Flip LED chip array structure and preparation method thereof

A technology of LED chip and array structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high current density, increased number of chip cutting, small chip power, etc., to achieve uniform current density distribution and effective light emitting area. Improve, fit the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

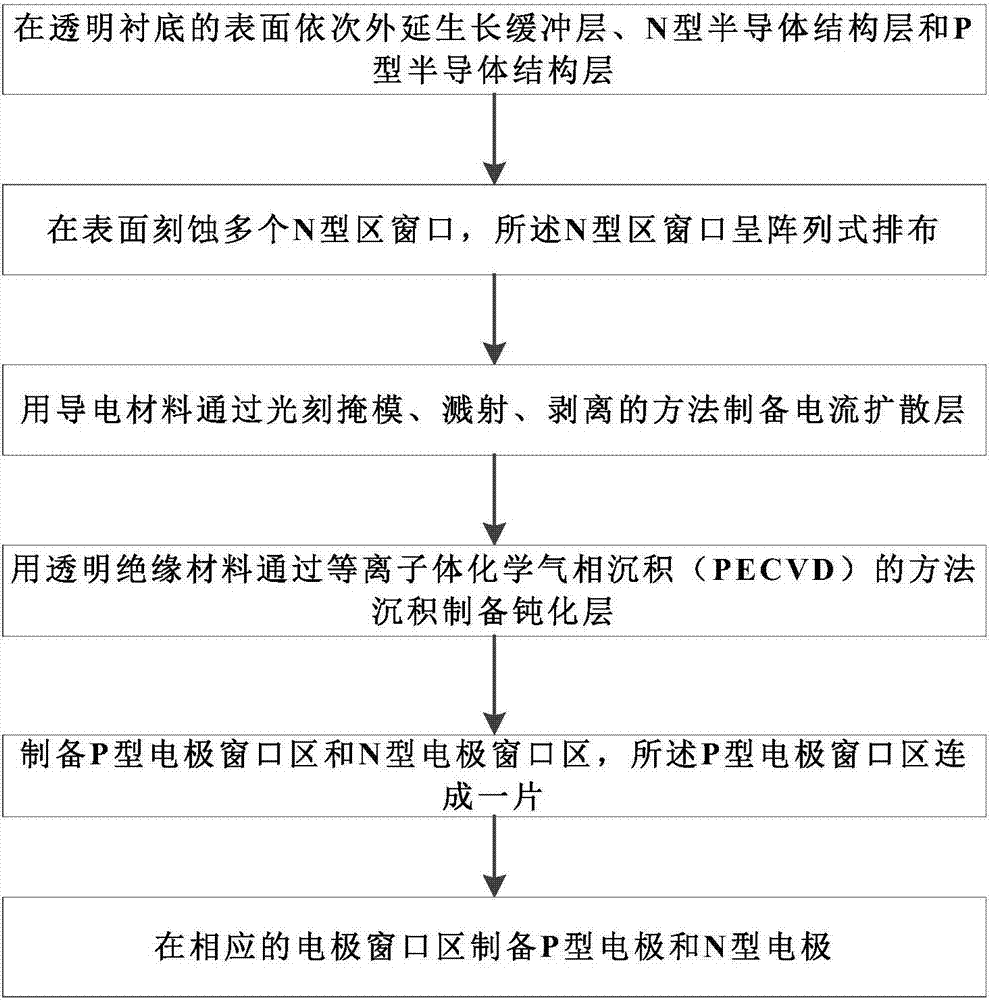

[0045] Such as figure 1 As shown, the preparation method of the flip-chip LED chip array structure includes the following steps:

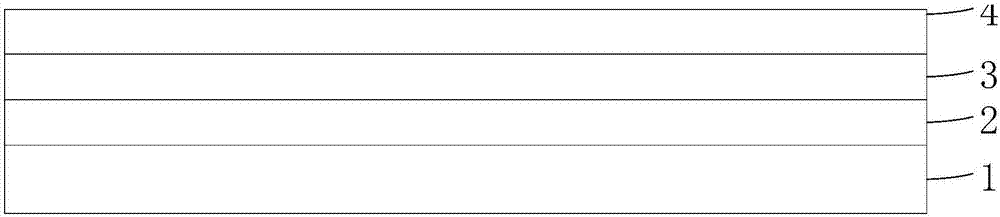

[0046] (1) A multi-element composite of one or more materials among sapphire, gallium nitride, and aluminum nitride is selected as the transparent substrate 1 for epitaxial growth.

[0047] (2) On the surface of the transparent substrate 1, the buffer layer 2, the N-type GaN semiconductor structure layer 3 and the P-type GaN semiconductor structure layer 4 are epitaxially grown in sequence to obtain a substrate epitaxial wafer, such as figure 2 shown.

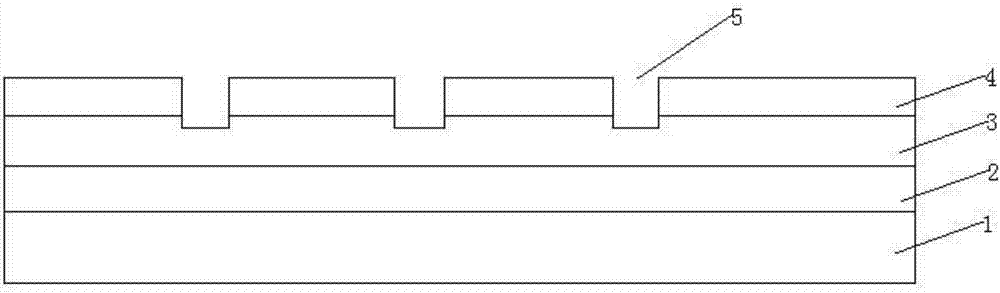

[0048] (3) A plurality of N-type region windows 5 are etched on the surface of the epitaxial structure layer by using semiconductor process technologies such as photolithography, development, and etching, and a plurality of small-area N-type region windows 5 are arranged in an array, such as image 3 shown.

[0049] (4) The current diffusion layer 6 is prepared by photolithographic masking, sput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com