Magnetic suspension vacuum pipeline transmission system for freight transport

A technology of vacuum pipes and transmission systems, applied in transportation and packaging, conveyors, non-mechanical conveyors, etc., can solve the problems of high freight costs, flight delays, and time-consuming in civil aviation, and achieve low production and operation and maintenance costs. The effect of fast shipping and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

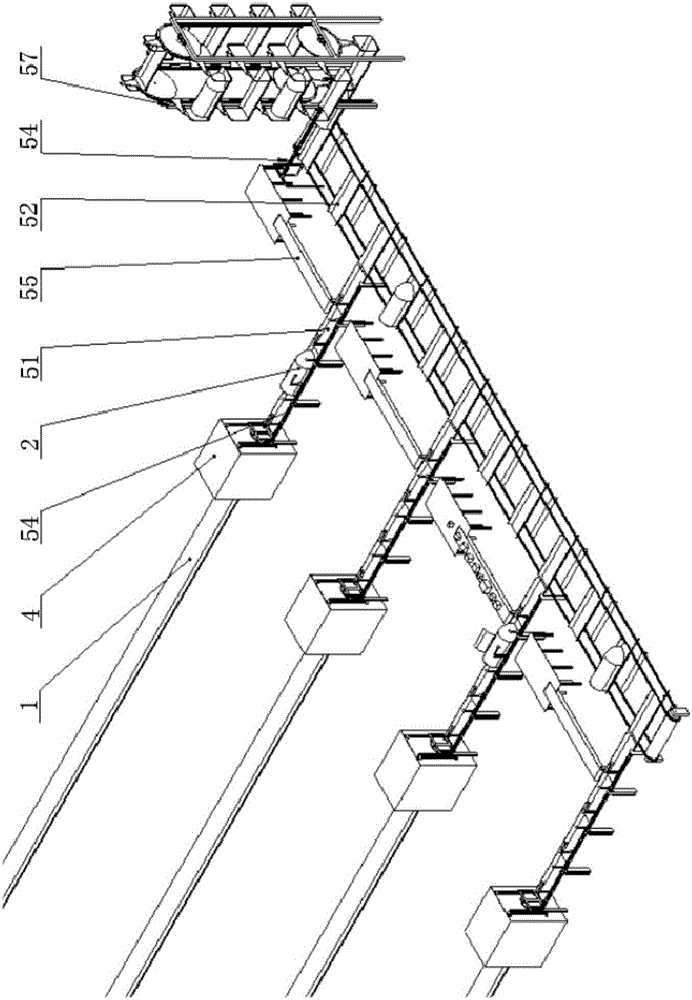

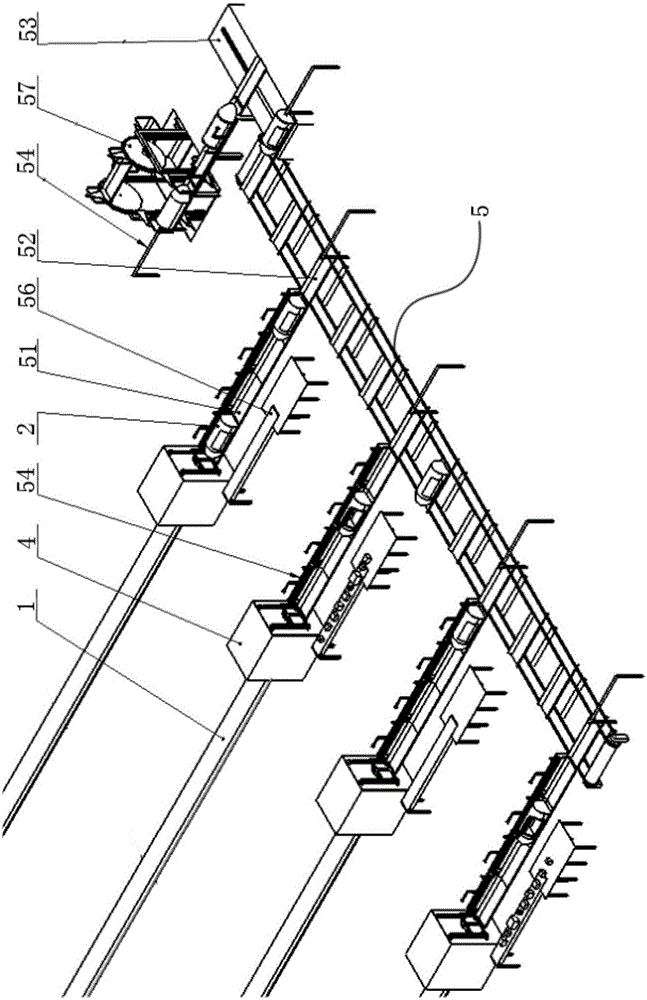

[0031] The specific embodiment of the present invention is asfigure 1 with figure 2 As shown, a freight magnetic levitation vacuum pipeline transmission system includes at least two vacuum transportation pipelines 1, which can be stainless steel, engineering plastics or composite material seamless pipes, and the size of the pipe diameter is 60cm to 160cm. Considering the freight carrying capacity and For factors such as construction convenience and the maintainability of the vacuum degree in the pipeline, generally 110cm is more suitable. It also includes a cargo compartment 2 for movement within the vacuum transport tube 1 . A matching concavo-convex structure is provided between the cargo compartment body 2 and the vacuum transportation pipeline 1 . The side or tail of the cargo cabin body 2 is provided with a hatch, and the container body 3 can be loaded in the cabin. The end of the vacuum transportation pipeline 1 is provided with a cargo cabin transmission line 5 for l...

Embodiment 2

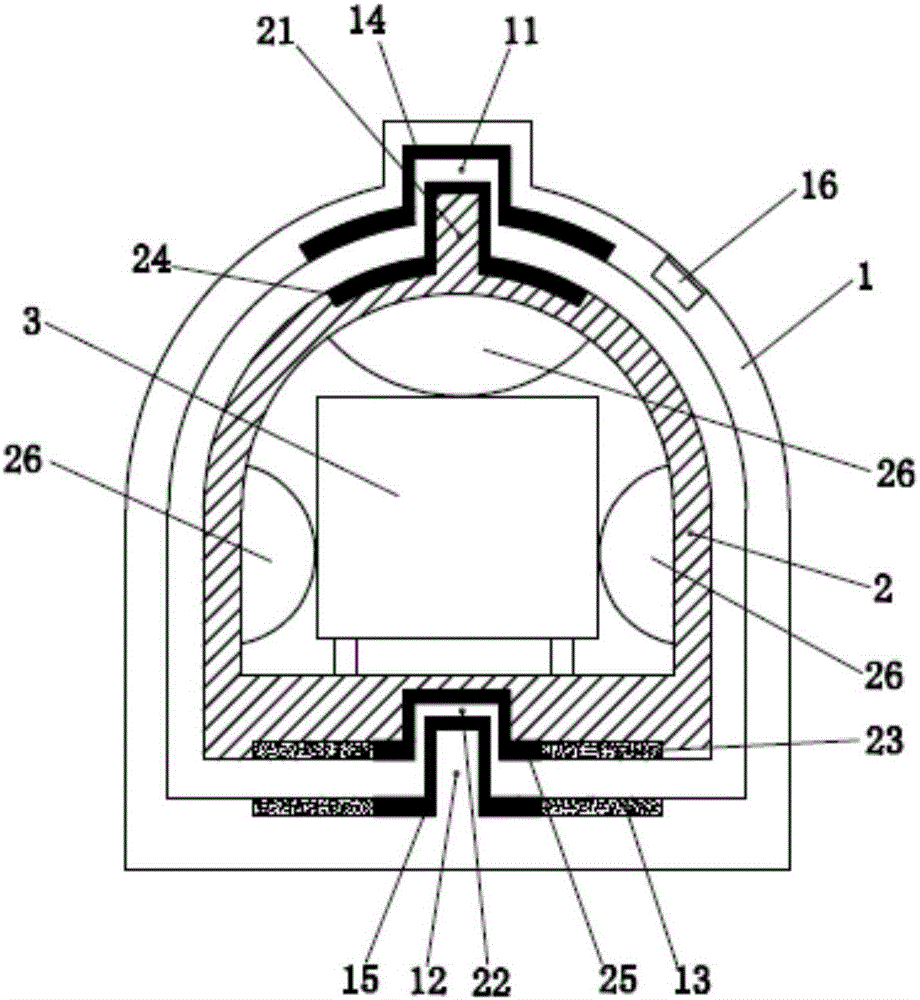

[0049] Such as Figure 4As shown, the difference from Embodiment 1 is that the concavo-convex structure adapted between the cargo compartment body 2 and the vacuum transportation pipeline 1 includes two pipeline grooves 11 arranged on the inner wall of the vacuum transportation pipeline 1 and two pipeline grooves 11 arranged on the inner wall of the vacuum transportation pipeline 1 and Two cabin convex grooves 21 on the outer wall of the cargo cabin body 2. Two pipe grooves 11 are arranged horizontally and symmetrically along the center of the inner wall of the vacuum transport pipe 1 . Two cabin convex grooves 21 are arranged horizontally and symmetrically along the center of the outer wall of the cargo cabin 2 . Wherein, the depth of the pipeline groove 11 is 80mm, and the width is 60mm; the height of the cabin convex groove 21 is 80mm, and the width is 30mm. The first pipeline magnetic body 14 is embedded in the inner side and both sides of the pipeline groove 11 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com