Polyurethane composition for automobile sunroof buffer pad, and preparation method of polyurethane composition

A technology for automotive sunroofs and cushions, applied in the field of polyurethane applications, to achieve long service life, improved sound insulation and noise reduction performance, and flexible molecular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

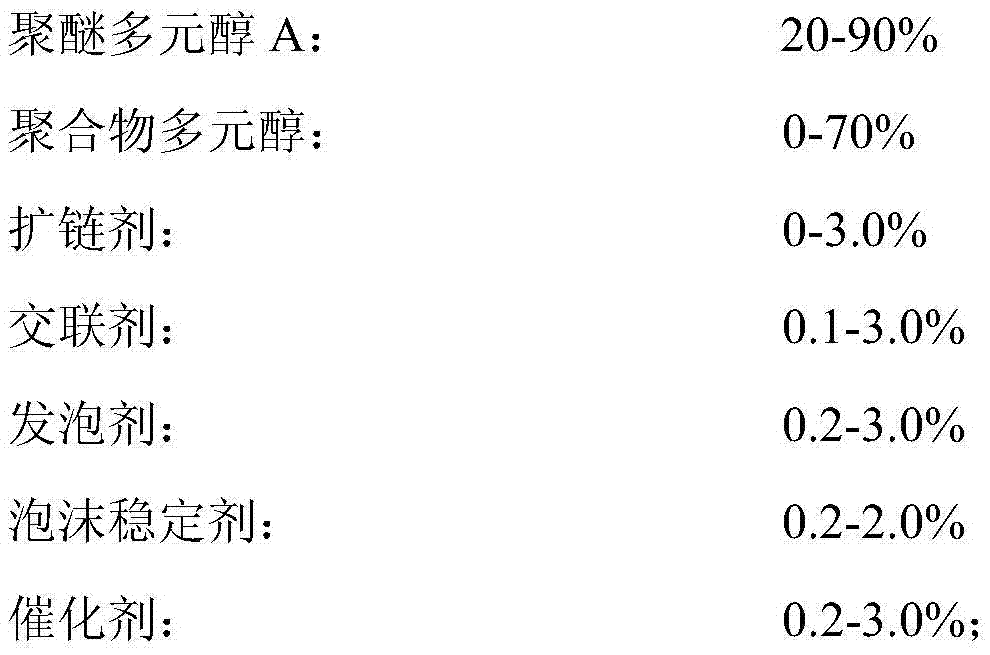

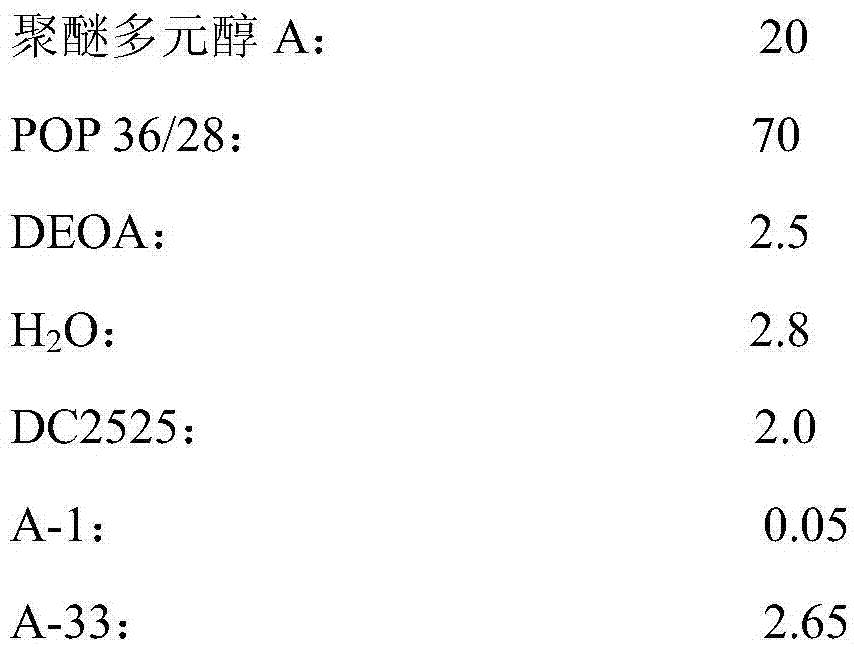

[0035] A component:

[0036]

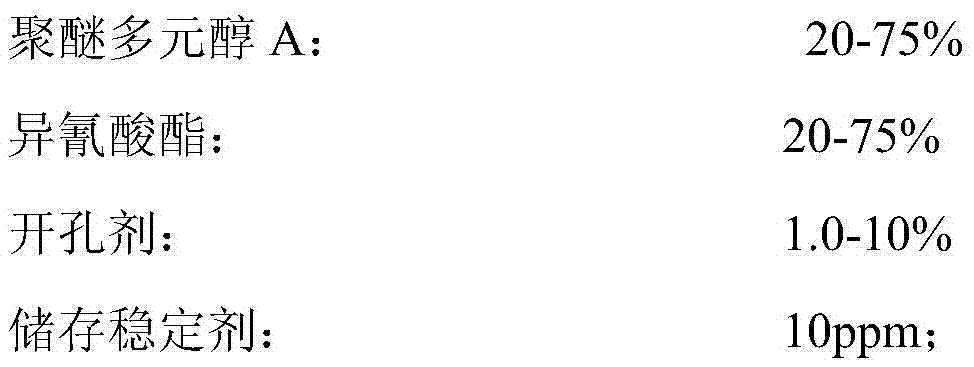

[0037] B component:

[0038]

[0039]

[0040] (1) Preparation of component A: the measured polyether polyol A, POP36 / 28, DEOA, DC2525, A-1, A-33, H 2 Put O into the reaction kettle in turn, set the speed at 60 rpm, stir for 1 hour, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0041] (2) Preparation of component B: Put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 80°C, stir, vacuumize and dehydrate and degas for 2 hours, cool down to about 10°C and add Pure MDI, MDI-50, and carbodiimide-modified MDI are reacted at 80°C for 2 hours. After the detection reaches the set NCO% content value, cool down to about 10°C, add polymeric MDI and phosphoric acid, and stir well.

[0042] (3) When in use, the components A and B are mixed and injected in a weight ratio of 100 / 80, and the mold is open...

Embodiment 2

[0044] A component:

[0045]

[0046] B component:

[0047]

[0048] (1) Preparation of component A: the measured polyether polyol A, KGP545, TEA, DEG, DC2525, A1, A33, H 2 O is put into the reaction kettle one by one, set the rotation speed at 100 rpm, stir for 2 hours, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0049] (2) Preparation of component B: put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 100°C, stir, vacuumize, dehydrate and degas for 3 hours, cool down to about 40°C and add For pure MDI and MDI-50, react at 85°C for 3 hours. After the detection reaches the set NCO% content value, cool down to about 40°C, add polymeric MDI and phosphoric acid, and stir well.

[0050] (3) When in use, the components A and B are mixed and injected in a weight ratio of 100 / 60, and the mold is opened in 6 minutes to obtain ...

Embodiment 3

[0052] A component:

[0053]

[0054] B component:

[0055] Polyether polyol A: 25

[0056] Pure MDI: 70

[0057] Benzoyl chloride: 10ppm

[0058] (1) Preparation of component A: the measured polyether polyol A, DEOA, 1,4-BG, DC2525, A-33 and H 2 Put O into the reaction kettle in turn, set the speed at 80 rpm, stir for 1 hour, take a sample for inspection, meet the process parameters, and produce satisfactory foam to obtain component A.

[0059](2) Preparation of component B: Put the polyether polyol A and SD-75 based on the formula into the reaction kettle at room temperature, raise the temperature to about 90°C, stir, vacuumize and dehydrate and degas for 2 hours, cool down to about 20°C and add For pure MDI and MDI-50, react at about 80°C for 3 hours. After the detection reaches the set NCO% content value, cool down to about 20°C, add polymeric MDI and benzoyl chloride, and stir well.

[0060] (3) When in use, the components A and B are mixed and injected in a weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com