Metal shell cast bus and method for manufacturing same

A technology of metal casing and cast busbar, which is applied in the direction of cable/conductor manufacturing, line/collector parts, conductors, etc., can solve the problems of weak magnetic field shielding effect of metal casing, shorten the design and production cycle, flexibly apply layout, and improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

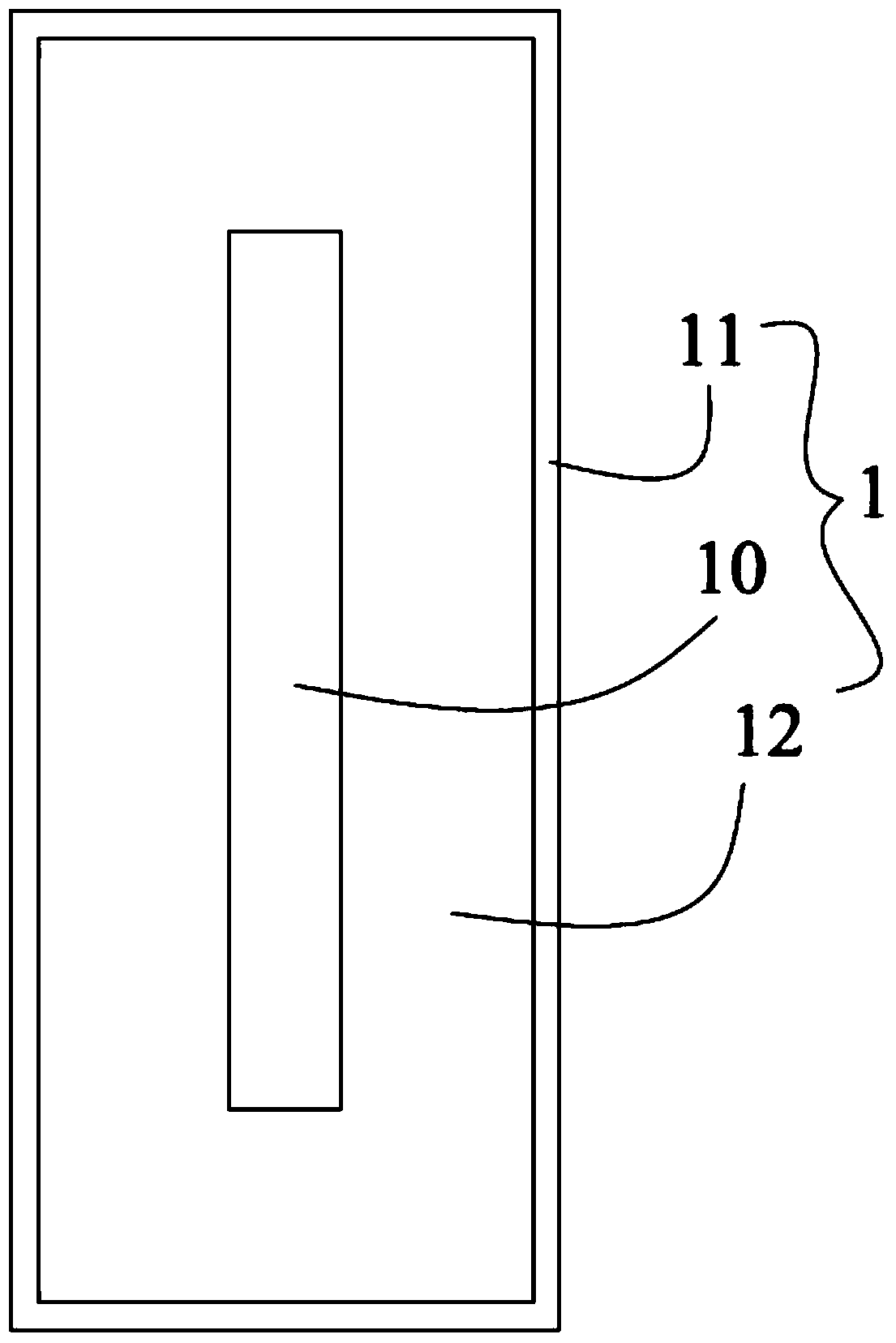

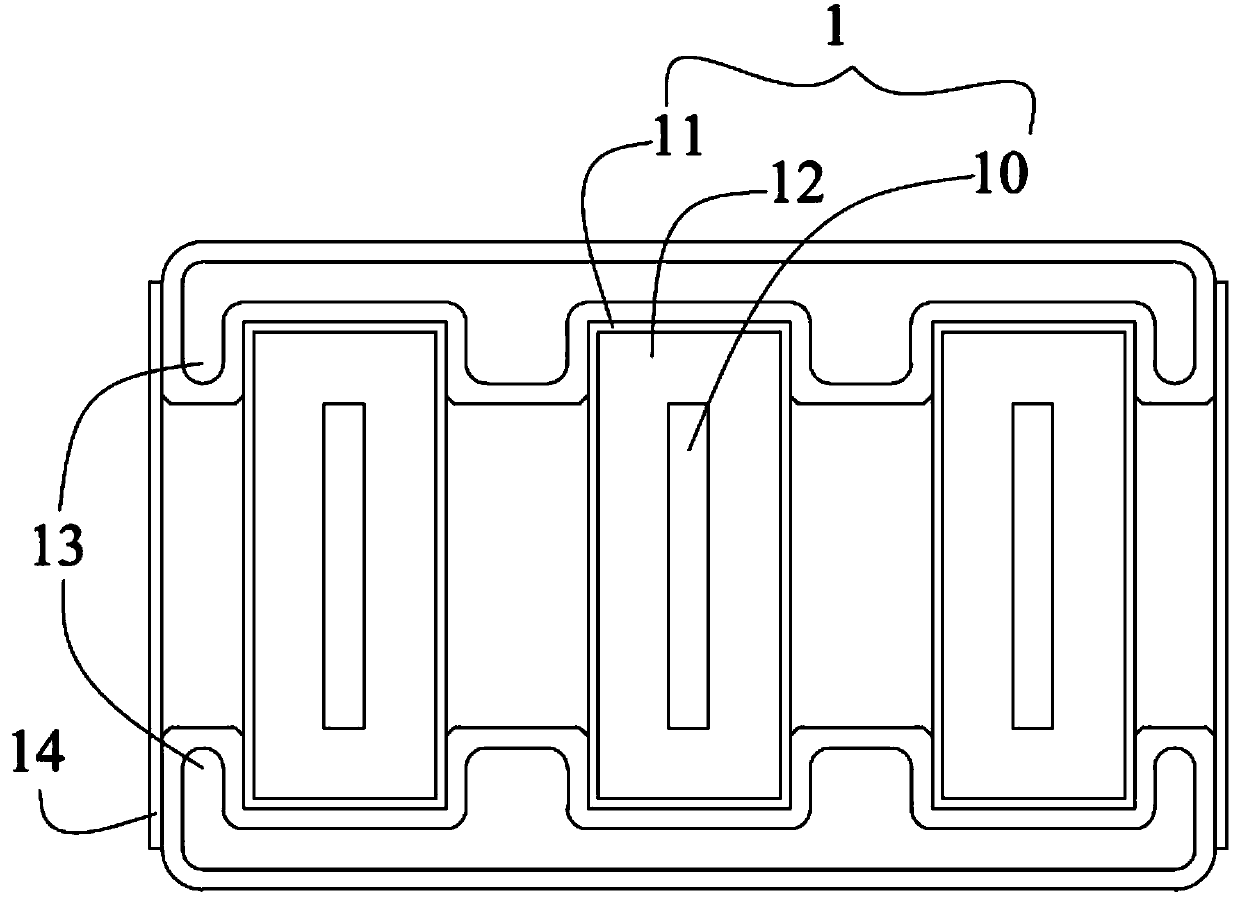

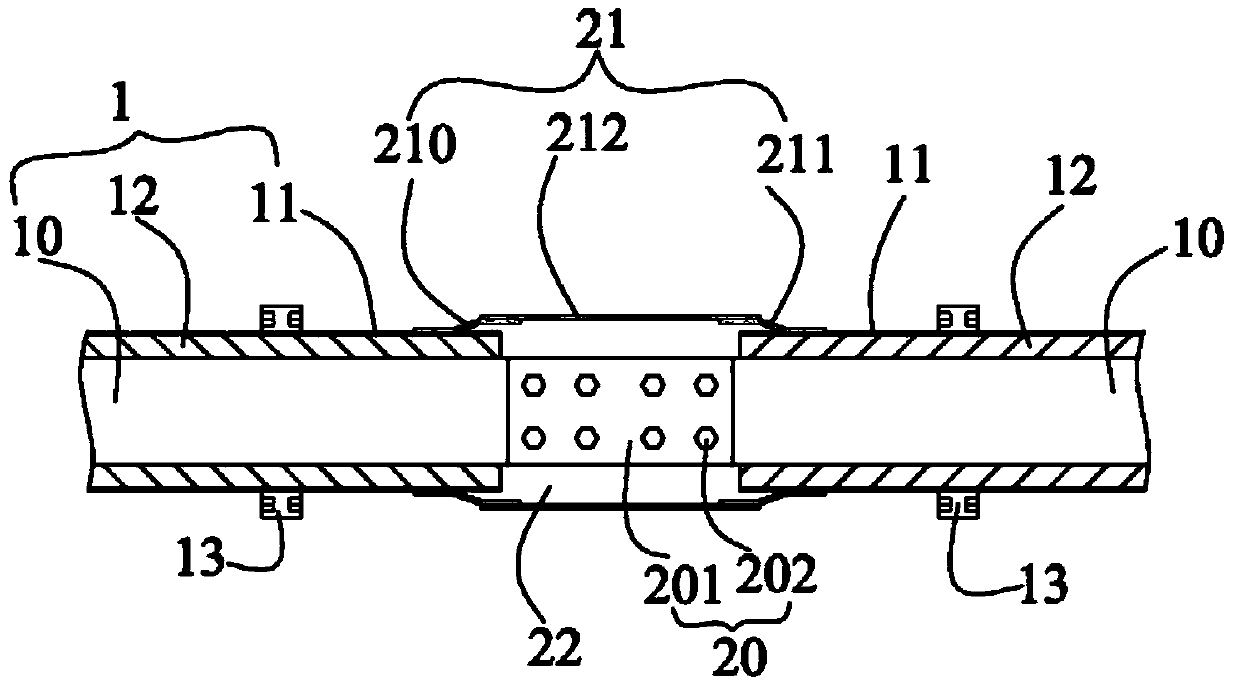

[0043] see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a metal casing pouring busbar, which includes: a plurality of standard unit sections 1; 1 combo linked together.

[0044] Among them, see figure 1 As shown, any standard unit segment 1 includes: an inner conductor 10 , a metal shell 11 and an intermediate insulating layer 12 . The metal shell 11 is sleeved on the outer side of the inner conductor. Preferably, the axis of the metal shell 11 coincides with the axis of the inner conductor 10 , and the length of the metal shell 11 is equal to the length of the inner conductor 10 . The mixed insulating material is poured between the inner conductor 10 and the metal shell 11 to form the intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com