Lightened rim for a bicycle wheel and method for manufacturing such a rim

A technology for bicycles and rims, applied in the field of lightening rims, can solve the problems of reducing, not allowing consistent material removal, and not fully satisfying the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

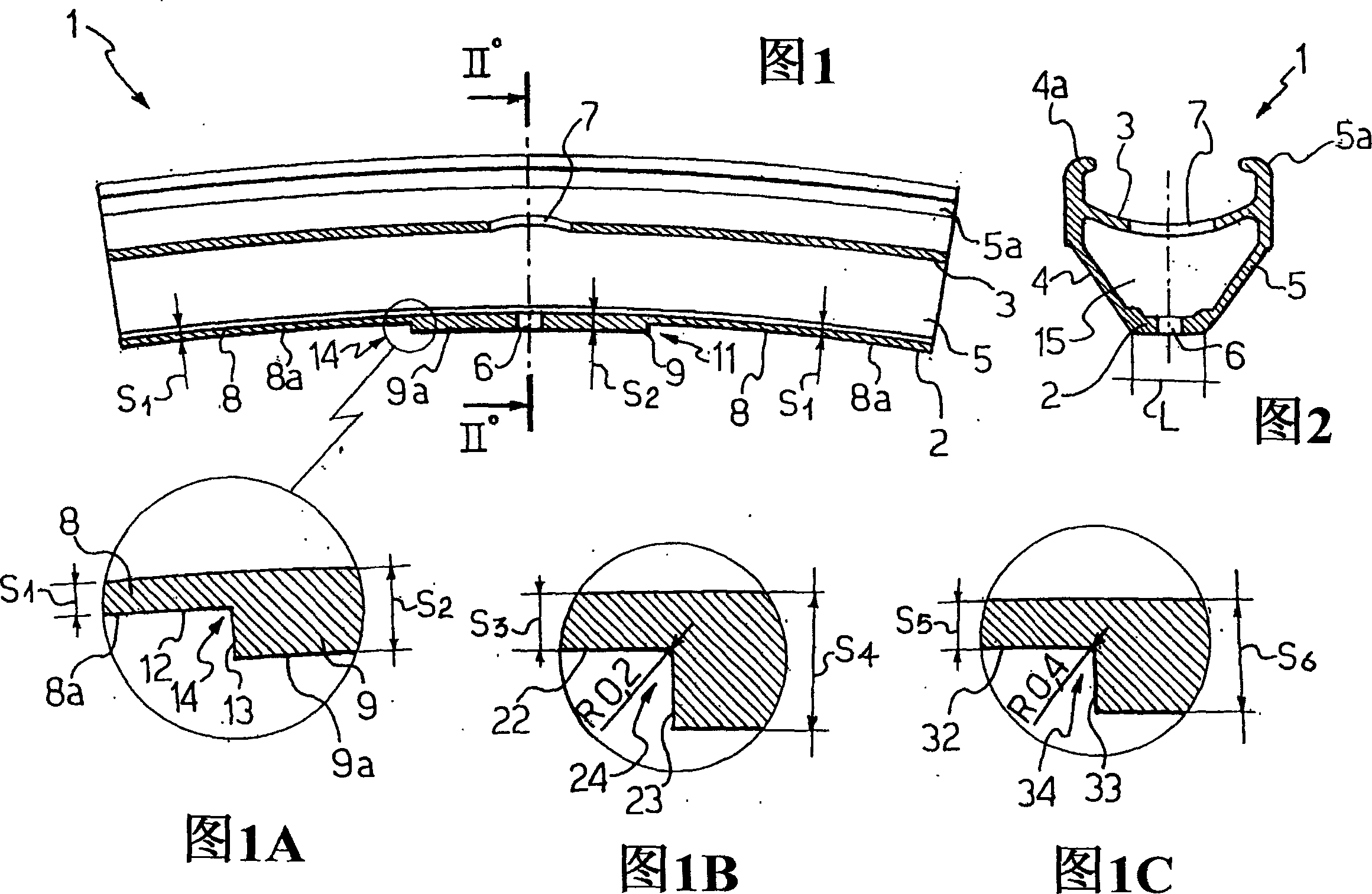

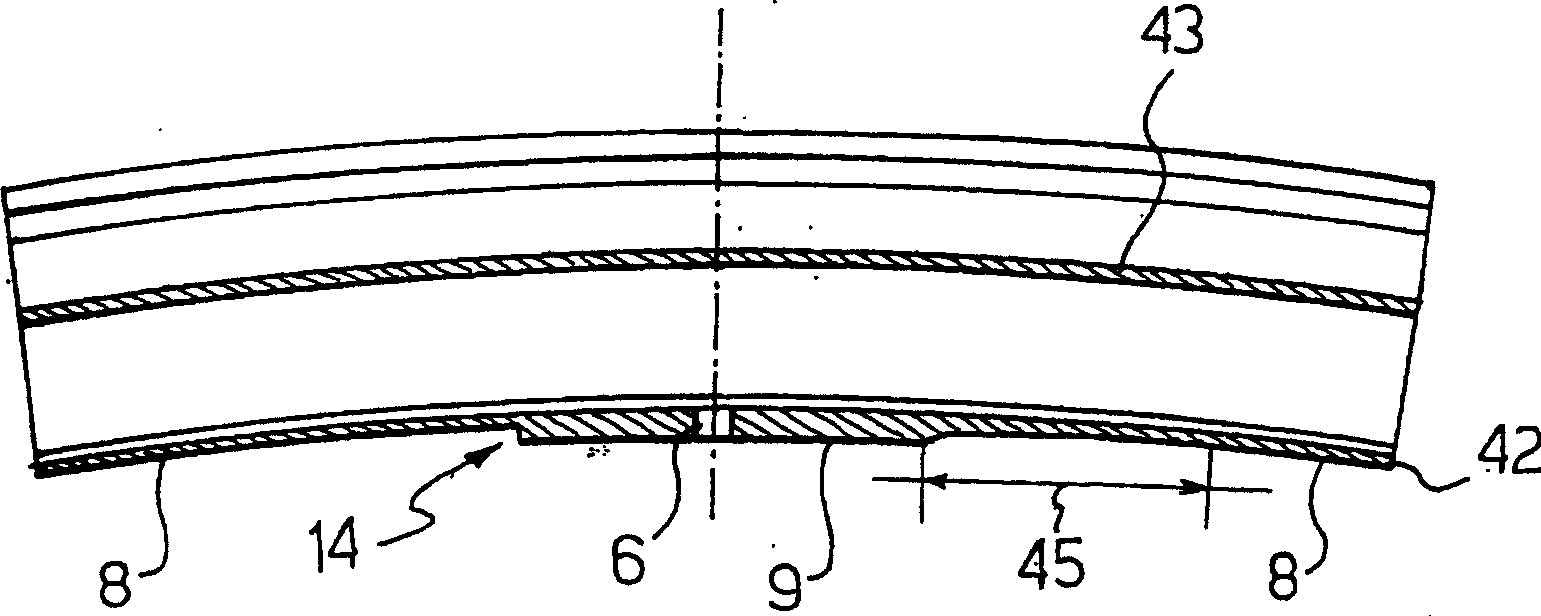

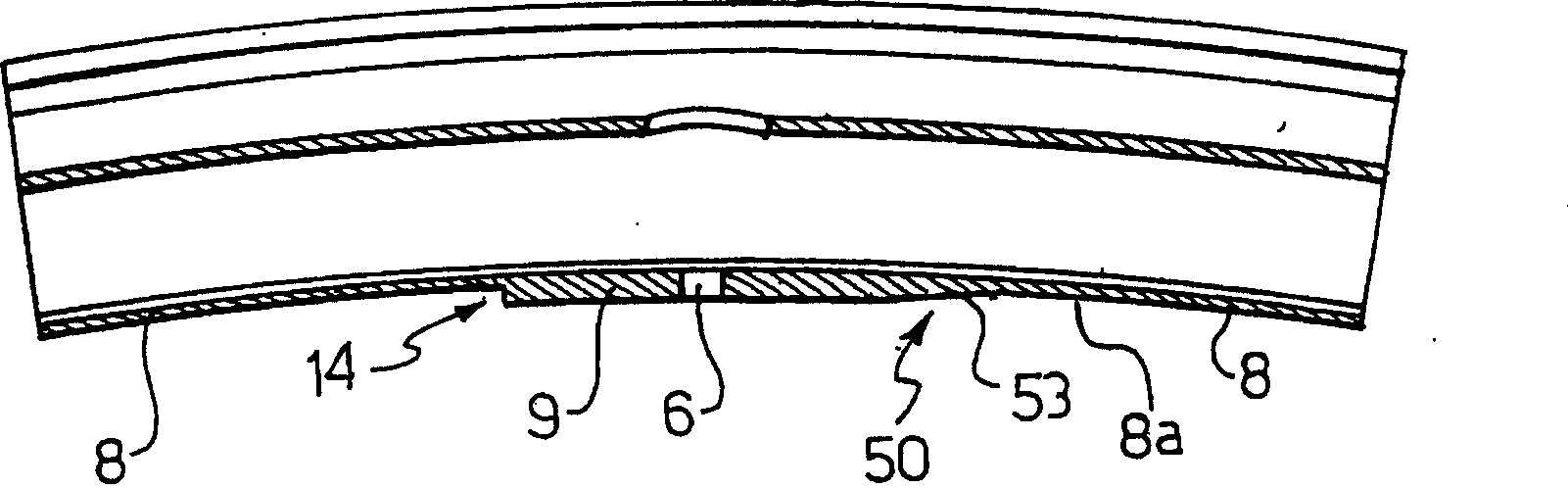

[0035] The wheel rim of the present invention is formed by extruding an aluminum alloy rod. The rod is formed into a circle, usually by calendering, and its ends joined by welding. Overall the rim indicated by 1, in Figure 9 and Figure 10 is shown in , where it is applied to two bicycle wheels W, W' having different spoke arrangements. The bicycle wheel W, W' already described is formed by a peripheral rim having an annular profile or rim 1, a central hub 18, 18' and spokes 19, 19', which are connected to the hub 18 , 18' and rim 1. FIG. 1 shows a section of such a rim 1 in longitudinal section, while FIG. 2 shows it in cross section.

[0036] As is clearly seen in the cross-sectional view of Figure 2, the rim 1 consists of two side walls 4, 5 connected at one end by a circumferential inner wall 2, known as a lower bridge, and at an intermediate point Connected by the peripheral outer wall 3 , known as the upper bridge, an essentially upwardly turned A-shaped cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com