Processing method for dangling gold fingers and circuit board

A golden finger and circuit board technology, which is applied in the directions of printed circuit components, electrical connection printed components, and the formation of printed component electrical connections, can solve the problems of resource waste cost, poor versatility, strong limitations, etc., and achieve resource and cost saving , Reduce cost and waste of resources, strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

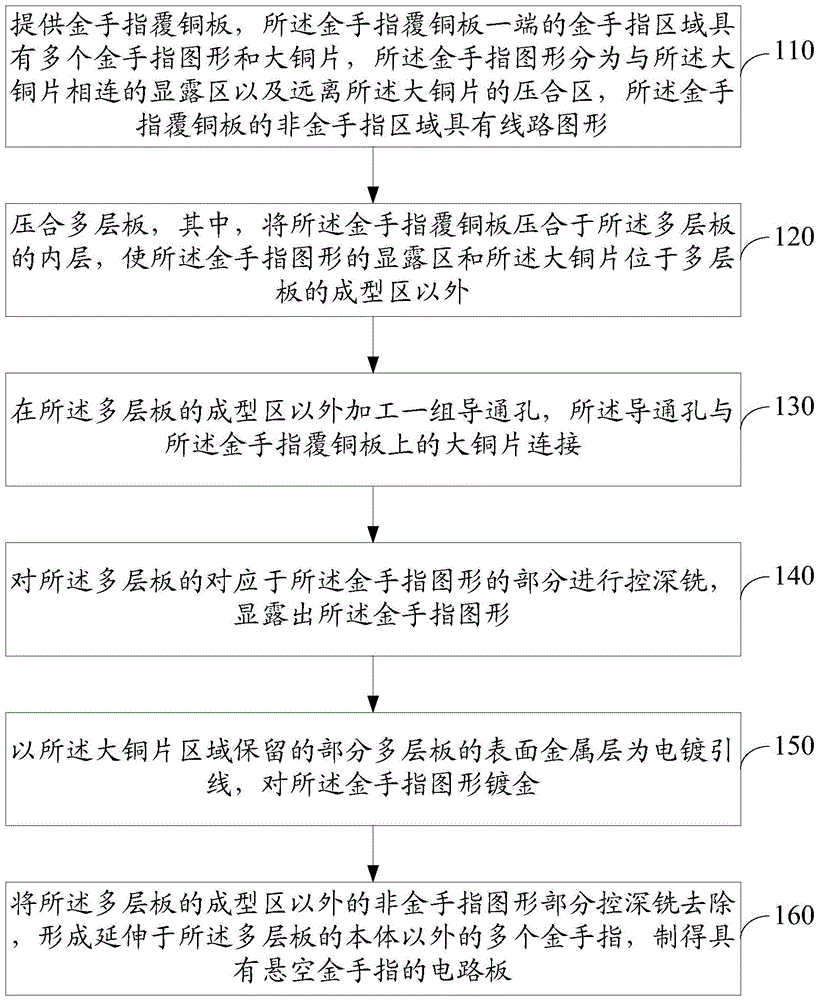

[0027] Please refer to figure 1 , The embodiment of the present invention provides a method for processing a floating gold finger, which may include:

[0028] 110. A gold finger copper clad laminate is provided. The gold finger area at one end of the gold finger copper clad laminate has a plurality of gold finger patterns and large copper pieces, and the gold finger patterns are divided into exposed areas connected to the large copper pieces and far away from all areas. In the pressing area of the large copper sheet, the non-gold finger area of the gold finger copper clad laminate has a circuit pattern.

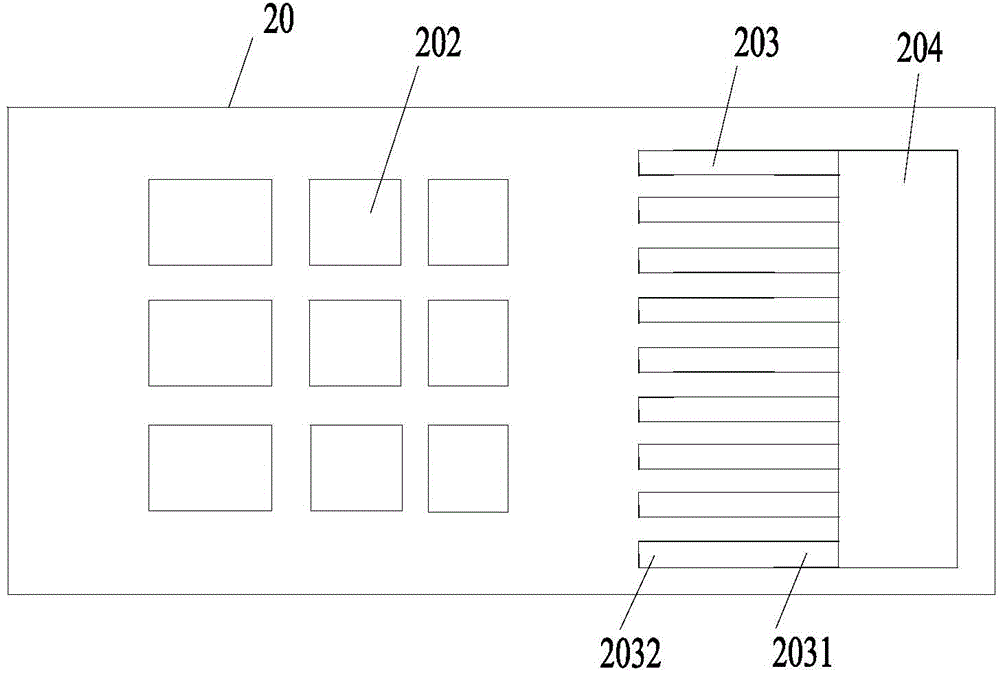

[0029] In the embodiment of the present invention, the provided gold finger copper clad laminate such as Figure 2a As shown, the gold finger copper clad laminate 20 includes an insulating medium in the middle and metal layers on both sides. One end is designed with a gold finger area. The metal layer of the gold finger area is processed into multiple gold finger patterns 203 a...

Embodiment 2

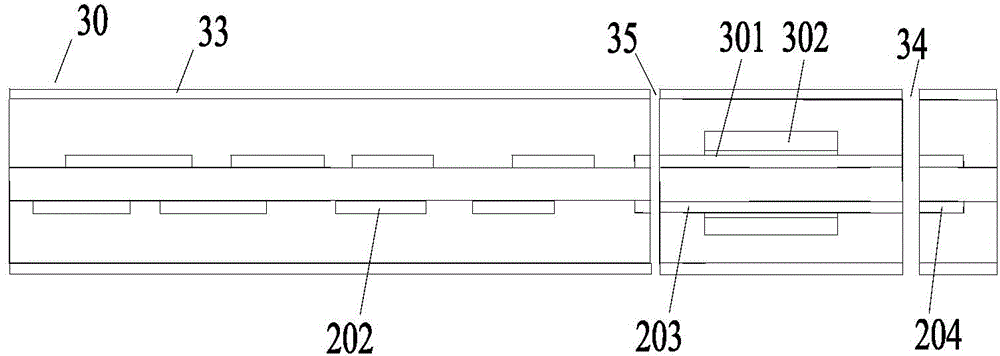

[0052] Please refer to Figure 2d with 2e , The embodiment of the present invention provides a circuit board with floating gold fingers, the circuit board may include:

[0053] The circuit board body 30 and at least one suspended gold finger 37, one end of the suspended gold finger 37 is embedded in the circuit board body 30, and the other end extends from a side wall of the circuit board body 30, the gold finger 37 is Gold-plated copper clad laminate structure.

[0054] The circuit board body may include multiple circuit layers, and each gold finger 37 can be connected to at least one of the multilayer circuit layers through a metalized through hole 35.

[0055] The circuit board provided by the embodiment of the present invention can be manufactured by the method of the first embodiment. For more detailed description, please refer to the first embodiment.

[0056] Above, the embodiment of the present invention provides a circuit board with floating gold fingers, which adopts the go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com