Straw compounded building material and preparation method thereof

A technology for composite building materials and straw, applied in the field of building materials, can solve the problems of low strength, poor frost resistance, and small straw content, and achieve the effects of improving thermal insulation performance, excellent thermal insulation performance, and large dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

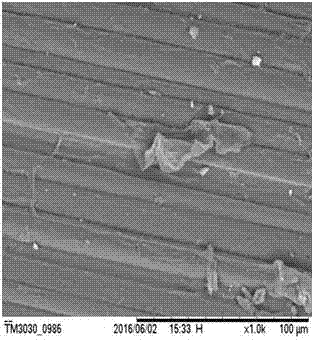

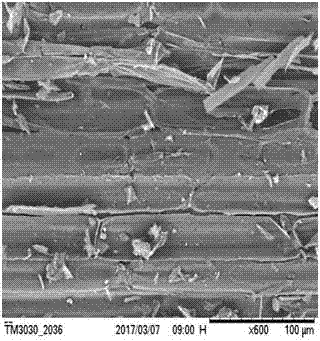

Image

Examples

Embodiment 1

[0029] 1) Take the corn stalks and crush them to 1-20mm filaments and fully dry them. After drying, carry out carbonization treatment in a vacuum state: carbonize under constant pressure nitrogen protection for 10 minutes, and the carbonization temperature is 200°C. Take out the stalks and wait until they drop to room temperature and seal them for later use. ;

[0030] 2) Take 50kg of sodium hydroxide and 30kg of sodium hydroxide as the alkali component materials, mix and stir evenly for use;

[0031] 3) Weigh 40 kg of slag, 10 kg of fly ash, 10 kg of alkali component, 4 kg of surface carbonized straw, 2 kg of silica fume, 2 kg of calcined diatomite, 1 kg of cement clinker, 25 kg of water and step 1) 2 kg of carbonized corn stalks on the surface of the mixture, and stir evenly after mixing;

[0032] 4) Mix the raw materials in step 1) and step 3) and perform mechanical stirring, run at low speed and slowly add 10kg of the alkali component solution in step 2) for mixing, stir ...

Embodiment 2

[0034] 1) Take the corn stalks and crush them to 1-20mm filaments and fully dry them. After drying, carry out carbonization treatment in a vacuum state: carbonize under constant pressure nitrogen protection for 20 minutes, and the carbonization temperature is 250°C. Take out the stalks and wait until they drop to room temperature and seal them for later use. ;

[0035] 2) Weigh 60kg of alkali component material water glass and 40kg of sodium hydroxide, mix and stir evenly for later use;

[0036] 3) Weigh 55 kg of slag, 20 kg of fly ash, 15 kg of alkali component, 10 kg of surface carbonized straw, 8 kg of silica fume, 4 kg of calcined diatomite, 3 kg of cement clinker, 40 kg of water and the surface carbonization of step 1) Corn stalks 10kg, mixed and stirred evenly;

[0037] 4) Mix the raw materials in step 1) and step 3) and then mechanically stir, run at low speed and slowly add the alkali component solution in step 2) for mixing, stir at a low speed of 60±2r / min for 90 se...

Embodiment 3

[0039] 1) Take the corn stalks and crush them to 1-20mm filaments and fully dry them. After drying, carry out carbonization treatment in a vacuum state: carbonize under constant pressure nitrogen protection for 25 minutes, and the carbonization temperature is 300°C. Take out the stalks and wait until they drop to room temperature and seal them for later use. ;

[0040] 2) Weigh 65kg of alkali component material water glass and 45kg of sodium hydroxide, mix and stir evenly for use;

[0041] 3) Weigh 60 kg of slag, 25 kg of fly ash, 20 kg of alkali component, 15 kg of carbonized straw on the surface, 10 kg of silica fume, 8 kg of calcined diatomite, 4 kg of cement clinker, 45 kg of water and the surface of step 1). 20kg of carbonized corn stalks, mixed and stirred evenly;

[0042] 4) Mix the raw materials in step 1) and step 3) and then mechanically stir, run at low speed and slowly add 20kg of the alkali component solution in step 2) for mixing, stir at a low speed of 60±2r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com