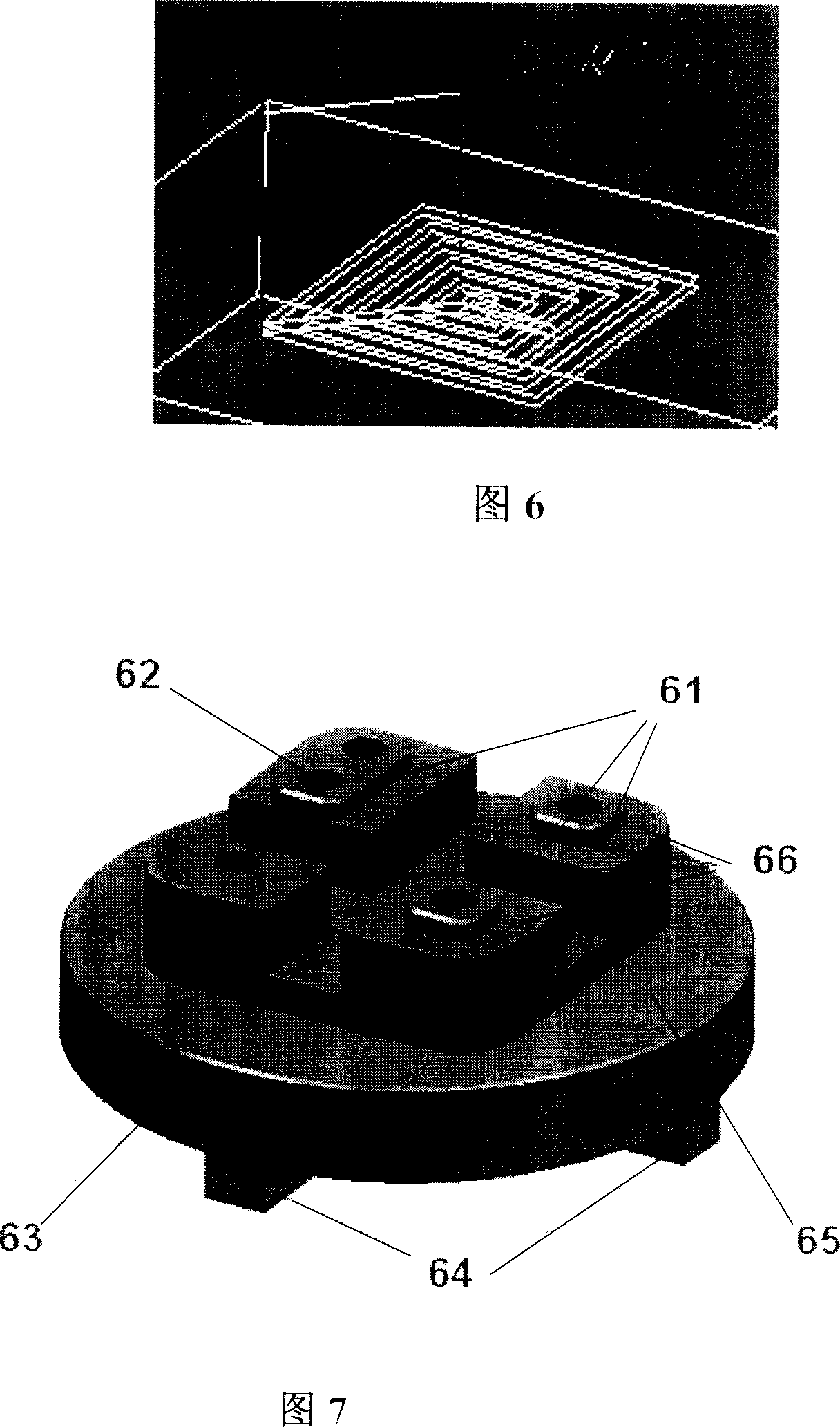

[0061] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0062] A kind of complex shape contour segmentation combined numerical control milling manufacturing method, comprises the following steps:

[0063] (1) Import or create solid models with complex shapes

[0064] Import the geometric information and manufacturing attributes of the complex body into the 3D graphics interactive CAD design system through the data interface, or directly create the solid model of the complex body in the system; this embodiment is carried out with the CAXAME system, and it can also be used in other systems with this function computer software system.

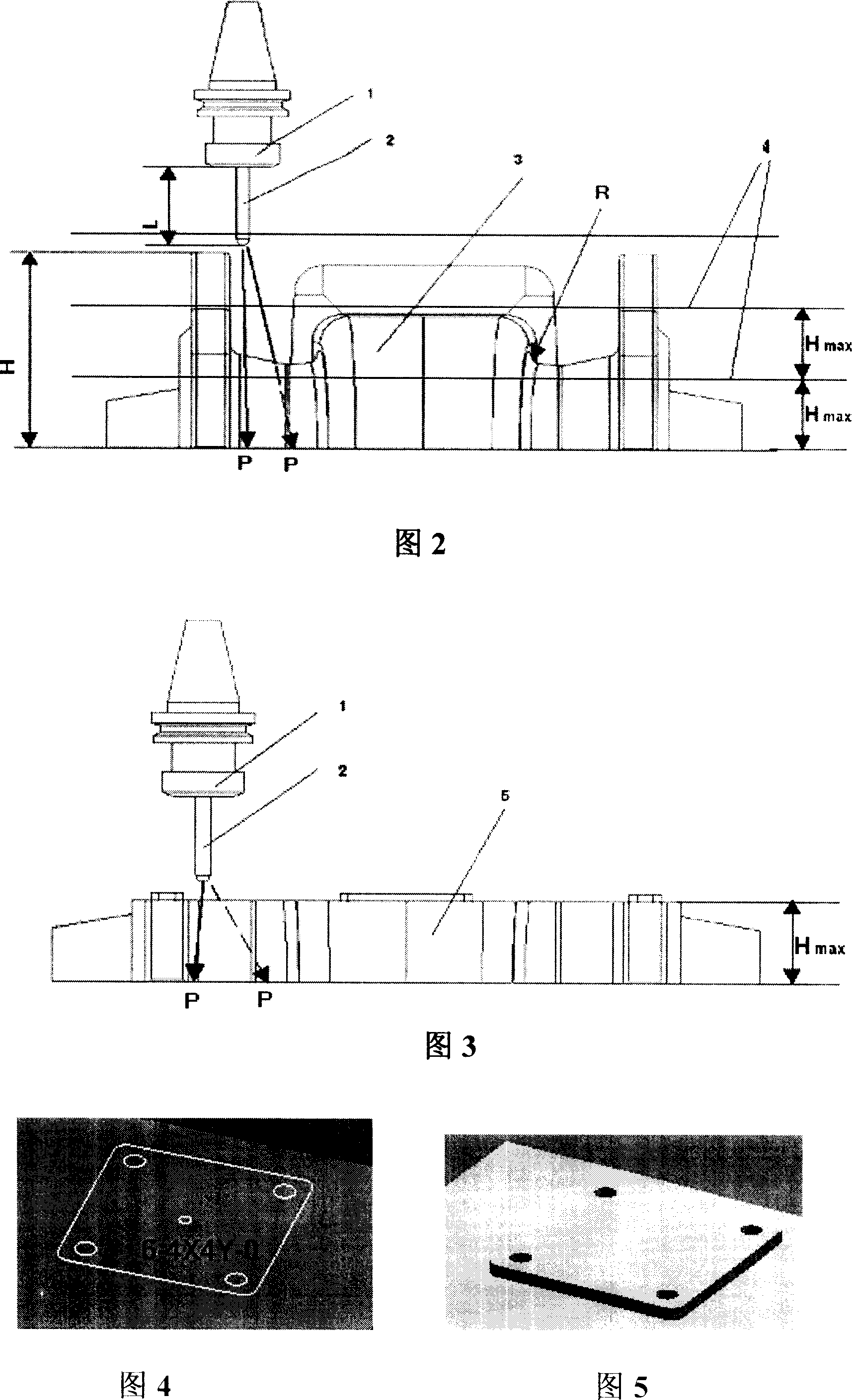

[0065] (2) Determine the contour segmentation parameter H max

[0066] Determine the diameter D of the milling cutter according to the minimum concave radius Rmin of the shape of the complex shape, the cutter diameter D is less than or equal to 2Rmin, the cutter len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com