Conductive lead-free tin alloy -coated copper belt for solar photovoltaic cell

A photovoltaic cell, tin alloy technology, applied in the direction of metal/alloy conductors, circuits, electrical components, etc., can solve the revelation that the combination of Si, P and Cu, Ti is not disclosed, the technical solution that contains Cu and Ti at the same time is not disclosed, and there is no disclosure. Alloy mechanical properties, physical properties test data reports and other issues, to achieve the effect of dense crystallization, lower production costs, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

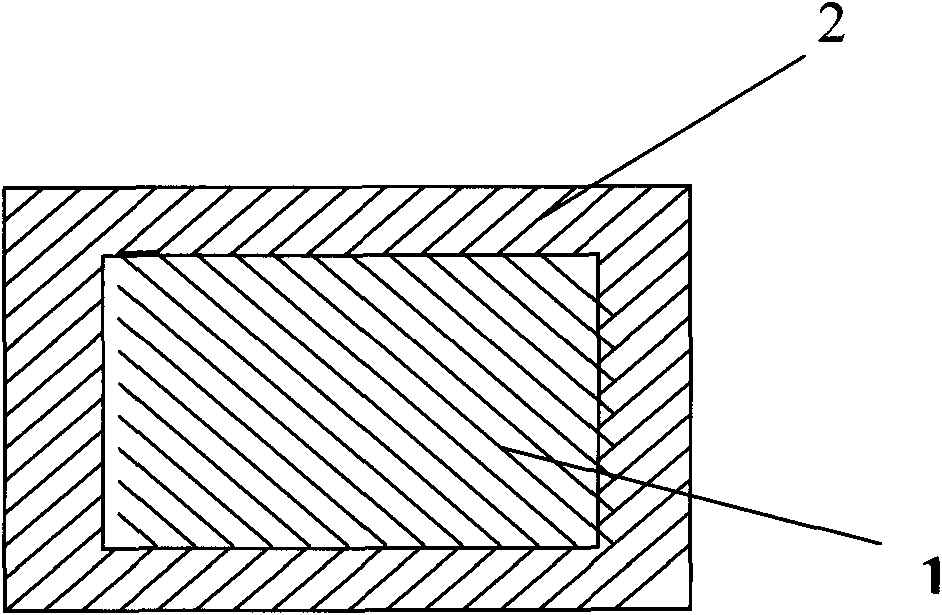

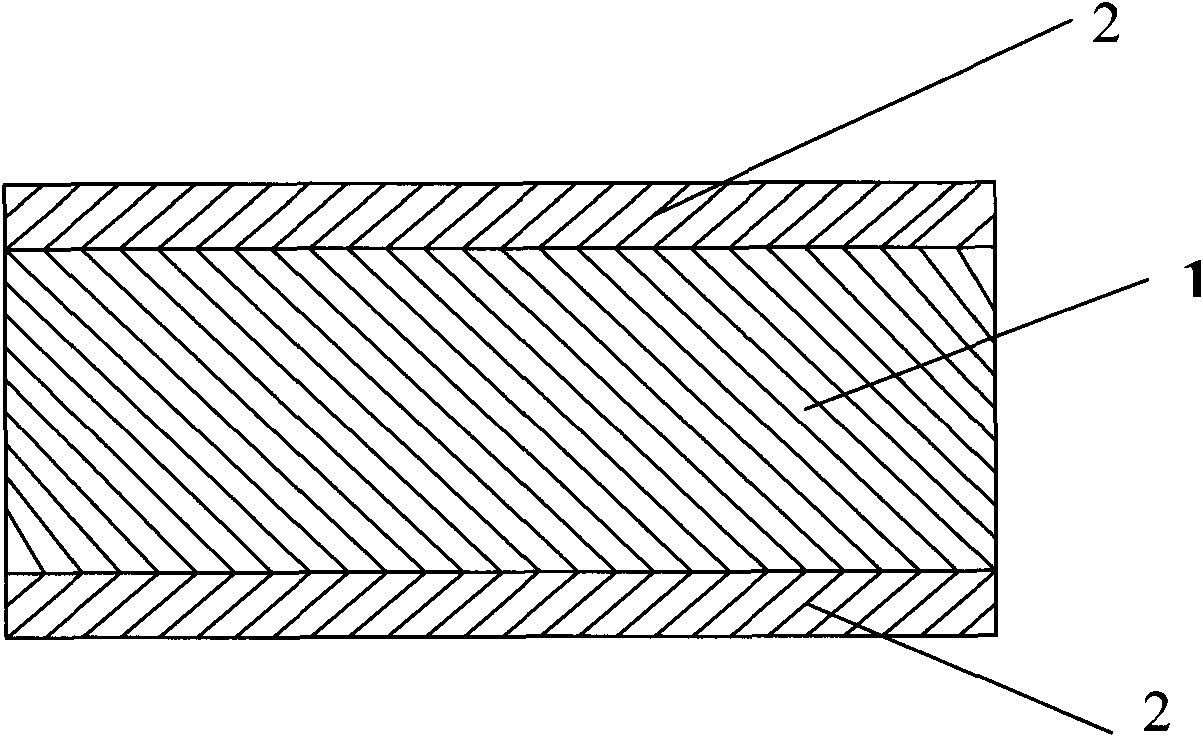

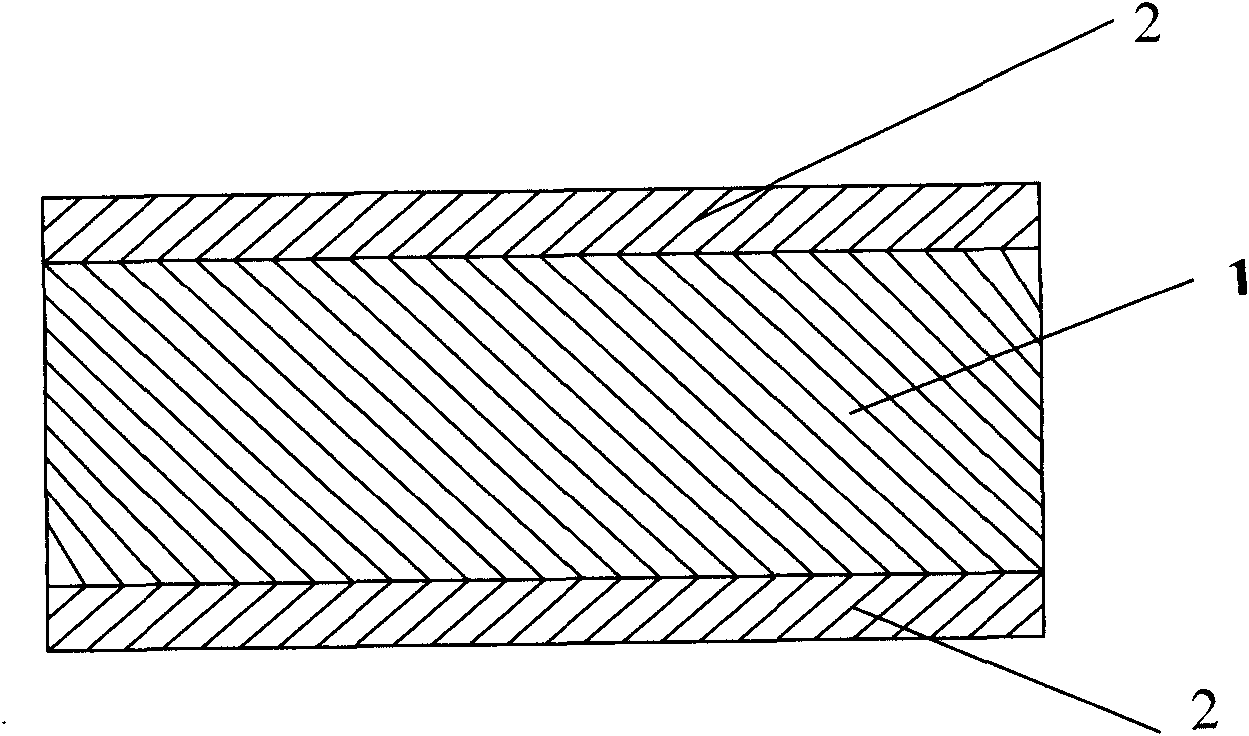

[0016] Such as figure 1 with 2 As shown, 1 in the figure is a copper strip, and 2 is a tin alloy layer wrapped on the outside of the copper strip. Said tin alloy layer is clad on the copper strip by hot dip coating method. The total thickness of the tin alloy copper strip is 0.05mm, the width is 0.10mm, and the thickness of the tin alloy layer is 0.015mm. The composition of the tin alloy layer is calculated by weight %: Cu1.00, Ti0.05, Si0.05, P0.05, and the balance is Sn.

Embodiment 2

[0018] The situation is basically the same as in Example 1, except that the total thickness of the tin-alloy-coated copper strip is 0.16mm, the width is 2.0mm, and the thickness of the tin-alloy layer is 0.032mm. The composition of the tin alloy layer is calculated by weight %: Cu0.10, Ti0.30, Si0.01, P0.20, and the balance is Sn.

Embodiment 3

[0020] The situation is basically the same as in Example 1, except that the total thickness of the tin-alloy-coated copper strip is 0.2mm, the width is 8mm, and the thickness of the tin-alloy layer is 0.04mm. The composition of the tin alloy layer is calculated by weight %: Cu2.00, Ti0.01, Si0.50, P0.8, and the balance is Sn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com