Composite diaphragm slurry, preparation method thereof and battery diaphragm

A composite diaphragm and battery diaphragm technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems affecting the liquid absorption rate and retention rate of the diaphragm, unfavorable electrolyte infiltration and absorption, etc., to improve the ratio and Long-term cycle performance, good rate and safety performance, and the effect of uniform current density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

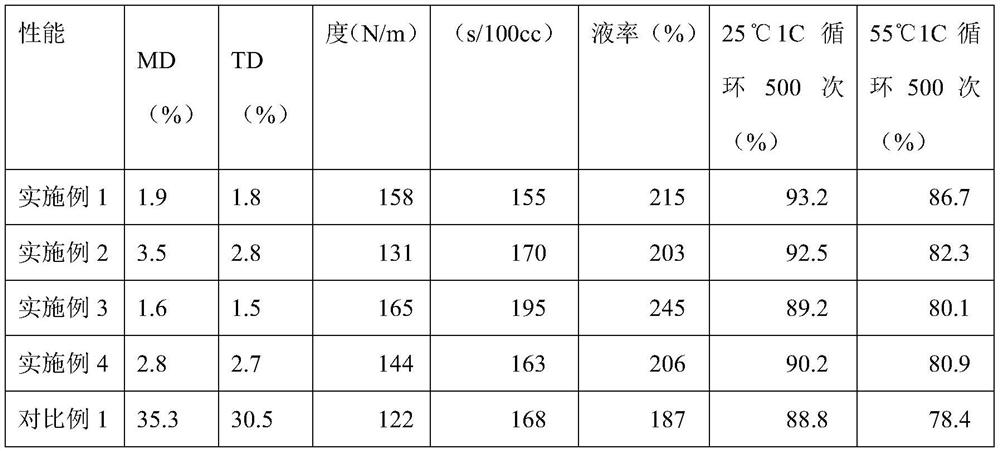

Examples

Embodiment 1

[0047] Dissolve 0.5 g of polyimide (PI) powder (molecular weight 60,000 to 85,000) in 77 g of dimethylacetamide, heat and stir at 60°C to prepare a polymer solution. Add 0.1g dispersant (BYK-LPN25432), 10g Al 2 o 3 Powder (D50 is 0.6-1.2 μm), stirred evenly to make precursor slurry. The rotational speed of stirring and mixing was 400 rpm / min, and the stirring time was 2 hours.

[0048] The above precursor slurry is passed through a fully enclosed spray dryer, using nitrogen as the inert gas, and the slurry is dried and transported in an oxidation-resistant environment of a closed loop system. The atomization drying temperature is 90 ° C, and the atomization pressure is 0.2 MPa. The feeding rate is 100ml / h, and the polymer-coated ceramic particles are prepared, with a particle size of 0.7-1.6 μm.

[0049] According to the mass ratio, polymer-coated ceramic particles: deionized water: cellulose ether dispersant: sodium carboxymethyl cellulose: acrylate adhesive = 38%: 45%: 0....

Embodiment 2

[0054] Dissolve 0.1 g of polyimide (PI) powder (molecular weight 60,000 to 85,000) in 74.07 g of dimethylacetamide, heat and stir at 60°C to prepare a polymer solution. Add 0.1 g of dispersant (BYK-LPN25432) and 10 g of Al2O3 powder (D50 is 0.6-1.2 μm) to the above polymer solution, and stir evenly to make a precursor slurry. Other preparations are the same as in Example 1.

Embodiment 3

[0056] Dissolve 1 g of polyimide (PI) powder (molecular weight 60,000 to 85,000) in 80.67 g of dimethylacetamide, heat and stir at 60°C to prepare a polymer solution. Add 0.1 g of dispersant (BYK-LPN25432) and 10 g of Al2O3 powder (D50 is 0.6-1.2 μm) to the above polymer solution, and stir evenly to make a precursor slurry. Other preparations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com