A high power thyristor

A thyristor and high-power technology, applied in the field of power switching devices, can solve the problems of reduced on-state average current density, poor distribution uniformity of on-state current density, and prolonged turn-on time, achieving high on-state average current density and high current Uniform density distribution and low on-state power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

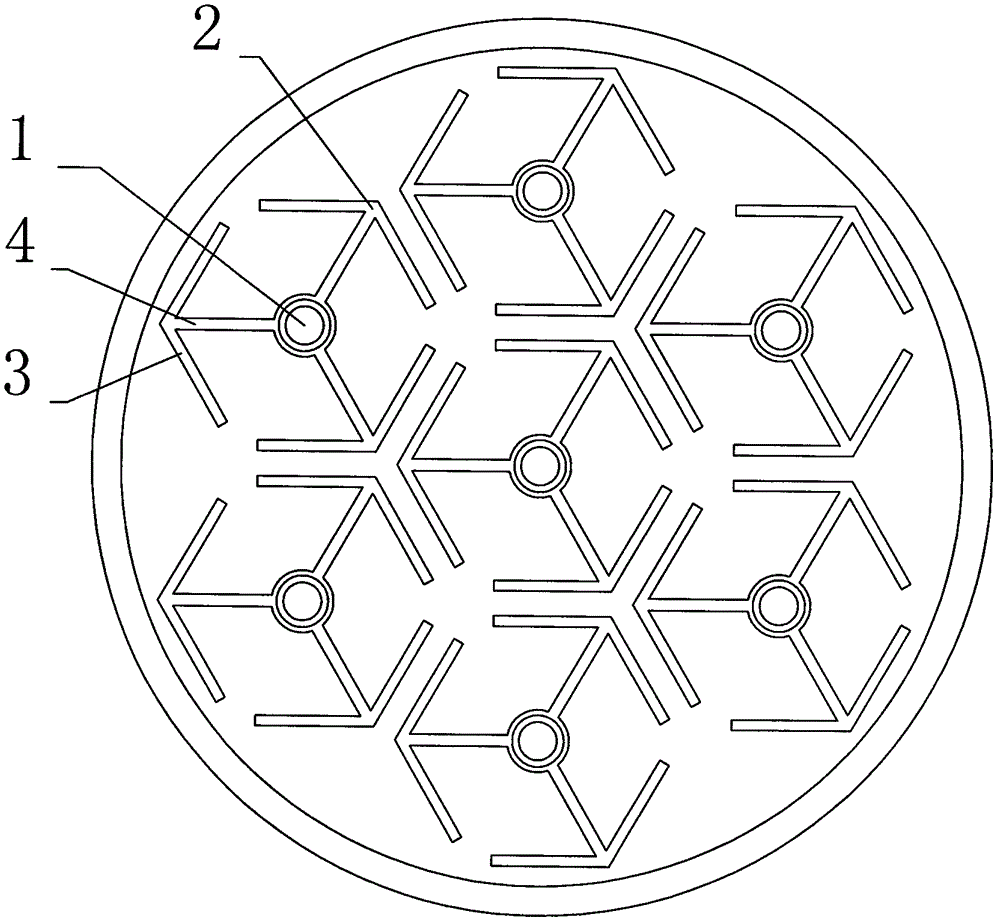

[0011] The high-power thyristor of the first embodiment of the present invention is provided with a silicon wafer, and seven unit cell gates with the same structure are provided on the silicon wafer. Such as figure 1 As shown, each cell gate is composed of a central gate 1 and an enlarged gate 2. The enlarged gate 2 includes three arrow-shaped fingers. Each finger is provided with a flange part 3 that is bent 120 degrees. The center gate electrode is in the middle of the flange part 3, that is, at the junction of the two sides. A connecting part 4 is provided in the direction of 1. The sub-fingers are distributed around the central gate 1 in a circle with an interval of one hundred and two degrees. The connecting parts 4 of the three sub-fingers are interwoven and connected around the central gate 1, and then the connecting parts 4 of the sub-fingers are in a radius centered on the central gate 1 In the direction, the folded edges 3 of adjacent finger points are separated.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com