Method for calculating engagement noises of spiral bevel gear pair

A spiral bevel gear, calculation method technique, applied in noise calculation. field, it can solve problems such as strong dependence on test data, increasing process difficulty, and increasing manufacturing costs, and achieve the effects of shortening the design and manufacturing cycle, improving design efficiency, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

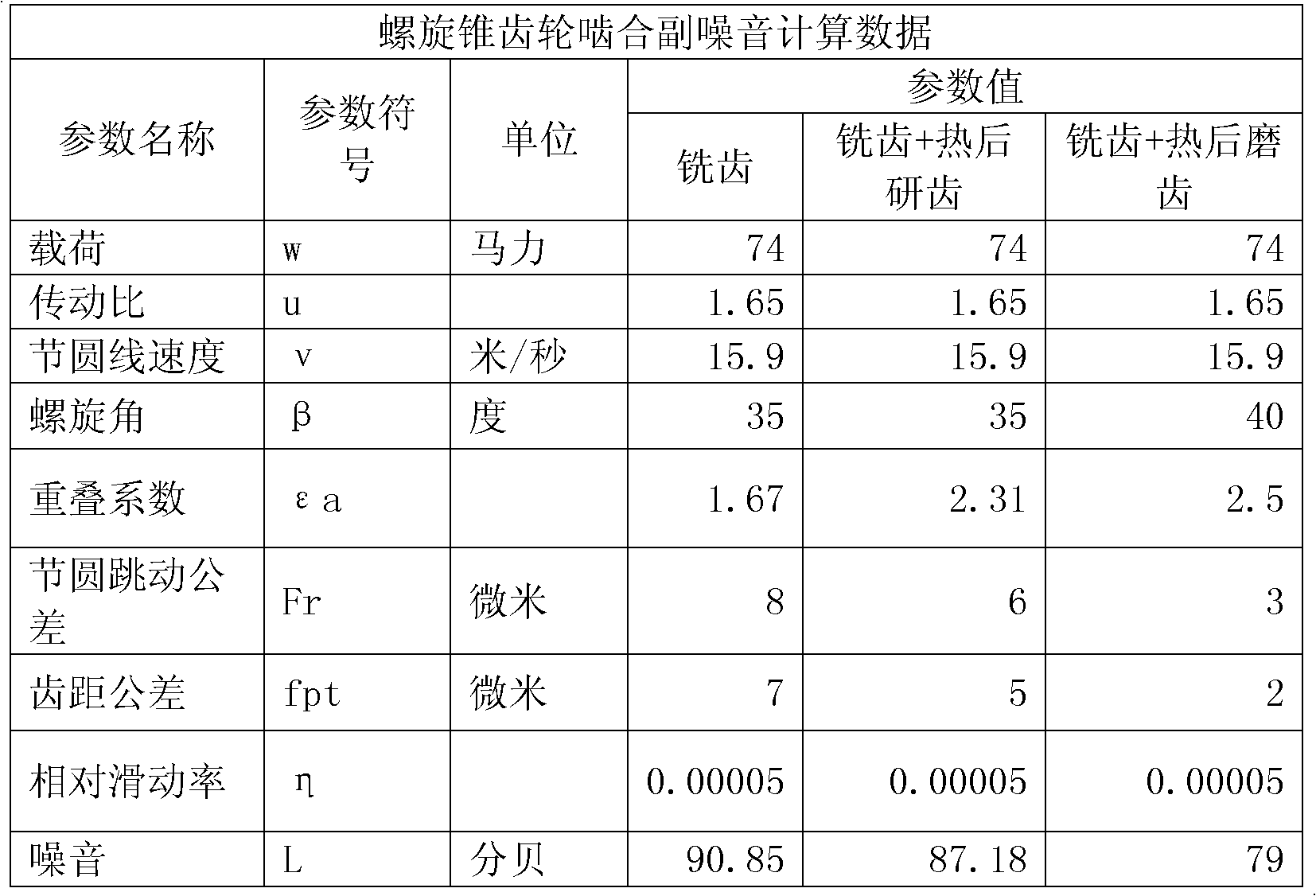

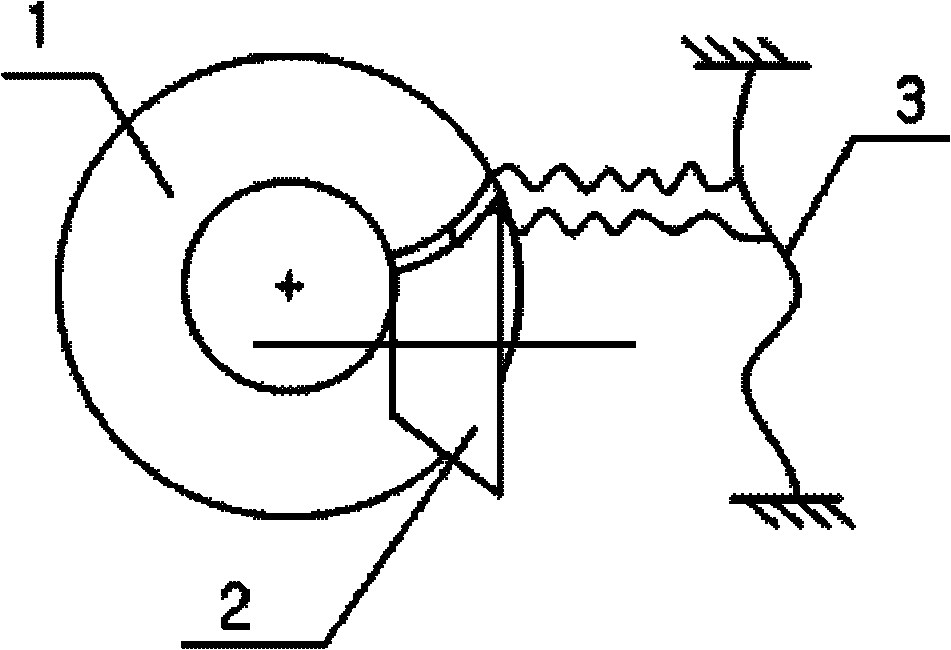

[0040] The teeth of the spiral bevel gear pair are used as springs, and the gear body is used as the vibration system of the mass; the installation system is set to be rigid without vibration, and the environmental noise is not included; the given load of the spiral bevel gear pair is 74 horsepower and the noise value is 80 decibels And select reference point 3, the distance between reference point 3 and the spiral bevel gear pair is 1 meter, the calculation steps of the meshing noise of the spiral bevel gear pair are as follows: see the attached table for the calculation data.

[0041] schedule

[0042]

[0043] 1. According to the vehicle design requirements, the meshing noise value of the spiral bevel gear pair is below 80 decibels, the input load of the driving wheel is 74 horsepower, the pitch circle speed of the driving wheel is 15.9 m / s, and the transmission ratio is 1.65. The helix angle of the gear pair is 35°;

[0044] 2. According to the above parameters, calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com