Floating type honeycomb-shaped platform wind turbine

A honeycomb-shaped wind turbine technology, which is applied to wind turbine components, wind turbines, motors, etc., can solve the problems of complex structure, long design and manufacturing cycle, and high cost of floating wind turbines on cylindrical platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

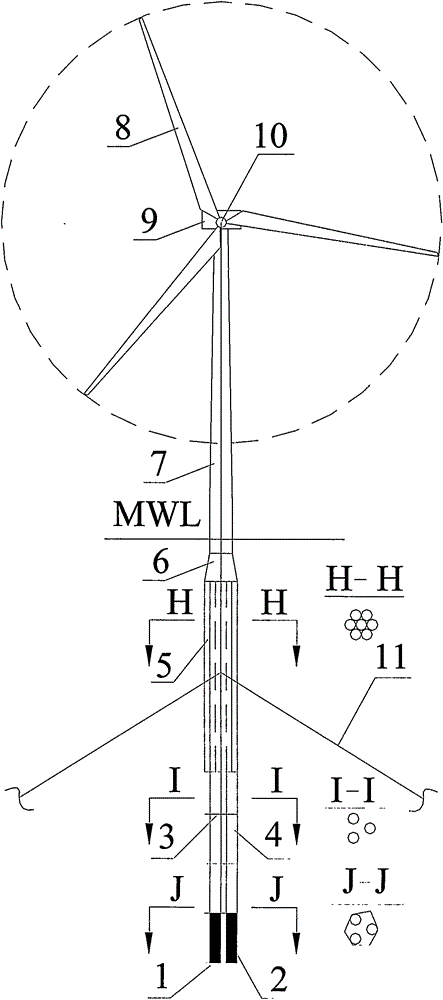

[0010] As shown in the drawings, a floating honeycomb platform wind generator is composed of blades 8, a generator cabin 9, a hub 10, a tower 7, a wedge 6 and a honeycomb platform. The rotor diameter of the blade is 126 meters, the power of the generator is 5MW, and the hub is 90 meters away from the sea level. The draft of the entire honeycomb-shaped platform is 120 meters, and the upper part of the honeycomb-shaped platform is composed of six peripheral steel pipes 5 surrounding a central steel pipe, which provide the required buoyancy for floating offshore wind turbines. These seven steel pipes are bundled together by welding their top ends to the bottom plate of the wedge 6, and further fastened by spot welding steel strips at the connection transition areas on the surfaces of the six peripheral steel pipes. The lower half of the honeycomb platform is formed by extending three of the above six peripheral steel pipes 4 to the keel plate 1 (please note that although the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com