Non-isocyanate polyurethane and preparation method thereof

A non-isocyanate, polyurethane technology, applied in the field of non-isocyanate polyurethane and its preparation, can solve the problems of affecting the health of users, affecting the functionality of the final product, and being unfriendly to operators, achieving stable reaction, excellent mechanical properties, and improved safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of non-isocyanate polyurethane, comprises the following steps:

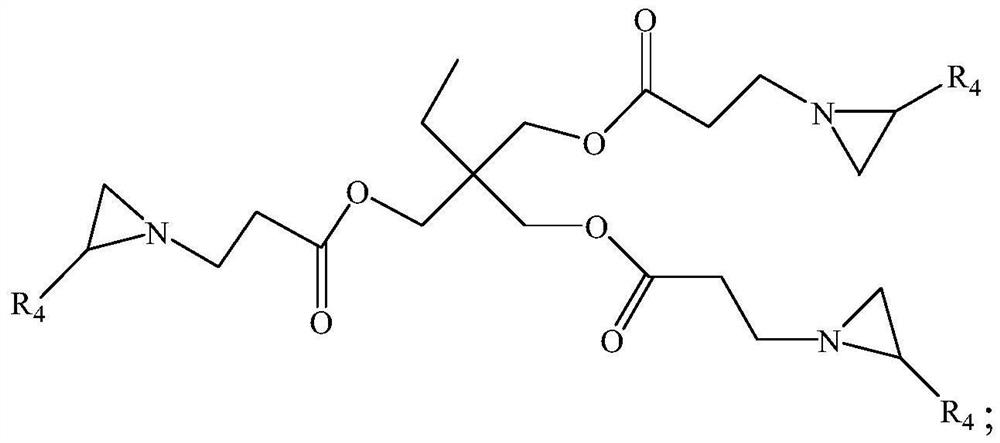

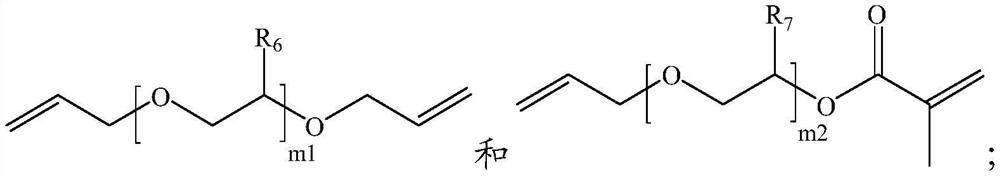

[0014] Step 1. Mix trifunctional aziridine polymer, double-terminated allyl compound, macroporous cation exchange resin and catalyst, feed carbon dioxide under vacuum, then raise the temperature to 65-85°C, react for 2-5 hours and then cool down to 30-40°C to obtain the first reactant;

[0015] The macroporous cation exchange resin is a hydrogen-type macroporous cation exchange resin containing hydrogen ions;

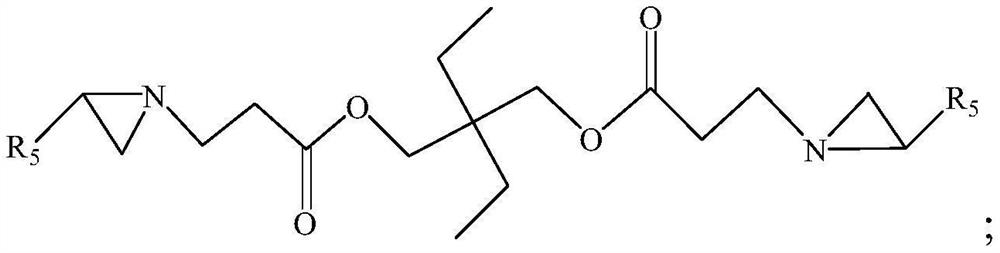

[0016] Step 2. Add a difunctional aziridine polymer, a double-ended allyl compound, 2,3-epoxysuccinic acid and a solvent to the first reactant in step 1, feed carbon dioxide under vacuum conditions, and heat up to 70-95°C, react for 2-5h and then cool down to 30-40°C to obtain the second reactant;

[0017] Step 3. Filter the macroporous cation exchange resin in the second reactant obtained in step 2, then adjust the pH of the system to 7-9, add w...

Embodiment 1

[0041] The preparation method of non-isocyanate polyurethane specifically comprises the following steps:

[0042] Step 1, 1mol trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate, 3mol double-ended allyl polyoxyethylene ether-20, 0.27mol hydrogen ion-containing NRW160 and 0.01mol[BMIM]Br were added into the high-pressure reactor lined with tetrafluoroethylene membrane through the feed valve, the high-pressure reactor was sealed, the feed valve, discharge valve, and inlet valve were closed, and the outlet valve was opened to vacuum Suction filter to remove the air in the reactor; close the outlet valve, open the inlet valve, charge 14mol carbon dioxide, close the inlet valve, heat up to 65°C, cool down to 30°C after 5 hours of reaction, open the outlet valve, and release the remaining carbon dioxide , to obtain the first reactant;

[0043] Step 2, open the feed valve, quickly add 8mol 3,3-dimethylolpentane-bis[3-(2-methylaziridinyl)]propionate, 8mol double-ended allyl po...

Embodiment 2

[0046] The preparation method of non-isocyanate polyurethane specifically comprises the following steps:

[0047] Step 1, 1mol trimethylolpropane-tris[3-(2-ethylaziridinyl)] propionate, 3mol double-ended allyl polyoxyethylene ether-45, containing 0.19mol hydrogen ion NRW160 and 0.04mol[BMIM]I are added into the high-pressure reactor lined with tetrafluoroethylene membrane through the feed valve, the high-pressure reactor is sealed, the feed valve, discharge valve, and inlet valve are closed, the outlet valve is opened, and the vacuum Remove the air in the reactor by suction filtration; close the outlet valve, open the inlet valve, charge 10mol carbon dioxide, close the inlet valve, raise the temperature to 85°C, cool down to 35°C after 2 hours of reaction, open the outlet valve, and release the remaining carbon dioxide , to obtain the first reactant;

[0048] Step 2, open the feed valve, quickly add 18mol 3,3-dimethylolpentane-bis[3-(2-methylaziridinyl)]propionate, 18mol dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com