Polyurethane mixed component applied to slow-rebound damping pad and preparation method of polyurethane mixed component

A technology of polyurethane composite materials and vibration damping pads, which is applied in the field of polyurethane applications, and can solve the problems of single appearance color, narrow adjustment range of density and hardness of vibration damping sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

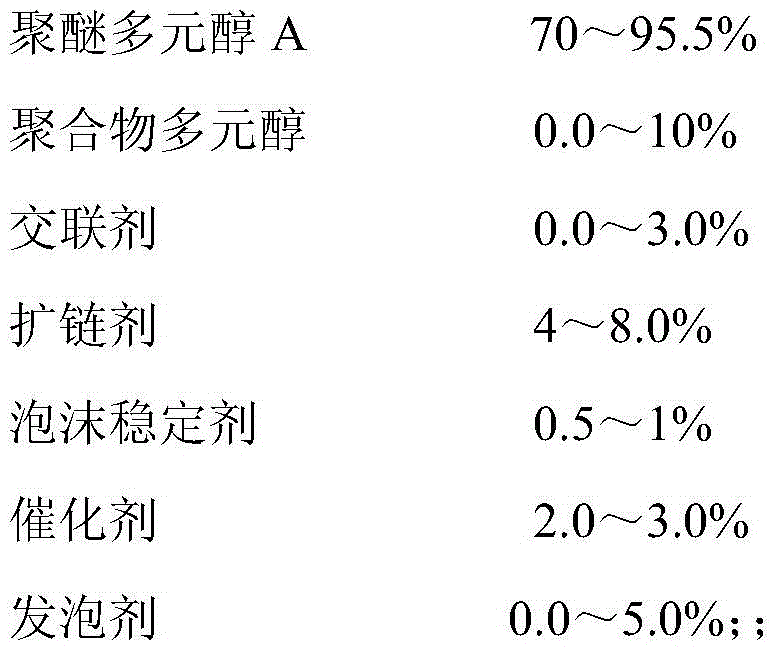

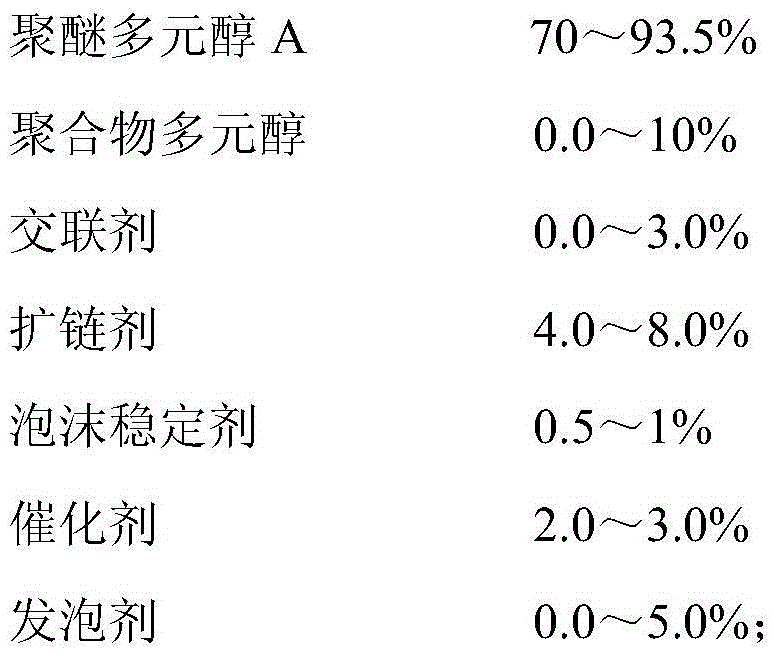

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of component A: Weigh 50kg of polyether polyol A (EP-330NG, Shandong Bluestar Dongda Chemical Co., Ltd.), 40kg of (SR-308, Kelia Polyol Co., Ltd.), CHP- H45 (Jiangsu Changhua Polyurethane Technology Co., Ltd.) 10kg. Ethylene glycol 6kg, organic silicon surfactant DC193 (American Gas Chemical Products Co., Ltd.) 0.5kg, AK-7703 (American Gas Chemical Products Co., Ltd.) 0.5kg, tertiary amine catalyst A-33 and delayed catalyst C-225 1.5kg and 1.5kg respectively, placed in the reactor and stirred for 20 minutes, after mixing evenly, discharged and sealed for storage.

[0037] (2) Preparation of component B: Weigh 10kg of polyether polyol B (EP3600, Shandong Bluestar Dongda Chemical Co., Ltd.), add at a temperature of 50-60°C, add MDI-50 (commercially available, Yantai Wanhua Polyurethane Co., Ltd.) 50kg, MDI-100 (commercially available, Yantai Wanhua Polyurethane Co., Ltd.) 10kg, M20S (commercially available, Shanghai BASF Co., Ltd.) 30kg, slowly raise the ...

Embodiment 2

[0040] (1) Preparation of component A: Weigh 55kg of polyether polyol A (ED-28, Shandong Bluestar Dongda Chemical Co., Ltd.), 20kg of (SR-308, Kelia Polyol Co., Ltd.), (DL -400, Shandong Bluestar Dongda Chemical Co., Ltd.) 20kg, diethylene glycol 6kg, organic silicon surfactant AK-7703 (American Gas Chemical Products Co., Ltd.) 0.5kg, tertiary amine catalyst A-33 and delayed Catalyst C-225 is 1kg and 1kg respectively, blowing agent HCFC-141B is 2kg, placed in the reaction kettle and stirred for 30min, after mixing evenly, the material is discharged and sealed for storage.

[0041] (2) Preparation of component B: Weigh 15kg of polyether polyol B (ED28, Shandong Bluestar Dongda Chemical Co., Ltd.), add at a temperature of 50-60°C, add MDI-50 (commercially available, Yantai Wanhua Polyurethane Co., Ltd.) 60kg, PM200 (commercially available, Wanhua Chemical Co., Ltd.) 25kg, slowly warming up to 70°C, heat preservation reaction for 40 minutes, sampling and testing, the mass content...

Embodiment 3

[0044] (1) Preparation of component A: Weigh 45kg of polyether polyol A (ED-28, Shandong Bluestar Dongda Chemical Co., Ltd.), (SR-308, 25kg of Kelia Polyol Co., Ltd., CHP-H45 (Jiangsu Changhua Polyurethane Technology Co., Ltd.) 10kg, glycerin 3kg, organic silicon surfactant (American Gas Chemical Products Co., Ltd.) AK-7703 (American Gas Chemical Products Co., Ltd.) 1kg, tertiary amine catalyst A-33 and delayed class Catalyst C-225 is 1.5kg and 1.5kg respectively, foaming agent water is 5kg, placed in the reaction kettle and stirred for 25min, after mixing evenly, the material is discharged and sealed for storage.

[0045](2) Preparation of component B: Weigh 20kg of polyether polyol B (ED-28, Shandong Bluestar Dongda Chemical Co., Ltd.), add at a temperature of 50-60°C, MDI-50 (commercially available, Yantai Wan Hua Polyurethane Co., Ltd.) 50kg, M20S (commercially available, Shanghai BASF Co., Ltd.) 30kg, slowly warming up to 75°C, keeping warm for 60 minutes, sampling and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com