Flat oscillating motor

A vibration motor, flat type technology, used in electric components, magnetic circuit rotating parts, electromechanical devices, etc., can solve problems such as increased vibration, poor wire breakage, shortened motor life, etc., to prevent deformation of the coil and prevent breakage. The effect of poor line and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

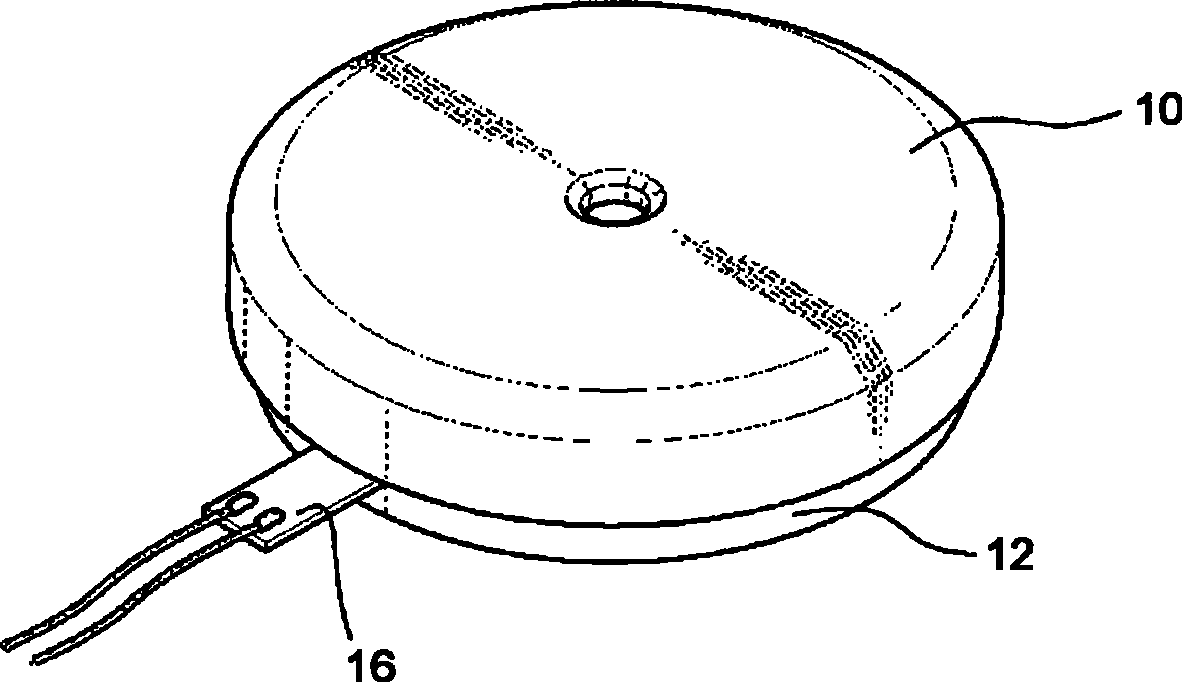

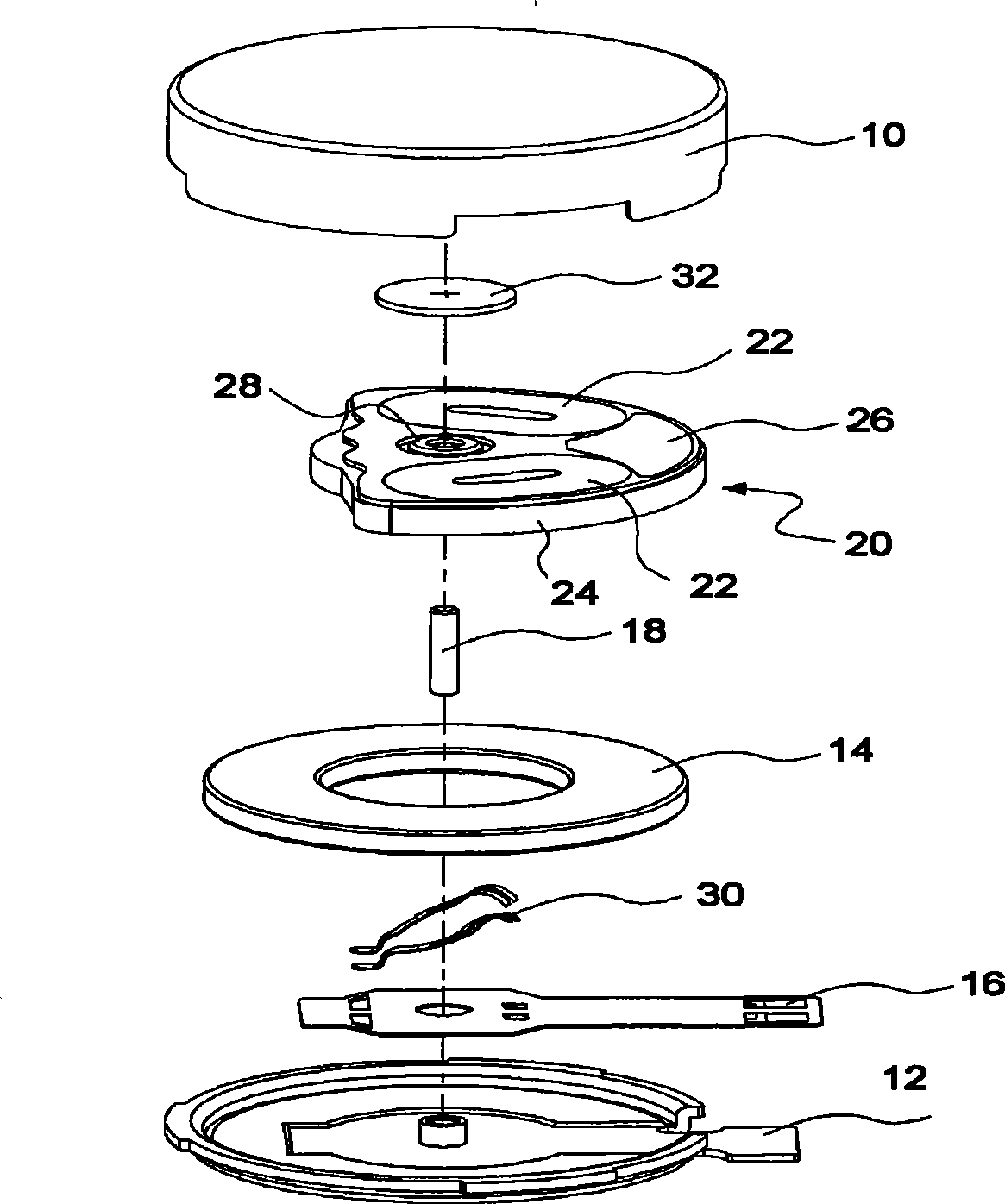

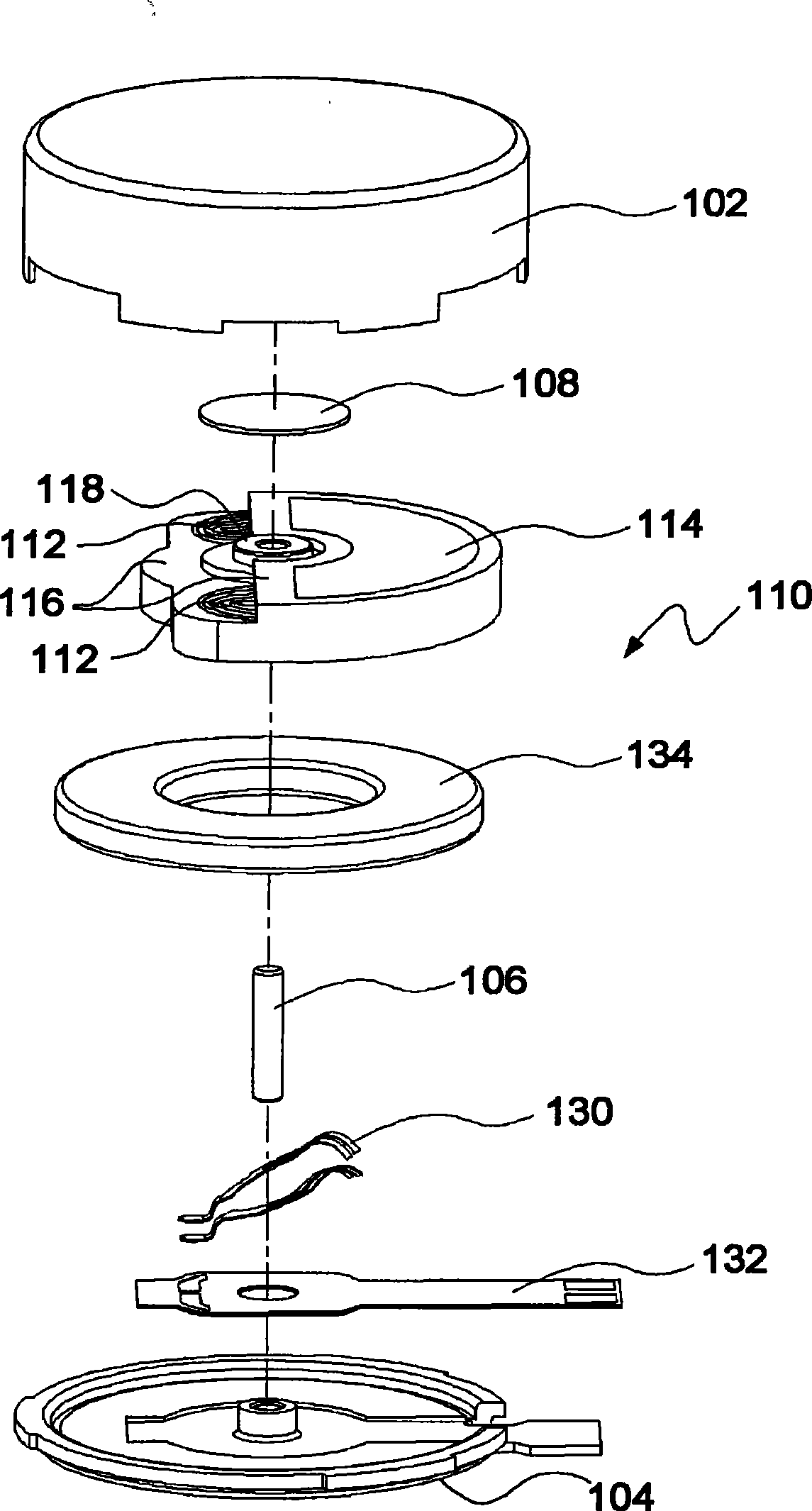

[0032] As shown in the accompanying drawings, with reference to the following accompanying drawings, the present invention will be described in detail

[0033] image 3 It is an exploded perspective view of a flat vibrating motor (100) of the present invention, Figure 4 It is the internal perspective sectional view of the vibrating motor (100), Figure 5 is a plan view of a rotor (110) suitable for a vibration motor (100), Image 6 to press Figure 5 The cross-sectional view viewed by the A-A line, Figure 7 for Figure 5 The bottom view of the rotor (110).

[0034] image 3 and Figure 4 As shown in the figure, the flat vibrating motor (100) comprises a cup-shaped upper casing (102) and a plate-shaped lower casing (104) that seals the inlet of the casing (102), and the casing is made of a metal material to be suitable for pressing In combination, there are grooves and holes in the center of the upper casing (102) and the lower casing (104), and the fixed rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com