Method for adjusting star wheel-rotor engagement accuracy of single screw rod type refrigerating compressor

A technology of refrigeration compressor and adjustment method, which is applied to rotary piston type machinery, rotary piston type/swing piston type pump components, mechanical equipment, etc., can solve the problem of low meshing precision between star wheel and screw rotor and low product assembly efficiency , the debugging process is cumbersome and other problems, to achieve the effect of high assembly efficiency, prolong service life, and reduce the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

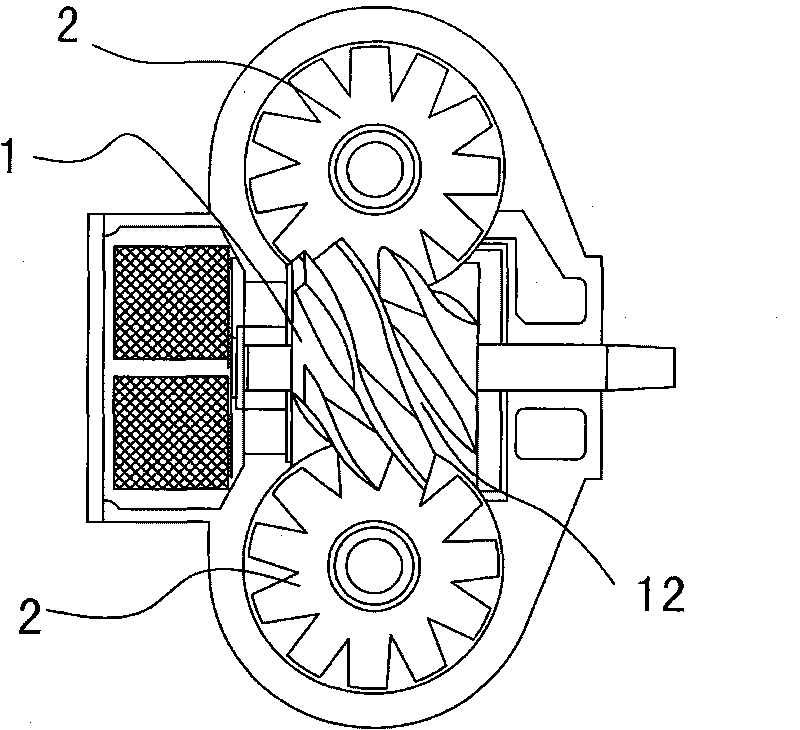

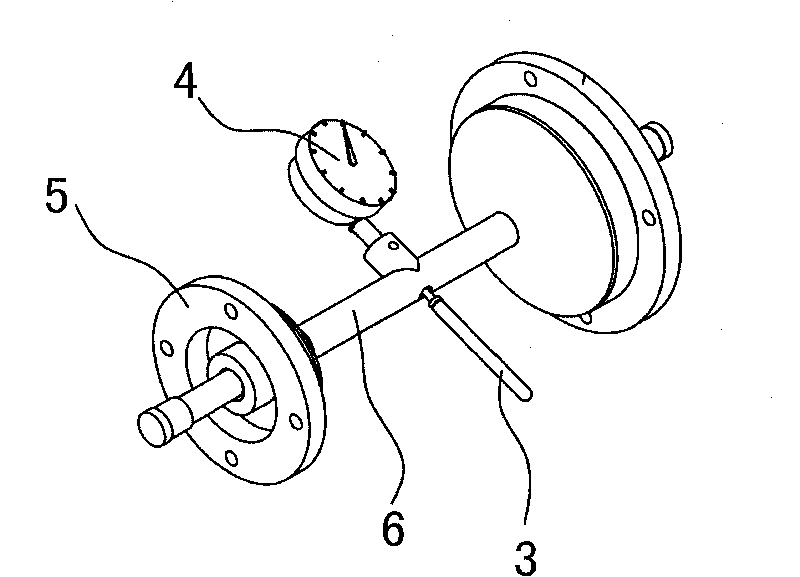

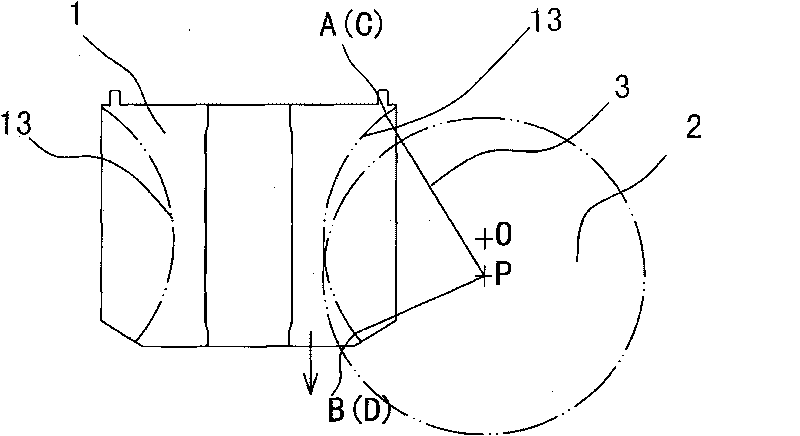

[0034] Such as Figure 2-4 As shown, a single-screw refrigeration compressor star wheel-rotor meshing precision adjustment method, before the adjustment, such as figure 2 As shown, a centering tool is produced, which is composed of two flanges 5, a rotating shaft 6, a dial indicator 4 and a centering needle 3, and the rotating shaft 6 is rotatably connected between the two flanges 5, The dial indicator 4 is arranged in the middle of the rotating shaft 6 , and its probe end is perpendicular to the rotating shaft 6 and fixedly connected with the aligning needle 3 .

[0035] The steps of the adjustment method are as follows:

[0036] (1) Put the main shaft component composed of screw rotor 1, main shaft 8, bearing 9 and bearing housing 10 into the housing 7 from one end of the housing 7, and the shaft shoulder of the bearing housing 10 is along the circumferential direction of the housing 7 opening. The mouth fits to form a pair of fixed mating surfaces perpendicular to the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com