Method for preparing hydrogen storing alloy powder

A hydrogen storage alloy and alloy powder technology, which is applied in the field of hydrogen storage alloy powder manufacturing, can solve the problems of poor reproducibility of battery performance, unstable alloy performance, and slow cooling of the melt, so as to improve the uniformity of composition and structure, The effect of comprehensive performance improvement and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

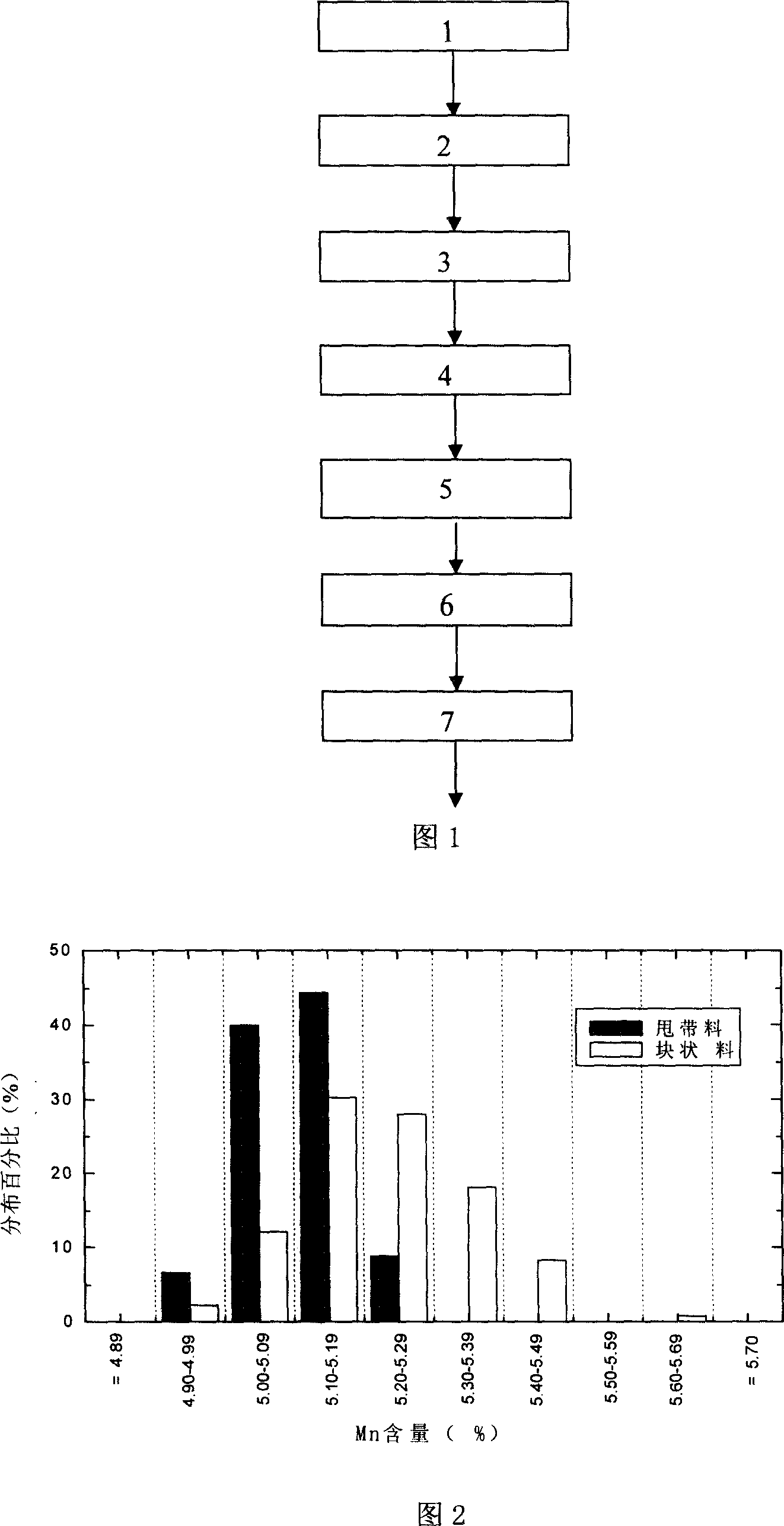

[0036] Embodiment 1: Referring to Fig. 1, the process steps of this embodiment are provided below.

[0037] 1) Batching and composition control: Use a polishing machine and a dryer to pretreat the raw materials to remove some impurities and moisture in the raw materials. The raw materials are nickel, misch, magnesium, cobalt, manganese, aluminum and copper, and the misch Each raw material containing "lanthanum, cerium, praseodymium, and neodymium" and its content after refinement (in Kg) are nickel: lanthanum: cerium: praseodymium: neodymium: magnesium: cobalt: manganese: aluminum: copper = 55:5:15 :1:2:1.5:7:4.5:1.2:2.5;

[0038] 2) Melting process: use a vacuum induction melting furnace to melt the raw materials at a temperature of 1500 ° C, pour the melt on the quenching belt equipment, and the cooling rate is 5×10 5 K / s, made of hydrogen storage alloy flakes with a thickness of 0.2mm;

[0039] 3) Annealing process: annealing the fabricated hydrogen storage alloy flakes i...

Embodiment 2

[0070] Example 2: Similar to Example 1, ingredients and composition control: use a polishing machine and a dryer to pretreat the raw materials to remove some impurities and moisture in the raw materials, and the mixed rare earths contain "lanthanum, cerium, praseodymium, and neodymium" The refined raw materials and their contents (in Kg) are nickel: lanthanum: cerium: praseodymium: neodymium: magnesium: cobalt: manganese: aluminum: copper=55:10:25:0.3:3:3:8:5 : 1: 2; the raw material is smelted, the temperature is 1400 ℃, and the melt is poured on the quenching belt equipment, and the cooling rate is 6×10 5 K / s, made into a hydrogen storage alloy sheet with a thickness of 0.15mm. Anneal the prepared hydrogen storage alloy flakes, the annealing temperature is 900°C, and the annealing time is 8h; the annealed hydrogen storage alloy flakes are made into powder in an inert atmosphere of 5 MPa after nitrogen and argon are compressed by an air compressor, Obtain hydrogen storage al...

Embodiment 3

[0071] Embodiment 3: Similar to Example 1, each raw material and its content (in Kg) after the refinement of "lanthanum, cerium, praseodymium, neodymium" contained in the mixed rare earth are nickel: lanthanum: cerium: praseodymium: neodymium: magnesium: Cobalt: manganese: aluminum: copper = 55: 15: 8: 1.5: 2.5: 0.1: 5: 6.5: 2.5: 3 The raw materials are smelted at a temperature of 1300°C, and the melt is poured on the quenching belt equipment, and the cooling rate is 8×10 5 K / s, made into a hydrogen storage alloy sheet with a thickness of 0.25mm. The hydrogen storage alloy flakes were annealed, the annealing temperature was 800°C, and the annealing time was 5h; the annealed hydrogen storage alloy flakes were compressed by an air compressor to form a powder in an inert atmosphere of 5 MPa, Obtain hydrogen storage alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com