Anti-reflection coating of crystalline silicon solar cell and preparation method thereof

A technology of crystalline silicon solar cells and anti-reflection coatings, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of poor hydrogen passivation effects of anti-reflection films, inability to meet the needs of solar cells, and poor anti-reflection effects. Achieve clear industrialization prospects, easy to operate and realize, and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

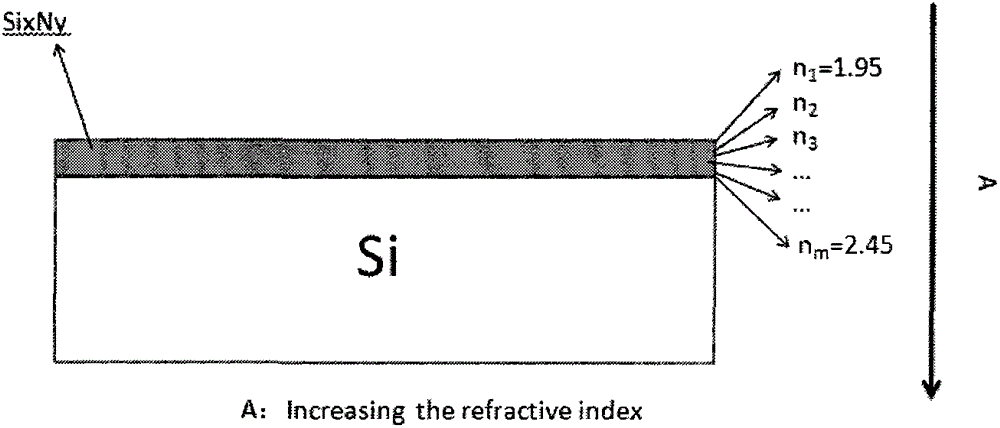

[0019] The preparation method of the novel crystalline silicon solar cell anti-reflection film with constantly changing refractive index of the present invention comprises the following steps:

[0020] (1) Using a graphite boat to carry monocrystalline / polycrystalline silicon wafers, the temperature is 450°C, the single crystal power is 4100Watt, the polycrystalline power is 6000Watt, the RF duty ratio is 5:55, the pressure is 1500mTorr, and silane and ammonia gas are introduced Coatings deposited by glow discharge.

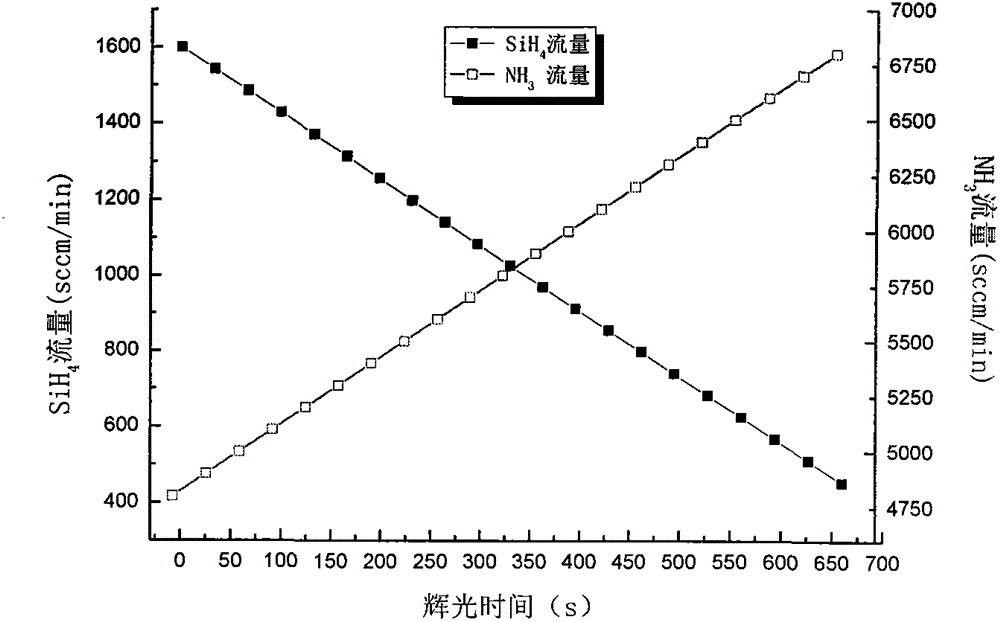

[0021] The silane flow decreases with the glow time, the ammonia flow increases with the glow discharge time, the ratio of silane to ammonia decreases from 1:3 to 1:15, and the mass flow control is adjusted by computer during the glow discharge time The device reduces the silane flow rate from 1600ml / min to 453ml / min at a constant speed, and the ammonia flow rate increases from 4800ml / min to 6800ml / min at a constant speed. The total flow difference during the glo...

example 1

[0026] 1. Before the production of the anti-reflection film, according to the conventional production process of monocrystalline silicon solar cells, that is, cleaning→diffusion→etching→phosphorus washing→PE→printing→sintering, the monocrystalline silicon wafer with a resistivity of 1-3Ω·cm is washed After phosphorous, prepare for coating.

[0027] 2. A graphite boat is used to carry a single crystal silicon wafer, the temperature is 450°C, the power is 4100Watt, the radio frequency duty ratio is 5:55, the pressure is 1500mTorr, and the coating is deposited by glow discharge under the condition of feeding silane and ammonia gas.

[0028] The silane flow decreases with the glow time, the ammonia flow increases with the glow discharge time, the ratio of silane to ammonia decreases from 1:3 to 1:15, and the mass flow control is adjusted by computer during the glow discharge time The device reduces the silane flow rate from 1600ml / min to 453ml / min at a constant speed, and the ammo...

example 2

[0036] 1. Before making the anti-reflection film, according to the conventional production process of polycrystalline silicon solar cells, that is, cleaning→diffusion→etching→phosphorus washing→PE→printing→sintering. coating.

[0037] 2. Use a graphite boat to carry the polysilicon wafer. The temperature is 450°C, the power is 6000Watt, the radio frequency duty ratio is 5:55, the pressure is 1500mTorr, and the film is deposited by glow discharge under the condition of feeding silane and ammonia gas.

[0038] The silane flow decreases with the glow time, the ammonia flow increases with the glow discharge time, the ratio of silane to ammonia decreases from 1:3 to 1:15, and the mass flow control is adjusted by computer during the glow discharge time The device reduces the silane flow rate from 1600ml / min to 453ml / min at a constant speed, and the ammonia flow rate increases from 4800ml / min to 6800ml / min at a constant speed. The total flow difference during the glow process is less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com