Coal burning heat medium furnace high-precision temperature regulation and combustion control method

The technology of a heat carrier furnace and a control method is applied in the combustion method, adjusting the supply of fuel, controlling the combustion, etc., which can solve the problems of emission, environmental pollution, and difficulty in controlling the combustion of a coal-fired heat medium furnace, and achieves the effect of improving troubleshooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

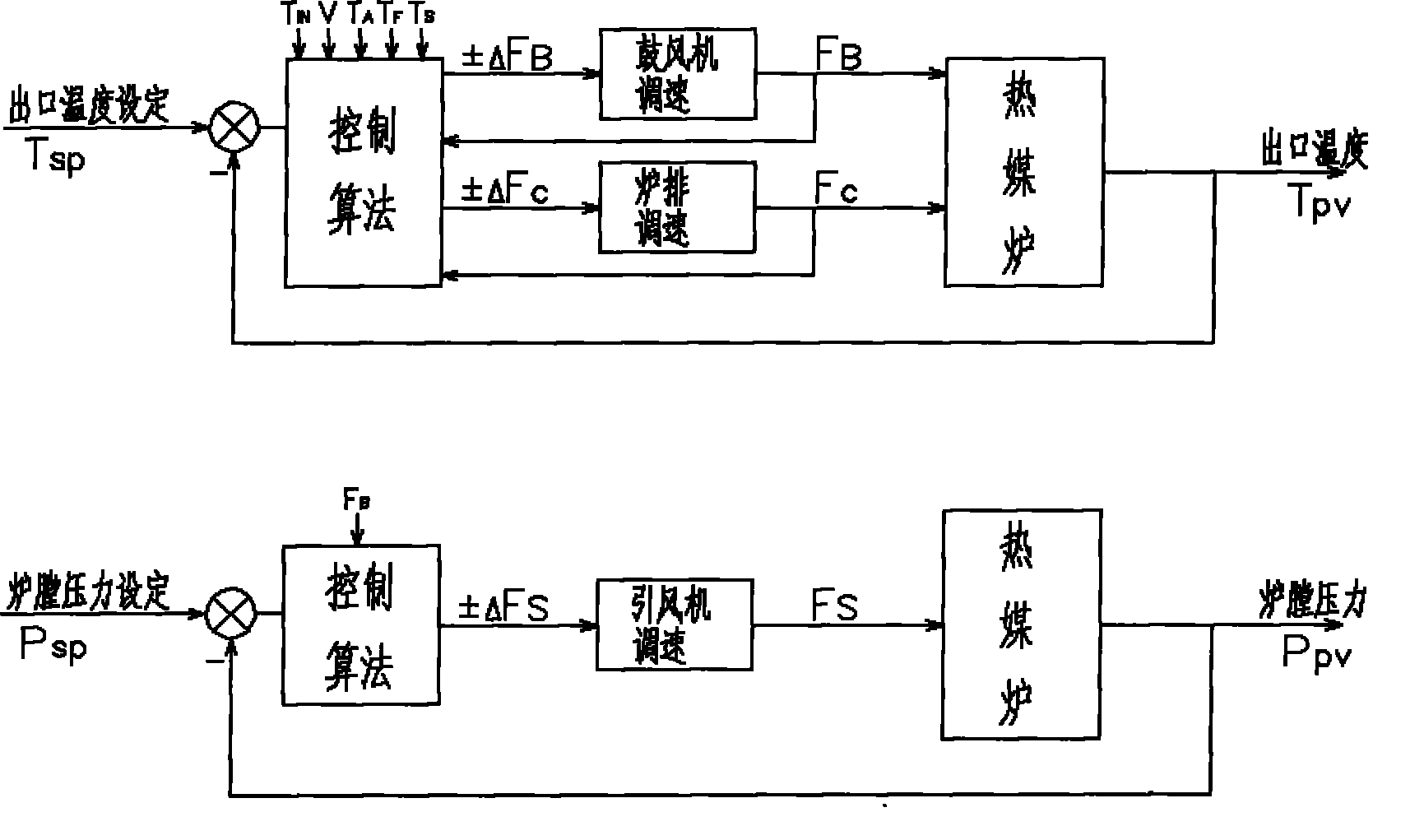

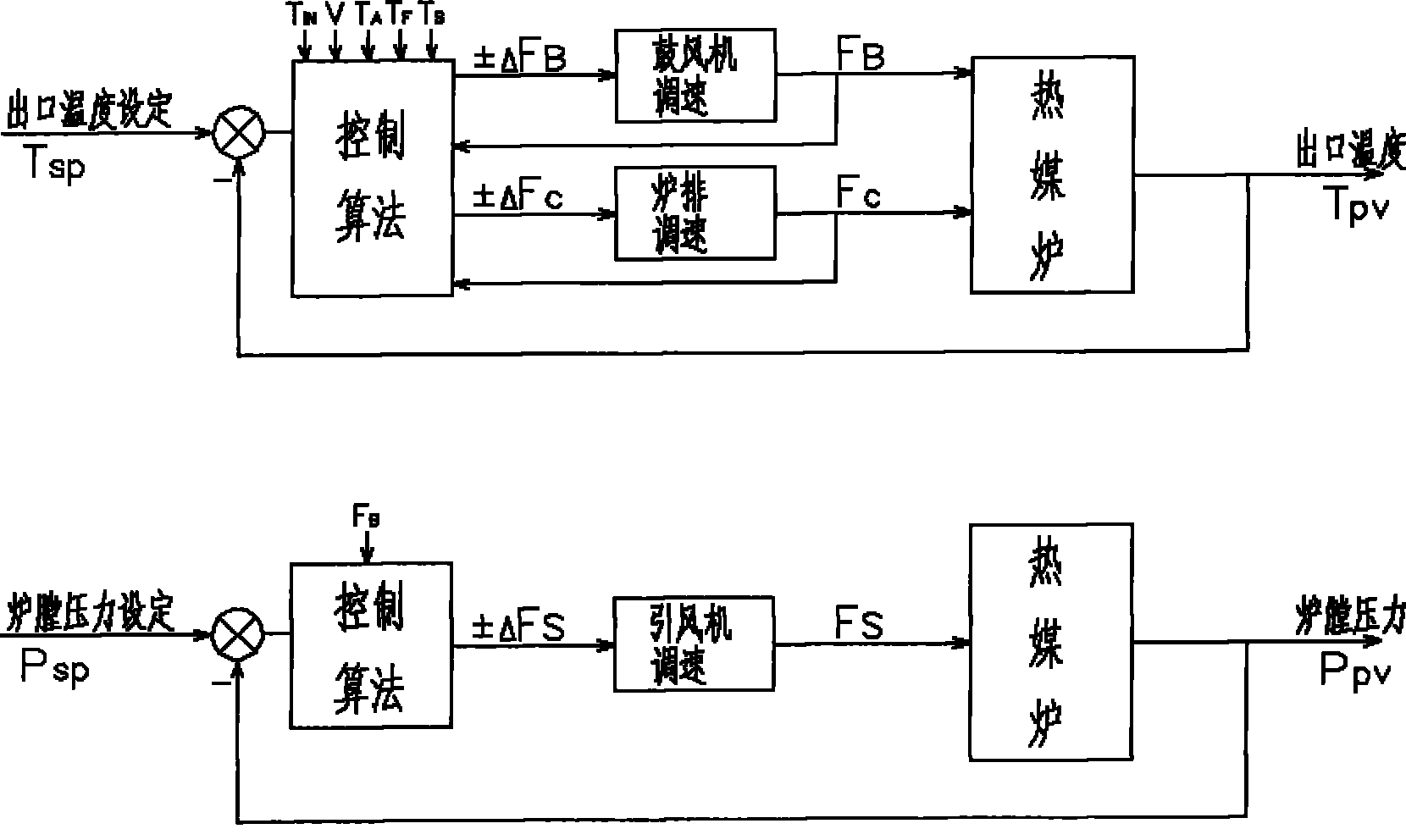

[0031] The following is a schematic diagram of the combustion control regulation loop (such as figure 1 shown). A high-precision temperature-regulated combustion control method for a coal-fired heat carrier furnace of the present invention includes heat medium temperature regulation and furnace negative pressure regulation. The main objects for regulating combustion are blower, induced draft fan and fire grate. The blast and induced air provide the oxygen required for combustion; the fire grate provides fuel for combustion.

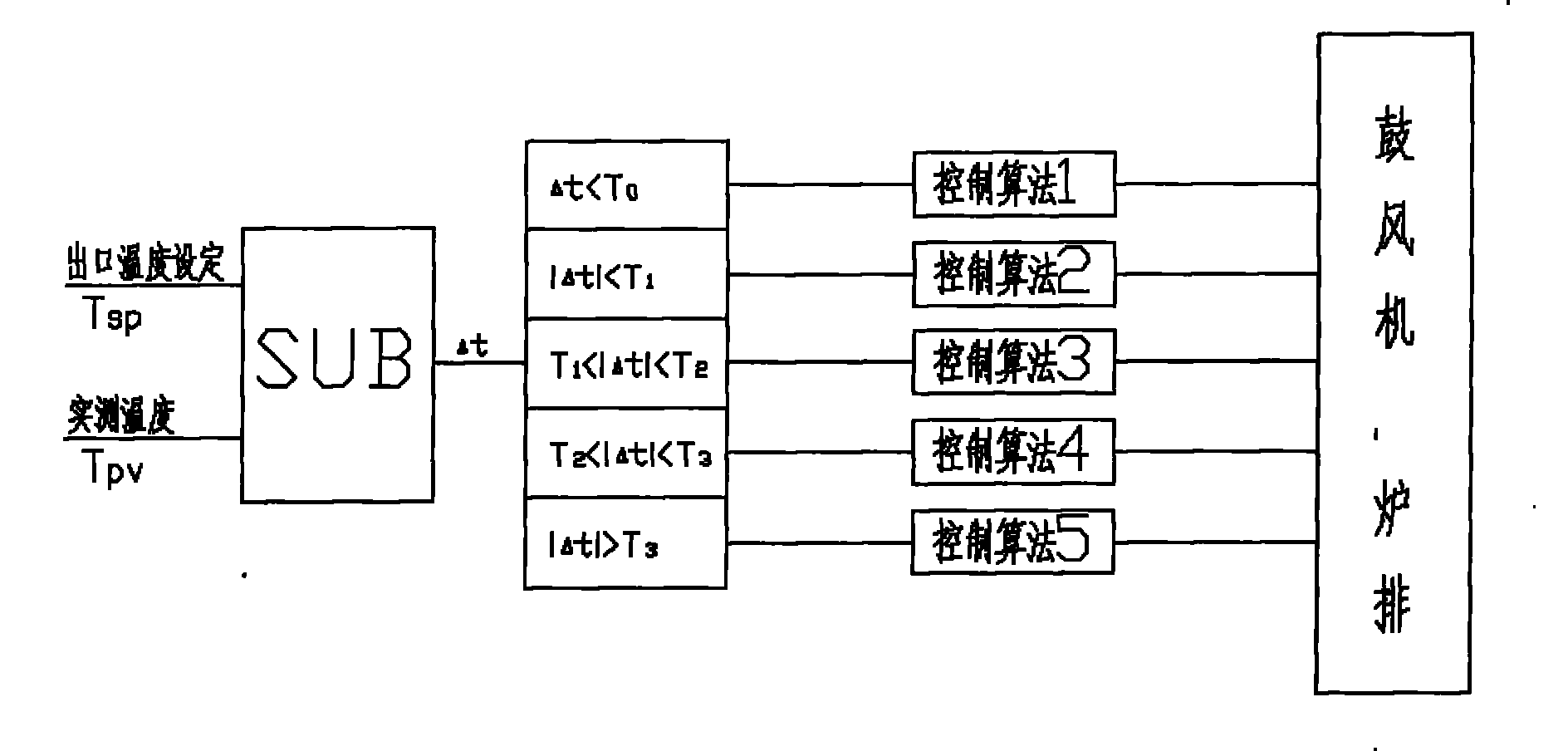

[0032] The temperature control of the coal-fired heat medium furnace depends on the combustion control of the coal-fired heat medium furnace. The high-precision control of the temperature of the heat medium in the present invention: the temperature of the inlet and outlet of the hot coal, the flow rate of the hot coal, the pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com