LED chip and manufacturing method thereof

A technology of LED chip and manufacturing method, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as uneven current density distribution, achieve uniform current density distribution, and improve luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

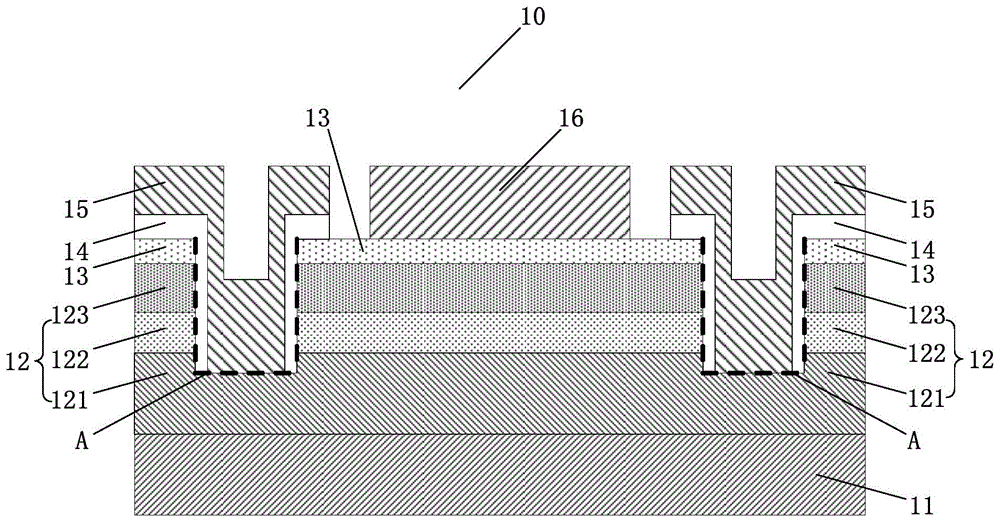

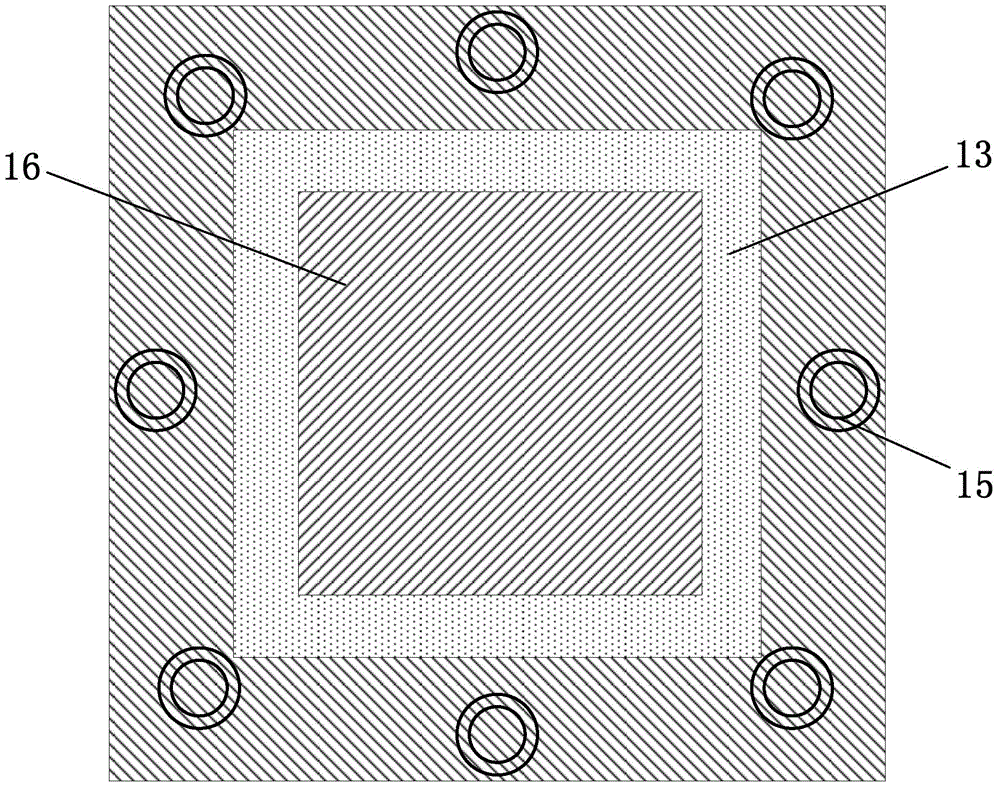

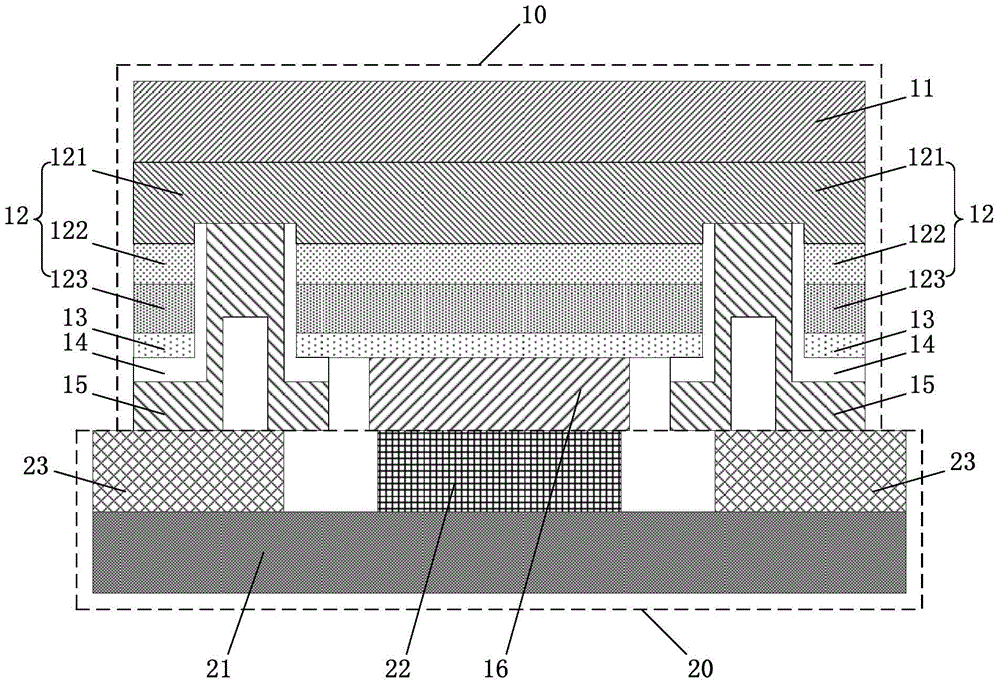

[0039] Embodiment 1 of the present invention provides an LED chip. figure 1 It is a schematic cross-sectional view of an LED chip provided by Embodiment 1 of the present invention. like figure 1 As shown, the LED chip 10 includes: a substrate 11; an epitaxial layer 12, the epitaxial layer 12 is located on the substrate 11; a transparent electrode layer 13, the transparent electrode layer 13 is located on the epitaxial layer 12; At least two grooves (shown in the area A surrounded by a dotted line in the figure), the grooves pass through the transparent electrode layer 13 in the longitudinal direction and the bottom is located in the epitaxial layer 12, and the grooves extend along the transparent electrode layer 13 edge distribution; insulating layer 14, the insulating layer 14 is lined on the side wall of the groove and the transparent electrode layer 13 on the edge of the groove; N-type electrode 15, the N-type electrode 15 is located on the insulating layer 14; and a P-ty...

Embodiment 2

[0059] Embodiment 2 of the present invention provides a method for manufacturing an LED chip. The manufacturing method of the LED chip in this embodiment can manufacture the LED chip described in the first embodiment above, and the manufacturing process is compatible with the existing process. In this embodiment, for the explanation of the concept and the detailed description of the working principle, please refer to Embodiment 1, which will not be repeated here.

[0060] Figure 4 It is a schematic flow chart of a method for manufacturing an LED chip provided in Embodiment 2 of the present invention. like Figure 4 As shown, the manufacturing method of the LED chip of the present embodiment comprises:

[0061] Step 301, forming an epitaxial layer on the substrate;

[0062] In this step, further, forming an epitaxial layer on the substrate includes: sequentially forming an N-type GaN layer, an InGaN or GaN multi-quantum well active layer, and a P-type GaN layer on the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com