Gantry type high-power plasma arc 3D printing equipment and method

A 3D printing and plasma arc technology, applied in the field of additive manufacturing, can solve the problems of complex maintenance, slow development, unfavorable popularization of 3D printing technology, etc., to improve flexibility and stability, convenient use and maintenance, and broad market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The features and advantages of the present invention can be further understood through the following detailed description in conjunction with the accompanying drawings. The examples provided are only illustrative of the method of the present invention and do not limit the rest of the present disclosure in any way.

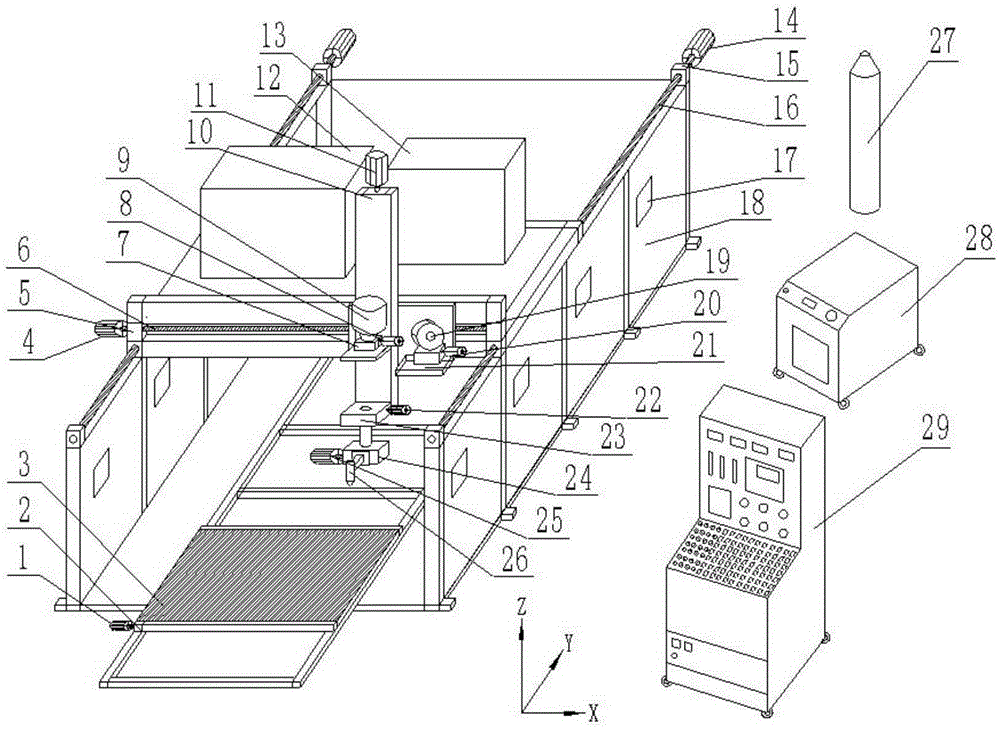

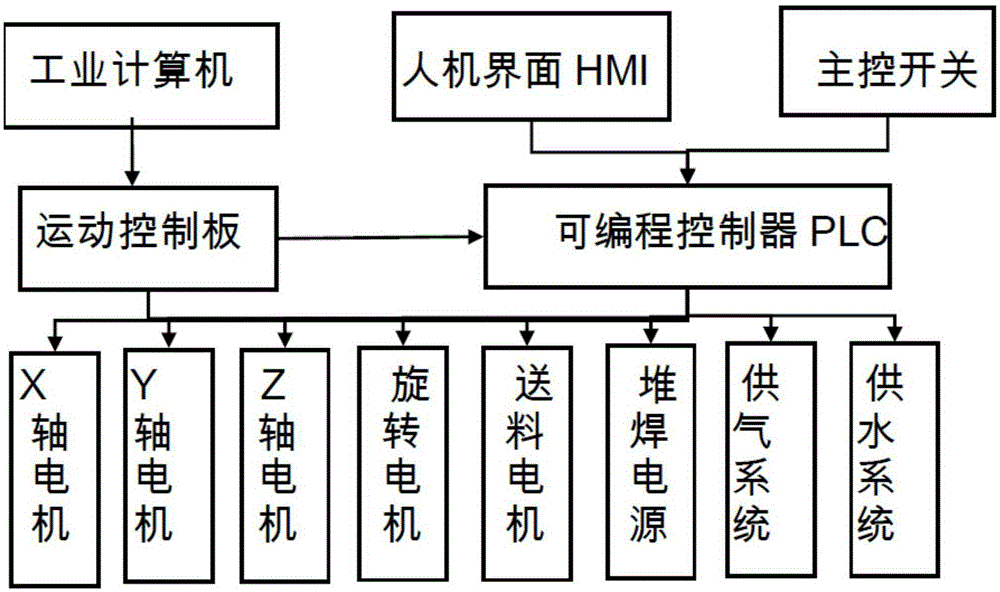

[0037] Such as figure 1 As shown, a gantry-type high-power plasma arc 3D printing equipment includes a frame, an elevated support wall, a printer head, a printing platform, an X-axis motion component, a Y-axis motion component, a Z-axis motion component, a powder feeding mechanism, and a swing device, printer head rotation mechanism, wire feeding device, surfacing welding power supply, electrical cabinet, the frame is a gantry structure, and the gantry platform of the frame is installed The platform is erected on the platform track of the frame, the Y-axis motion assembly is installed on both sides of the frame, the X-axis motion assembly is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com