Preparation method of cobaltosic oxide

A technology of tricobalt tetroxide and cobalt hydroxide, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of cumbersome process, inability to prepare cobalt hydroxide, and unfavorable industrial production, so as to increase the number of crystal nuclei and promote the gradual and rapid growth of crystal nuclei The effect of growing and reducing the number of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

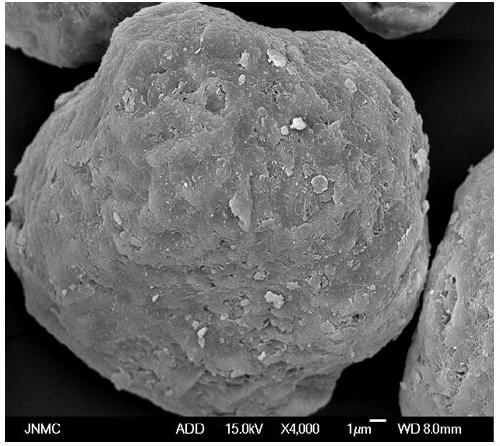

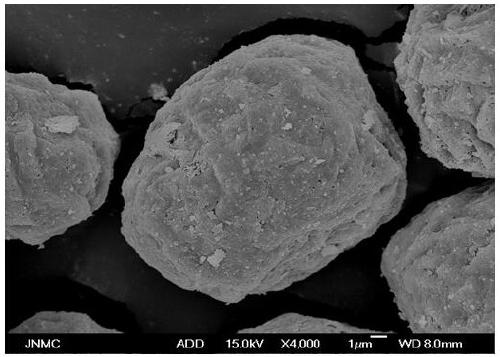

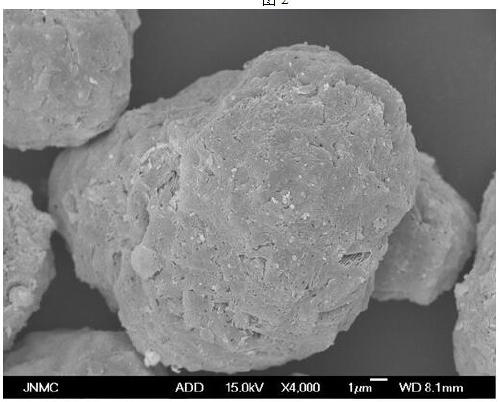

Image

Examples

Embodiment 1

[0051] A preparation method of large-size cobalt tetroxide, specifically comprising the following steps:

[0052] Step (a), dosing:

[0053] Configured A solution: 10m 3 The cobalt concentration is 20g / L cobalt nitrate solution;

[0054] Prepared B solution: 15m 3 Cobalt concentration is the cobalt nitrate solution of 160g / L;

[0055] Prepared solution C: Take ammonia water with a concentration of 180g / L, add 5ml of hydrazine hydrate solution with a mass concentration of 80% per liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 200g / L at a volume ratio of 0.1:1 income.

[0056] Step (b), synthesis reaction:

[0057] At the beginning of the synthesis reaction, add solution B to solution A at a flow rate of 300 L / h. At the same time, solution A and B are mixed with solution C at a flow rate of 500 L / h. Cobalt hydroxide synthesis is carried out under the agitation intensity of the reactor. When the volume of the slurry in th...

Embodiment 2

[0065] A preparation method of large-size cobalt tetroxide, specifically comprising the following steps:

[0066] Step (a), dosing:

[0067] Configured A solution: 10m 3 The cobalt concentration is 30g / L cobalt sulfate solution;

[0068] Prepared B solution: 15m 3 Cobalt concentration is the cobalt sulfate solution of 150g / L;

[0069] Preparation of solution C: Take ammonia water with a concentration of 180g / L, add 15ml of hydrazine hydrate solution with a mass concentration of 80% per liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 250g / L at a volume ratio of 0.15:1. .

[0070] Step (b), synthesis reaction:

[0071] At the beginning of the synthesis reaction, the B solution was added to the A solution at a flow rate of 300L / h. At the same time, the A and B solutions were mixed and fed into the reactor with the C solution at a flow rate of 500L / h. The cobalt hydroxide is synthesized under the agitation of the reactor. W...

Embodiment 3

[0079] A preparation method of large-size cobalt tetroxide, specifically comprising the following steps:

[0080] Step (a), dosing:

[0081] Configured A solution: 10m 3 Cobalt concentration is 40g / L cobalt chloride solution;

[0082] Prepared B solution: 15m 3 Cobalt concentration is the cobalt chloride solution of 140g / L;

[0083] Preparation of solution C: Take ammonia water with a concentration of 180g / L, add 20ml of hydrazine hydrate solution with a mass concentration of 80% to each liter of ammonia solution, and then mix it with a sodium hydroxide solution with a concentration of 300g / L at a volume ratio of 0.2:1 .

[0084] Step (b), synthesis reaction:

[0085] At the beginning of the synthesis reaction, the B solution was added to the A solution at a flow rate of 300L / h. At the same time, the A and B solutions were mixed and fed into the reactor with the C solution at a flow rate of 500L / h. The cobalt hydroxide is synthesized under the agitation of the reactor. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com