Patents

Literature

68results about How to "Uniform distribution of current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

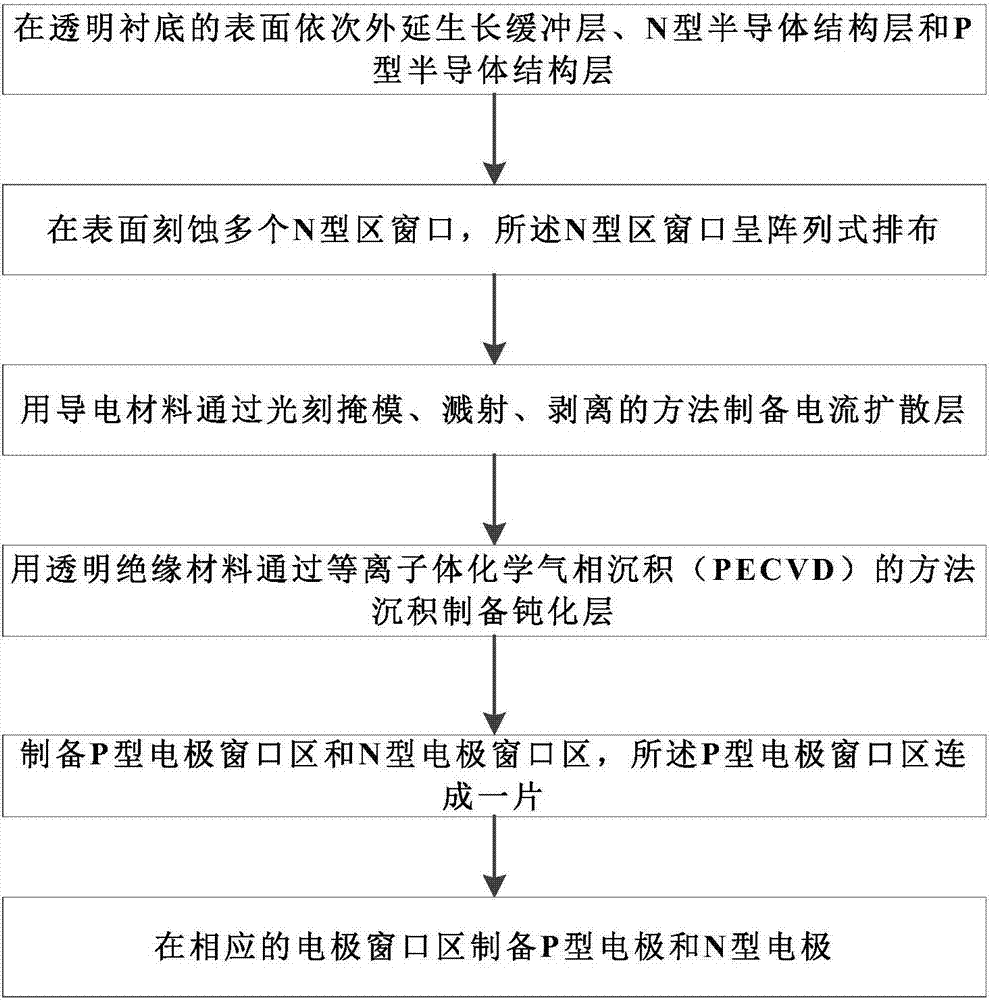

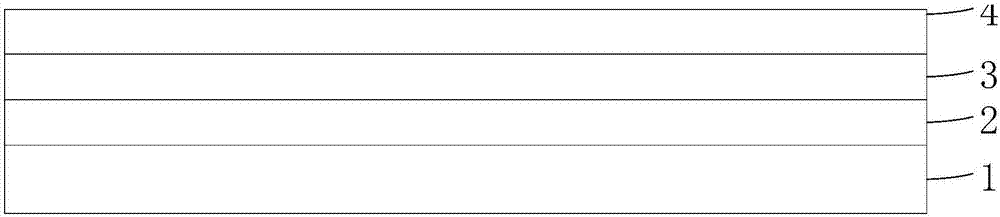

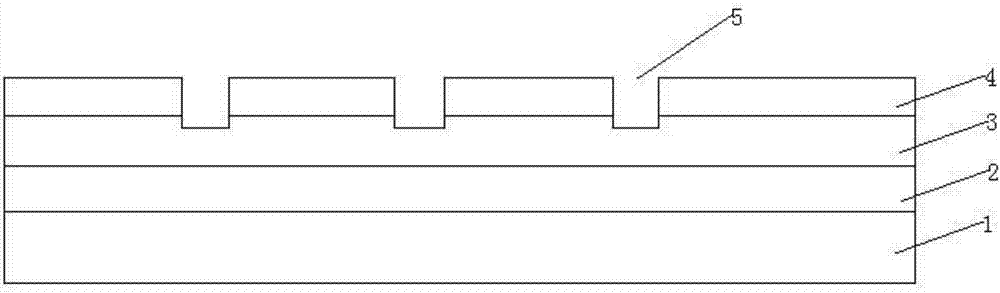

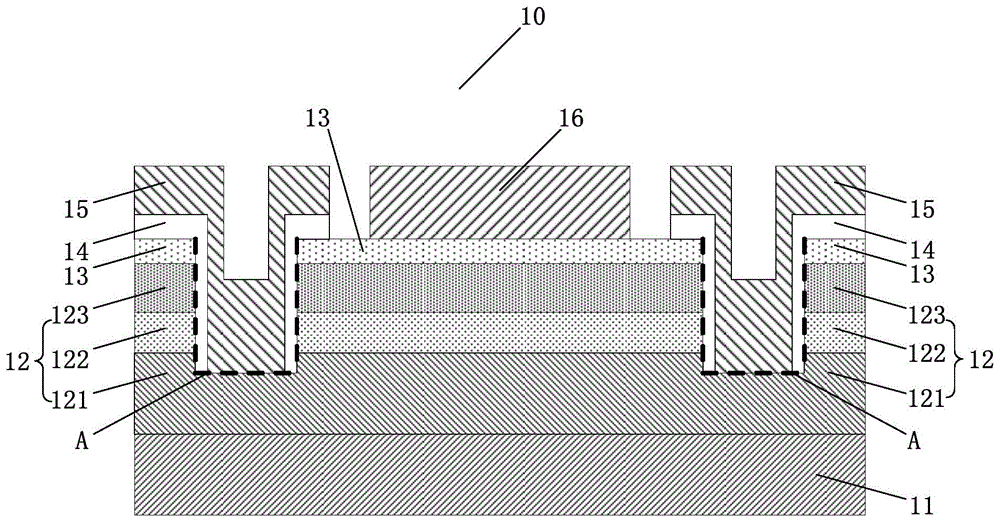

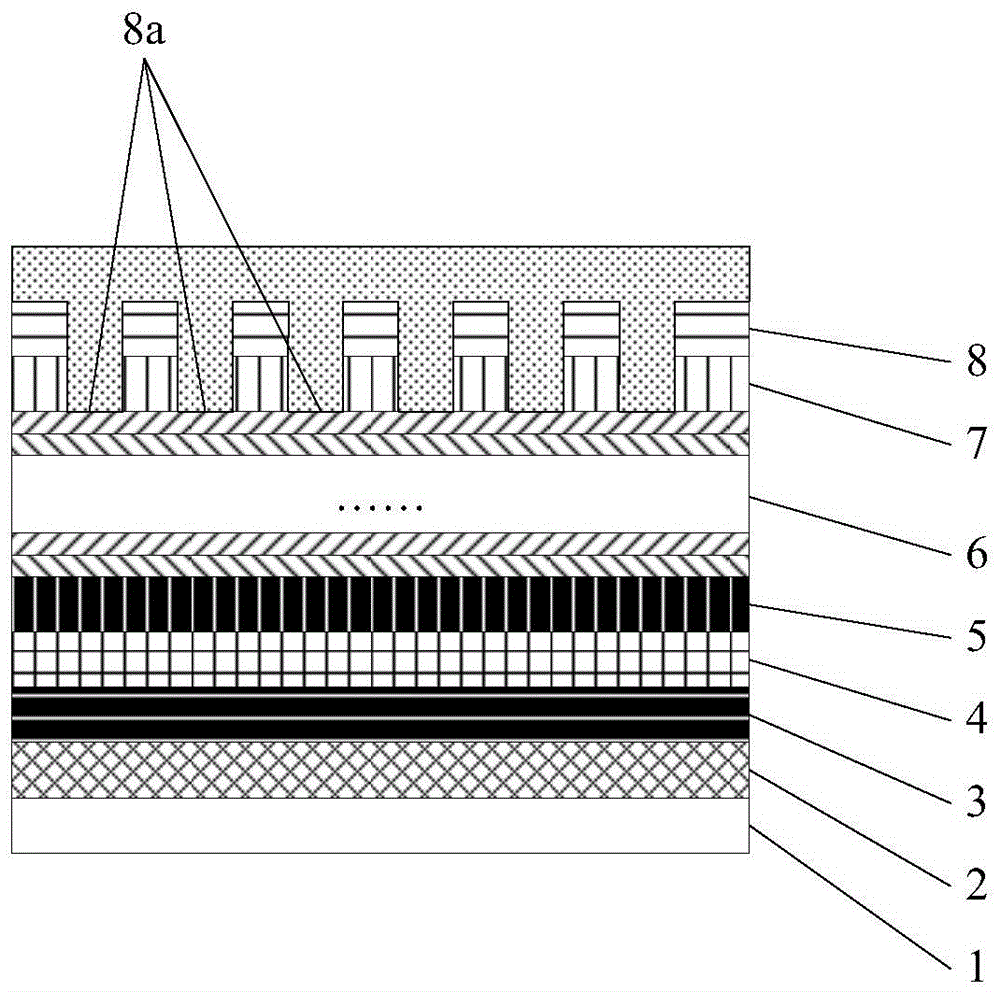

Flip LED chip array structure and preparation method thereof

PendingCN107146840AUniform distribution of current densityIncrease powerSemiconductor devicesElectrically conductiveEngineering

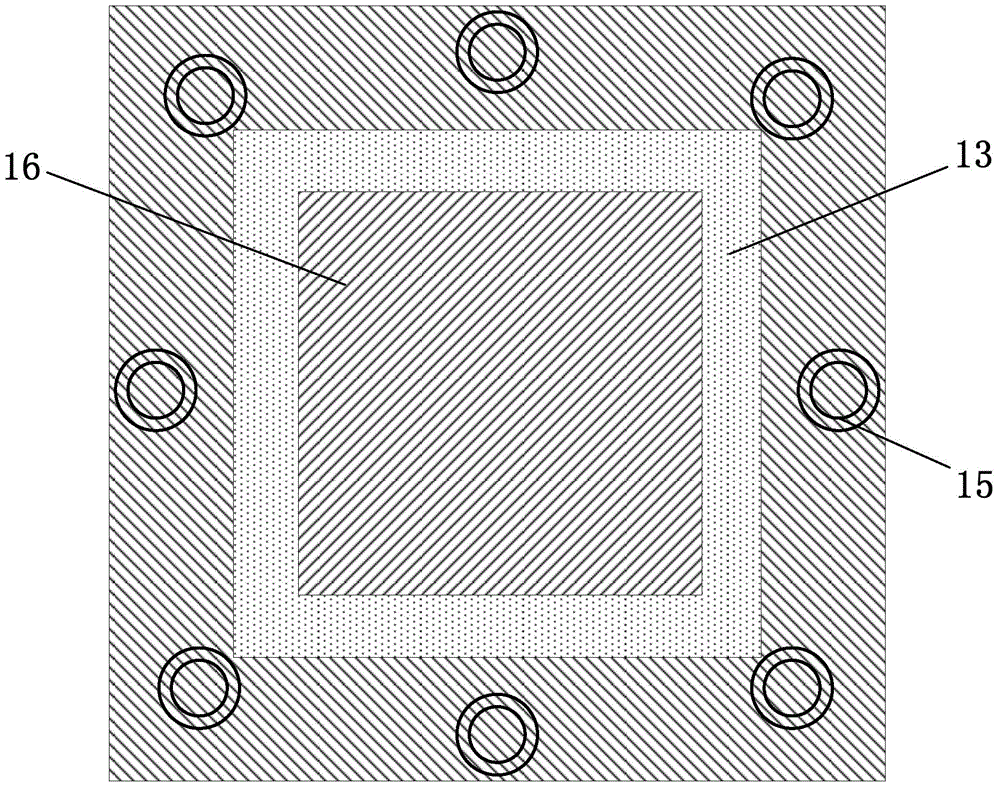

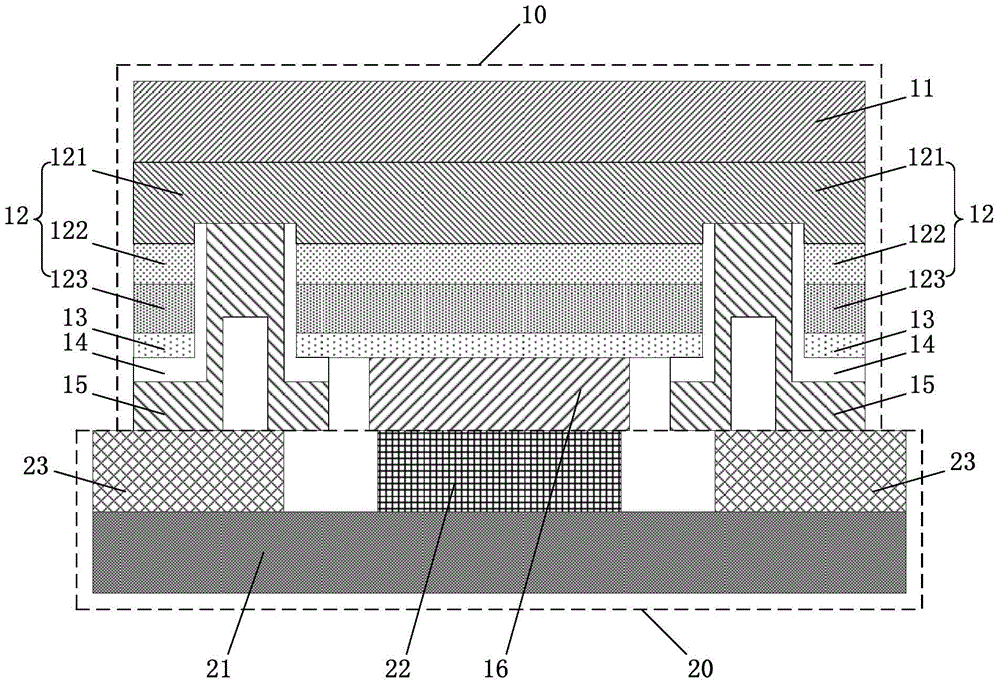

The invention discloses a flip LED chip array structure. The flip LED chip array structure comprises a transparent substrate made of a transparent material; a buffer layer arranged on one surface of the transparent substrate; an N-type semiconductor structural layer and a P-type semiconductor structural layer formed on the buffer layer; a current diffusion layer made of a conductive material; a passivation layer arranged above the P-type semiconductor structural layer, made of a transparent insulating material, and covering the current diffusion layer, the P-type semiconductor structural layer, and the N-type semiconductor structural layer; a plurality of N-type electrode window regions arranged in an array manner and contacted with the N-type semiconductor structural layer; and P-type electrode window regions contacted with the P-type semiconductor structural layer. The N-type electrode window regions are provided with N-type electrodes, the P-type electrode window regions are provided with P-type electrodes, and the heights of the P-type electrodes and the N-type electrodes are the same. According to the flip LED chip array structure, the effective light-emitting area of the high-power LED chip is increased, the effective contact area between the chip electrodes and the heat radiation substrate is increased, the heat radiation effect is better, and the service lifetime of the chip is prolonged.

Owner:苏州瑞而美光电科技有限公司

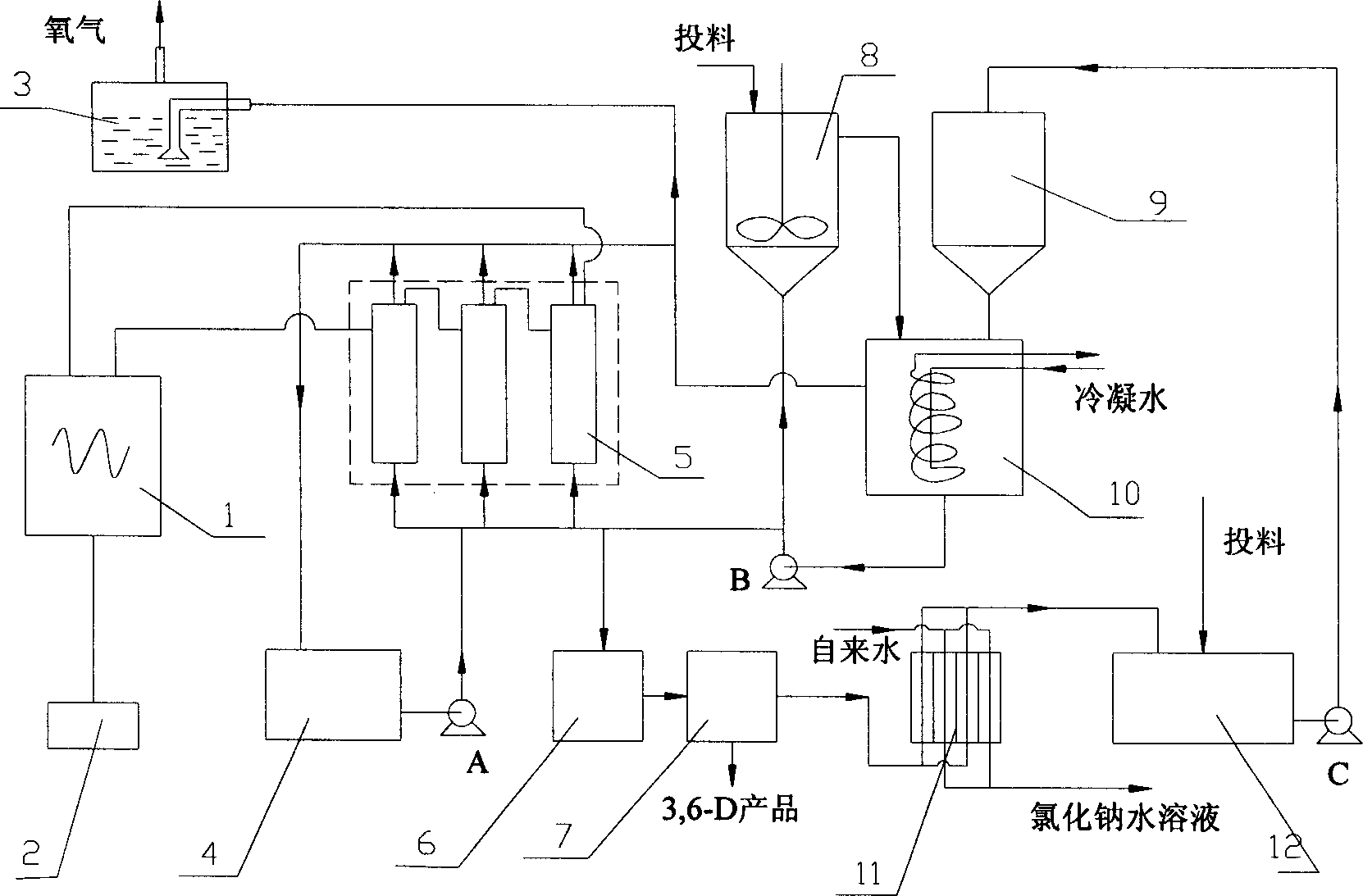

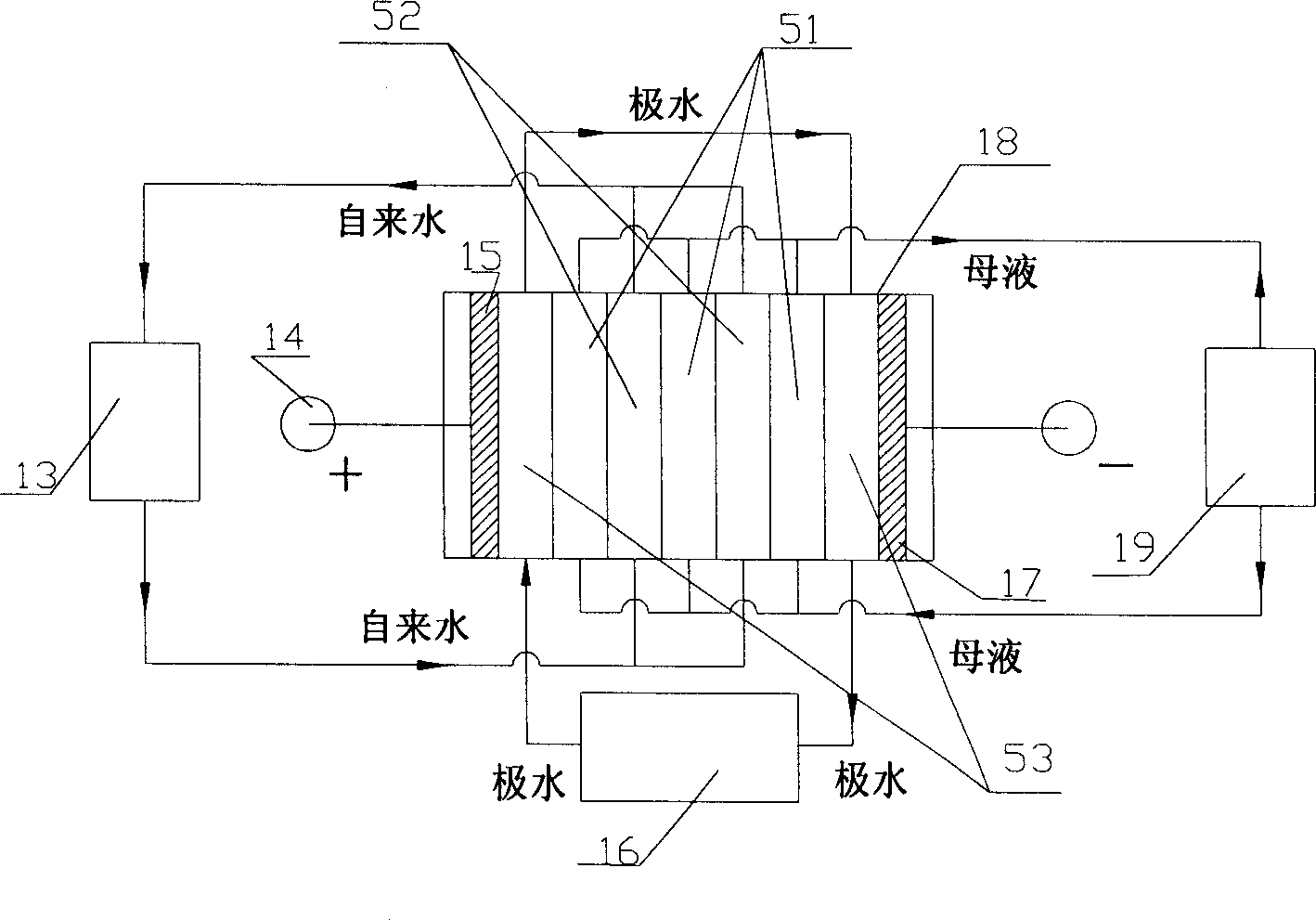

Method and apparatus for electrolytic synthesis of 3,6-dichloropyridine-carboxylic acid

InactiveCN1807691ALow energy consumption in the production processLess side effectsOrganic chemistryElectrolysis componentsElectrolysisSynthesis methods

The invention discloses a 3, 6- dichloro pyridine methanamine electrolytic synthesis method and device, which comprises the following steps: using 3, 4, 5, 6-tetrachloro pyridine aminic acid for main electrolysis material; placing electrolytic solution in electrolysis bath to electrolyze; getting 3, 6- dichloro pyridine methanamine by neutralizing, cooling, crystallizing, filtering and drying; carrying on toughening treatment for cathode of electrolysis bath by periodic reversible power of thyristors. The device is composed of power, dosage bunker, electrolysis bath, wherein the power is stabilized voltage and permanent flow, which can control the cycle reverse power; the power connects to current commutator; program control unit is installed for current commutator; the anode of power is connected to anode of electrolysis bath; the minus pole of power connects to cathode of electrolysis bath.

Owner:ZHEJIANG UNIV OF TECH

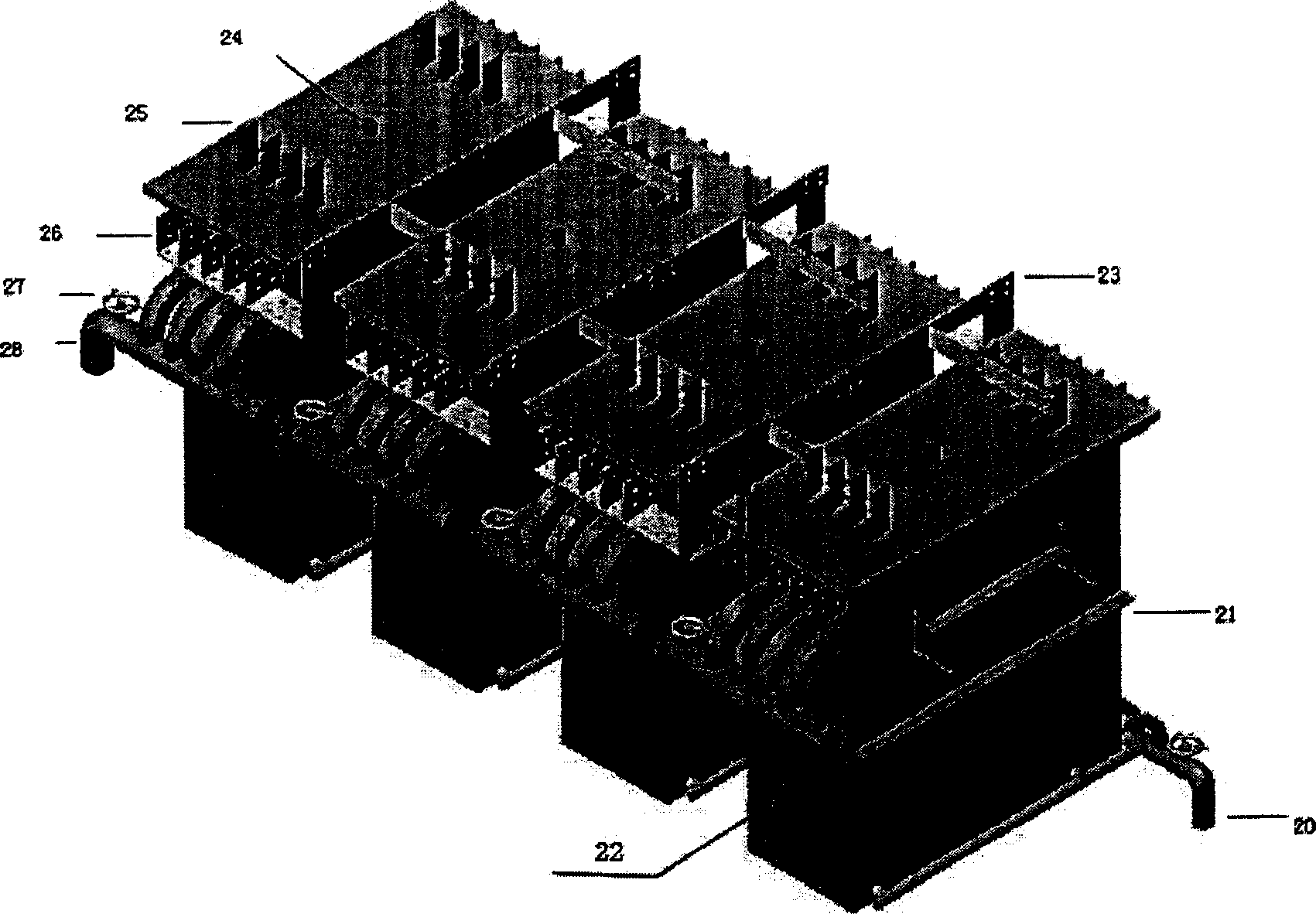

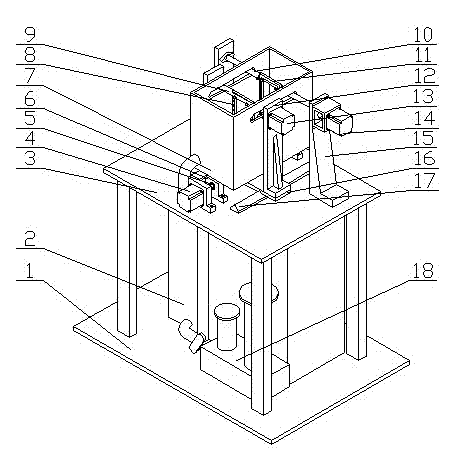

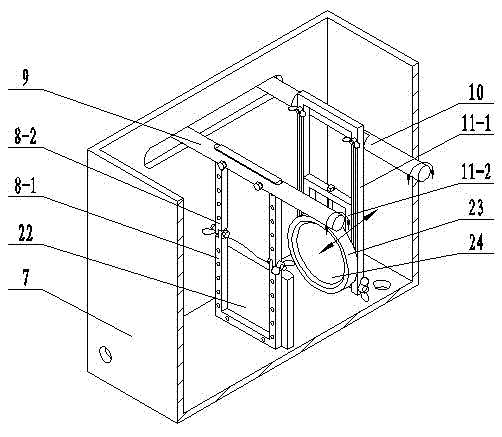

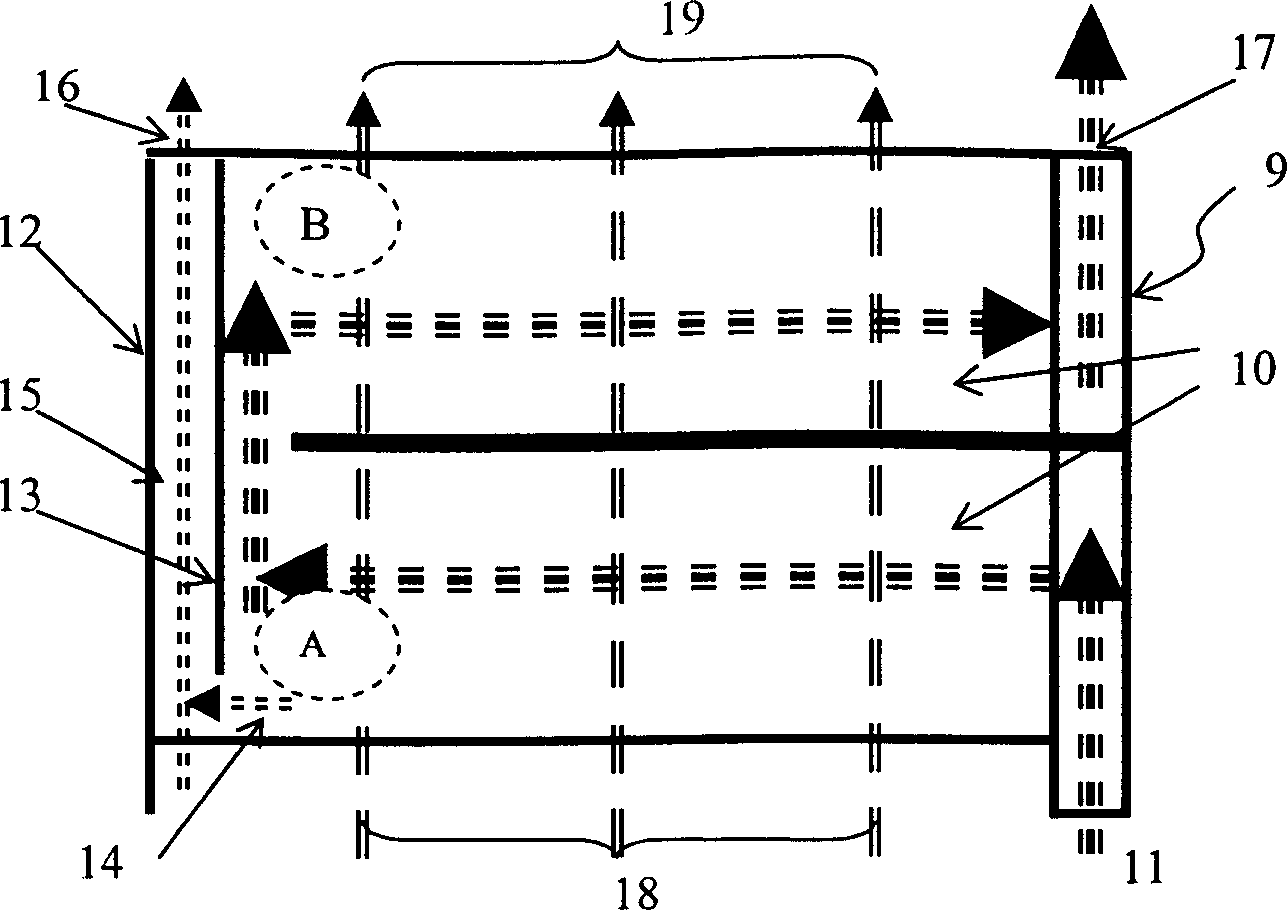

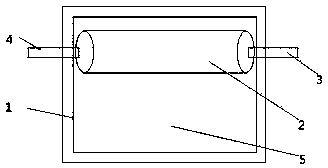

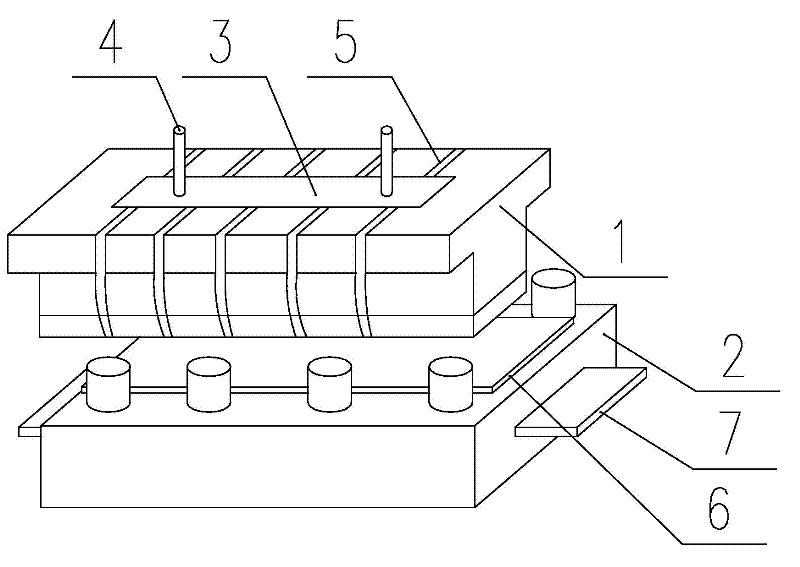

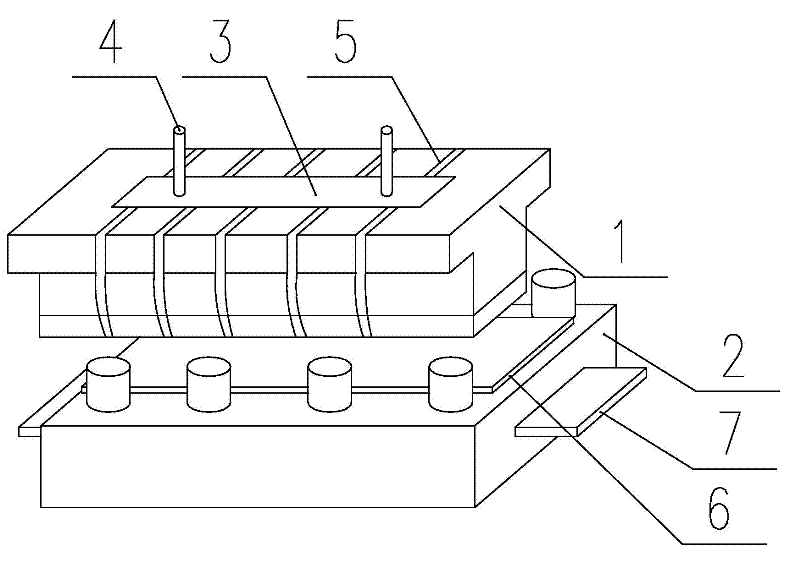

Microelectroforming machine tool

InactiveCN102586813AFlexible electrode placementMeet different electroforming process requirementsElectroforming processesFiltrationControl system

The invention discloses a microelectroforming machine tool. The microelectroforming machine tool comprises a base of the machine tool, wherein a workbench is arranged on the base, a liquid storage groove is arranged below the workbench, an electroforming groove is arranged on the workbench, an anode clamping unit and a cathode clamping unit are arranged in the electroforming groove, the anode clamping unit is used for placing an anode, a cathode clamping unit is used for placing a cathode, a filtration circulating unit connected with the liquid storage groove is arranged on the base, and the microelectroforming machine tool further comprises an anode horizontal feed unit, an anode rotating unit, a cathode rotating unit and a motion control system. The microelectroforming machine tool disclosed by the invention is compact in structure, the arrangement ways of electrodes are flexible and changeable, the motion modes of the electrodes are diverse, the operation is simple and convenient, the functions are abundant and automatic, and the microelectroforming machine tool can meet different application requirements of an electroforming process and give a full play to the potential of the electroforming device.

Owner:HENAN POLYTECHNIC UNIV

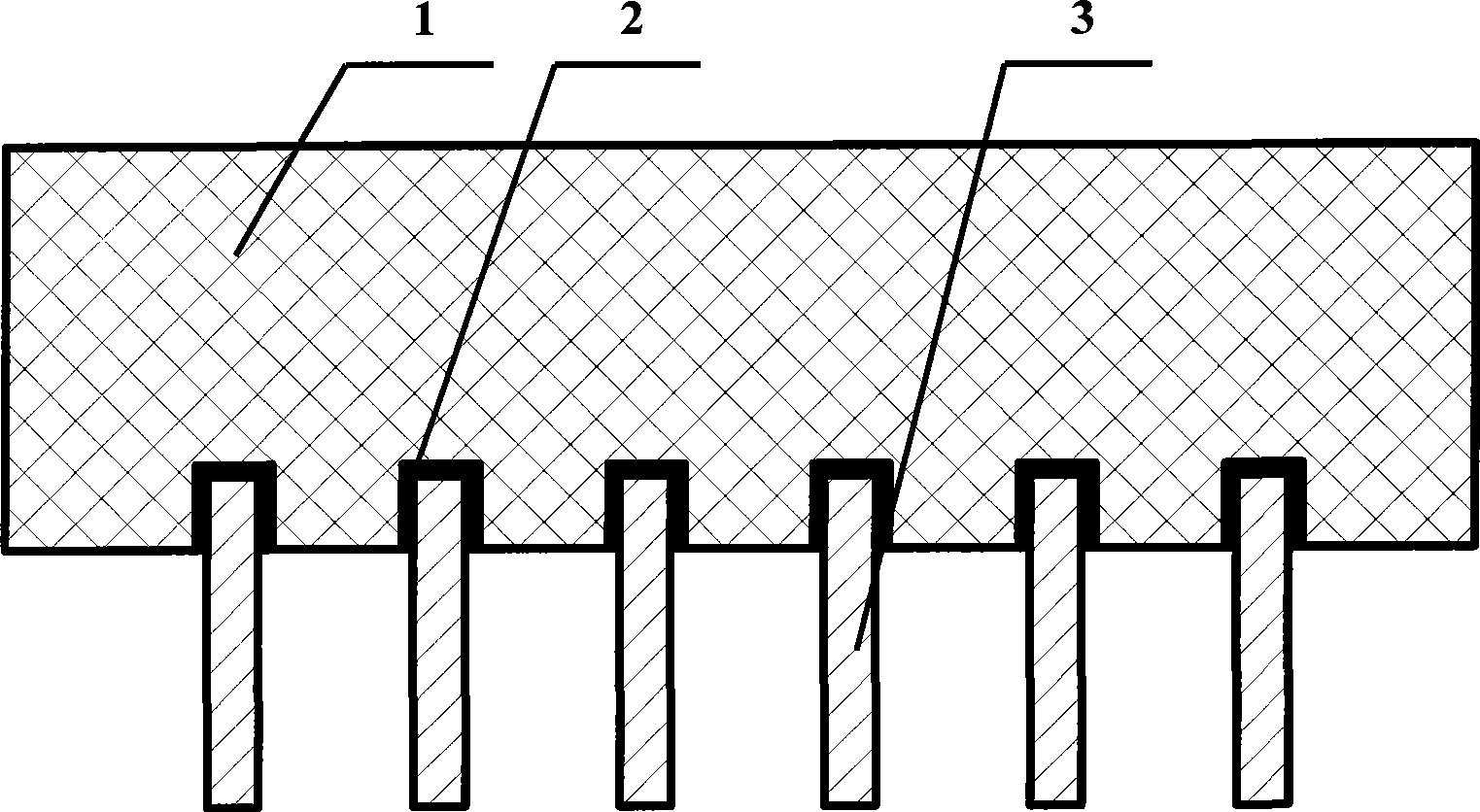

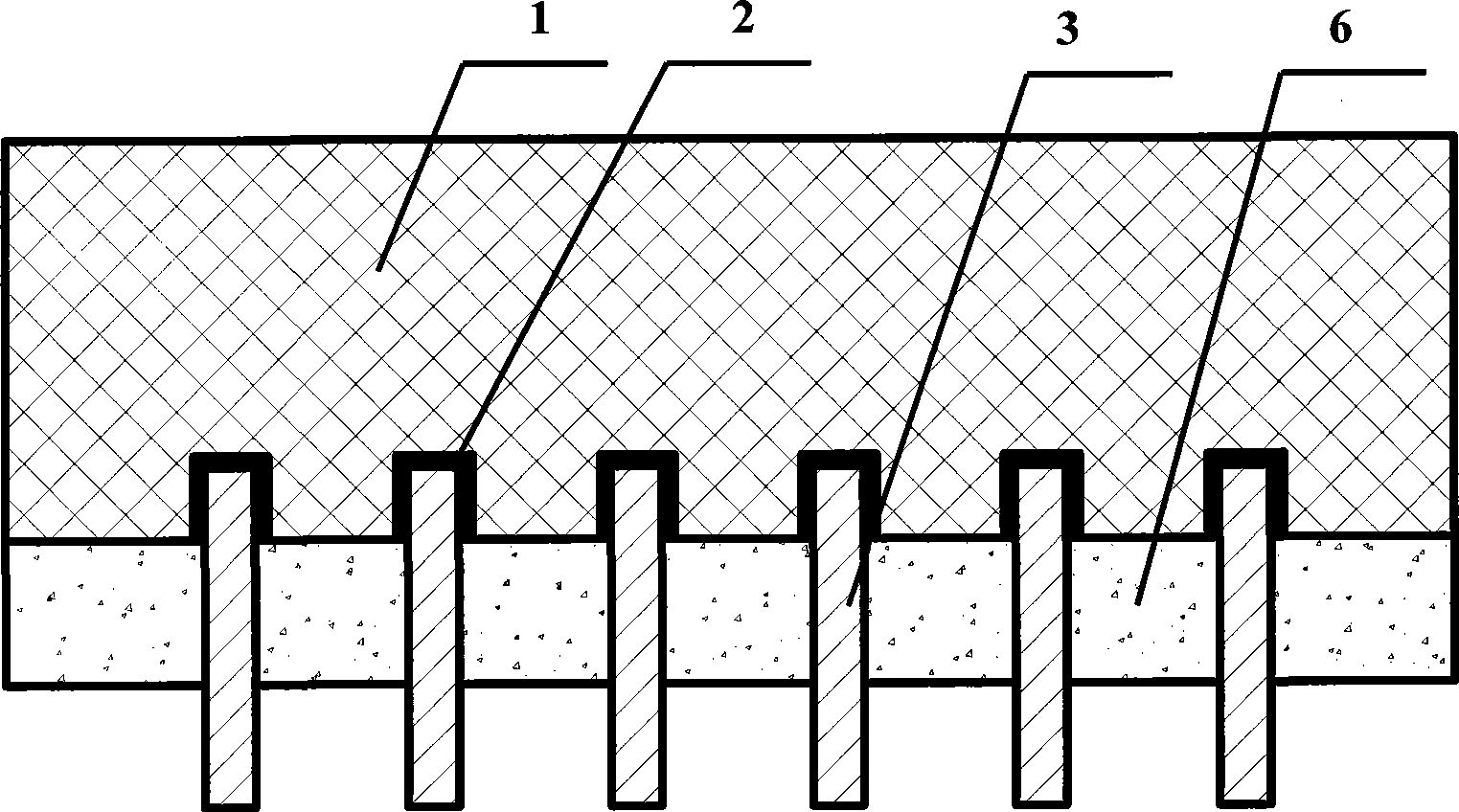

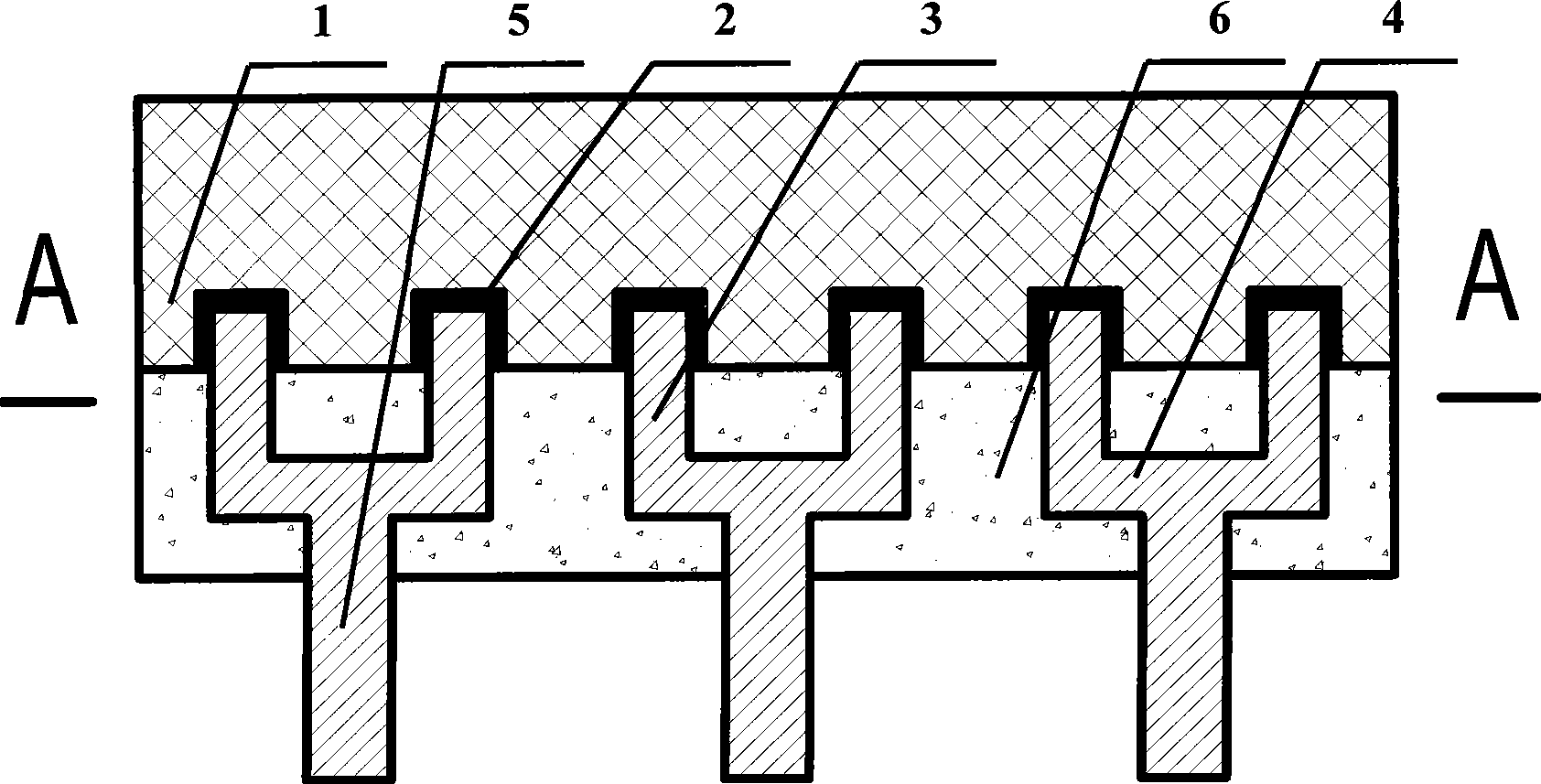

Method for eliminating horizontal current in aluminum cell aluminum liquor

The invention belongs to the technical field of aluminum electrolysis tank which is used in the production of primary aluminum by the Hall-Herolut electrolysis method. Particularly, the invention relates to a method for eliminating horizontal current in aluminum liquid in the aluminum electrolysis tank. The method comprises: the lower part or lower surface of a cathode carbon block is provided with an electric conductor directly penetrating the tank bottom. The method has the advantages of eliminating the horizontal current in the aluminum liquid in the aluminum electrolysis tank, making the current density distribution on the surface of the cathode carbon block more uniform, improving current efficiency, greatly improving stability of the aluminum electrolysis tank and prolonging service life of the aluminum electrolysis tank. The method is strong in practicability. The method can fundamentally solve the problem of the horizontal current in the aluminum liquid, and has very important directive significance on the development of the large-sized aluminum electrolysis tank.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

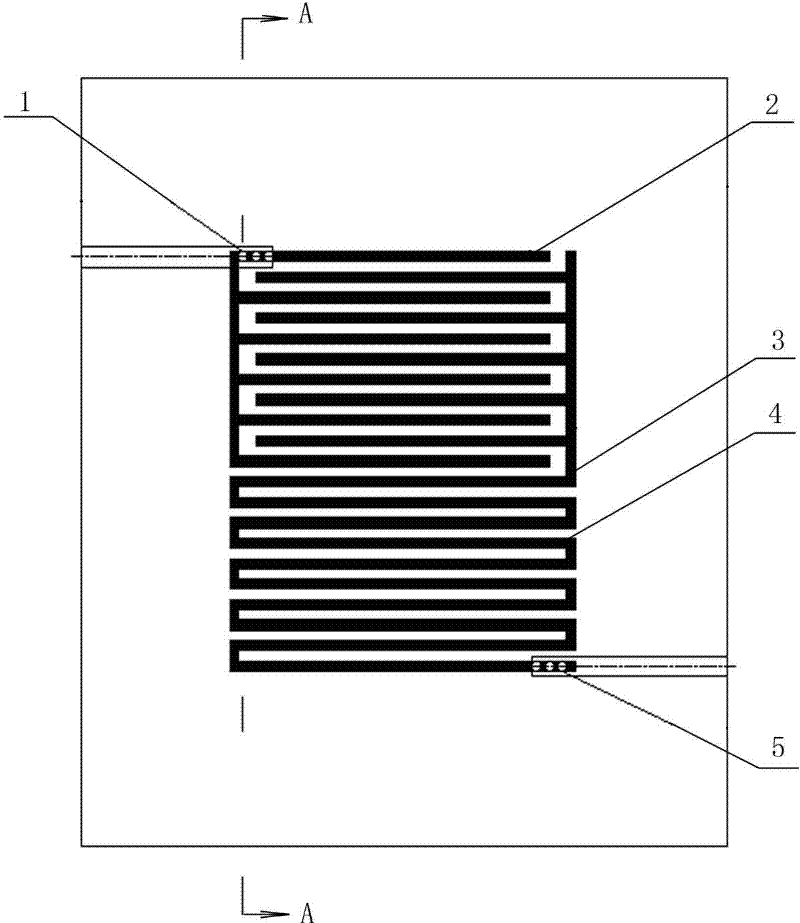

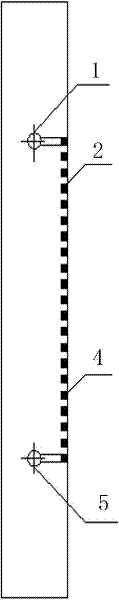

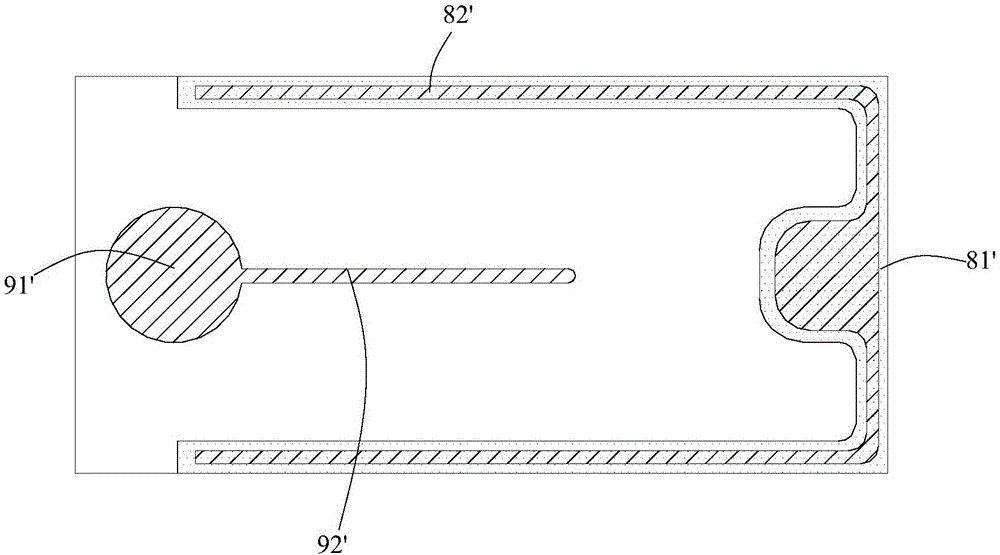

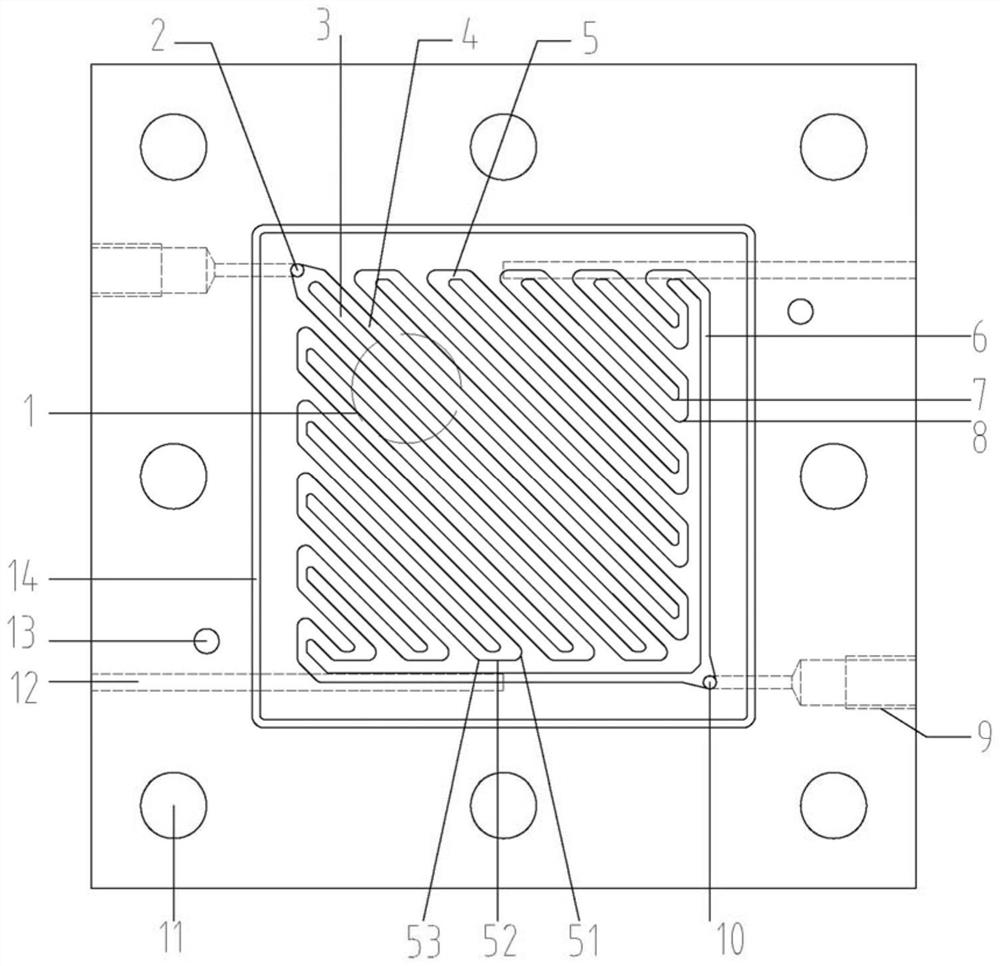

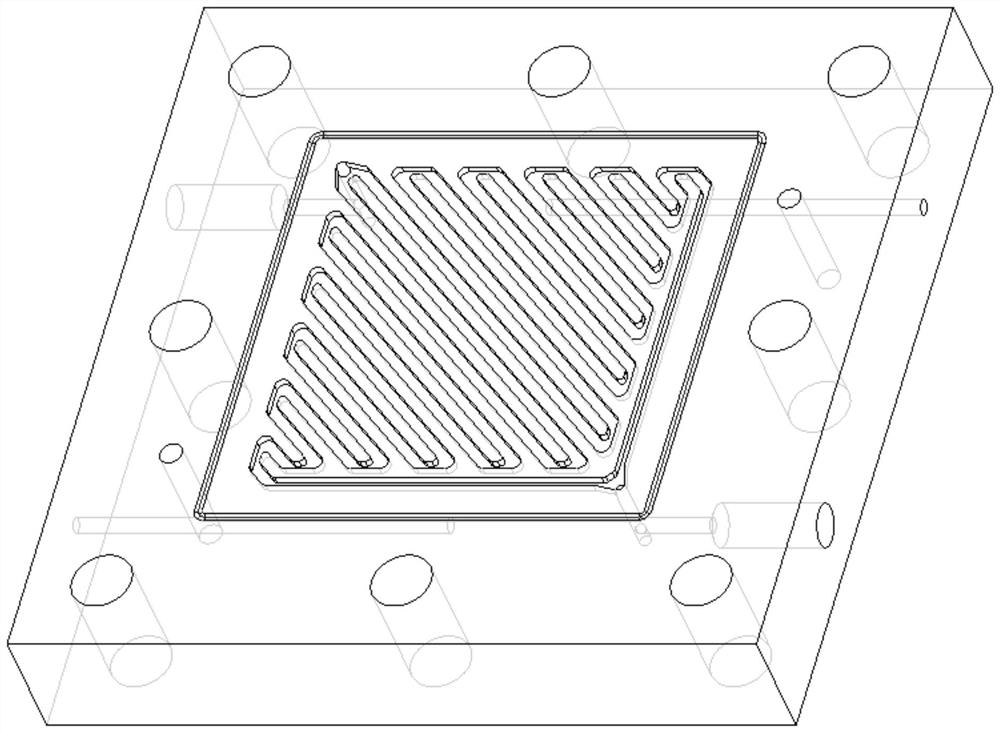

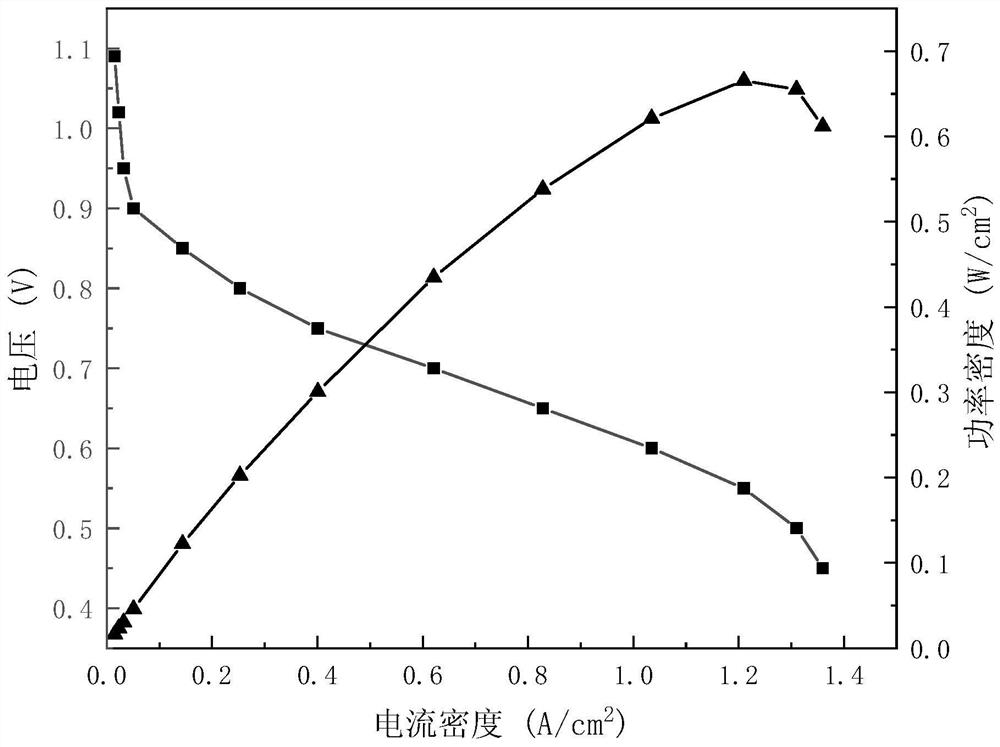

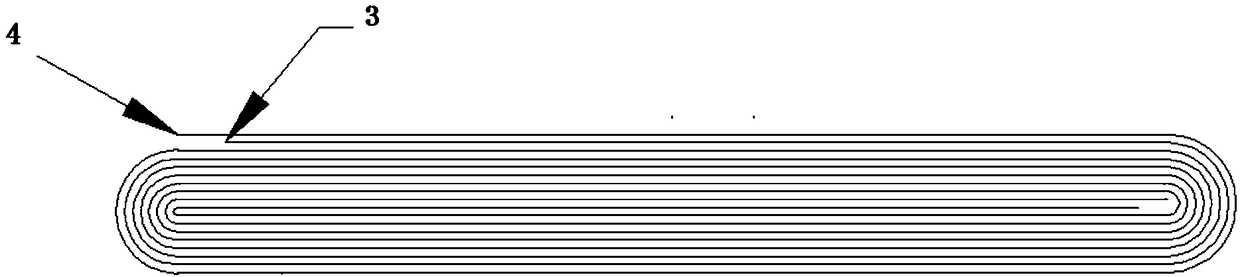

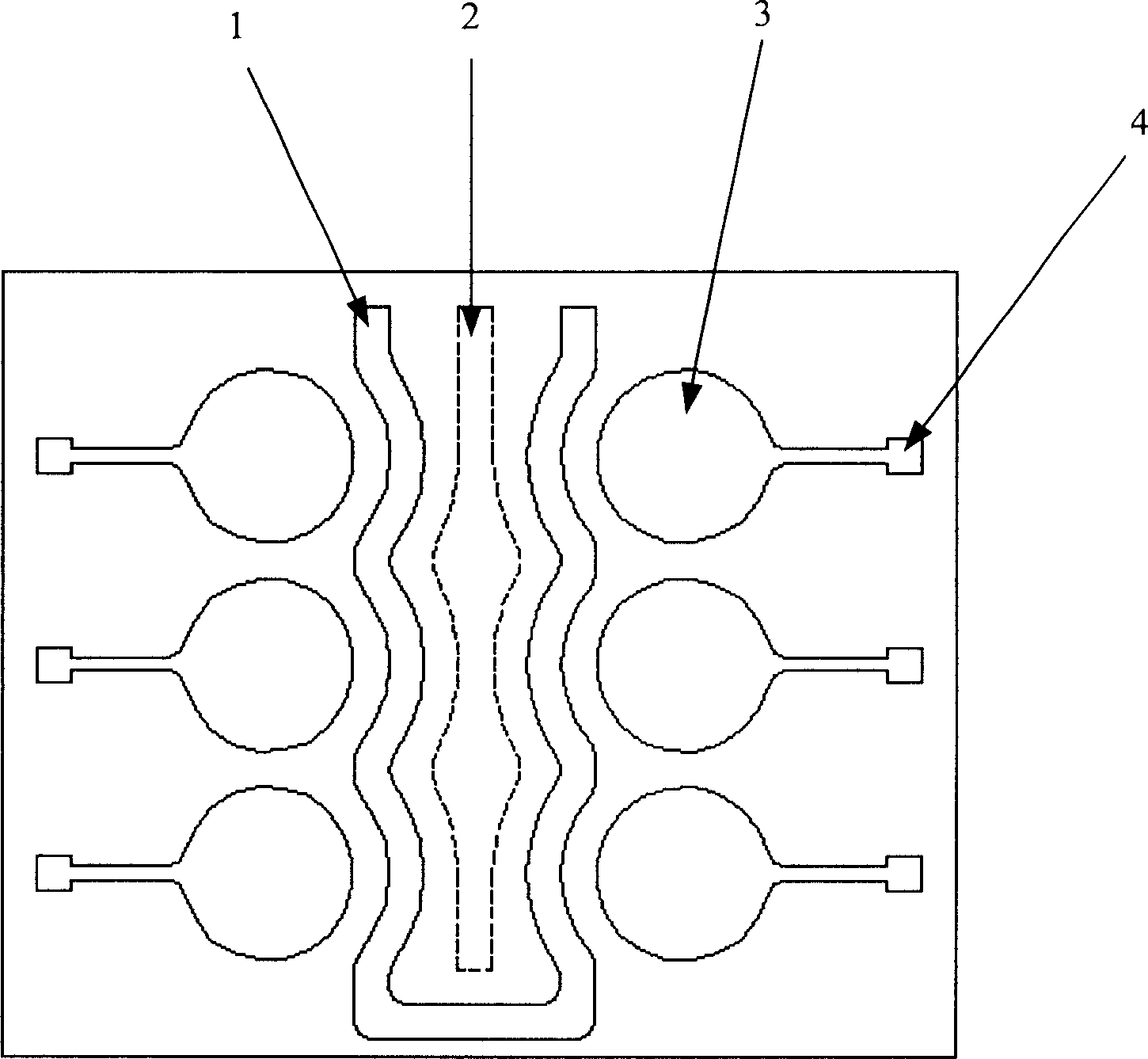

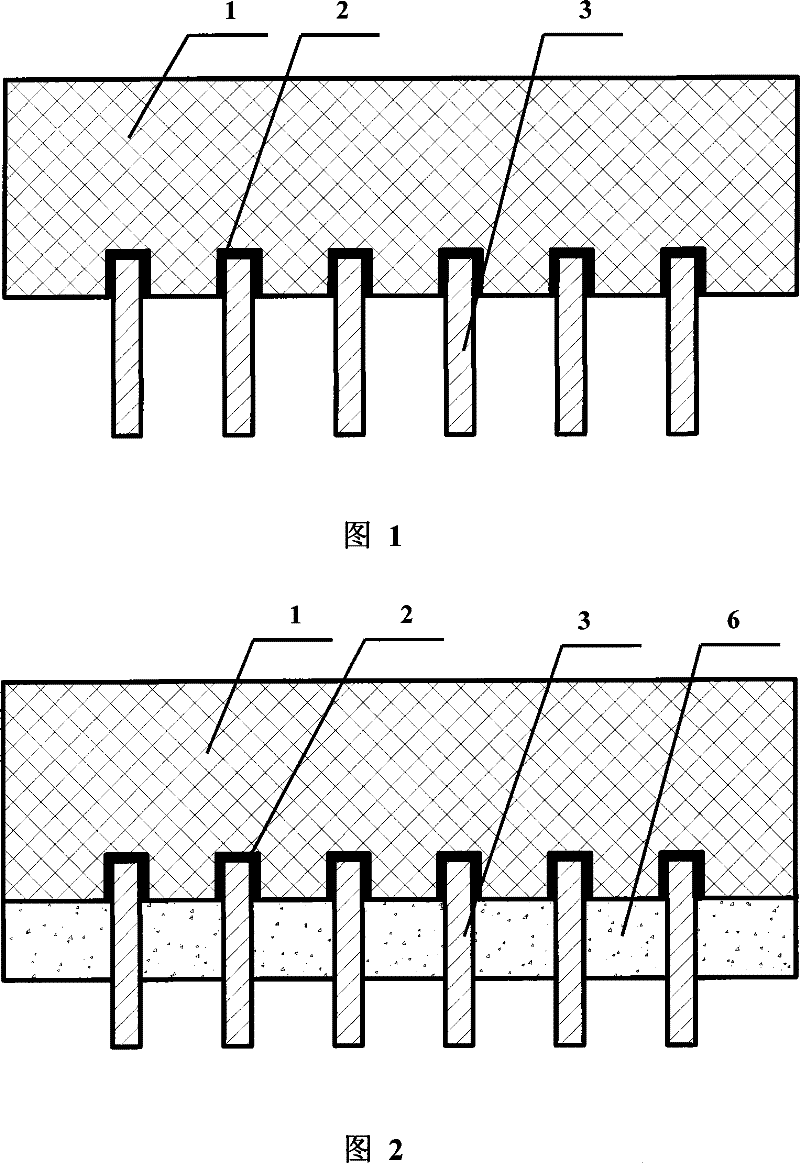

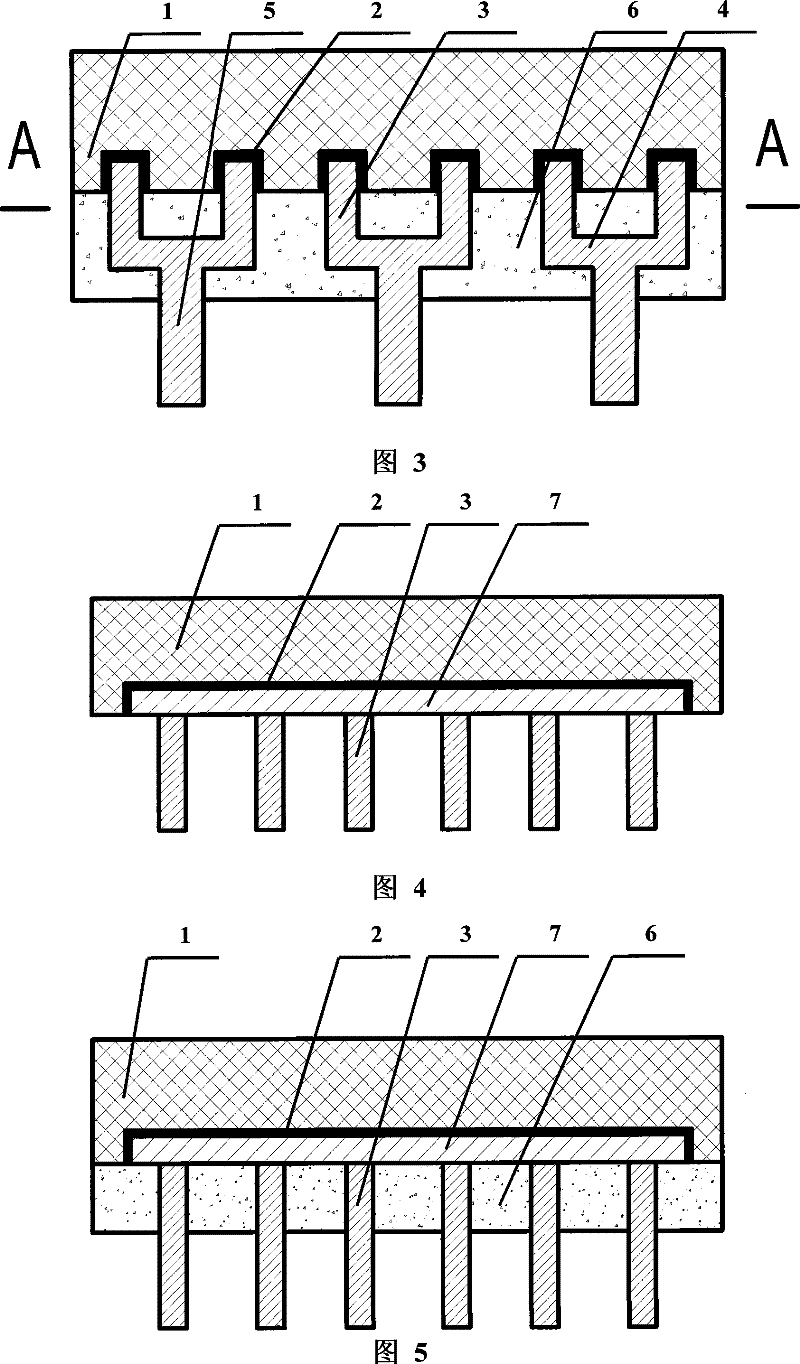

Proton exchange membrane fuel cell flow field structure

InactiveCN102201583AFast deliveryReduce concentration polarizationFinal product manufactureFuel cell detailsSocial benefitsEngineering

The invention relates to a fuel cell flow field structure, in particular to a proton exchange membrane fuel cell flow field structure. The proton exchange membrane fuel cell flow field structure comprises an interdigitated flow field runner and a snake-shaped flow field runner; a plurality of runners consisting of the interdigitated flow field runner and the snake-shaped flow field runner are arranged on the same side of a flow field board; a runner air inlet hole is formed at a proper position of one end of the interdigitated flow field runner; a runner air outlet hole is formed at a proper position of one end of the snake-shaped flow field runner; and the interdigitated flow field runner and the snake-shaped flow field runner are connected with each other through a connecting runner. In the proton exchange membrane fuel cell flow field structure, the flow field runners are quick in water drainage; moreover, runner plugged, short circuit or channeling phenomena can be avoided; the current density distribution is uniform, the cell performance is higher, the structure is simple and rational, and the manufacturing cost is low; and the proton exchange membrane fuel cell flow field structure has wide social benefit and market prospect.

Owner:SHENYANG JIANZHU UNIVERSITY

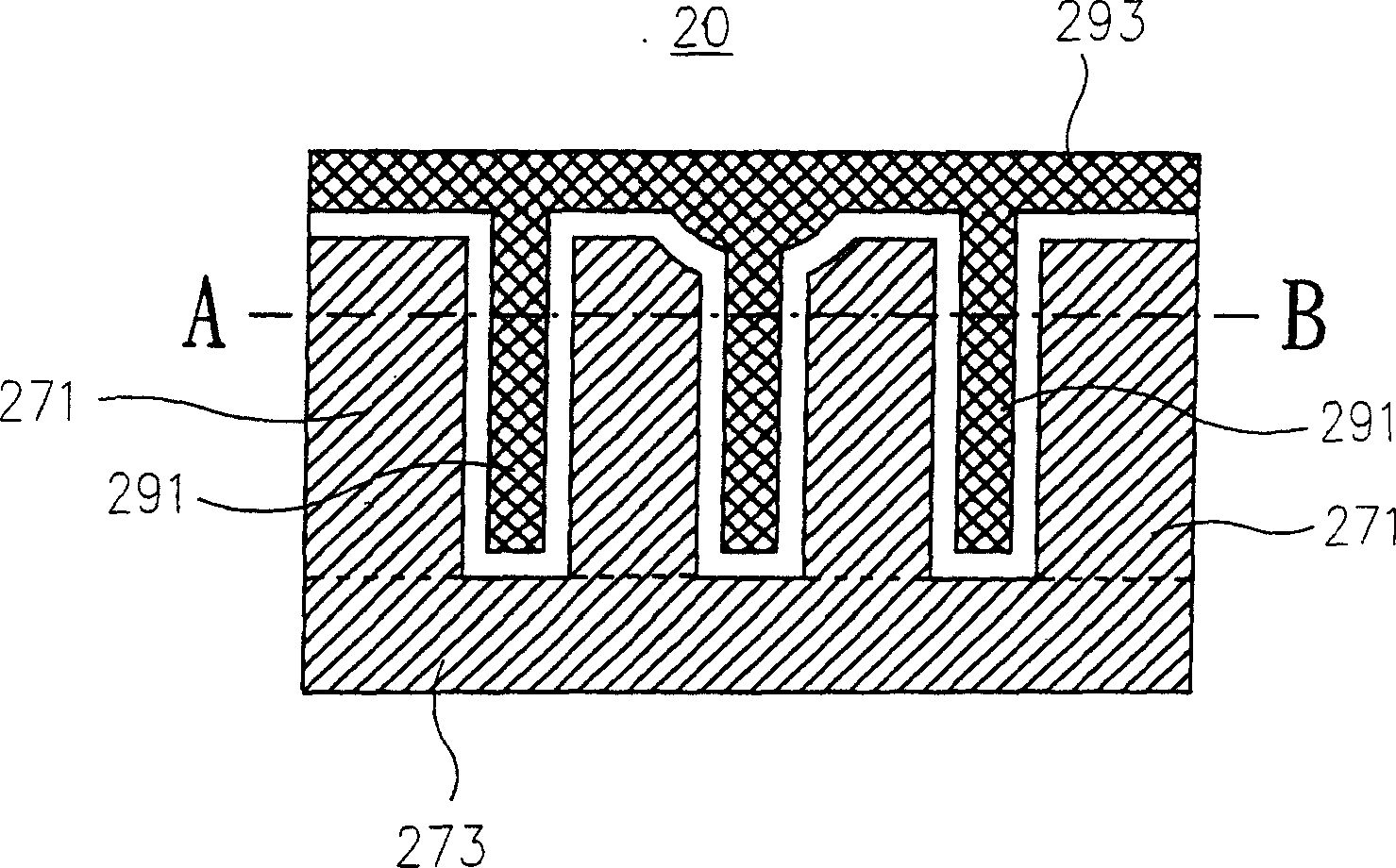

LED chip and manufacturing method thereof

InactiveCN105449068AImprove luminous efficiencyUniform distribution of current densitySemiconductor devicesInsulation layerEngineering

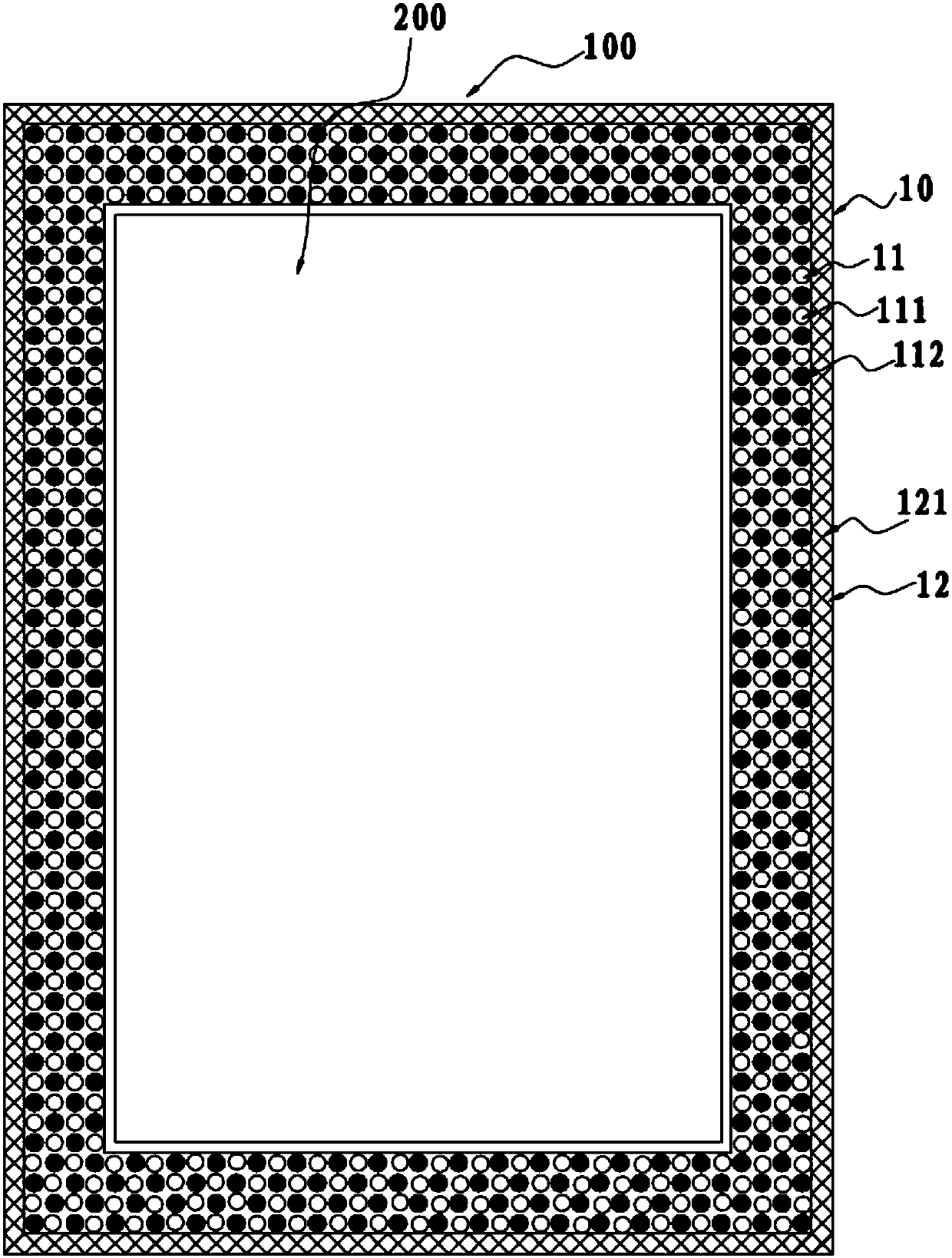

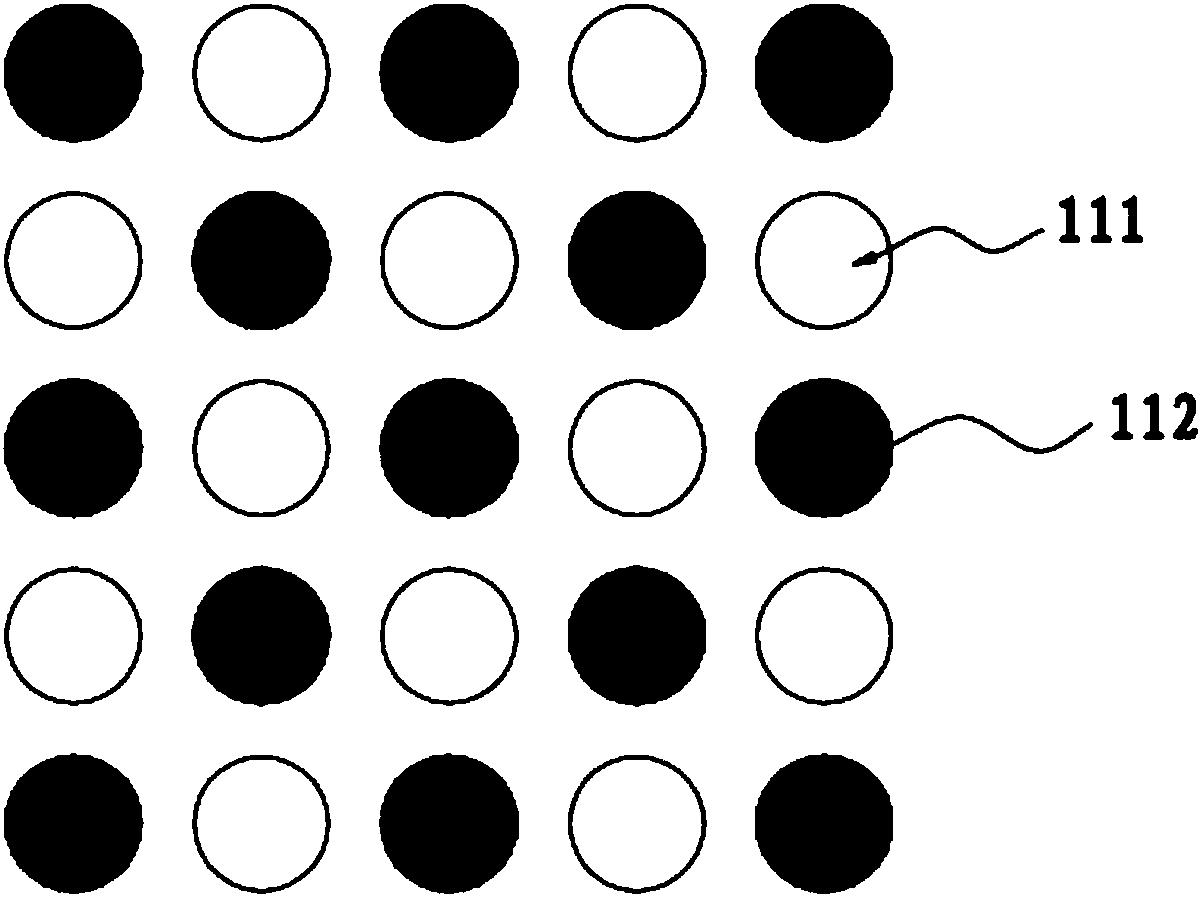

The invention discloses an LED chip and a manufacturing method thereof. The LED chip comprises a substrate; an epitaxial layer, which is arranged on the substrate; a transparency electrode layer, which is arranged on the epitaxial layer; at least two grooves, which vertically pass through the transparency electrode layer and the bottoms of which are arranged in the epitaxial layer, and which are distributed along the edge of the transparency electrode layer; an insulation layer, which is lined to the side walls of the grooves and on the transparency electrode layer at the edges of groove openings; N electrodes, which are arranged on the insulation layer; and a P electrode, which is arranged on the transparency electrode layer, wherein the distances between the P electrode and the N electrodes are same. The N electrodes of the LED chip encircle the P electrode, and the distances between the P electrode and the N electrodes are same, so that when the LED chip works, flow direction of the current between the N electrodes and the P electrode is allowed to be scattered, current density distribution is allowed to be more uniform, and luminous efficiency of the LED chip can be improved.

Owner:WUXI CHINA RESOURCES HUAJING MICROELECTRONICS

Spliced board process side and board splicing method

ActiveCN107567182AEnsure consistencyImprove consistencyPrinted circuits structural associationsEngineeringCopper

The invention discloses a spliced board process side and a board splicing method. The spliced board process side is arranged at the periphery of the pattern units of a circuit board. The spliced boardprocess side comprises at least two layers of laminated process sides. Each layer of process side is provided with balance copper points, and the residual copper rate of each layer of process side isthe same with the residual copper rate of the pattern units of the corresponding layer. The spliced board of the board splicing method comprises the spliced board process side and the pattern units and test strips or test modules which are arranged in the spliced board process side. According to the spliced board process side, the residual copper rate of each layer is the same with the residual copper rate of the pattern units of the corresponding layer so that the consistency of the dielectric layer thickness of the spliced board process side and the pattern units after lamination and glue filling can be guaranteed, the board thickness consistency of the spliced board can be enhanced, the current density distribution of the spliced board process side and the pattern units in electroplating is ensured to be more uniform, the accuracy of the test result of the test strips or the test modules arranged in the process side can be enhanced and the relevant real value of the pattern units can be effectively represented.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

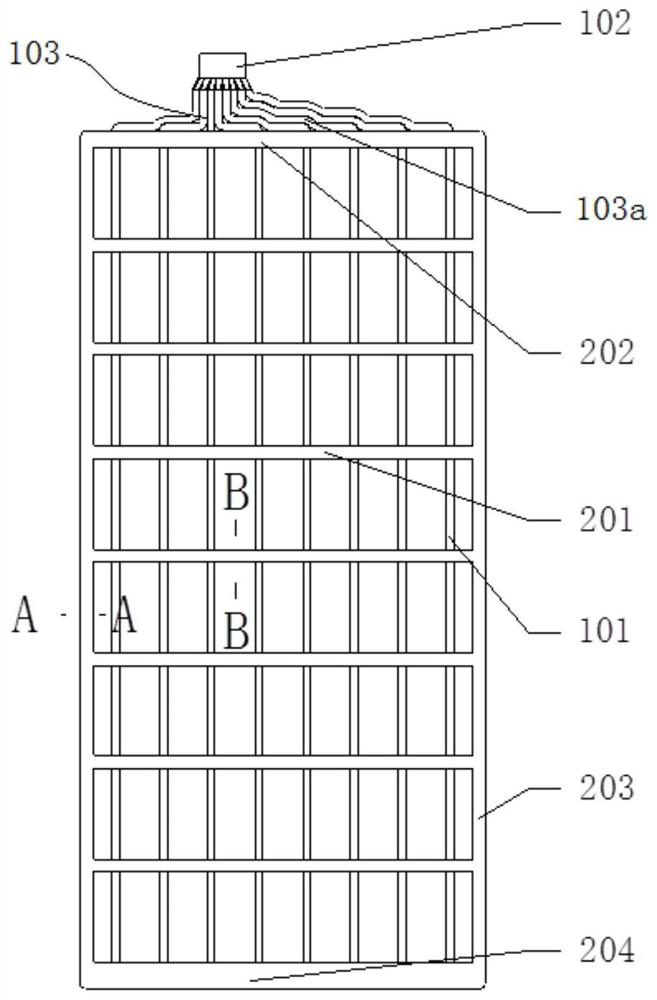

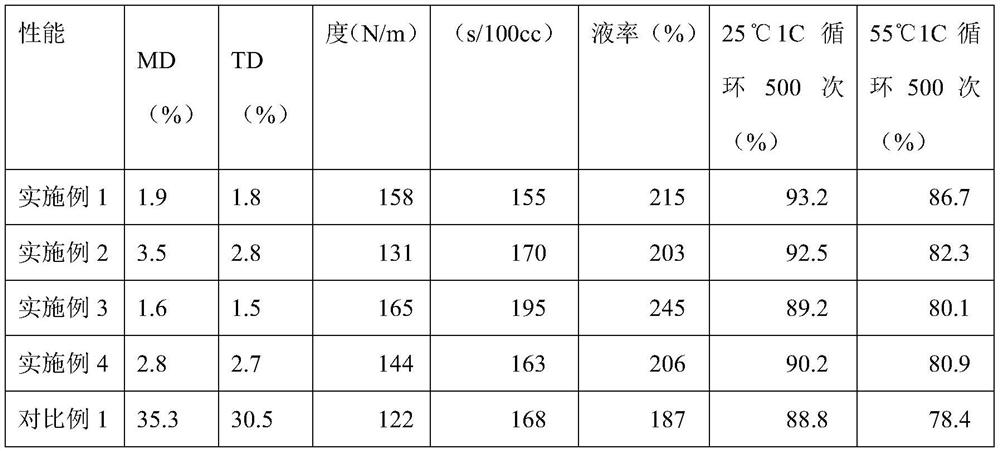

Pole piece and application thereof, and low temperature rise safety lithium ion battery containing the pole piece

ActiveCN111785925AUniform internal temperature distributionReduce temperature riseFinal product manufacturePositive electrodesThermodynamicsPole piece

The invention provides a pole piece and an application thereof, and a low temperature rise safety lithium ion battery containing the pole piece, the pole piece comprises a current collector, and at least two active coatings and at least one efficient conductive PTC film are fixedly arranged on each of two opposite surfaces of the current collector; the active coating and the efficient conductive PTC film are arranged at intervals from inside to outside from the surface of the current collector, and the outermost side is the active coating; the conductivity of the active coating on the outermost layer is smaller than that of the other active coatings, and / or the active substance of the active coating on the outermost layer adopts an active substance with high thermal stability. According tothe pole piece disclosed by the invention, the internal temperature distribution is more uniform, the temperature rise of conventional use or internal short circuit of the battery is reduced, and thermal runaway can be slowed down, so that the safety of the lithium ion battery is improved.

Owner:TIANJIN ENERGIES

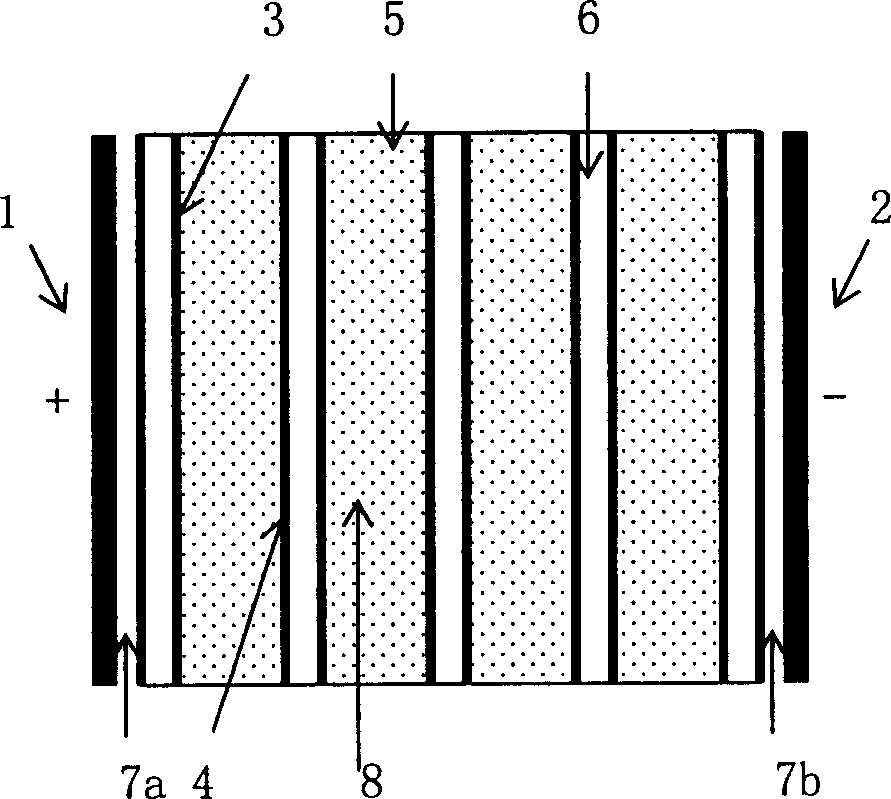

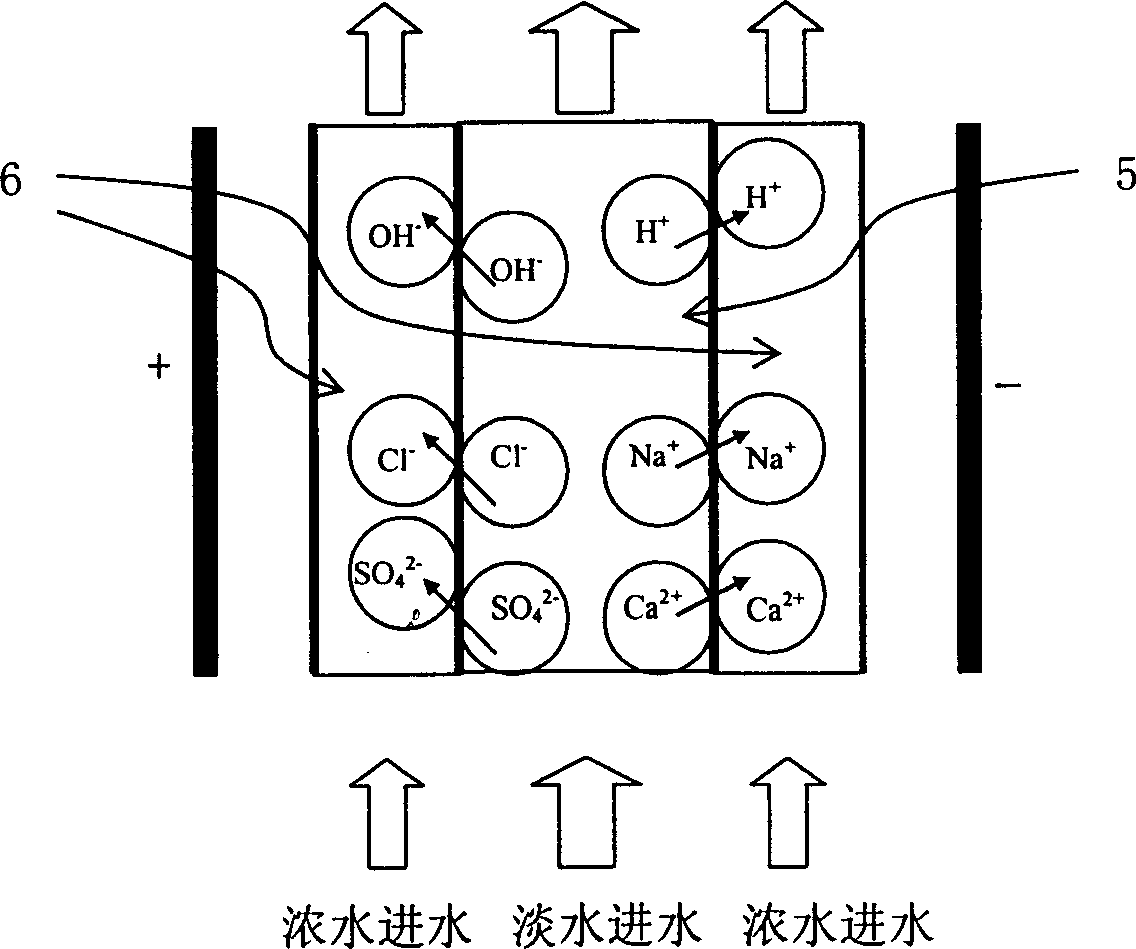

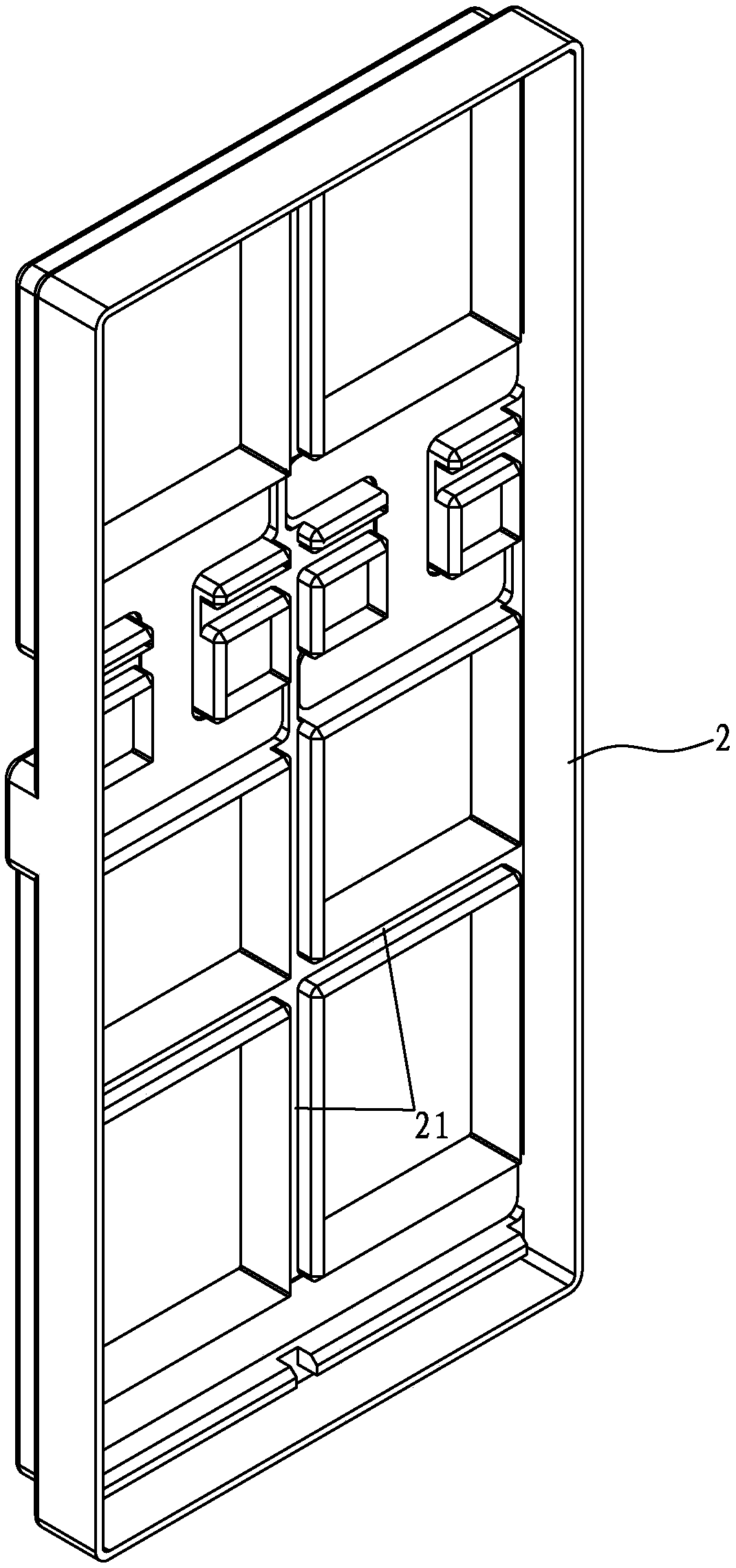

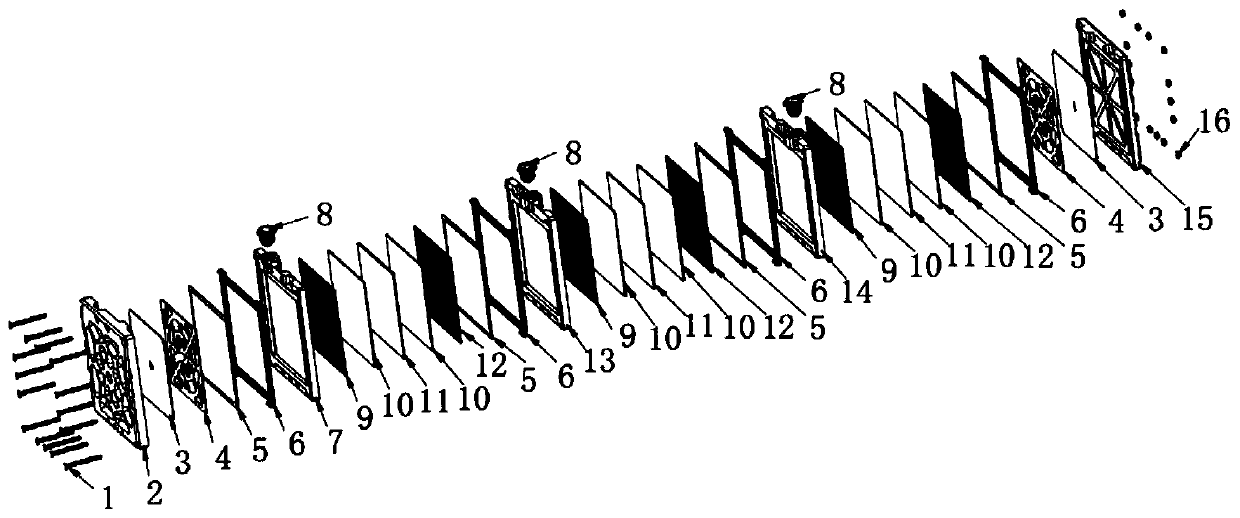

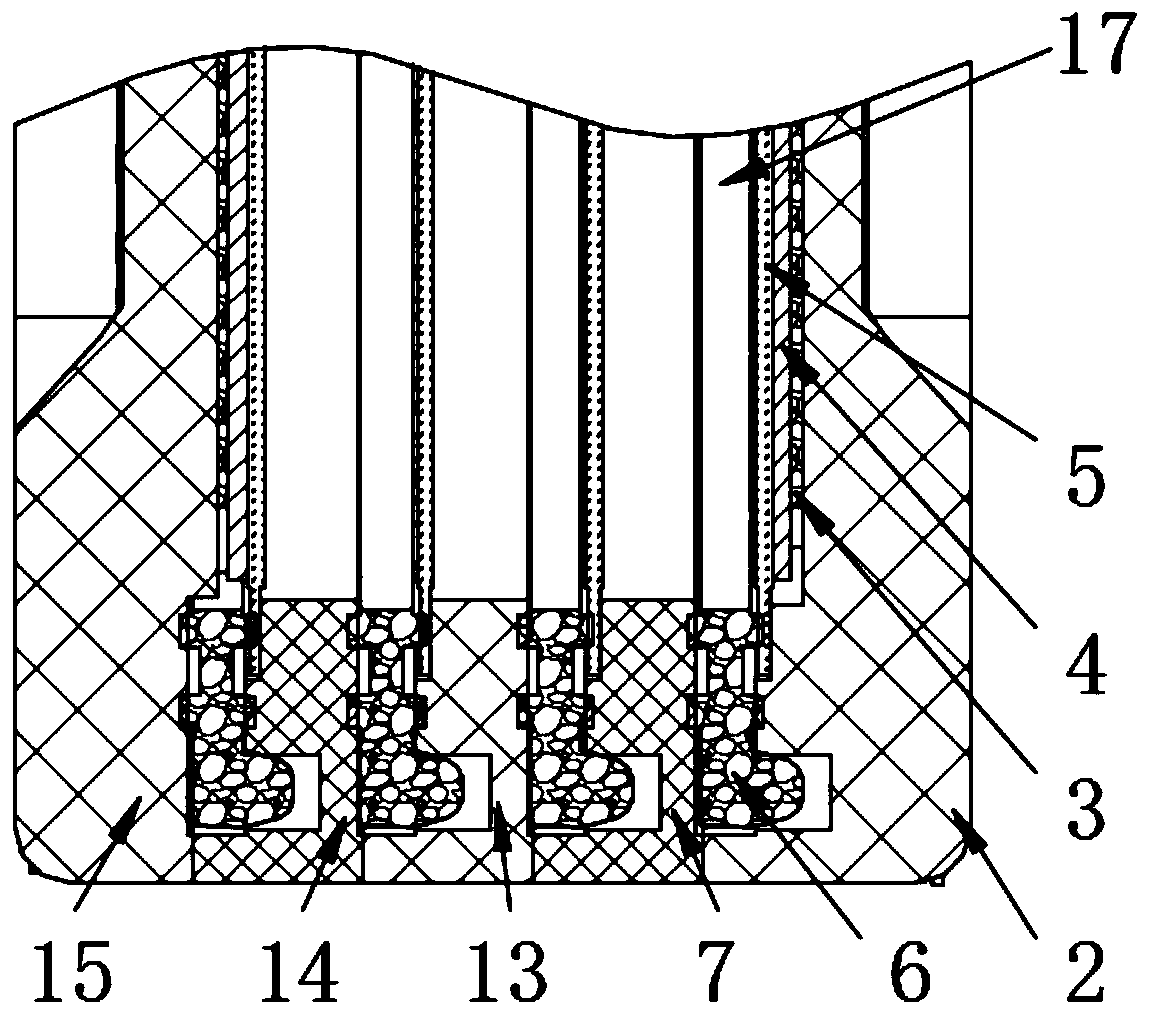

Continuous electrodeionization device

InactiveCN1864823ASimplify the assembly processShorten assembly cycleDispersed particle separationElectrodialysisElectricityWater flow

The invention discloses a plate-and-frame electric deionizing unit. One side of working zone of freah water room is equipped with a fresh water room opening (21) connected to it; said opening is used as filling port for filling or changing ion material, and is sealed by sealing baffle; the two relative sides in heavy concentration water room working zone paralleling to fresh water flowing direction are provided with water inlet (25) and outlet (26) for heavy concentration room respectively; said inlet and outlet extend along direction parallelling to fresh water flowing direction. It is convenient for said device to fill and change resin on the pot, and adjust the resin filling ratio; the sealing problem caused by resin particle is avoided; and the water flow direction of fresh water and heavy concentration water is in cross flow.

Owner:四川龙瑞源环境科技股份有限公司

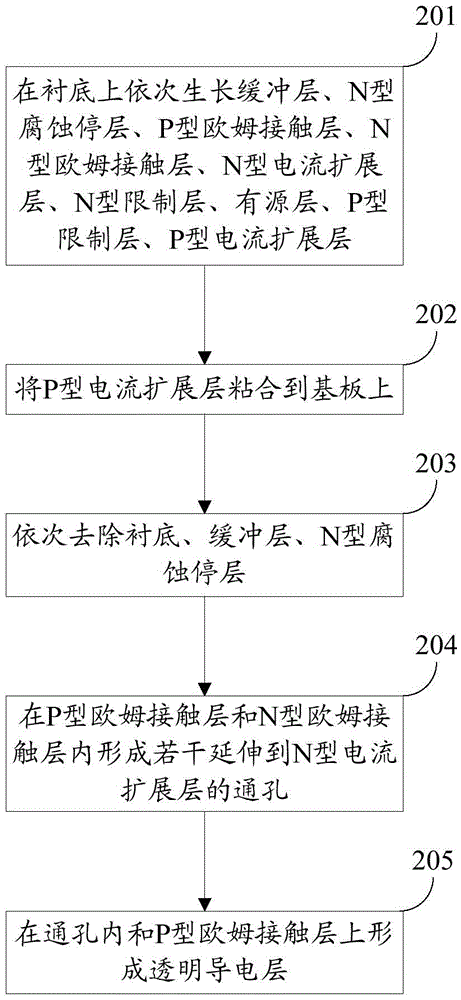

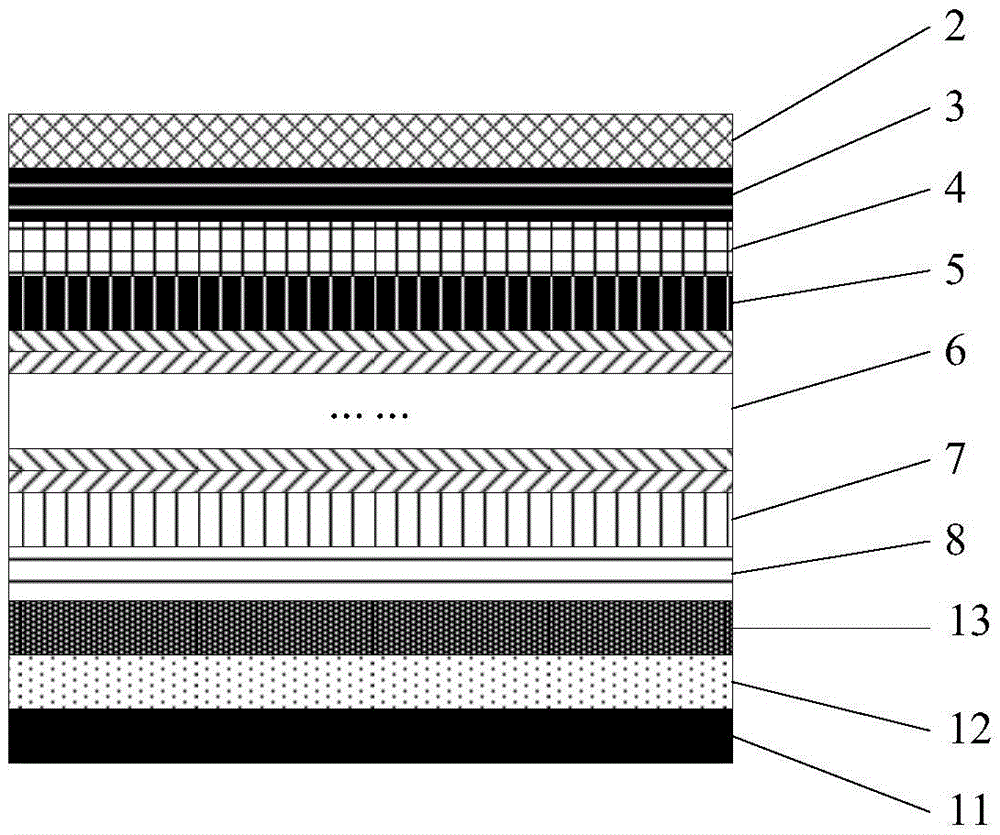

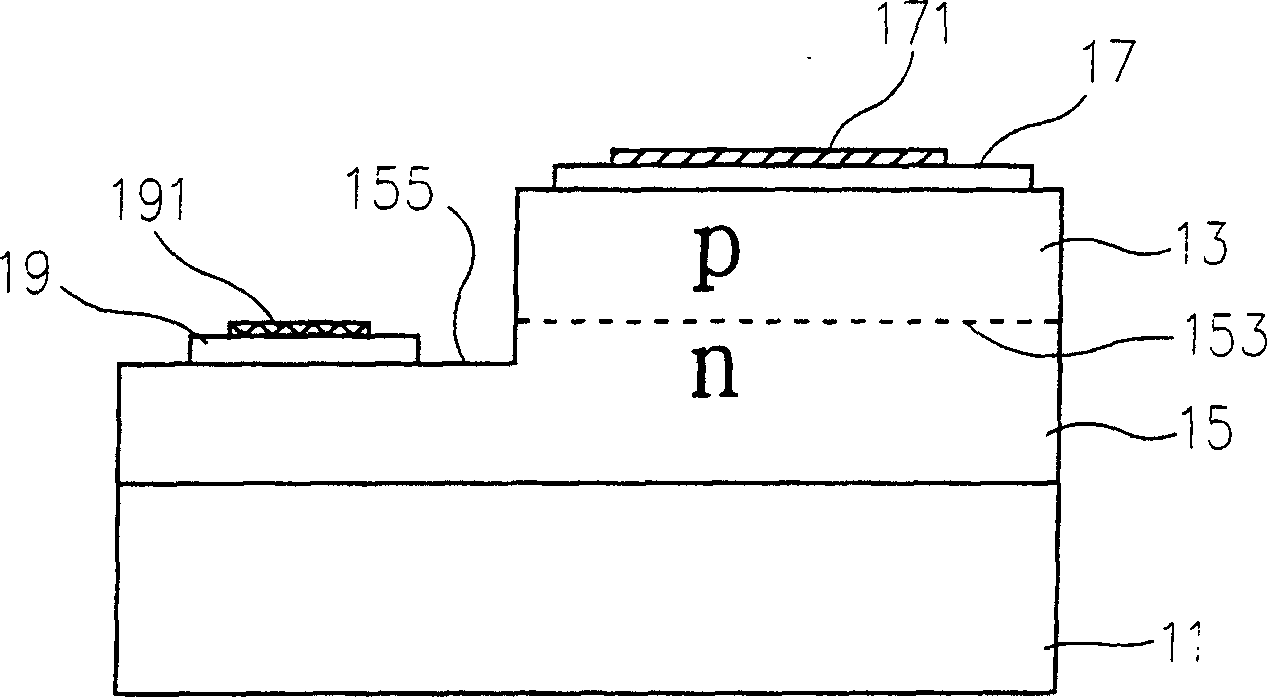

Light emitting diode chip with inverted structure and fabrication method of light emitting diode chip

The invention discloses a light emitting diode chip with an inverted structure and a fabrication method of the light emitting diode chip, belonging to the technical field of a semiconductor. The light emitting diode chip comprises a substrate and a P-type current extension layer, a P-type limiting layer, an active layer, an N-type limiting layer, an N-type current extension layer, an N-type ohmic contact layer, a P-type ohmic contact layer and a transparent conductive layer which are sequentially laminated on the substrate, wherein the P-type ohmic contact layer and the N-type ohmic contact layer are GaAs layers, the transparent conductive layer is an indium tin oxide (ITO) layer, and a plurality of through holes are formed in the P-type ohmic contact layer and the N-type ohmic contact layer and extend to the N-type current extension layer. With the adoption of the ITO transparent conductive layer, current extension is achieved, the extended current is injected into the N-type current extension layer through the ohmic contact layers, so that the current is extended very well, the current density distribution is uniform, and the luminous efficiency and the luminous intensity are improved.

Owner:HC SEMITEK SUZHOU

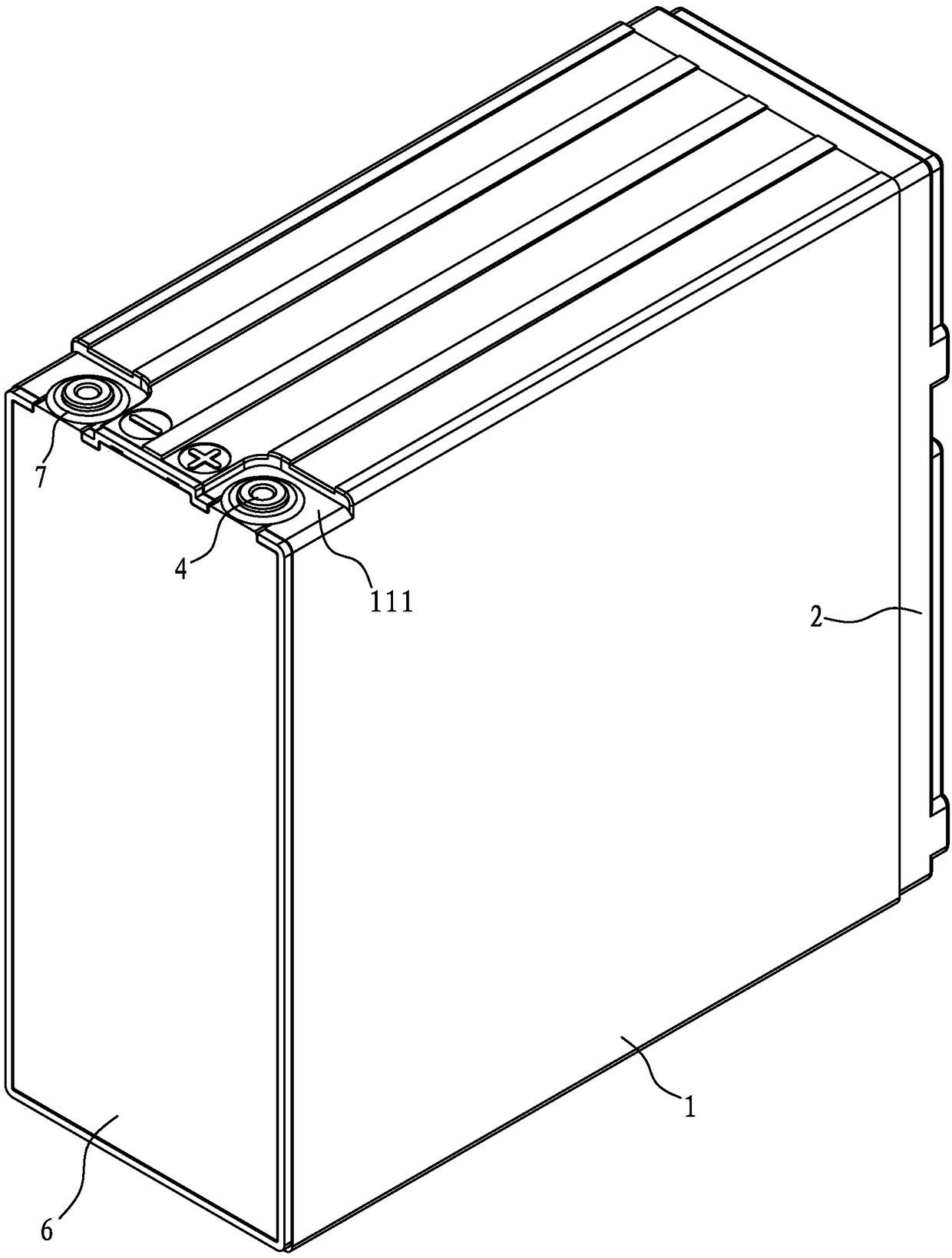

Lead-acid battery

ActiveCN109244562AExtended service lifeIncrease profitFinal product manufactureCell lids/coversConcentration polarizationEngineering

The invention discloses a lead-acid battery, comprising: a tank body with only one opening; A lid body cooperating with that groove body to seal the opening; a plurality of pole groups assembled inside the tank body and serially connected in series; the terminal is arranged on the side of the tank body. when in use, the opening of the tank body is placed laterally, and the bus bar is in a horizontal state. as that positive bus bar and the negative bus bars are respectively arranged on the two sides of the pole group, the current density distribution is more uniform, the utilization rate of theactive material at each part of the pole plate is effectively improved, and the service life of the battery is prolonged. When in use, the opening of the tank body is placed laterally, and the bus bar is in a horizontal state, which is equivalent to the height of the electrode plate vertically placed with the short side as the pole group, so that the pole group height is lowered, the phenomenon of acid stratification is effectively alleviated, the concentration polarization is reduced, the active substances in each part of the electrode plate are utilized more uniformly, and the service lifeof the battery is prolonged.

Owner:TIANNENG BATTERY GROUP

LED (Light-Emitting Diode) chip and production method thereof

InactiveCN106206901AStructural symmetryImprove luminous performanceSemiconductor devicesPower flowActive layer

The invention provides an LED (Light-Emitting Diode) chip and a production method thereof. The LED chip comprises a substrate, an N-type semiconductor layer located on the substrate, a light-emitting layer, a P type semiconductor layer, and N electrodes and P electrodes which are electrically connected with the N-type semiconductor layer and the P type semiconductor layer. The LED chip also comprises an N type table surface and a plurality of N type electrode slots which are etched to the N-type semiconductor layer. Insulation dielectric layers crossing the N type electrode slots are arranged on the side walls of the N type electrode slots and above the P type semiconductor layer. First transparent conductive layers connected with the bottoms of the N type electrode slots and electrically connected with the N-type semiconductor layer are formed in the insulation dielectric layers. A first N electrode is arranged on the N type table surface. Second N electrodes are arranged in the first transparent conductive layers of the N type electrode slots. The first N electrode and the second N electrodes are electrically connected through the first transparent conductive layers. According to the LED chip provided by the invention, the current density distribution is even, the light-emitting performance of the LED chip is improved; the area of an active layer is increased effectively; and the light-emitting efficiency of the chip is improved.

Owner:FOCUS LIGHTINGS SCI & TECH

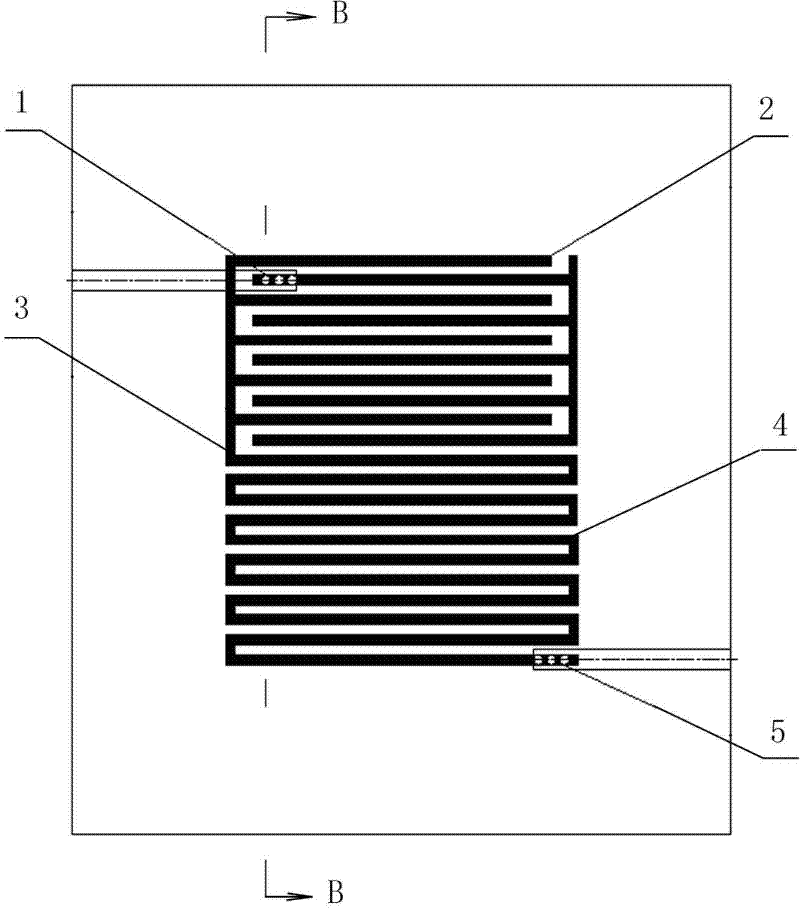

Proton exchange membrane fuel cell bipolar plate based on symmetrical serpentine structure flow field

ActiveCN112103531AImprove transmission performanceEven gas distributionWater management in fuel cellsGas transmissionMechanics

The invention discloses a proton exchange membrane fuel cell bipolar plate based on a symmetrical serpentine structure flow field. The bipolar plate comprises a gas flow field (1) and is characterizedin that the gas flow field (1) is symmetrically distributed in a serpentine shape; a reaction gas inlet (2) and a generated product outlet (10) of the gas flow field (1) are respectively positioned at two ends of one diagonal line of the gas flow field (1) and are diagonally distributed, and a ridge (3) positioned in a connecting line of the reaction gas inlet (2) and the generated product outlet(10) divides a flow channel starting from the reaction gas inlet (2) into two parts of snake-shaped flow channels which are symmetrically arranged. Compared with a traditional snakelike flow field, the symmetrical snakelike structure flow field overcomes the defect that the pressure drop of the snakelike flow field is large, enhances the gas transmission performance, enables the gas distributionto be more uniform, improves the generated water discharge performance of the fuel cell, enables the overall current density distribution to be more uniform, and thus improves the overall performanceof the fuel cell.

Owner:NANJING UNIV OF TECH

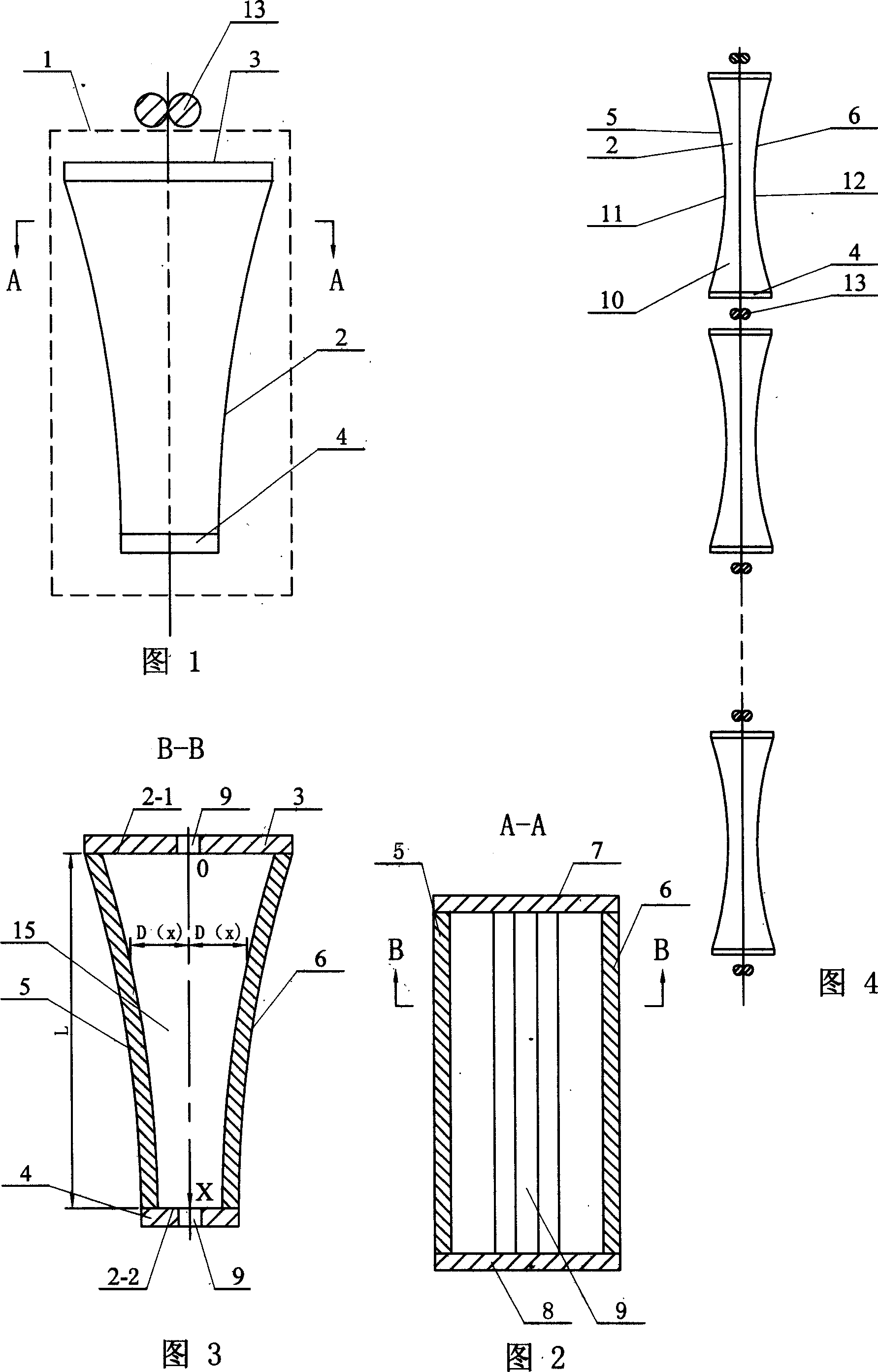

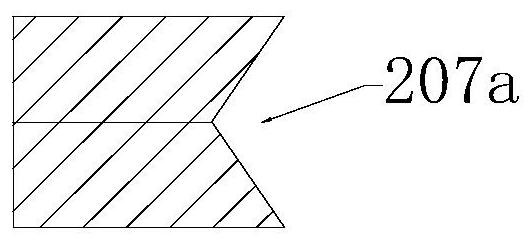

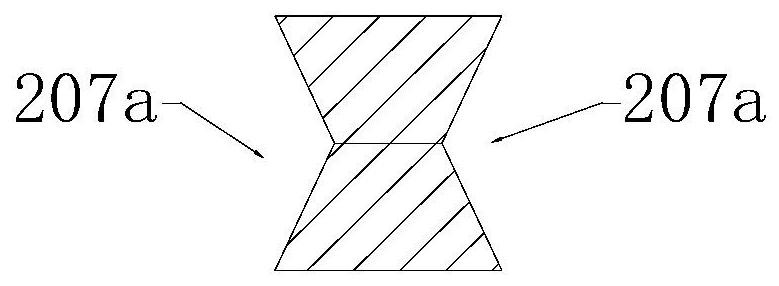

Anode unit for continuous electroplating of belt poor conductor

InactiveCN1637173AUniform distribution of current densityOptimal Current Density ControlElectrodesGalvanic anodeProduction line

The anode device for continuous electroplating of belt poor conductor consists of at least one anode unit. The anode unit consists of one through cavity, one upper insulating cover plate and one lower insulating cover plate. The through cavity is formed with the first anode plate, the first insulating baffle, the second anode plate and the second insulating baffle connected successively. The upper insulating cover plate is connected to the upper port of the through cavity, the lower insulating cover plate to the lower port, and both the upper insulating cover plate and the lower insulating cover plate have slot with symmetrical plane coinciding with that of the through cavity. The through cavity has flared longitudinal profile passing through two anode plates. Owing to the special shape of anode to control the current density for electrically depositing metal, the single electroplating bath may have maximum anode length, and the continuous electroplating production line may have least electroplating baths.

Owner:HARBIN INST OF TECH

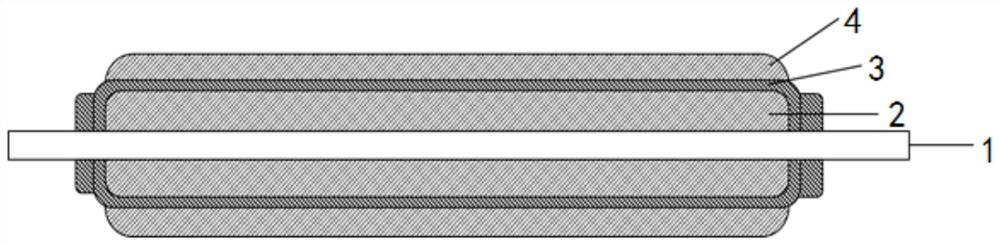

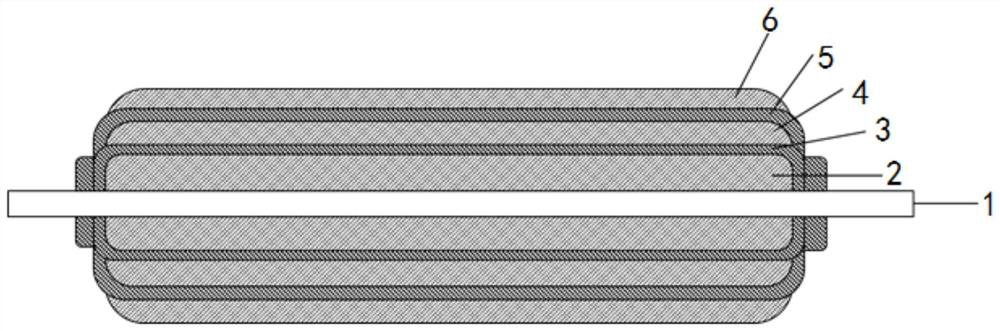

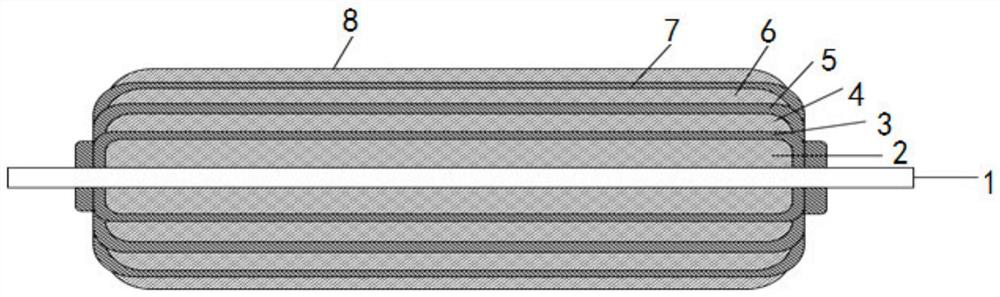

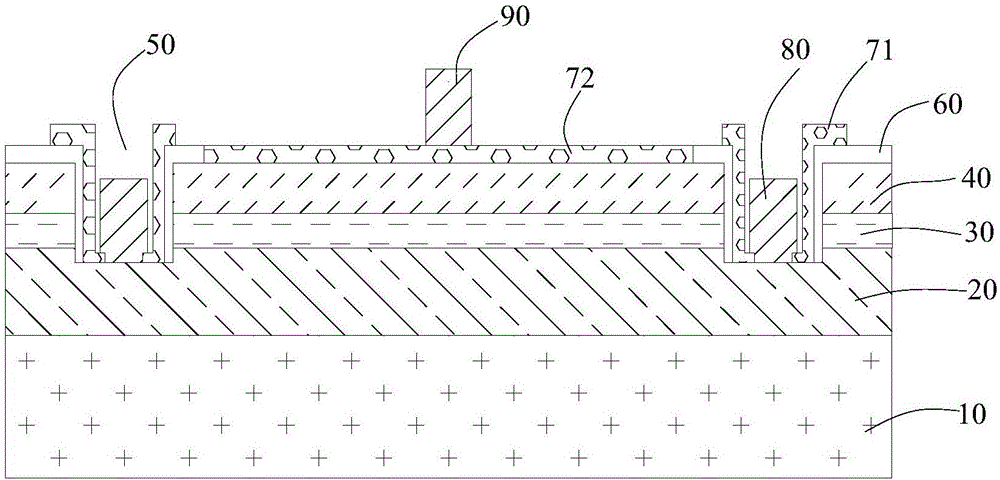

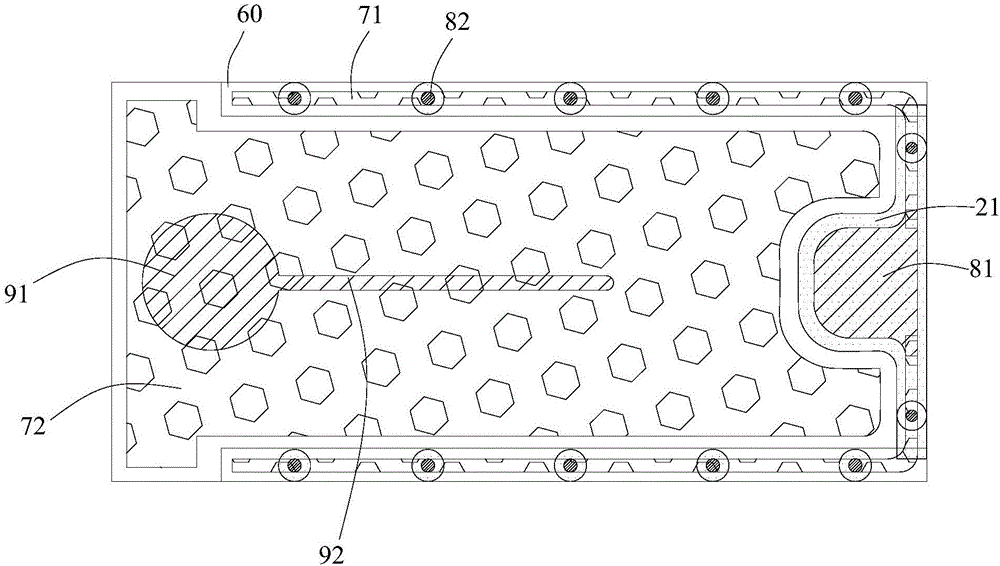

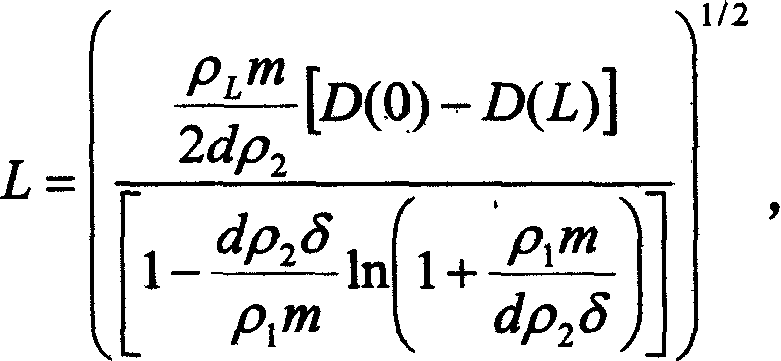

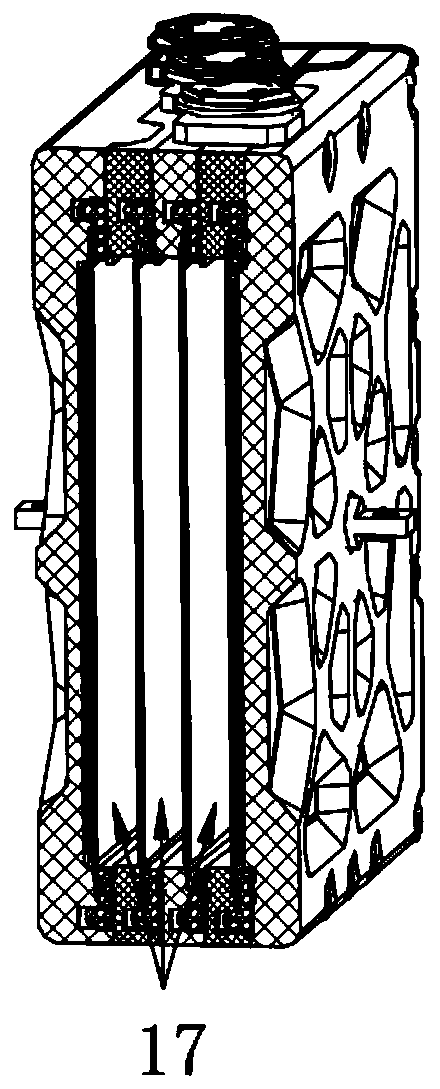

Lithium battery of high specific energy and high power, and manufacturing method thereof

InactiveCN108598598AUniform distribution of current densityLow calorific valueFinal product manufactureSecondary cellsElectrical batteryHigh energy

The invention discloses a lithium battery of high specific energy and high power, and a manufacturing method thereof. A first cell 1 provides specific energy as high as 150Wh / kg; a second cell 2 provides high power needed in cell pulse; by virtue of the characteristics of uniform current density distribution, low cell heating amount and heat uniform diffusion of the second cell 2, the battery canprovide high power when a high energy state is maintained; and heat is provided for the second cell 2 by the heating amount of the first cell 1 at a low temperature, so that the second cell 2 also canprovide excellent pulse charging-discharging performance at a low temperature, thereby improving the normal temperature and low temperature pulse charging-discharging performance of the cells.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

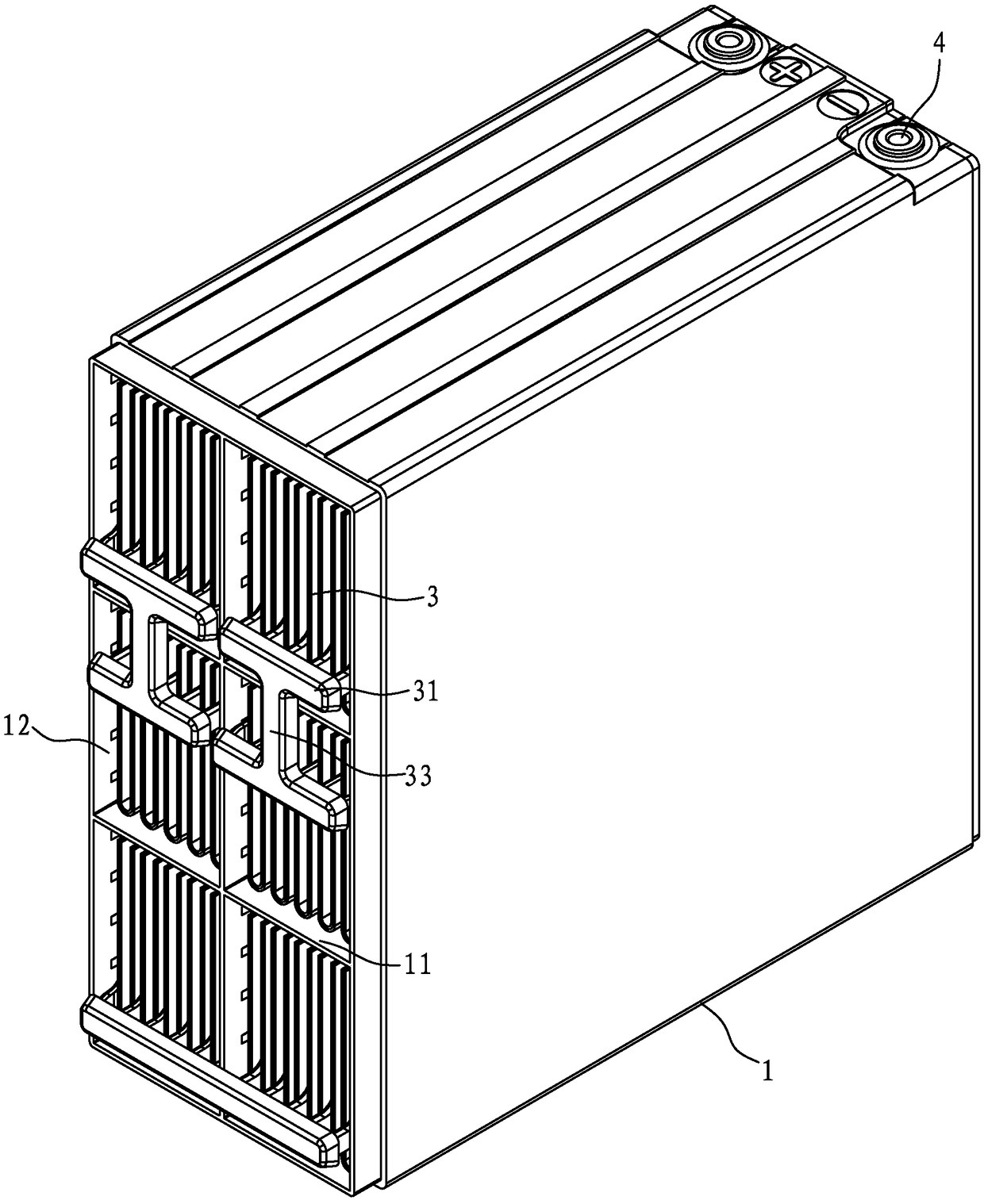

Lead-silicon composite bipolar battery

InactiveCN109818085AUniform distribution of current densityEven distribution of hot spotsFinal product manufactureElectrode carriers/collectorsElectrical batteryBusbar

The invention discloses a lead-silicon composite bipolar battery, belongs to the technical field of storage batteries, and solves the problems of high current density, non-uniform distribution, low gravimetric specific energy and short battery cycle life of a busbar and a pole of an existing lead-acid storage battery. Technical characteristics are as follows: the lead-silicon composite bipolar battery comprises a pole group for the lead-silicon composite bipolar battery, and also comprises a fastening screw, a first battery shell, a second battery shell, a third battery shell, a fourth batteryshell, a fifth battery shell and a battery inner cavity. According to the lead-silicon composite bipolar battery provided by the invention, the current density distribution is uniform during working,the hot spots on the surface of a pole plate are uniformly distributed, the heat management performance of the battery is better than that of the existing storage battery, and the acid corrosion resistance of a silicon wafer is strong. Compared with an existing lead-acid storage battery, the lead consumption of the lead-silicon composite bipolar battery with the same capacity can be reduced by about 40%. Under the same use condition (80%-100% DOD), the cycle life can be prolonged by 2-5 times.

Owner:ZHAOQING LEOCH BATTERY TECH +1

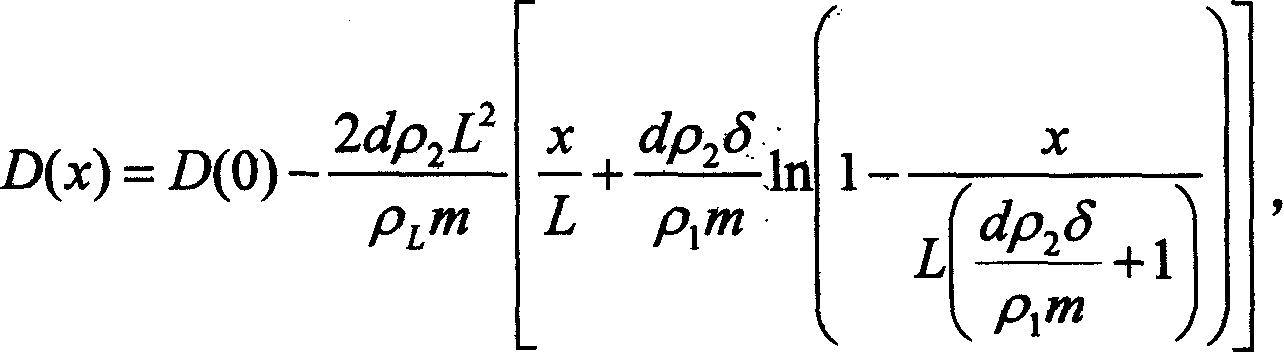

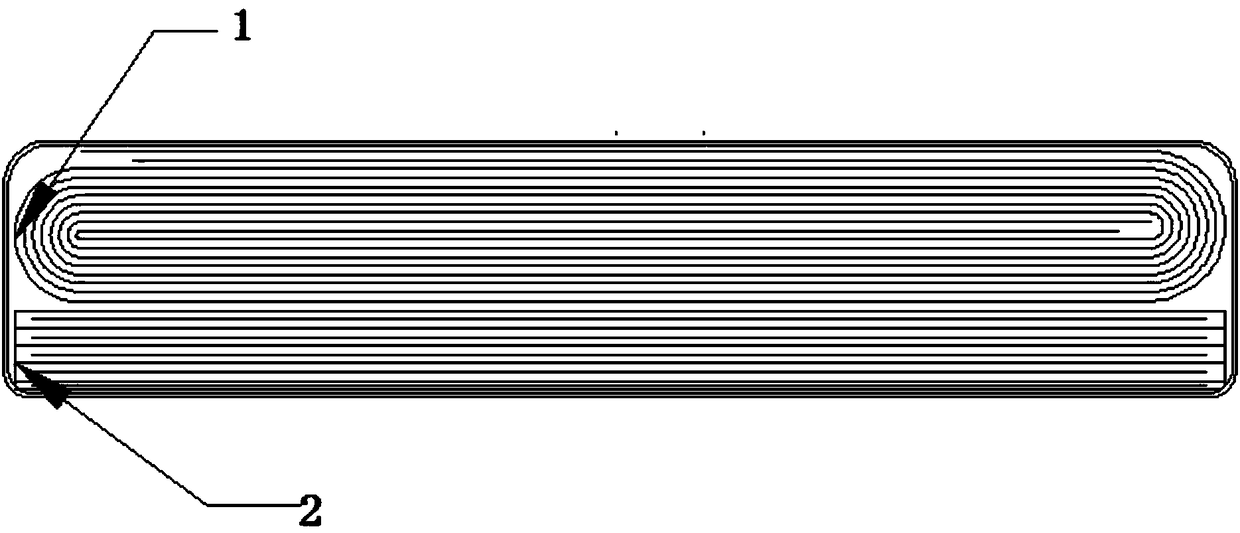

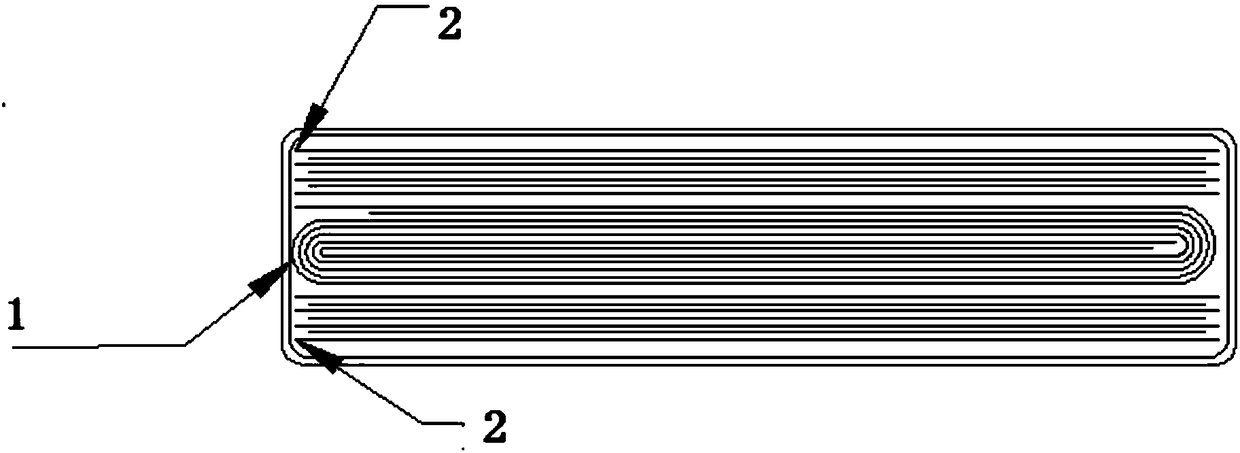

Method for manufacturing square-round core aluminum-plastic membrane lithium ion battery for evaluating

ActiveCN103682455AEasy extractionImprove reliabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringLithium-ion battery

The invention discloses a method for manufacturing a square-round core aluminum-plastic membrane lithium ion battery for evaluating. An anode and a cathode prepared by a general method according of a lithium ion battery, then are coiled to form a round core, and are sealed into a square battery-grade aluminum plastic membrane bag, and an air chamber is reserved. The structural design avoids defects that a current battery structure is not easy to control an assembling ratio and assembling pressure when evaluating an electrode material and the material is not continuously tested because of bulge and leakage of the battery caused by gas generation, has performance suitable for evaluating various materials under different technologies, and has characteristics of low investment equipment cost.

Owner:贵州芭田新能源材料有限公司

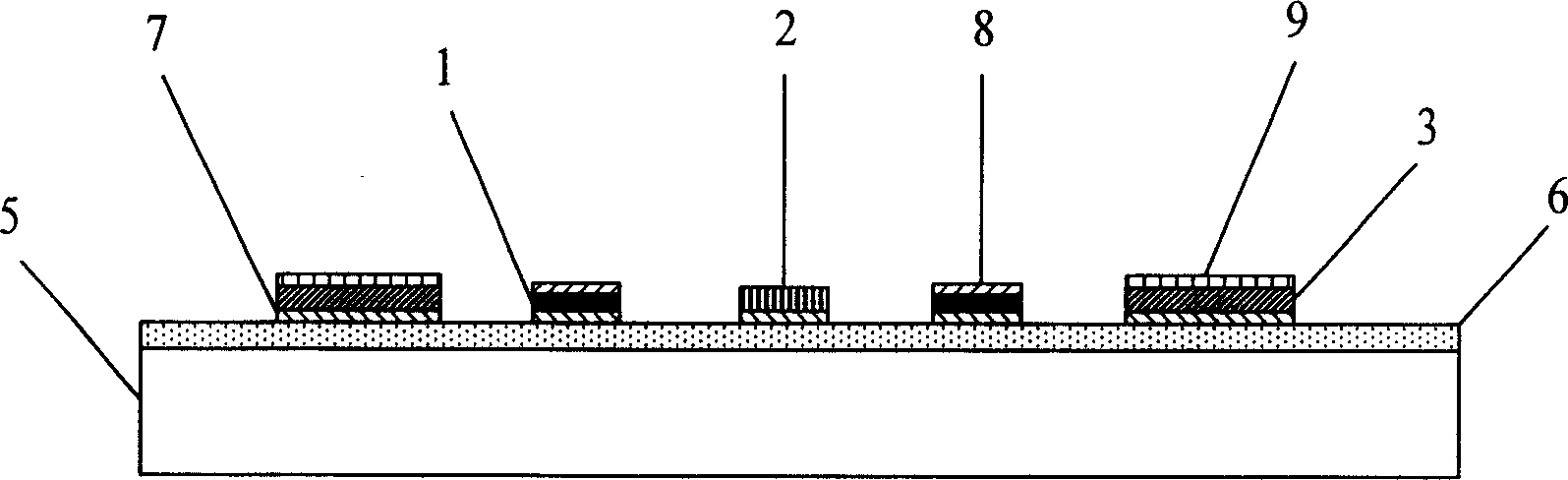

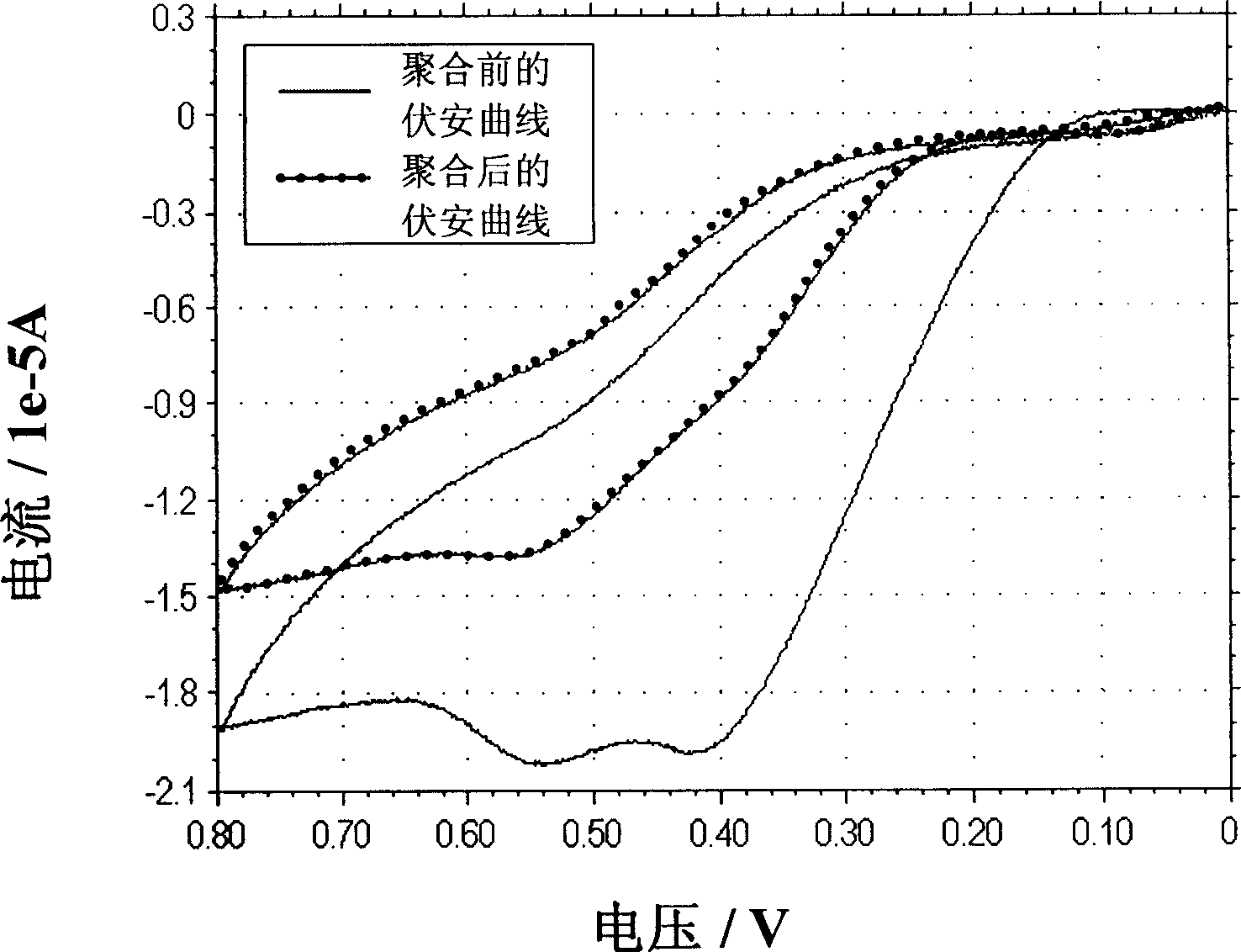

Micro sensor for detecting hepatic fibrosis based on method of antibody and antigen

InactiveCN1687768ASmall sizeUniform distribution of current densityBiological testingMaterial electrochemical variablesAntigenHepatic fibrosis

This invention belongs to the field of the silica micro-machine and the electrical chemistry, specific about a kind of micro sensor on the base of antibody and antigen method to detect the fibration of the liver. It is made up of the working electrode, reference electrode, pairing electrode and the base board. Among these, the working poles have the shape of circle or like a circle and they range symmetrically. And the reference electrode is like the letter 'U', set between the working electrode. Besides, the pair pole looks like a trip, set between the reference poles. The base board is made up of the composite silicon packing block and the SiO2 layer. There are 4-8 working electrode and the electrode and the SiO2 layer are bonded with the Ti tack coat, and each electrode can be made with the simple film technology of the IC technology. In a word, the invention has small micro-sensors, costs little and has high authenticity. It can detect out the concentration of the antigen in the serum quantitatively and meanwhile measure several data of the serum, and the quantity of the serum is small.

Owner:FUDAN UNIV

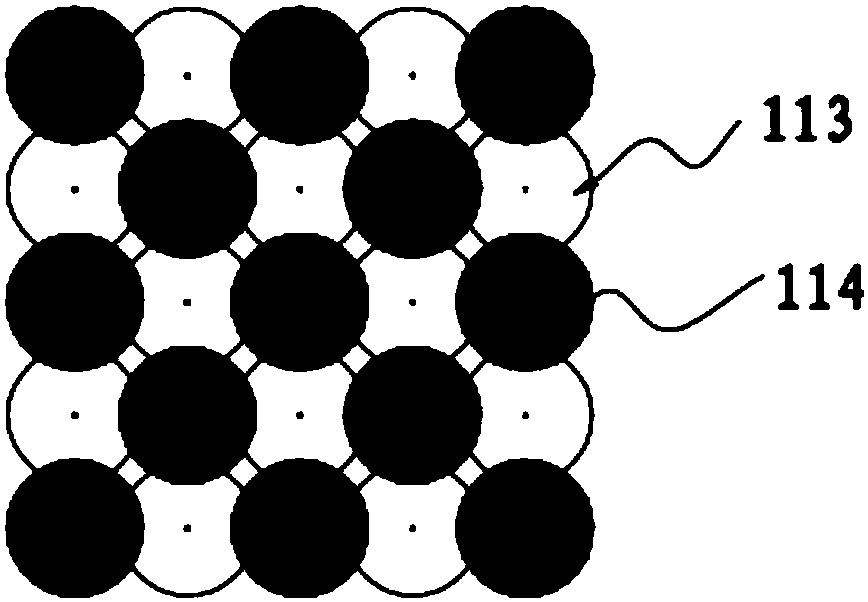

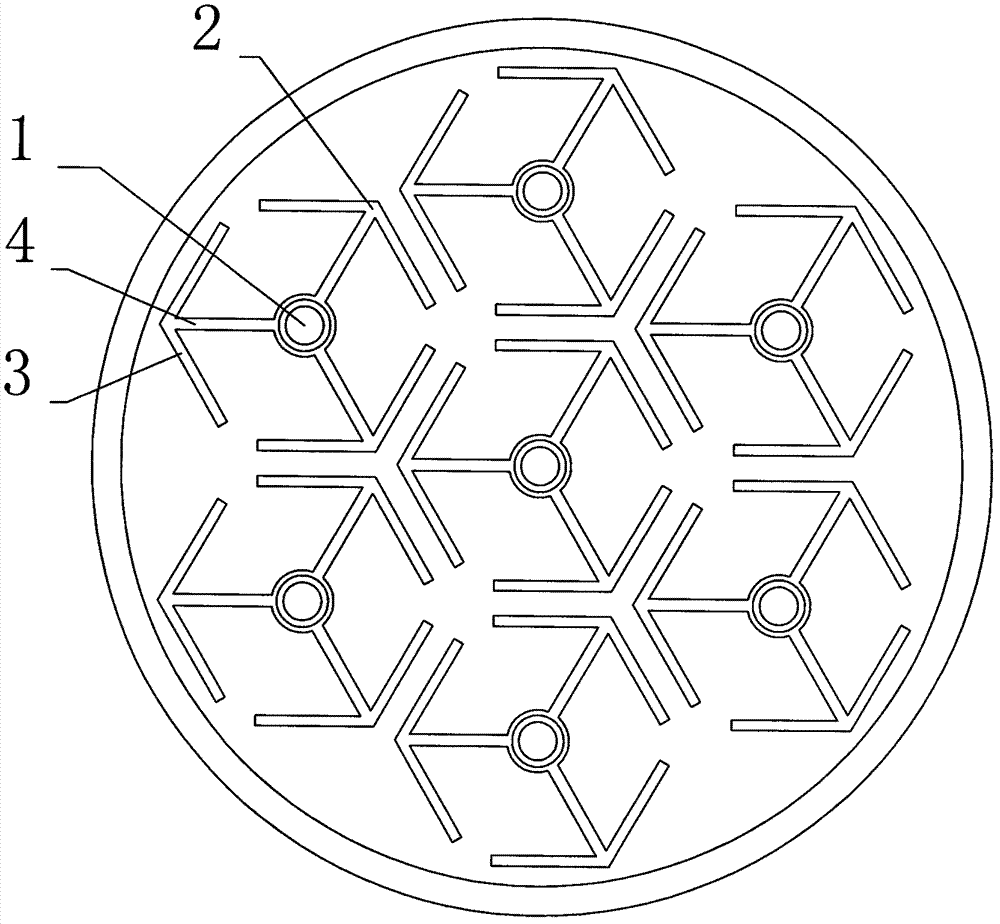

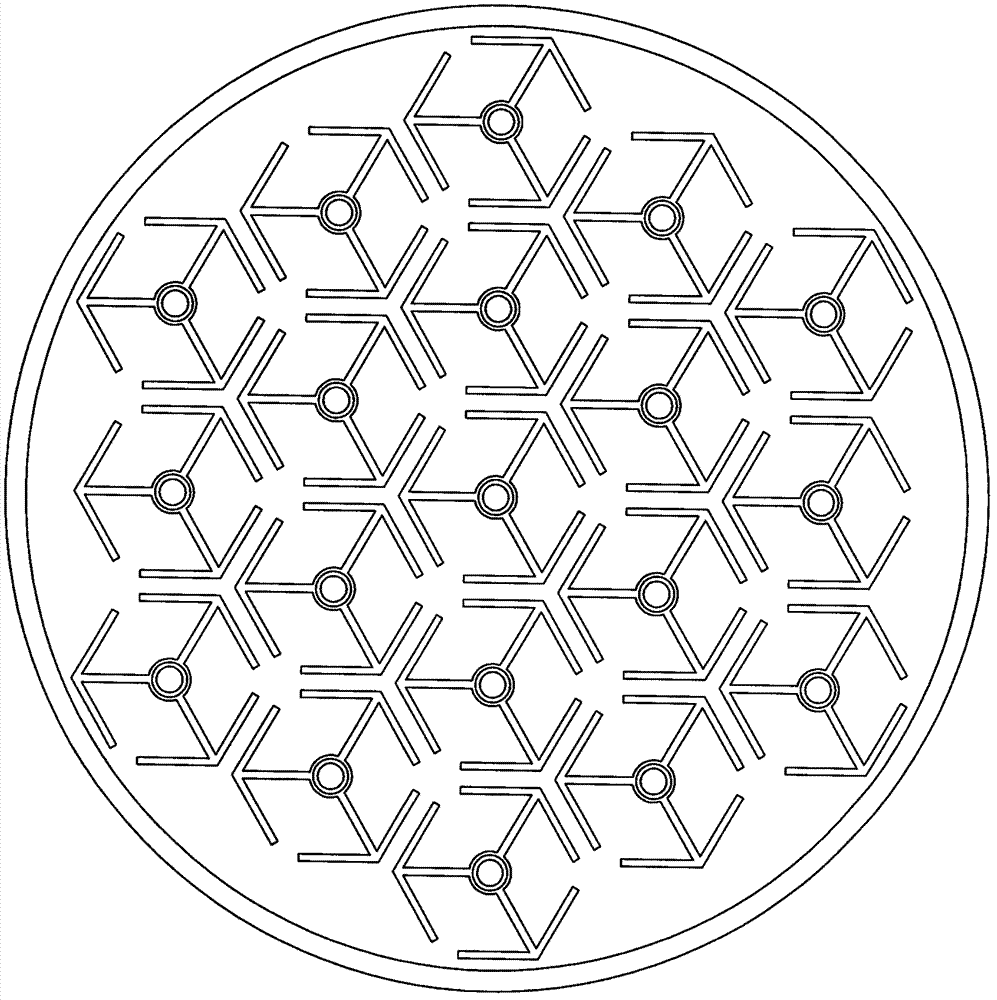

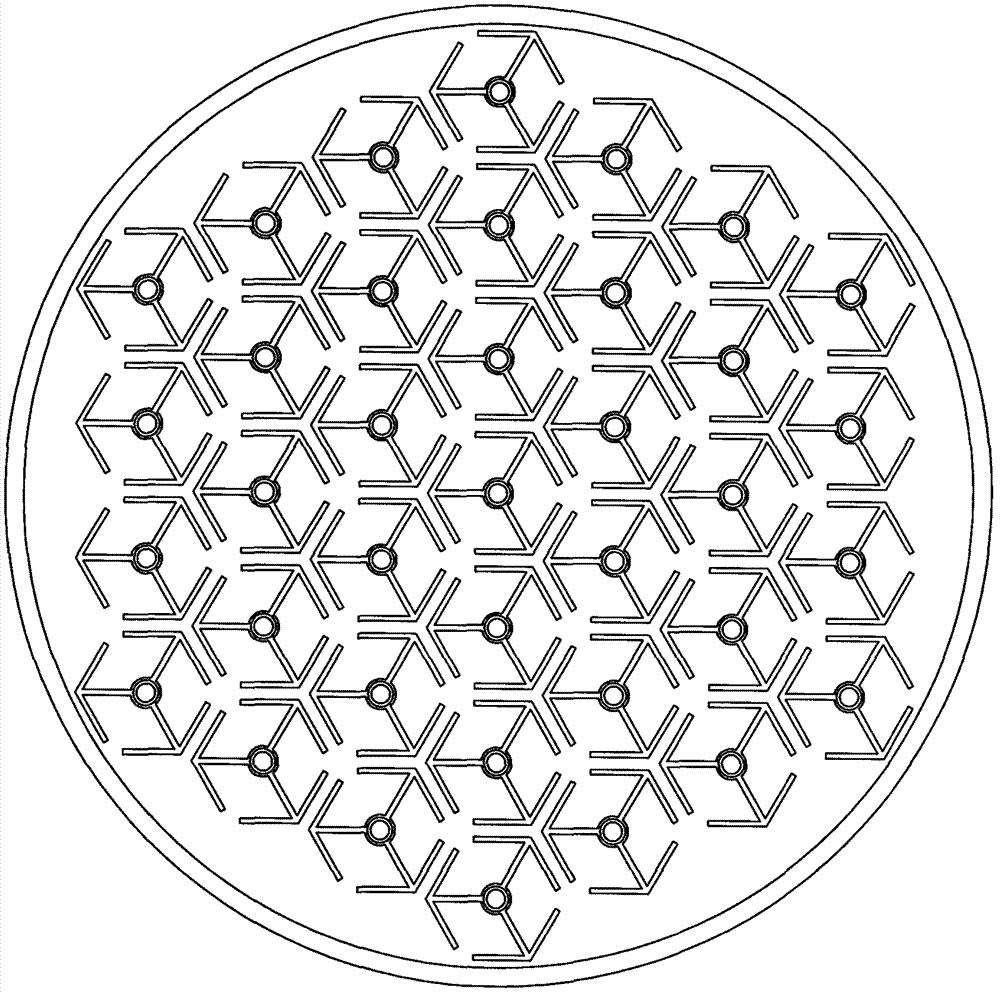

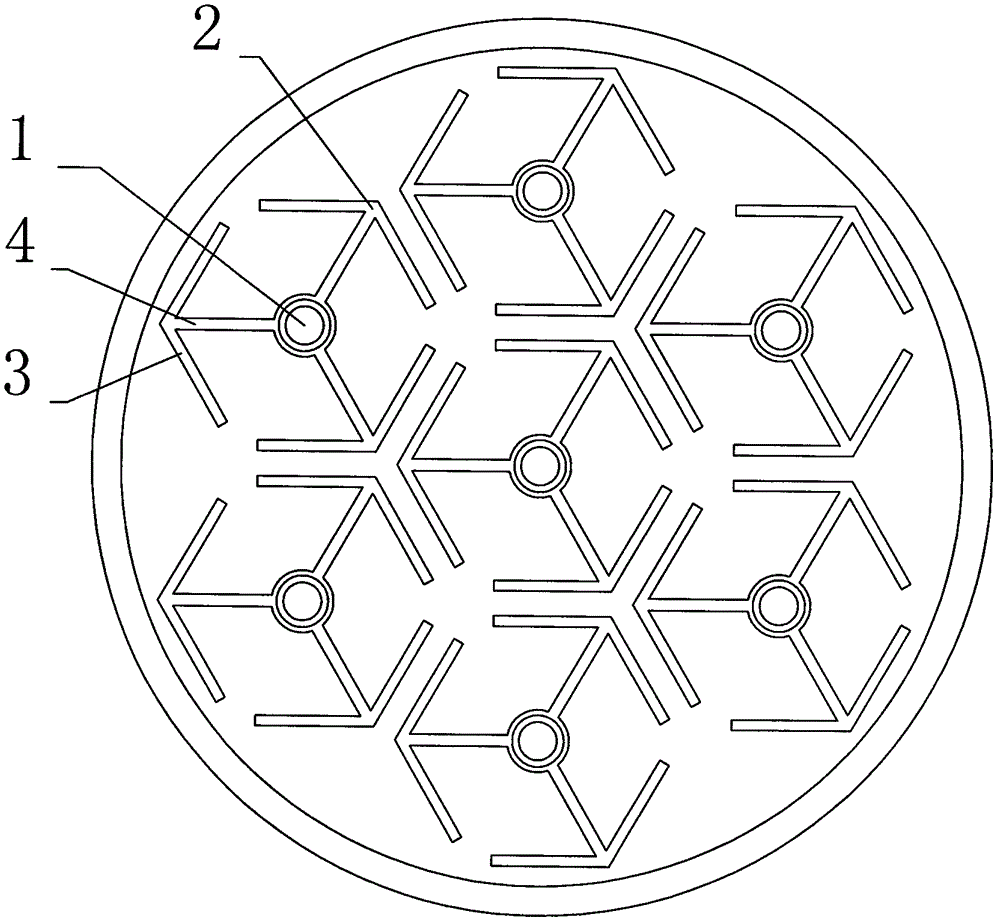

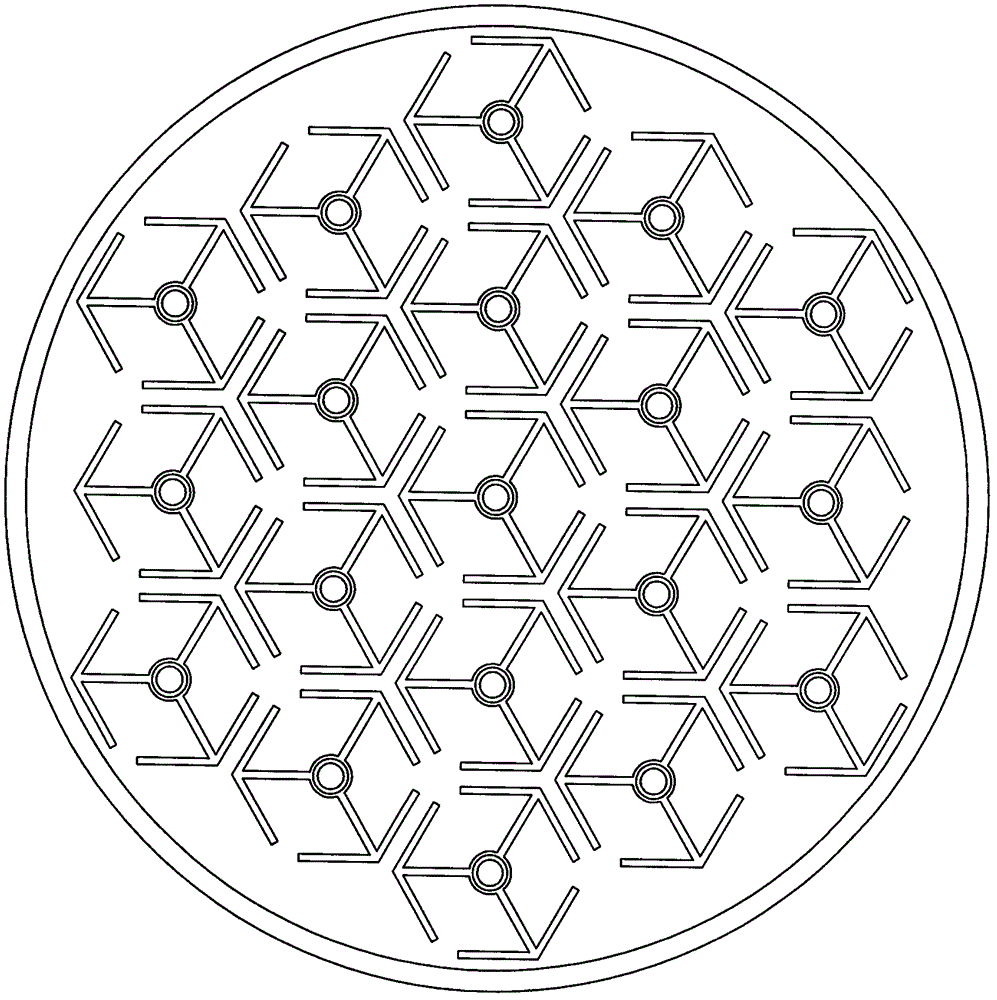

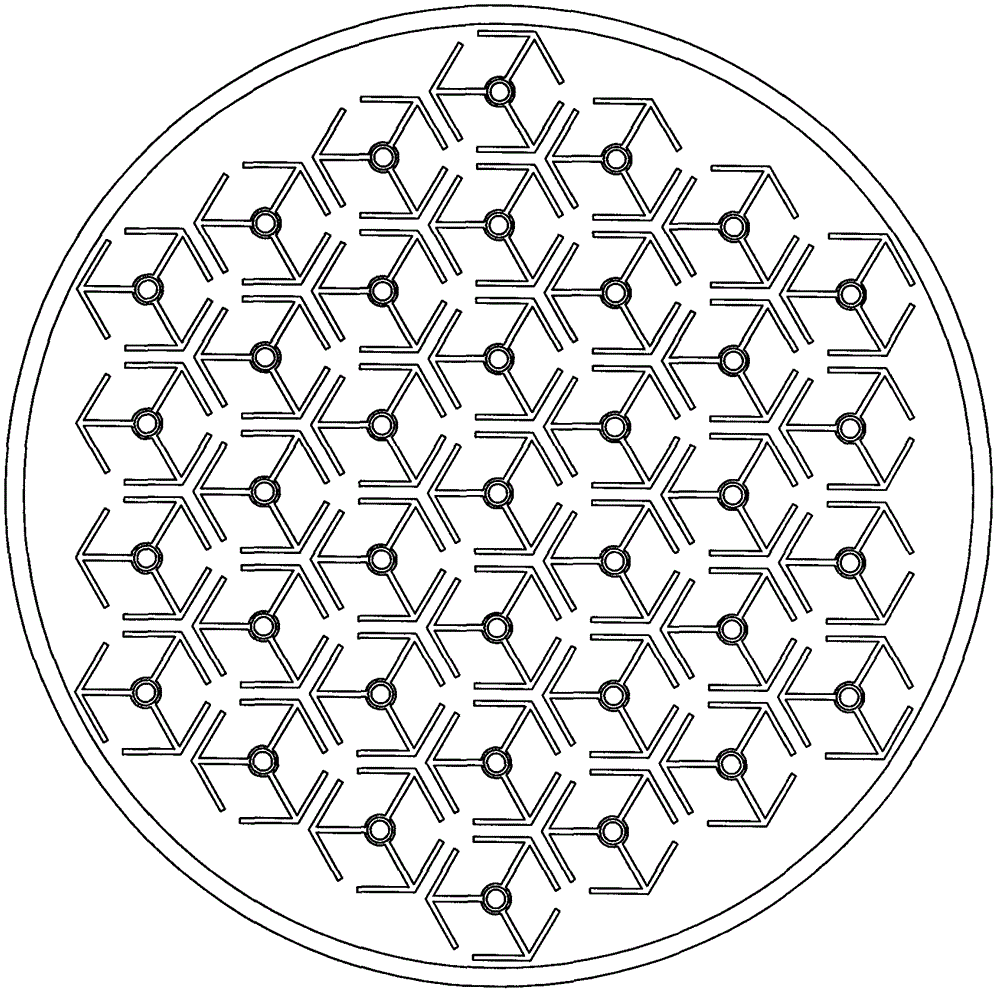

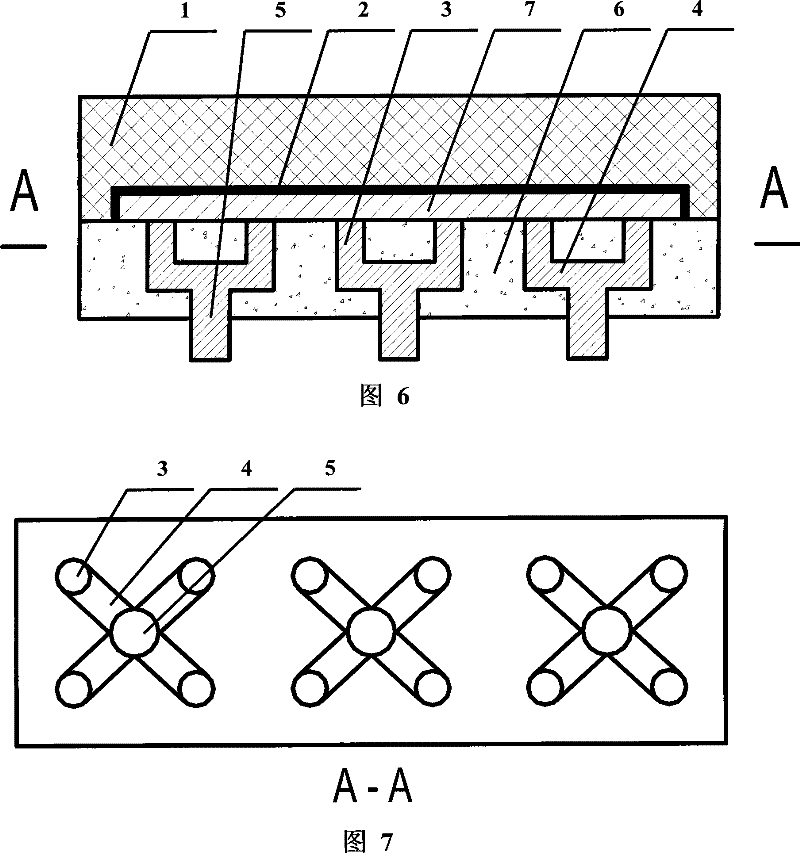

High-power thyristor

The invention discloses a high-power thyristor which comprises a silicon wafer, the silicon wafer is provided with unit cell gate poles, each unit cell gate pole comprises a central gate pole and an amplification gate pole, each central gate pole is located at the dead center of each amplification gate pole, the silicon wafer is provided with at least seven unit cell gate poles, and any three adjacent unit cell gate poles are distributed on the silicon wafer in a regular triangle shape. A plurality of small-size unit cell gate poles are installed on the silicon wafer of the high-power thyristor, multiple-unit cell structure gate poles are formed on the surface of the silicon wafer of the high-power thyristor, a plurality of parasitic resistors and a plurality of working areas which are small in capacitance are built on the surface of the silicon wafer, so that the thyristor which is large in size has the same working properties with a thyristor which is small in size, and the high-power thyristor has the advantages of being high in starting speed, even in current density distribution, high in on-state average current density, low in on-state voltage-drop, and low in on-state power consumption. Therefore, by means of the technical scheme, switching operation which is good in performance can be achieved on the high-power thyristor which is larger in size.

Owner:HANGZHOU HANAN SEMICON

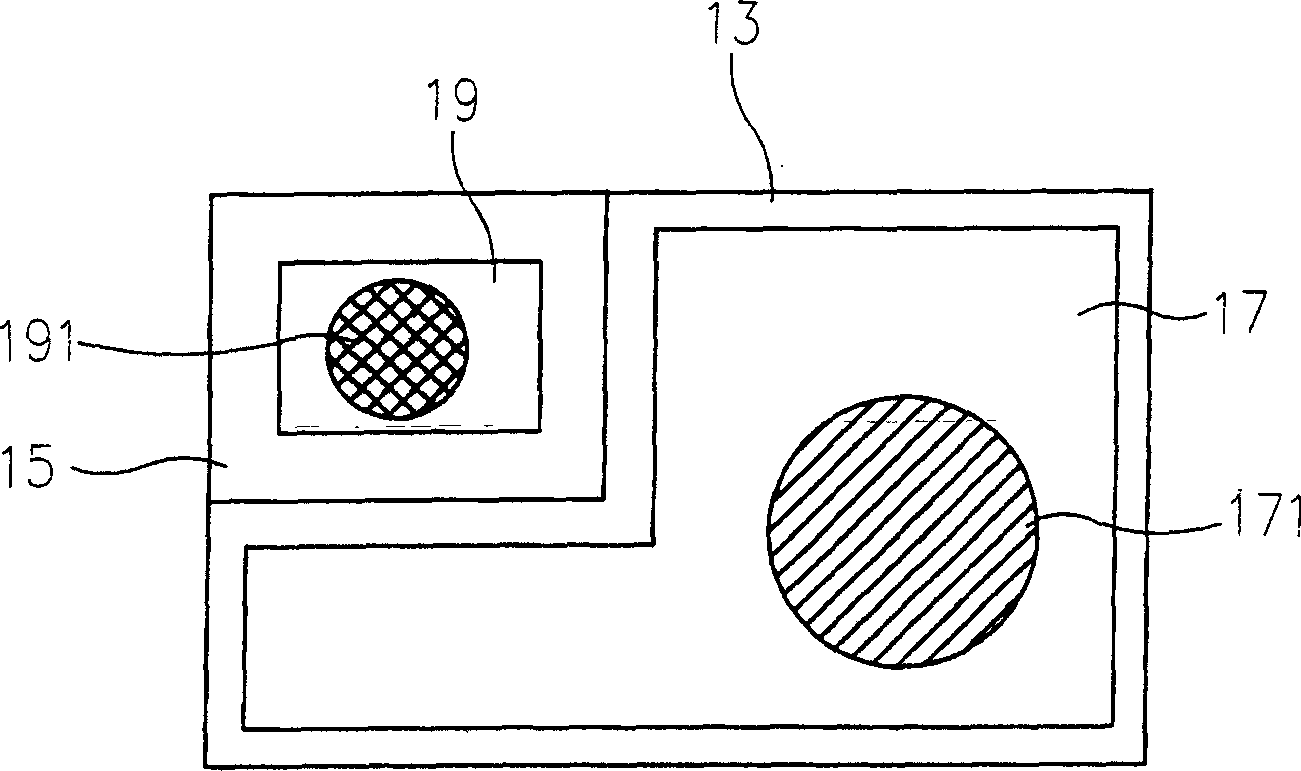

Light-emitting component capable of increasing light-emitting active area

InactiveCN1558450AIncrease the areaArea occupiedSemiconductor devicesEngineeringLight-emitting diode

The invention relates to a light-emitting component, in particular a light-emitting component for increasing light-emitting active region and raising luminescent brightness, wherein a second epitaxy layer and at least a first epitaxy layer are arranged on a crystal particle substrate, the upper surface of the first epitaxy is provided with at least a first electrode, a plurality of second electrodes insulated by the first electrode insulating layer and electrically connected to the second epitaxy layer, the first electrode and the second electrodes are in staggered arrangement.

Owner:OPTO TECH

Welding method of composite copper bar conducting layer, and composite copper bar

ActiveCN104319010AReduce hardnessReduce intensitySingle bars/rods/wires/strips conductorsSoldering apparatusBar productHardness

The invention relates to a welding method of a composite copper bar conducting layer. A welding part of a lead workpiece is positioned on a mounting part of a copper bar substrate by a positioning structure, so that next welding is facilitated. After positioning, a resistance soldering technology instead of chamfering is adopted, so that the mounting part can be arranged in any position of the copper bar substrate, the lead workpiece can be welded on the mounting part, a complicated composite copper bar product comprising a small forming part structure is obtained, and the welding strength and the connection reliability are improved. A non-welding part of the lead workpiece is placed in a heat-dissipation mold, so that heat of the non-welding part of the lead workpiece conducted by welding can be dissipated by the heat-dissipation mold, the non-welding part of the lead workpiece can avoid softening deformation and hardness and strength reduction due to overheating, the hardness and the strength of the non-welding part are ensured, and torsion resistance of riveting a nut in a non-welding area is ensured. In addition, the invention further relates to a composite copper bar.

Owner:浙江冠华电气有限公司

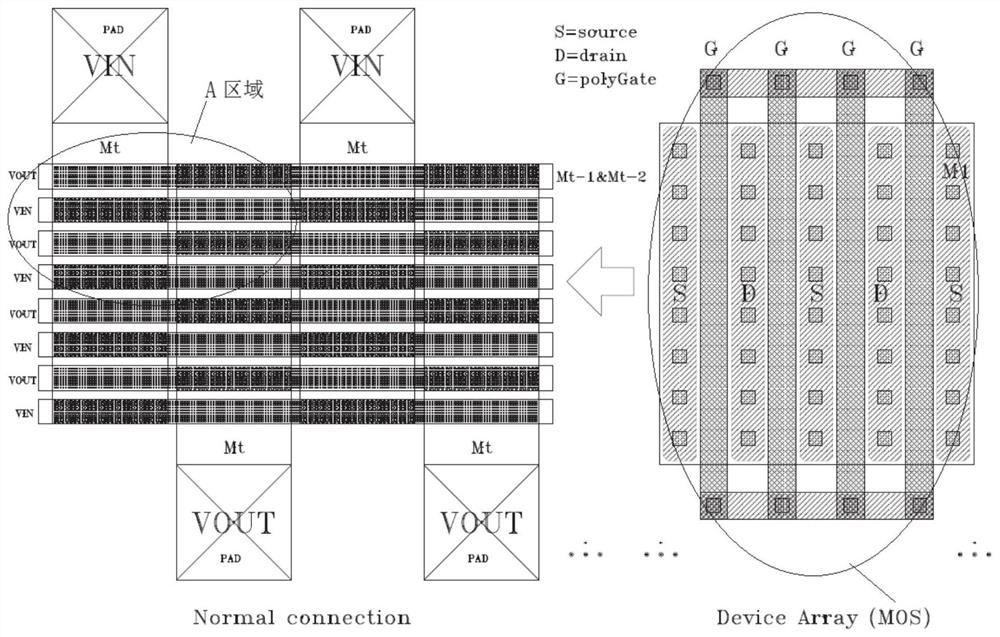

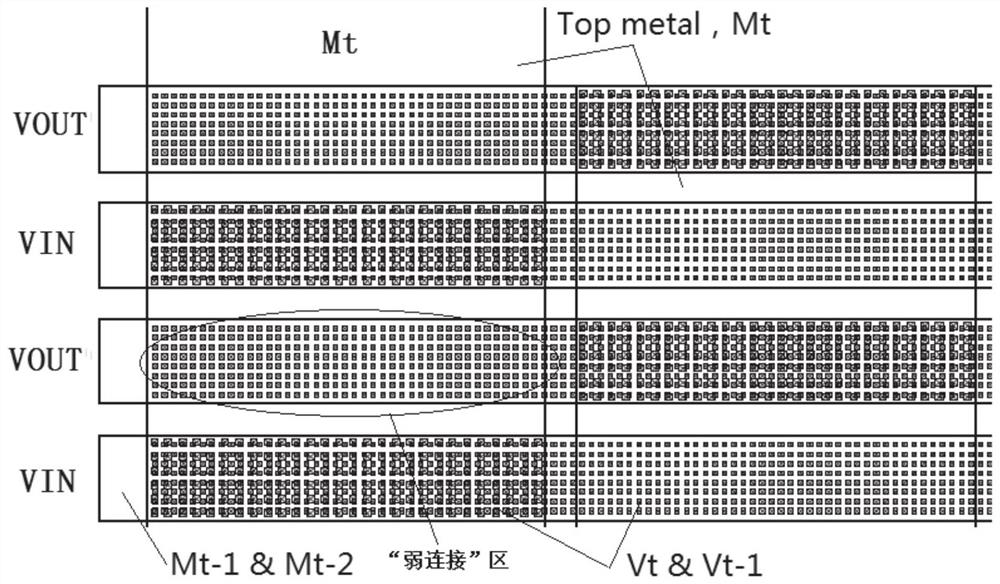

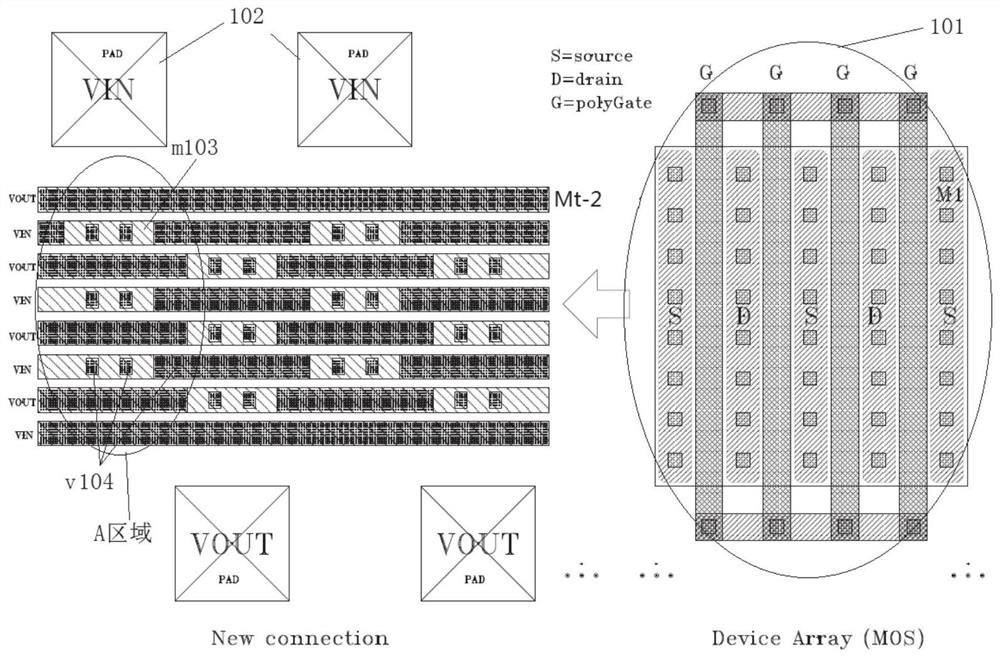

Method for designing metal connecting wires in power device layout

ActiveCN112541320AStrengthen connection and conduction abilityUniform distribution of current densitySemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceMechanical engineering

The invention provides a method for designing metal connecting wires in a power device layout, a power device comprises at least three layers of metal, in the design method, a secondary top metal layer Mt-1 can form a distribution structure similar to Slot under a top metal layer Mt representing opposite signals, so that signals represented by thesecondary top metal layer Mt-1 can be connected inboth the direction X and the direction Y, under the top metal layer Mt, the current on the third metal layer Mt-2 is directly connected and conducted to the top metal layer Mt through a contact hole Vt and a contact hole Vt-1, so that the connection and conduction capability of the secondary top metal layer Mt-1 in the layout is enhanced, and the reliability of the layout is improved. The difference between the conductivity of the secondary top metal layer Mt-1 and the conductivity of the top metal layer Mt in the layout connecting line is reduced, so that the current density distribution in the whole layout is more uniform, the on-resistance is reduced, the power consumption is reduced, and the efficiency is improved.

Owner:SHENZHEN INJOINIC TECH

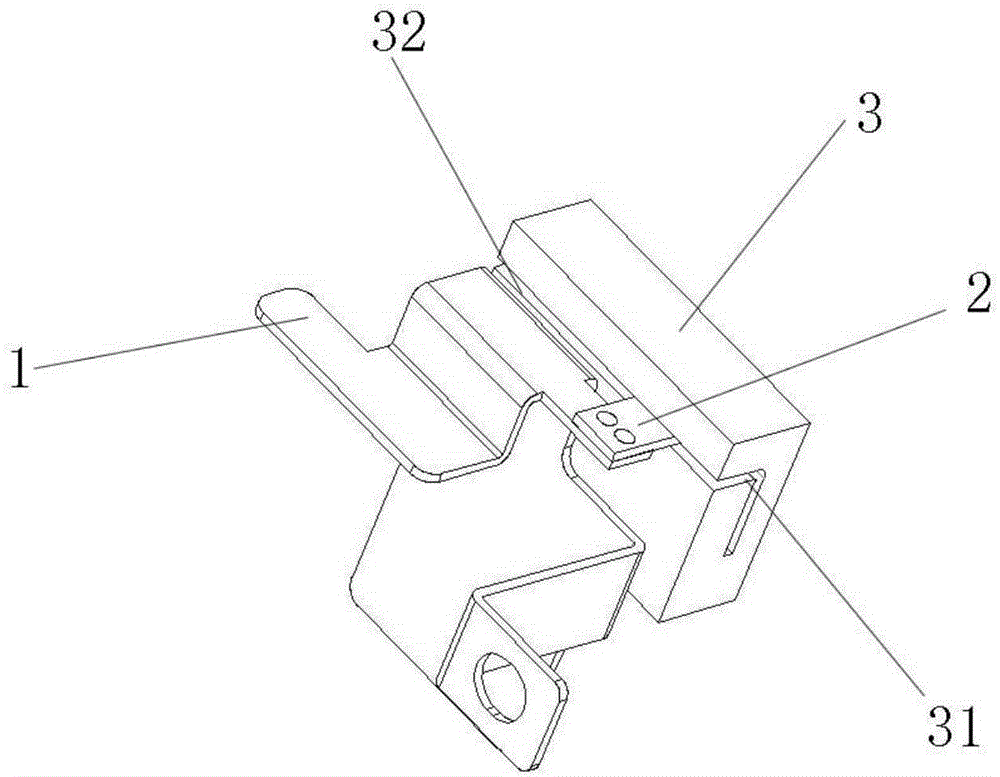

Electroplating electric-conducting device for integrated circuit lead frame

InactiveCN102383160ASimple structureEasy to useElectrolysis componentsSemiconductor/solid-state device detailsEngineeringLead frame

The invention relates to an electroplating electric-conducting device for an integrated circuit lead frame, which comprises an upper die and a lower die, wherein an electric-conducting strip is arranged in the upper die, two binding posts are arranged on the electric-conducting strip, each electric-conducting strip is provided with at least three pins arranged along the transverse direction, the end parts of the pins extend to the bottom of the upper die, and an anode plate is arranged in the lower die. The electroplating electric-conducting device is suitable for conducting electroplating on the integrated circuit lead frame, and can lead current density in the lead frame to be distributed uniformly, so that a silver layer on the lead frame has uniform thickness, the consumption of silver is reduced, and further the production cost is lowered.

Owner:顺德工业(江苏)有限公司

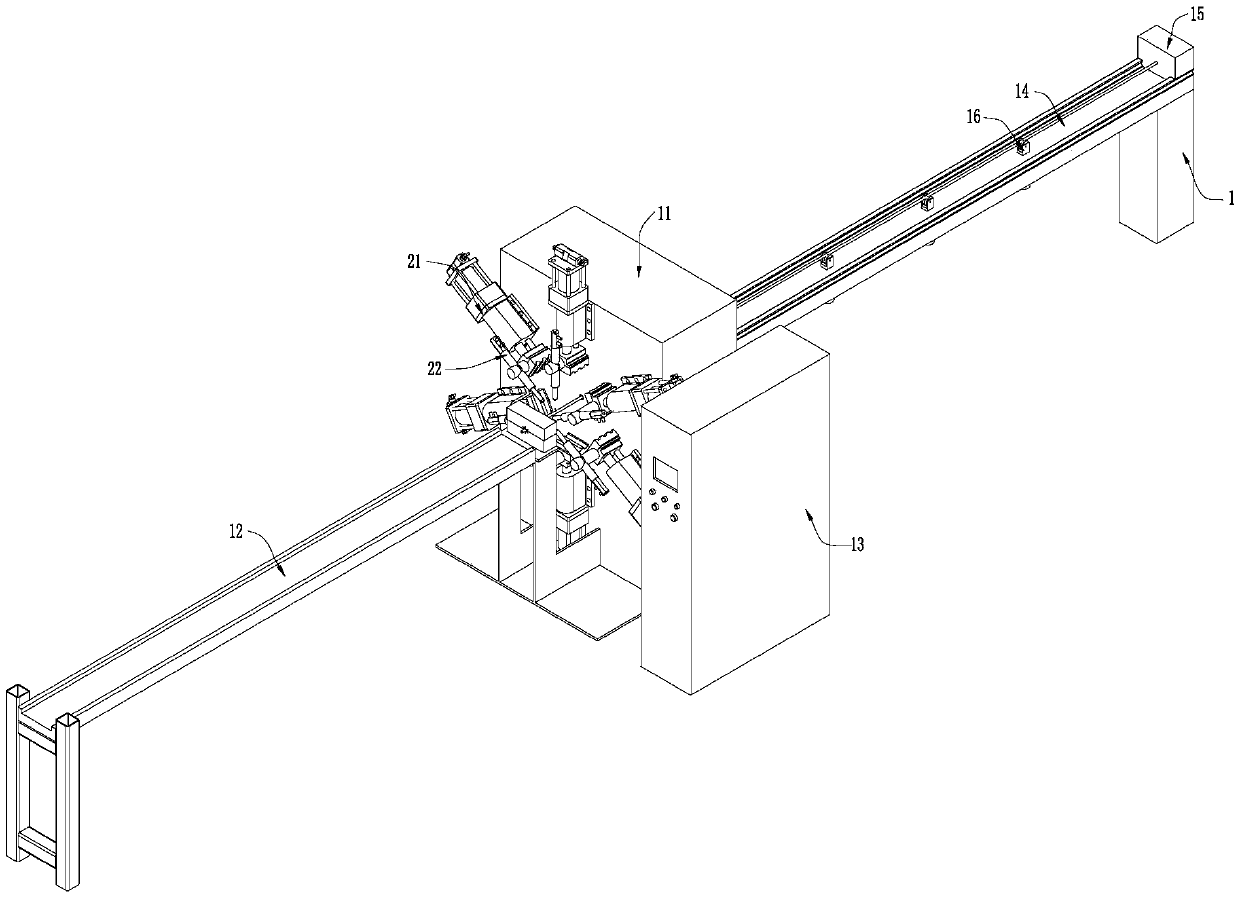

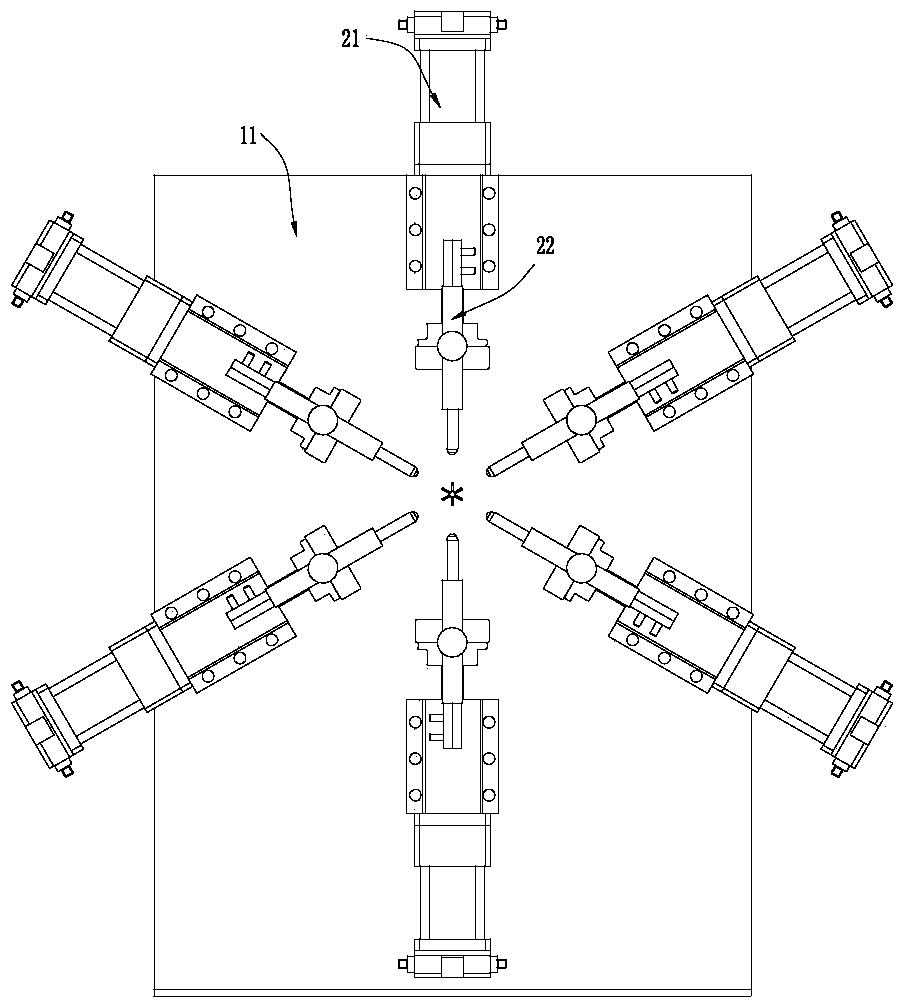

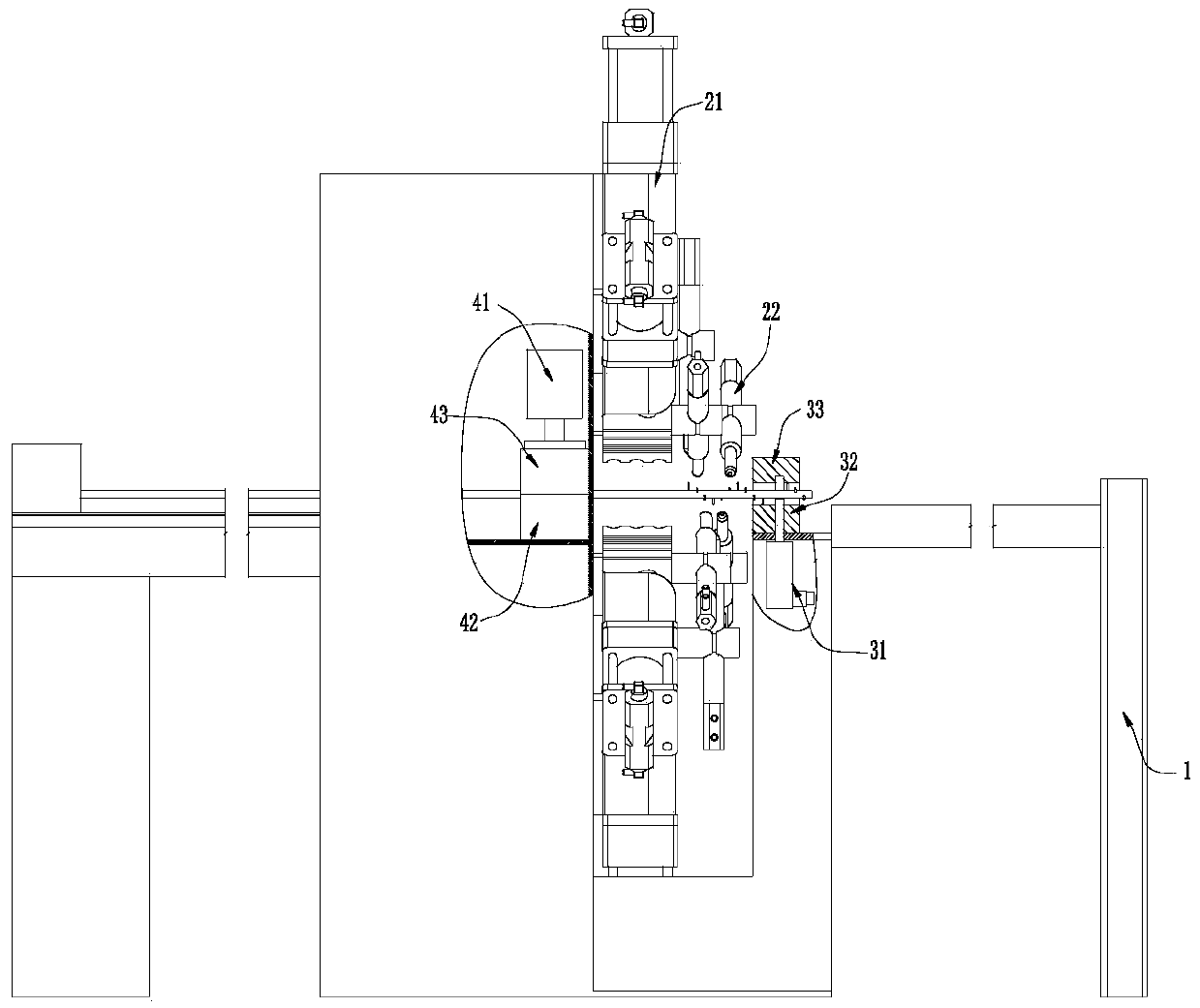

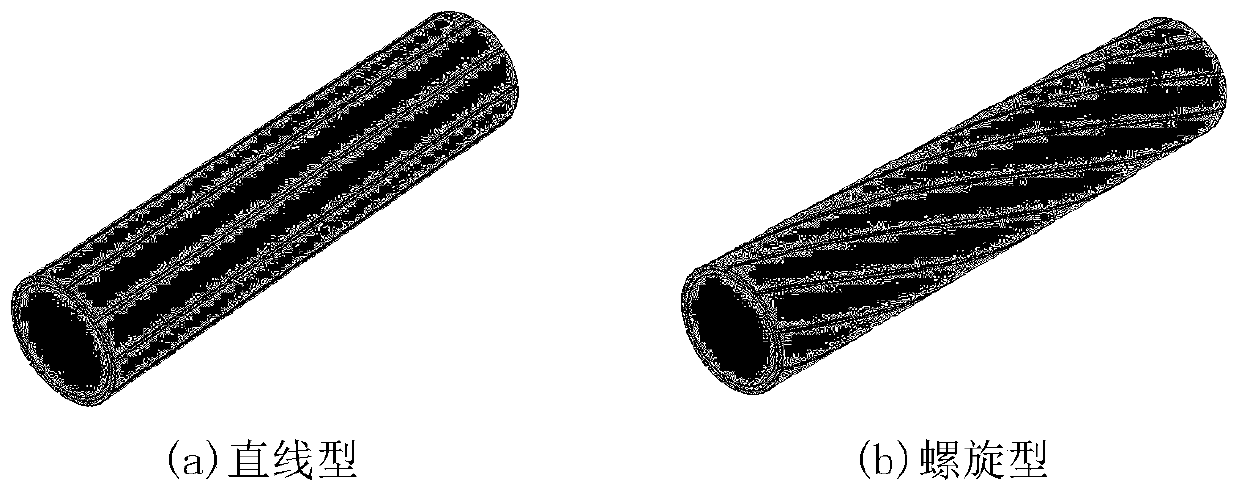

Cathode line welding equipment

ActiveCN105499868AEfficient productionGuaranteed straightnessWelding/cutting auxillary devicesAuxillary welding devicesFeed lineWaste management

The invention relates to the field of cathode line processing equipment, and in particular to cathode line welding equipment. The cathode line welding equipment comprises a rack, and a feeding assembly and a welding assembly which are arranged on the rack, wherein the welding assembly is arranged on a feeding line of the feeding assembly, an internal clamping device is arranged at the upstream of the welding assembly, and an external clamping device is arranged at the downstream of the welding assembly; the feeding assembly comprises a sliding rail on the rack and a feeding device arranged on the sliding rail in a sliding manner, and the feeding device, the internal clamping device and the external clamping device are arranged on one central axis; the welding assembly comprises six groups of welding components, which are circumferentially arranged in an array with the central axis as a center and are distributed spirally along the axial direction of the central axis, and the axial direction of the welding ends of two groups of welding components opposite to each other in the radial direction is equal to the axial length of half welding cycle of a cathode line to be welded. The special cathode line welding machine adopts a semi-automation production process, realizes automatic feeding and welding, and can be used for producing cathode lines quickly and efficiently.

Owner:ZHEJIANG TIANCHUANG ENVIRONMENTAL TECH CO LTD

Grid of lead-acid battery and lead-acid battery

PendingCN112310410ALight in massHas the function of collecting flowFinal product manufactureElectrode carriers/collectorsEngineeringStructural engineering

The invention relates to a grid of a lead-acid battery and a lead-acid battery. The grid comprises a grid-shaped current collector and a frame; the grid-shaped current collector comprises a pluralityof first ribs and tabs, wherein the first ribs extend in a preset direction, and the tabs are connected with the first ribs; the frame comprises a plurality of supporting strips and a border, whereinthe supporting strips are connected together; the first ribs intersect with the supporting strips; the same ends of the first ribs are fastened with the bottom edge of the frame; the first ribs are atleast partially embedded into the supporting strips; the grid-shaped current collector is connected with the frame, so that a mesh structure is formed in the middle of the grid; the density of the frame is smaller than that of the grid-shaped current collector.

Owner:SHANDONG NEW KEYLEAD POWER TECH CO LTD

A high power thyristor

The invention discloses a high-power thyristor which comprises a silicon wafer, the silicon wafer is provided with unit cell gate poles, each unit cell gate pole comprises a central gate pole and an amplification gate pole, each central gate pole is located at the dead center of each amplification gate pole, the silicon wafer is provided with at least seven unit cell gate poles, and any three adjacent unit cell gate poles are distributed on the silicon wafer in a regular triangle shape. A plurality of small-size unit cell gate poles are installed on the silicon wafer of the high-power thyristor, multiple-unit cell structure gate poles are formed on the surface of the silicon wafer of the high-power thyristor, a plurality of parasitic resistors and a plurality of working areas which are small in capacitance are built on the surface of the silicon wafer, so that the thyristor which is large in size has the same working properties with a thyristor which is small in size, and the high-power thyristor has the advantages of being high in starting speed, even in current density distribution, high in on-state average current density, low in on-state voltage-drop, and low in on-state power consumption. Therefore, by means of the technical scheme, switching operation which is good in performance can be achieved on the high-power thyristor which is larger in size.

Owner:HANGZHOU HANAN SEMICON

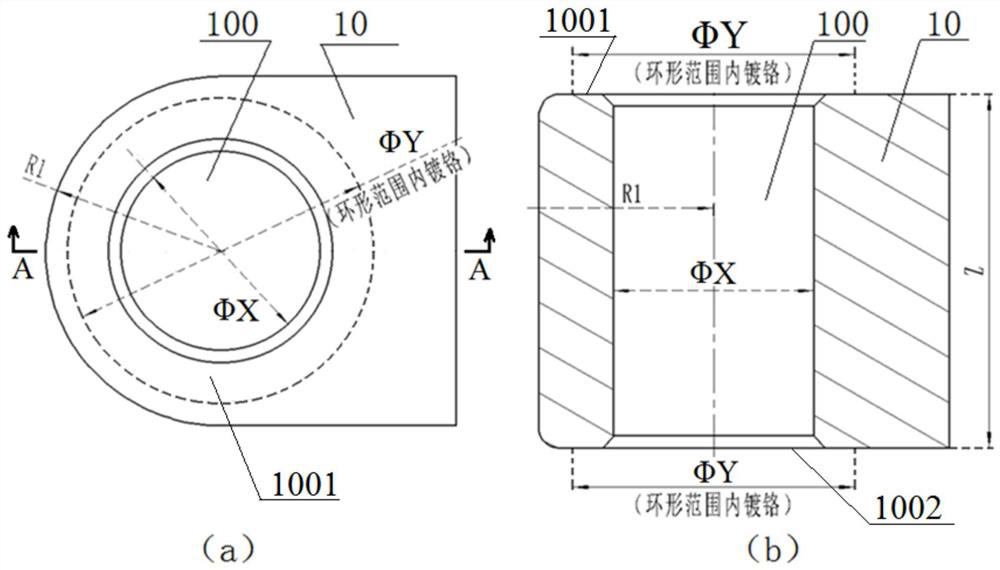

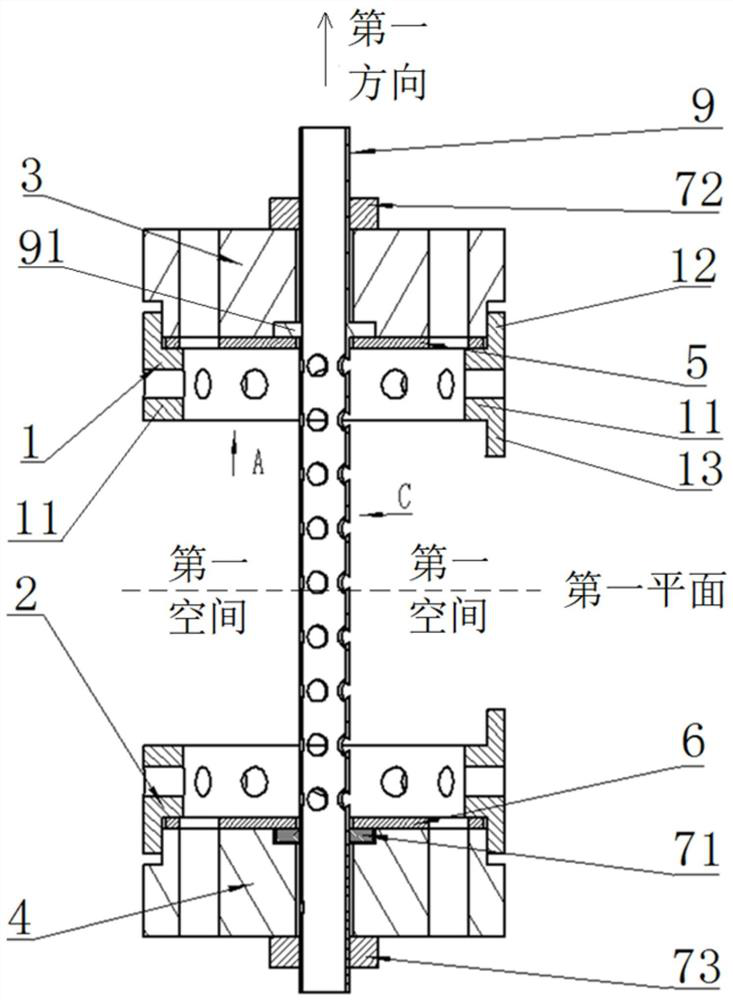

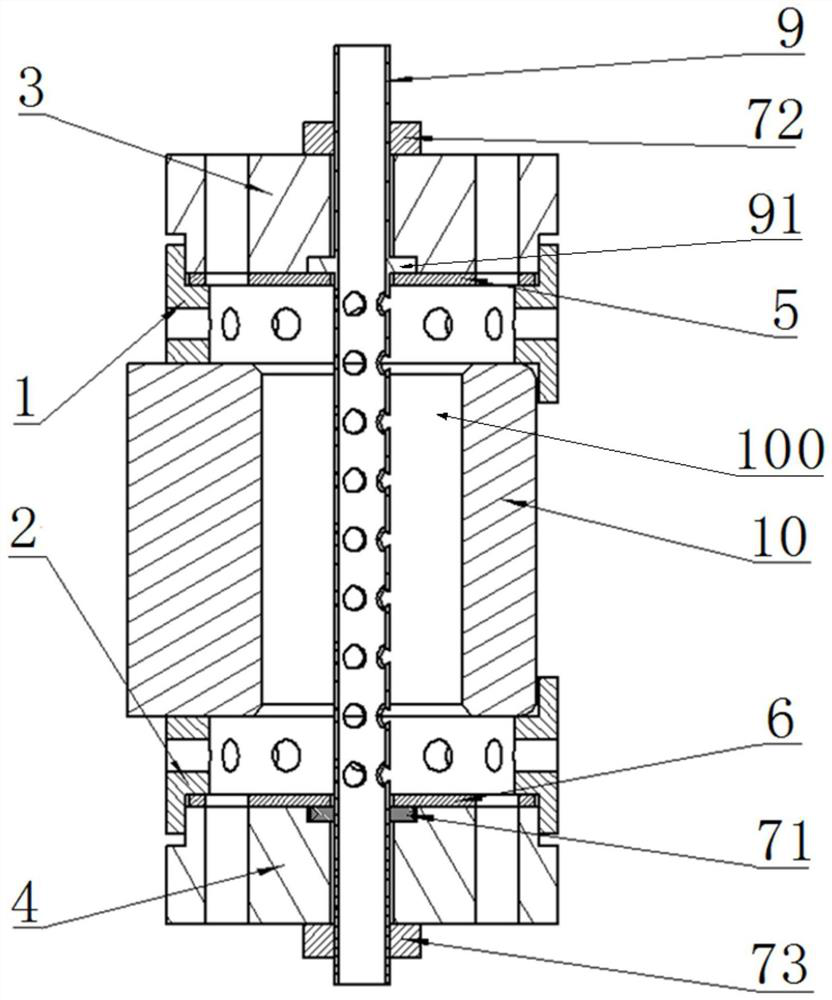

Electroplating processing device for inner bore and end faces of workpiece

ActiveCN112342599AAvoid cathodic interactionsAchieve shieldingCurrent conducting devicesElectrodesEngineeringChrome plating

The invention provides an electroplating processing device for an inner bore and end faces of a workpiece. The inner bore is formed in the processed workpiece in the length direction; a processing device includes an anode bar, and the axis direction of the anode bar is defined as a first direction; the processing device further includes a fastening structure, and a first anode plate, a first fixing piece, a second fixing piece and a second anode plate which are sequentially arranged on the anode rod in a sleeving manner in the first direction; the first fixing piece and the second fixing pieceare arranged at an interval; a first through hole is formed in the first fixing piece; and when the processed workpiece is arranged on the anode bar in a sleeving manner and is contained in a first space, the inner wall face of the first through hole is located at the outer side of the boundary of the inner bore in a first end face, and a gap is present between the first anode plate and the firstend face as well as between the second anode plate and a second end face. The electroplating processing device can change the distribution of power lines in the electroplating process of the workpiece, and thus, uniform distribution of the current density of the electroplated surface of the workpiece is promoted, plating is evenly deposited on the surface of the workpiece, so that chromium plating of multiple parts of the inner bore and the end faces is completed at a time.

Owner:LANDING GEAR ADVANCED MFG

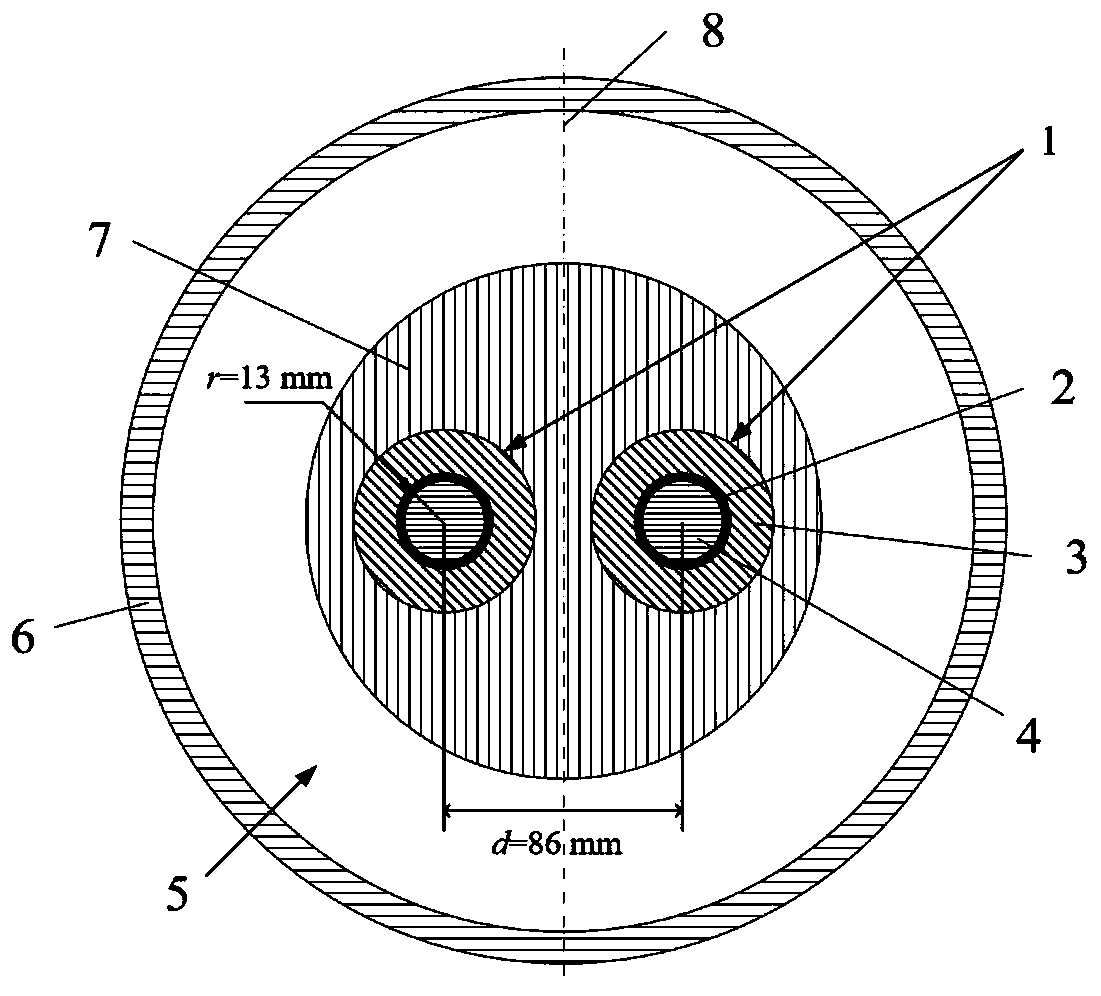

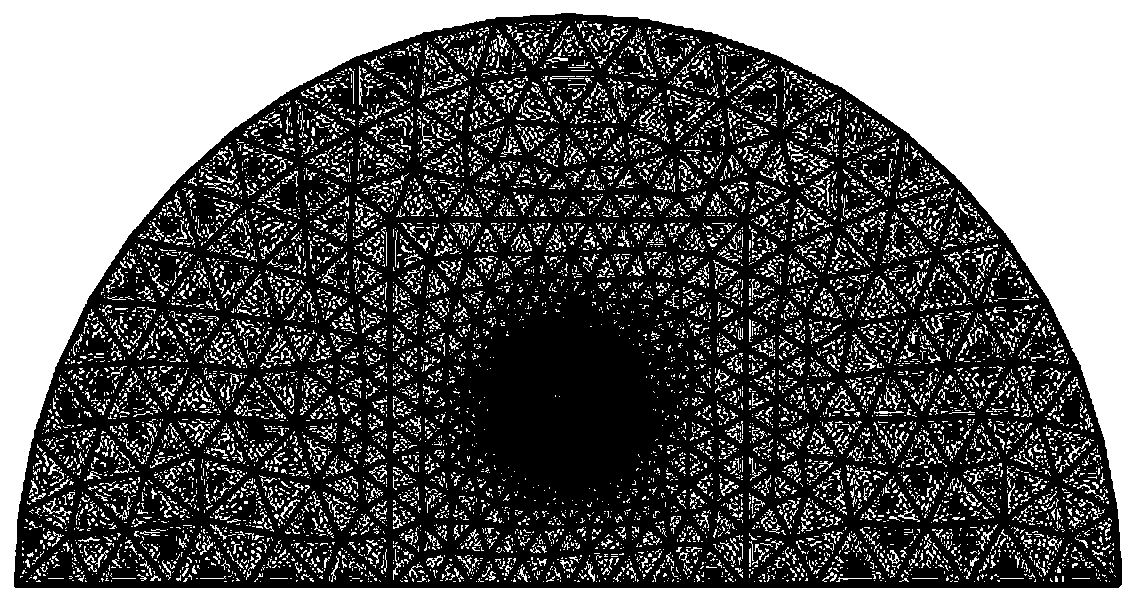

Simulation analysis method for current density distribution of high-temperature superconducting conductor

ActiveCN110705104AReduce dosageUniform current densityDesign optimisation/simulationElectrical conductorCurrent distribution

The invention provides a simulation analysis method for current density distribution of a high-temperature superconducting direct-current system considering the overall utilization rate of a superconducting tape. Firstly, a three-dimensional model is established for a high-temperature superconducting direct-current cable conductor, current distribution on the superconducting conductor is obtainedby solving the three-dimensional model, the overall utilization rate of strips is improved by optimizing the screw pitch of the superconducting strips, current distribution on each superconducting strip is uniform, and the use amount of the strips is small.

Owner:TSINGHUA UNIV +2

Composite diaphragm slurry, preparation method thereof and battery diaphragm

PendingCN113611983AImprove the interface binding forceInhibit sheddingSecondary cellsCell component detailsElectrolytic agentSlurry

The invention discloses composite diaphragm slurry and a composite diaphragm, and belongs to the technical field of lithium ion battery diaphragm production. The composite diaphragm comprises the following raw materials of: 10-20 parts of polymer coated ceramic particles, 10-25 parts of deionized water, 0.01-0.1 part of a dispersant, 1-3 parts of a binder and 0.01-1 part of an auxiliary agent. The preparation method of the polymer coated ceramic particles comprises the following steps of: uniformly mixing a polymer, ceramic particles and a dispersing agent; and then preparing the polymer coated ceramic particles in an inert atmosphere through a spray drying method. The polymer is one or two of polyisophthaloyl metaphenylene diamine and polyimide. A lithium ion battery prepared from the composite diaphragm has better multiplying power and safety performance. A coating layer has good wettability and liquid retention for electrolyte, and is beneficial to improving the rate and long cycle performance of the battery.

Owner:湖南烁普新材料有限公司

Method for eliminating horizontal current in aluminum cell aluminum liquor

The invention belongs to the technical field of aluminum electrolysis tank which is used in the production of primary aluminum by the Hall-Herolut electrolysis method. Particularly, the invention relates to a method for eliminating horizontal current in aluminum liquid in the aluminum electrolysis tank. The method comprises: the lower part or lower surface of a cathode carbon block is provided with an electric conductor directly penetrating the tank bottom. The method has the advantages of eliminating the horizontal current in the aluminum liquid in the aluminum electrolysis tank, making the current density distribution on the surface of the cathode carbon block more uniform, improving current efficiency, greatly improving stability of the aluminum electrolysis tank and prolonging servicelife of the aluminum electrolysis tank. The method is strong in practicability. The method can fundamentally solve the problem of the horizontal current in the aluminum liquid, and has very importantdirective significance on the development of the large-sized aluminum electrolysis tank.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com