Flexible welding jig device for automotive body

A technology for welding jigs and automobile bodies, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effects of reducing equipment costs, reliable structural design, and convenient welding and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

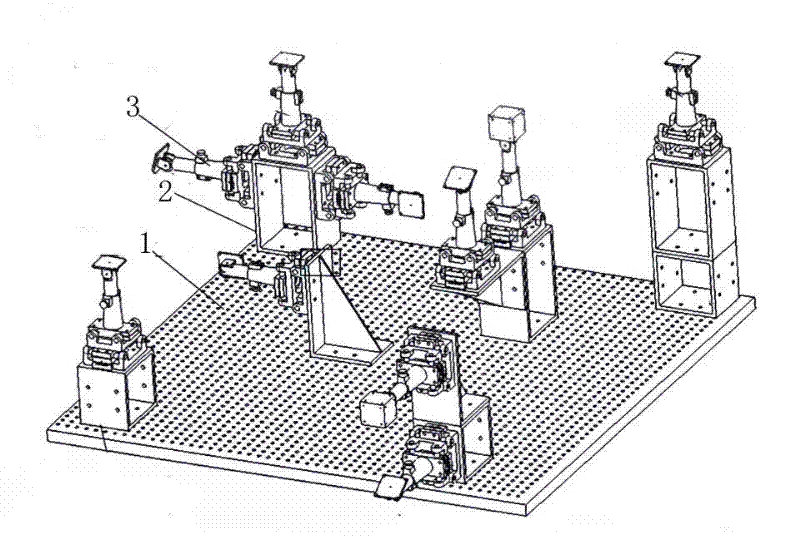

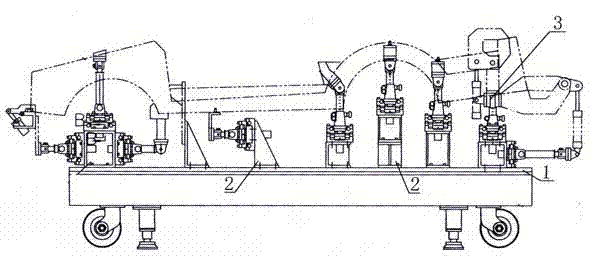

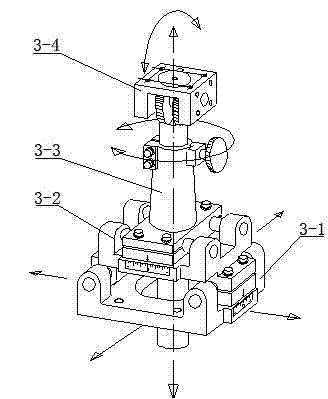

[0015] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-2 As shown, the automobile body flexible welding fixture device is composed of a hole system base plate 1, a transitional mounting bracket 2 and a flexible adjustable support 3. According to the requirements of different weldments, multiple flexible adjustable supports 3 can be installed on the base plate , to quickly build a welding fixture, characterized in that: such as Figure 3-6 As shown, the flexible adjustable support 3 is the core component of the flexible welding jig device for the automobile body, and consists of an X-direction adjustable sliding seat part 3-1, a Y-direction adjustable 3-3 and the swingable positioning clamp mounting seat part 3-4 are composed of four parts; as image 3 As shown, the X-direction adjustable sliding seat part 3-1 is composed of a guide shaft 3-1-1 and a base 3-1-2. The base 3-1-2 has a positioning pin hole, and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com