Rice subpackage machine

A packaging machine, rice technology, applied in the direction of packaging, conveyor, transportation and packaging, etc., to achieve the effects of labor saving, hygiene assurance, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Each invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

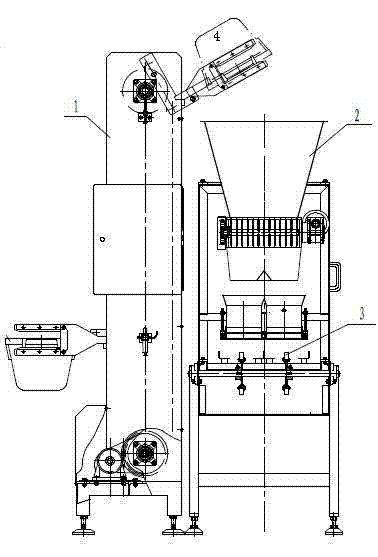

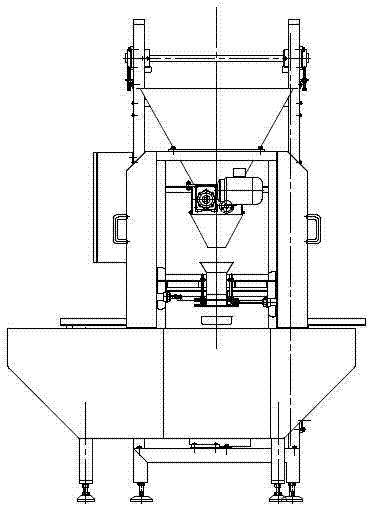

[0032] Such as figure 1 with figure 2 As shown, the rice subpackaging machine of the present embodiment mainly includes a lifting mechanism 1, a subpackaging mechanism 2 and a conveying mechanism 3, wherein:

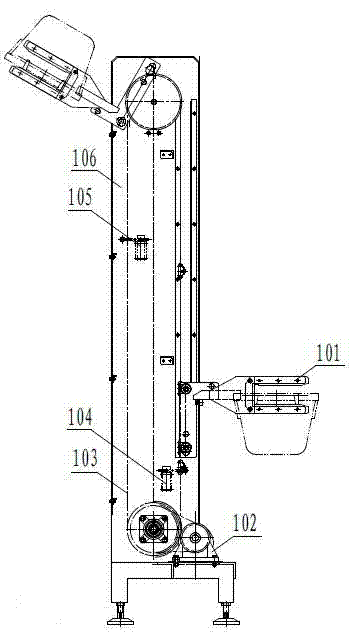

[0033] Lifting mechanism 1 comprises shift fork 101, speed reducer 102, conveying chain 103, two travel switches 104,105 and lifting mechanism frame 106, as image 3 , Figure 4 ,

[0034] The cooked rice is placed in the rice cooker 4, and the rice cooker 4 is manually placed on the shift fork 101. With the system starting, the shift fork 101 is driven by the reducer 102 to lift the pot to the top of the hopper of the packing mechanism. Rear ,First The travel switch 105 sends a signal, and the reducer 102 stops working. After the rice is poured into the hopper of the packing mechanism 2, the reducer 102 drives the conveying chain 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com