Oslasodine hydrochloride preparing process

A technology of solanamine hydrochloride and Australian eggplant, which is applied in the field of preparation of Australian solanamine hydrochloride, can solve the problems of product quality, poor curative effect, poor production safety, complicated and cumbersome process, etc., and achieve simple and convenient preparation process and equipment, The effect of low cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 prepares Australian solanamine hydrochloride with Solanum nigrum as raw material

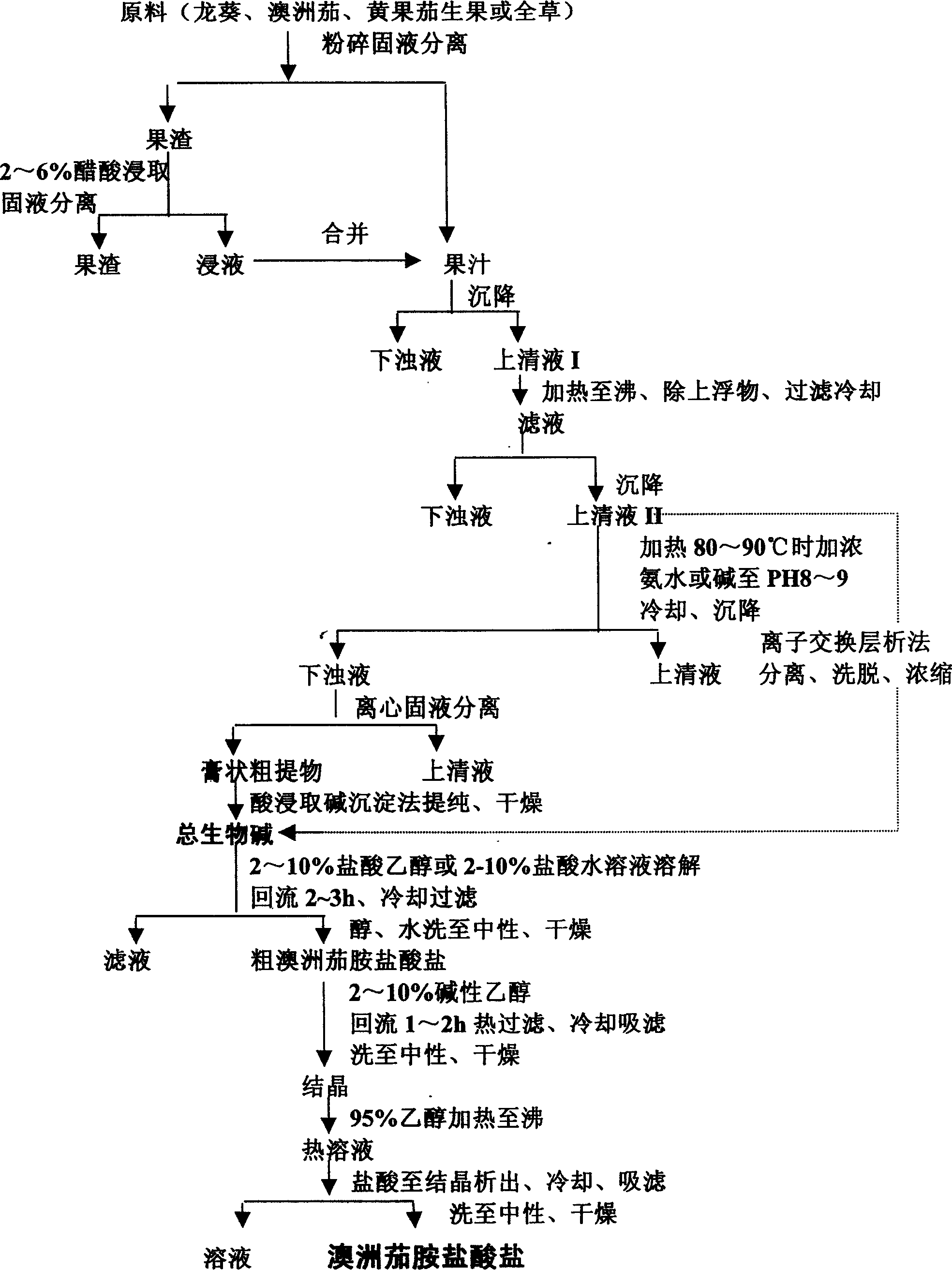

[0029] With reference to accompanying drawing, prepare Australian solanamine hydrochloride with nightshade fruit, its preparation method is as follows:

[0030] (1) Weigh 500kg of unripe nightshade fruits harvested from mid-October to late October to remove impurities, pulverize solid-liquid separation with a refiner to obtain fruit juice and pomace, and soak the nightshade pomace with 3% acetic acid aqueous solution 2 times, the weight ratio of solid to liquid is 1:1, the solid and liquid are separated to obtain the infusion, the fruit juice and the infusion are combined, and the supernatant I is obtained by standing and settling. Take the supernatant I and heat it to boiling, remove the floating green colloid, filter and cool, and place the filtrate to settle to obtain the supernatant II. Take the supernatant II and heat it to 85°C, add concentrated ammonia water to pH 8, ...

Embodiment 2

[0034] Example 2 Prepare Australian solanamine hydrochloride with yellow fruit eggplant as raw material

[0035] With reference to accompanying drawing, prepare Australian solanamine hydrochloride with yellow fruit eggplant fruit, its preparation method is as follows:

[0036] (1) Get 500kg of yellow fruit eggplant fruit, after crushing, solid-liquid separation is obtained to obtain fruit juice and pomace, and the pomace is leached twice with 3% acetic acid, with a solid-liquid weight ratio of 1: 1, and each leaching for 30 minutes, solid-liquid Separate the infusion, combine the fruit juice and the infusion, place and settle to obtain the supernatant I. Take the supernatant I and heat it to boiling, remove the floating green impurities, filter and cool, place and settle to get the supernatant II. Take the supernatant II and heat it to 80°C, add NaOH solution to PH8, cool and settle to remove the supernatant, and centrifuge the turbid liquid to separate the solid and liquid t...

experiment example 3

[0039] Experimental Example 3 Prepare Australian solanamine hydrochloride with Australian solanum as raw material

[0040] With reference to accompanying drawing, prepare Australian solanamine hydrochloride with Australian solanum fruit, its preparation method is as follows:

[0041] (1) Get 500kg Australian solanum fruit, and obtain supernatant II by the preparation method in Example 1 (1). The supernatant II flows through the styrene sulfonic acid type cation exchange resin column, and the flow rate is controlled until the effluent does not contain alkaloids. 2 Stop adding liquid until the ethanol solution turns reddish-purple, wash the resin column with distilled water to remove impurities until the effluent is colorless and transparent, take out the resin, dry it below 50°C, moisten it with concentrated ammonia water, put it into the column, and use Elute with 95% ethanol, concentrate the eluate to paste, and dry to obtain the total alkaloids of Solanum solanum.

[0042]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com