Insole and production method for same

A production method and a technology for insole, applied in the field of insole, can solve the problems of inability to reduce foot pressure and remove odor in shoes, high cost, etc., and achieve the effects of enhancing compactness and comfort, long service life, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

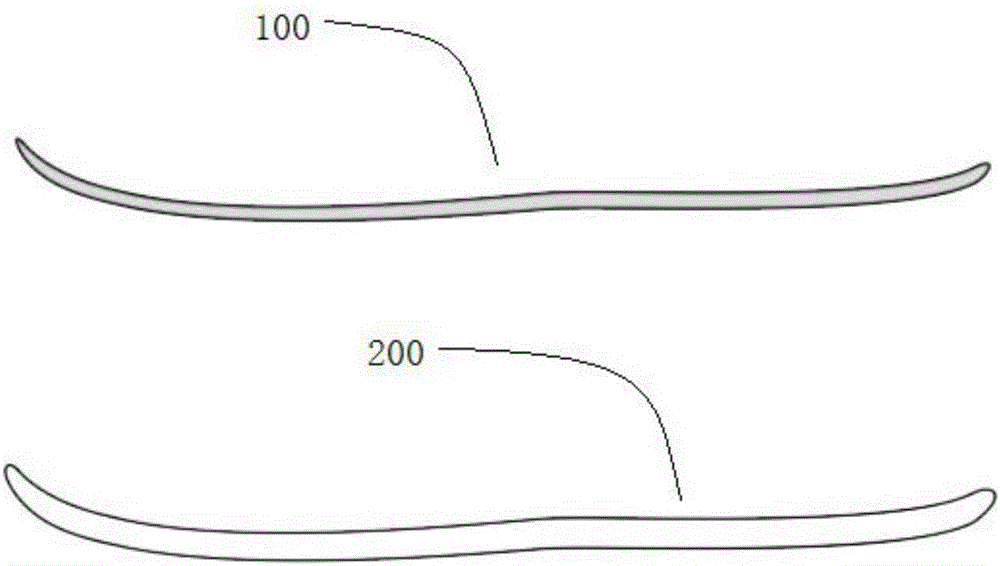

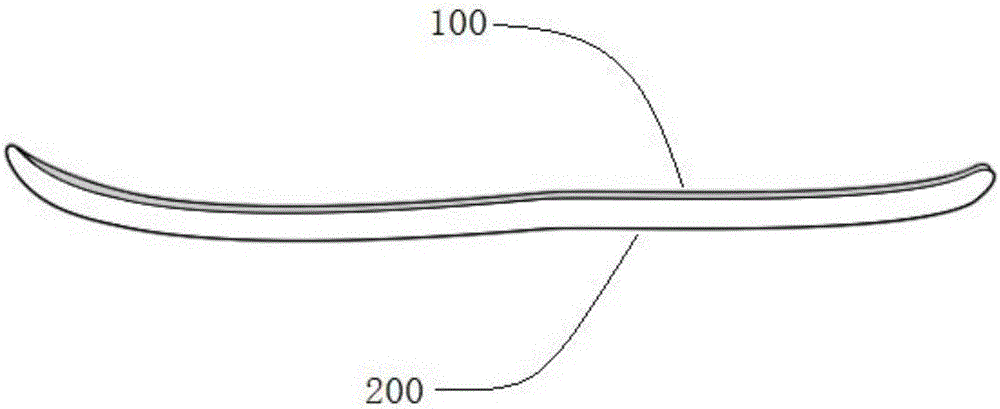

[0032] Such as figure 1 As shown, a kind of insole is provided in the present embodiment, comprises thin layer 100 and thick layer 200 of press-fitted structure, thin layer 100 is made of bamboo charcoal fiber and negative ion fiber, and thick layer 200 is made of 100% pure polyurethane production.

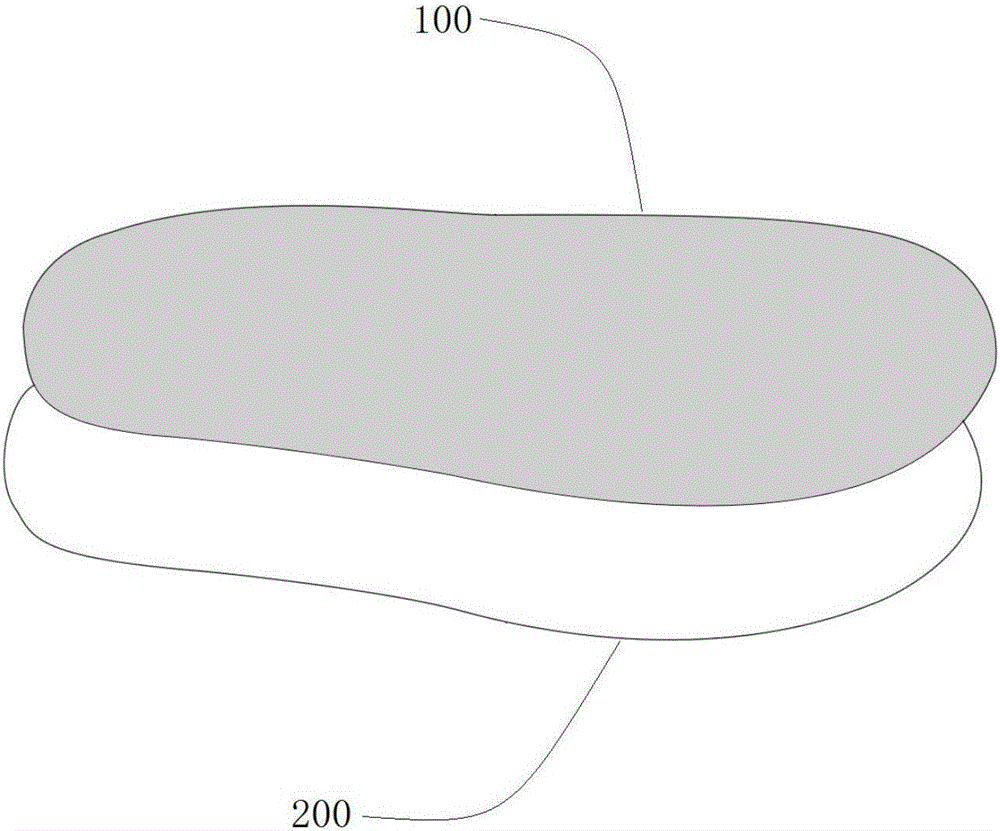

[0033] Such as image 3 As shown, the thin layer 100 and the thick layer 200 are pressed together from top to bottom into an integrated structure, wherein the sole and heel of the thick layer 200 are raised in an arc shape, and the middle of the foot at the junction of the sole and the heel is in a small arc protrusion. The size can be made according to the selection of the mold during molding or post-processing. The shape and area of the thin layer 100 are the same as those of the thick layer 200, which facilitates one-time molding between the two. Of course, it can also be slightly larger or smaller, so that it can be more accurate when cutting the insole.

[0034] Among ...

Embodiment 2

[0043] This embodiment provides a method for making an insole, comprising the following steps:

[0044] A. Molding process, adding non-toxic additives to polyurethane, foaming and injecting into a single mold, after the reaction is finished, take out the formed thick layer from the mold; the insoles made from this are all independently molded, And there is a layer of solidified thin skin on the surface of the insole, which has good hand feeling and excellent physical properties, which can prolong the service life of the insole.

[0045] B. Mixing process, adding textile negative ion additives to the bamboo charcoal fiber masterbatch and stirring evenly, and forming a thin layer after uniform mixing; the amount of negative ions in the formed thin layer is 500-1000 / cm 3 , combined with a specific shoe cavity space, can achieve the best adsorption and purification effect.

[0046] C. pressing process, on the thick layer that forms in step A, press the thin layer that is made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com