Polyurethane composition for automobile sunroof cushion block and preparation method thereof

A technology for automobile sunroofs and buffer pads is applied in the application field of polyurethane to achieve the effects of long service life, improved sound insulation and noise reduction performance, and flexible molecular design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

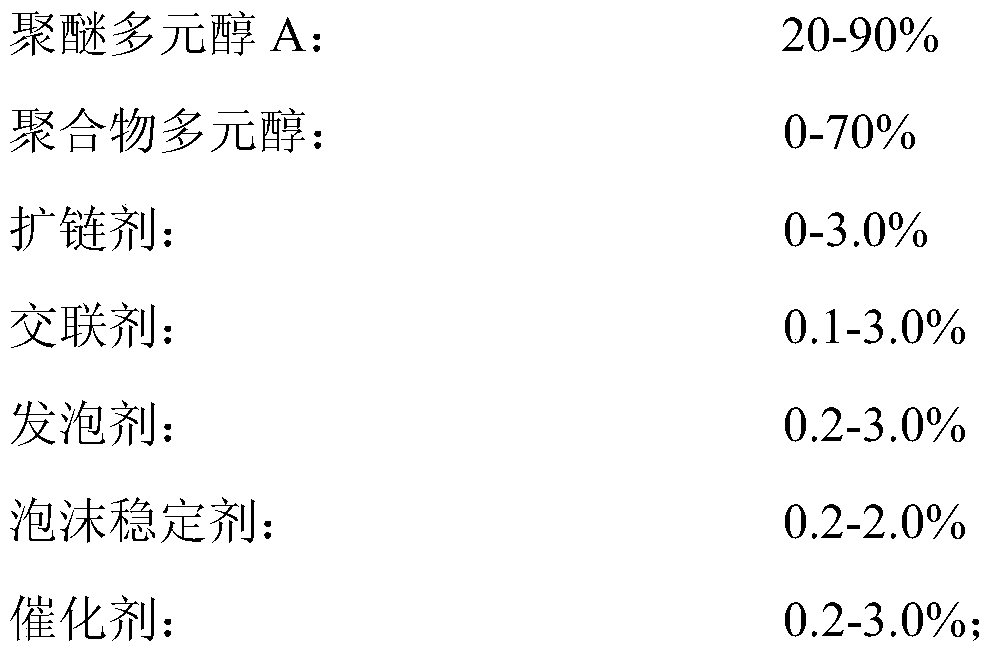

[0035] A component:

[0036]

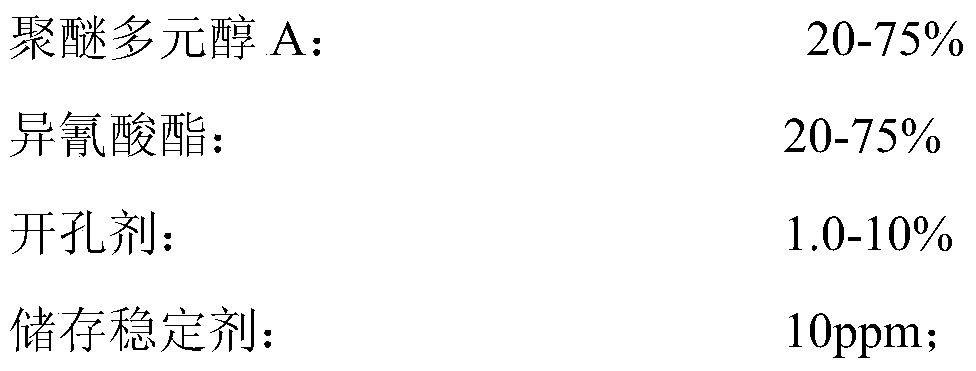

[0037] B component:

[0038]

[0039]

[0040] (1) Preparation of component A: the measured polyether polyol A, POP 36 / 28, DEOA, DC2525, A-1, A-33, H 2 Put O into the reaction kettle in turn, set the speed at 60 rpm, stir for 1 hour, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0041] (2) Preparation of component B: Put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 80°C, stir, vacuumize and dehydrate and degas for 2 hours, cool down to about 10°C and add Pure MDI, MDI-50, and carbodiimide-modified MDI are reacted at 80°C for 2 hours. After the detection reaches the set NCO% content value, cool down to about 10°C, add polymeric MDI and phosphoric acid, and stir well.

[0042] (3) When in use, the components A and B are mixed and injected in a weight ratio of 100 / 80, and the mold is ope...

Embodiment 2

[0044] A component:

[0045]

[0046] B component:

[0047]

[0048] (1) Preparation of component A: the measured polyether polyol A, KGP 545, TEA, DEG, DC2525, A1, A33, H 2 O is put into the reaction kettle one by one, set the rotation speed at 100 rpm, stir for 2 hours, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0049] (2) Preparation of component B: put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 100°C, stir, vacuumize, dehydrate and degas for 3 hours, cool down to about 40°C and add For pure MDI and MDI-50, react at 85°C for 3 hours. After the detection reaches the set NCO% content value, cool down to about 40°C, add polymeric MDI and phosphoric acid, and stir well.

[0050] (3) When in use, the components A and B are mixed and injected in a weight ratio of 100 / 60, and the mold is opened in 6 minutes to obtain...

Embodiment 3

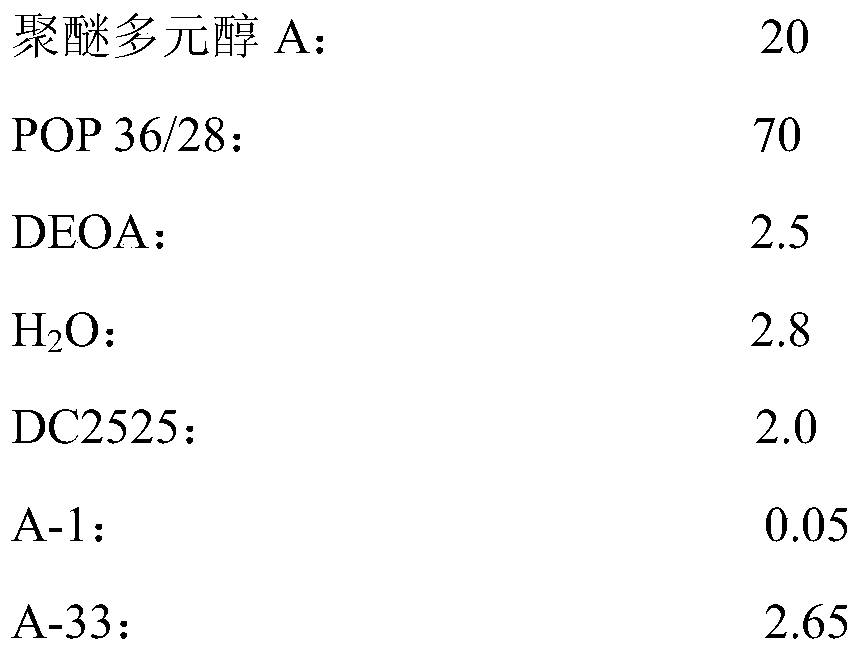

[0052] A component:

[0053]

[0054] B component:

[0055] Polyether polyol A: 25

[0056] Pure MDI: 70

[0057] Benzoyl chloride: 10ppm

[0058] (1) Preparation of component A: the measured polyether polyol A, DEOA, 1,4-BG, DC2525, A-33 and H 2 Put O into the reaction kettle in turn, set the speed at 80 rpm, stir for 1 hour, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0059](2) Preparation of component B: put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 90°C, stir, vacuum dehydrate and degas for 2 hours, cool down to about 20°C and add For pure MDI and MDI-50, react at about 80°C for 3 hours. After the detection reaches the set NCO% content value, cool down to about 20°C, add polymeric MDI and benzoyl chloride, and stir well.

[0060] (3) When in use, the components A and B are mixed and injected in a weight ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com