A preparation method for doping rare earth element tricobalt tetroxide

A technology of tricobalt tetroxide and rare earth elements, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of unfavorable industrial production and cumbersome process, and achieve the effects of stabilizing growth, increasing the number of crystal nuclei, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

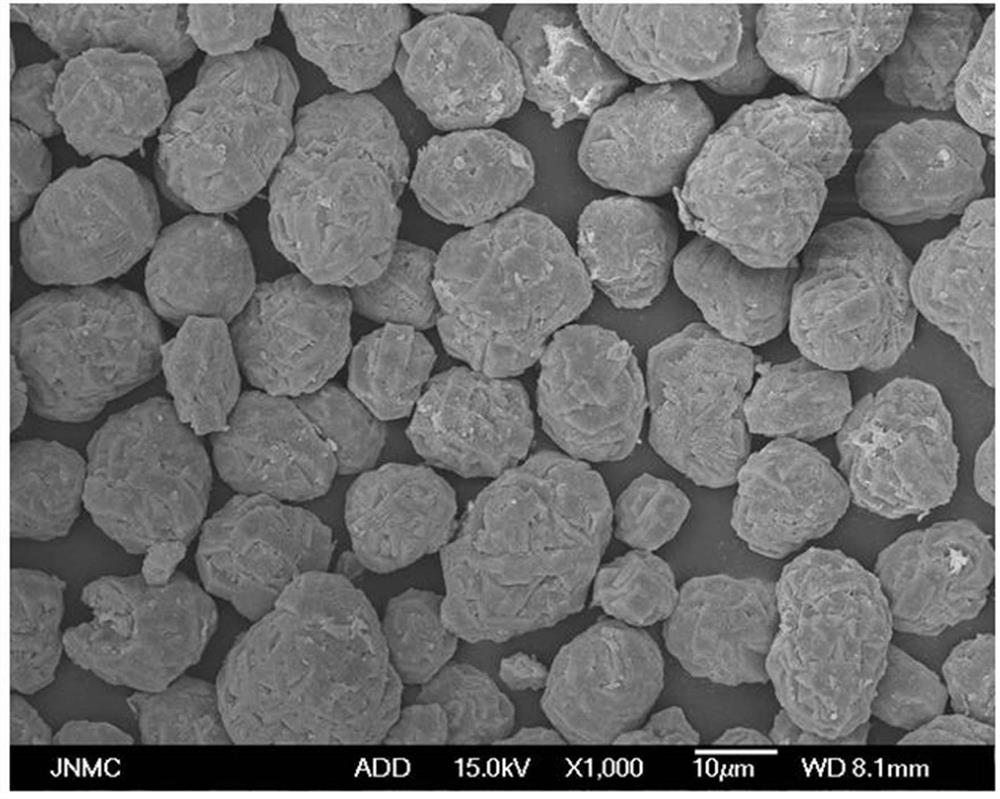

Embodiment 1

[0052] A method for preparing large-grained rare-earth element cobalt tetroxide, specifically comprising the following steps:

[0053] Step (a), dosing

[0054] The configured A solution is 10m 3 Cobalt concentration is 20g / L cobalt nitrate solution, lanthanum concentration is 0.11g / L lanthanum nitrate mixed solution; the prepared B solution is 15m 3 Cobalt nitrate solution with a cobalt concentration of 160g / L, and a mixed solution of lanthanum nitrate with a lanthanum concentration of 0.88g / L; preparation of solution C: a mixed solution of sodium hydroxide solution and ammonia solution containing hydrazine hydrate, that is: the concentration of ammonia solution is 180g / L, add 5mL hydrazine hydrate solution with a mass concentration of 80% per liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 200g / L in a volume ratio of 0.1:1.

[0055] Step (b), synthesis reaction

[0056] At the beginning of the synthesis reaction, add ...

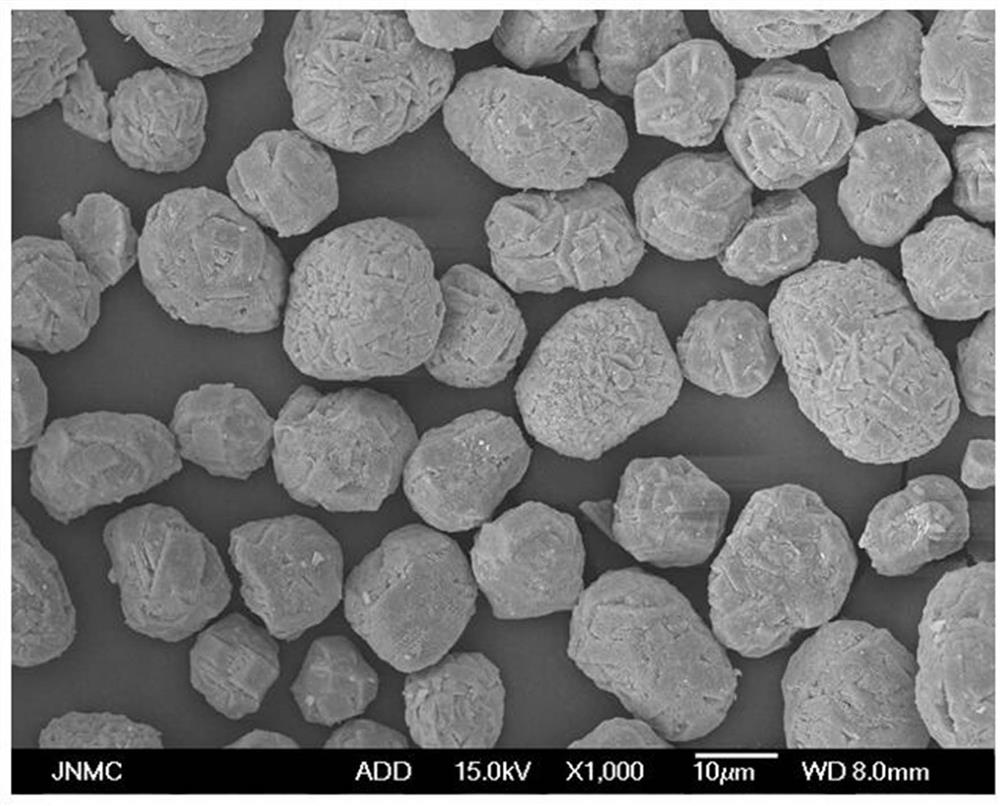

Embodiment 2

[0064] A method for preparing large-grained rare-earth element cobalt tetroxide, specifically comprising the following steps:

[0065] Step (a), dosing

[0066] The configured A solution is 10m 3 Cobalt concentration is 30g / L cobalt sulfate solution, cerium concentration is 0.21g / L cerium nitrate mixed solution; The prepared B solution is 15m 3 A cobalt sulfate solution with a cobalt concentration of 150g / L, and a mixed solution of cerium nitrate with a cerium concentration of 1.04g / L; prepare solution C: a mixture of sodium hydroxide solution and ammonia solution containing hydrazine hydrate, that is, the concentration of the ammonia solution is 180g / L, add 15mL of hydrazine hydrate solution with a mass concentration of 80% per liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 250g / L at a volume ratio of 0.15:1.

[0067] Step (b), synthesis reaction

[0068] At the beginning of the synthesis reaction, add the B solution ...

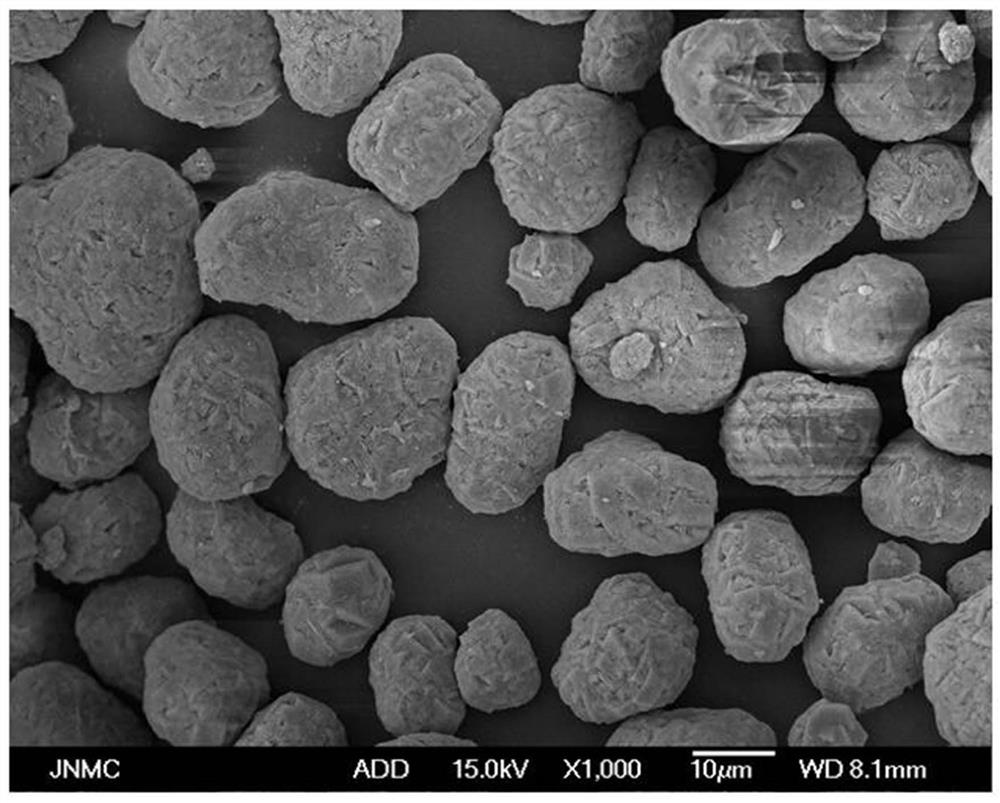

Embodiment 3

[0076] A method for preparing large-grained rare-earth element cobalt tetroxide, specifically comprising the following steps:

[0077] Step (a), dosing

[0078] The configured A solution is 10m 3 The cobalt concentration is 40g / L cobalt chloride solution, the yttrium nitrate mixed solution that yttrium concentration is 0.33g / L; The prepared B solution is 15m 3 The cobalt chloride solution that the cobalt concentration is 140g / L, the yttrium nitrate mixed solution that the yttrium concentration is 1.16g / L; Preparation C solution: be the mixed solution of sodium hydroxide solution and ammonia solution containing hydrazine hydrate, that is: the concentration of ammonia solution is 180g / L, add 20mL hydrazine hydrate solution with a mass concentration of 80% per liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 300g / L at a volume ratio of 0.2:1.

[0079] Step (b), synthesis reaction

[0080] At the beginning of the synthesis re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com