Patents

Literature

41results about How to "Low energy consumption in the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

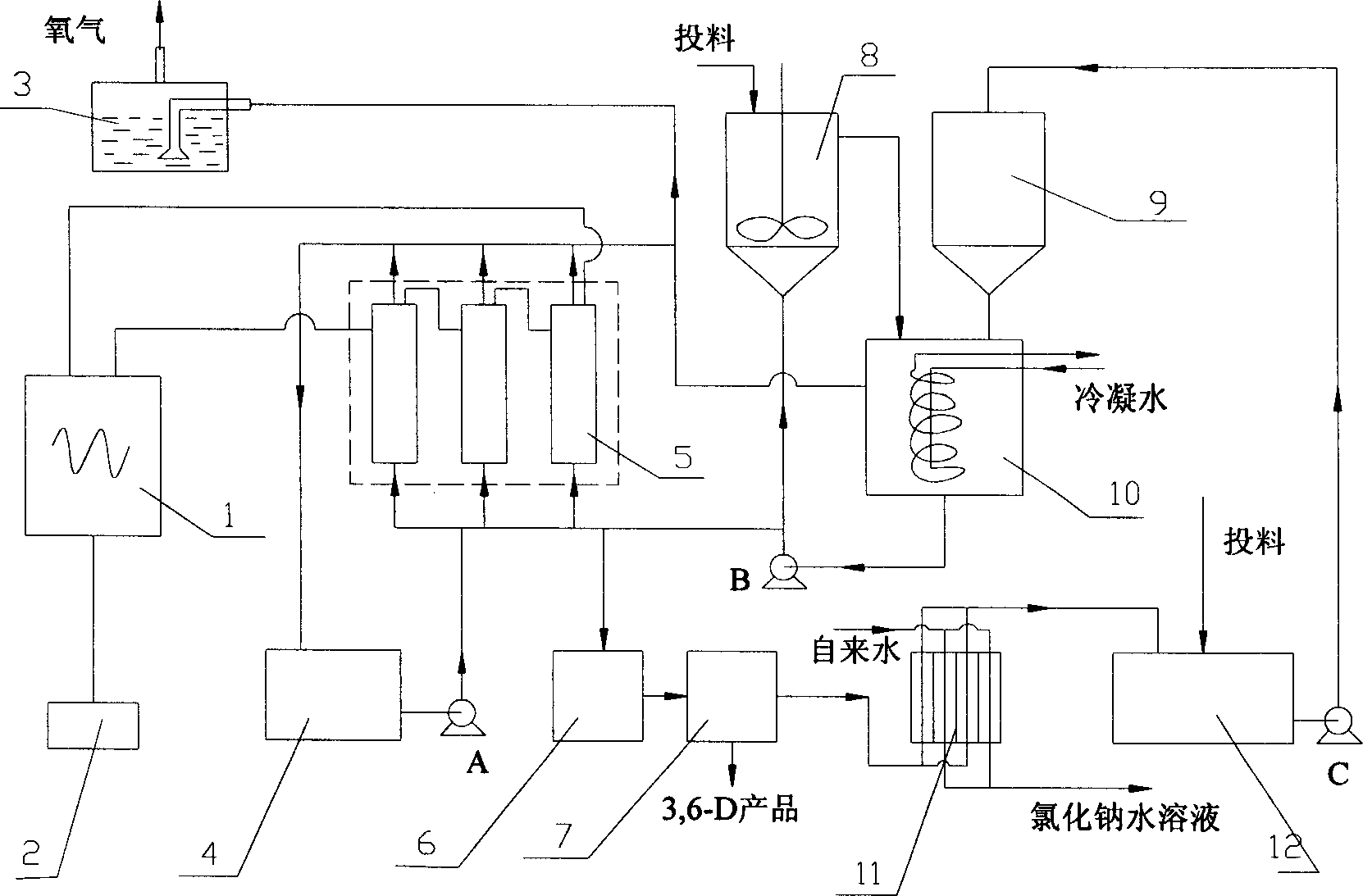

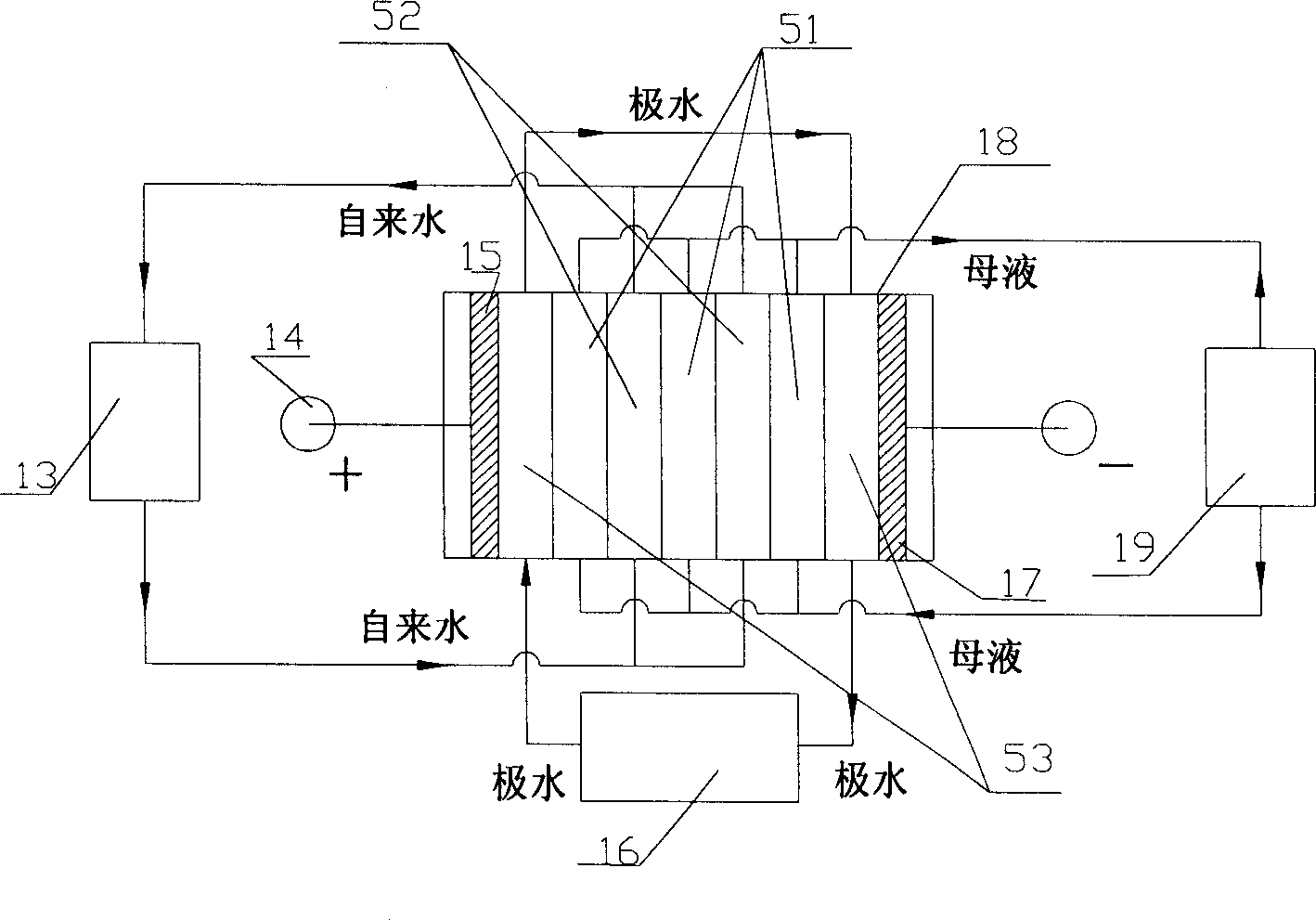

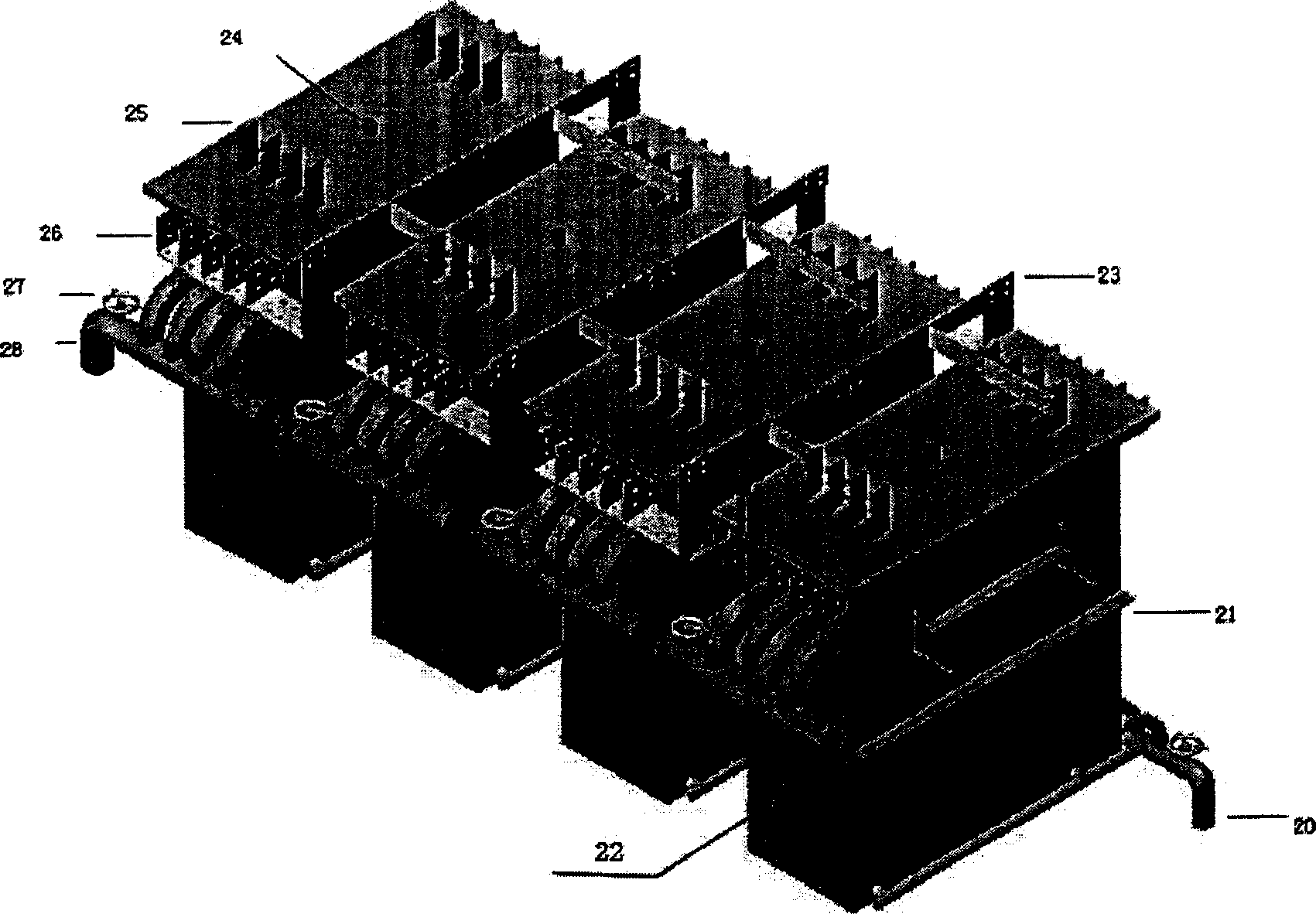

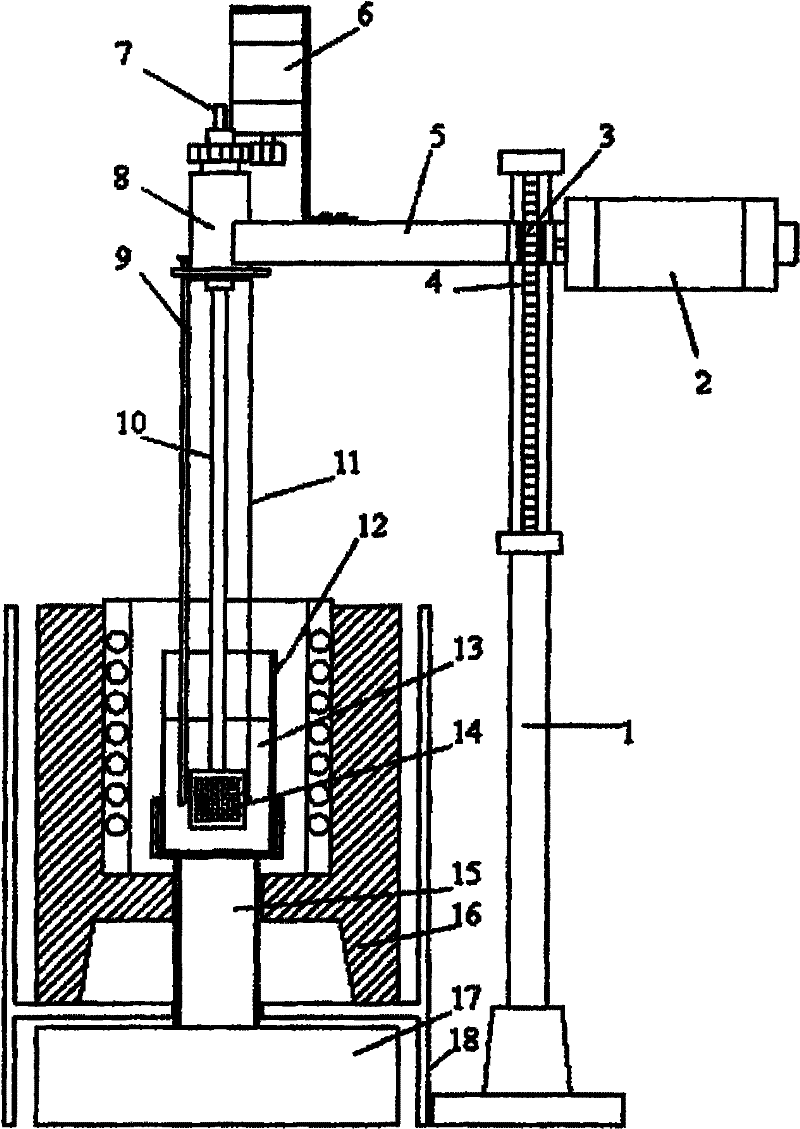

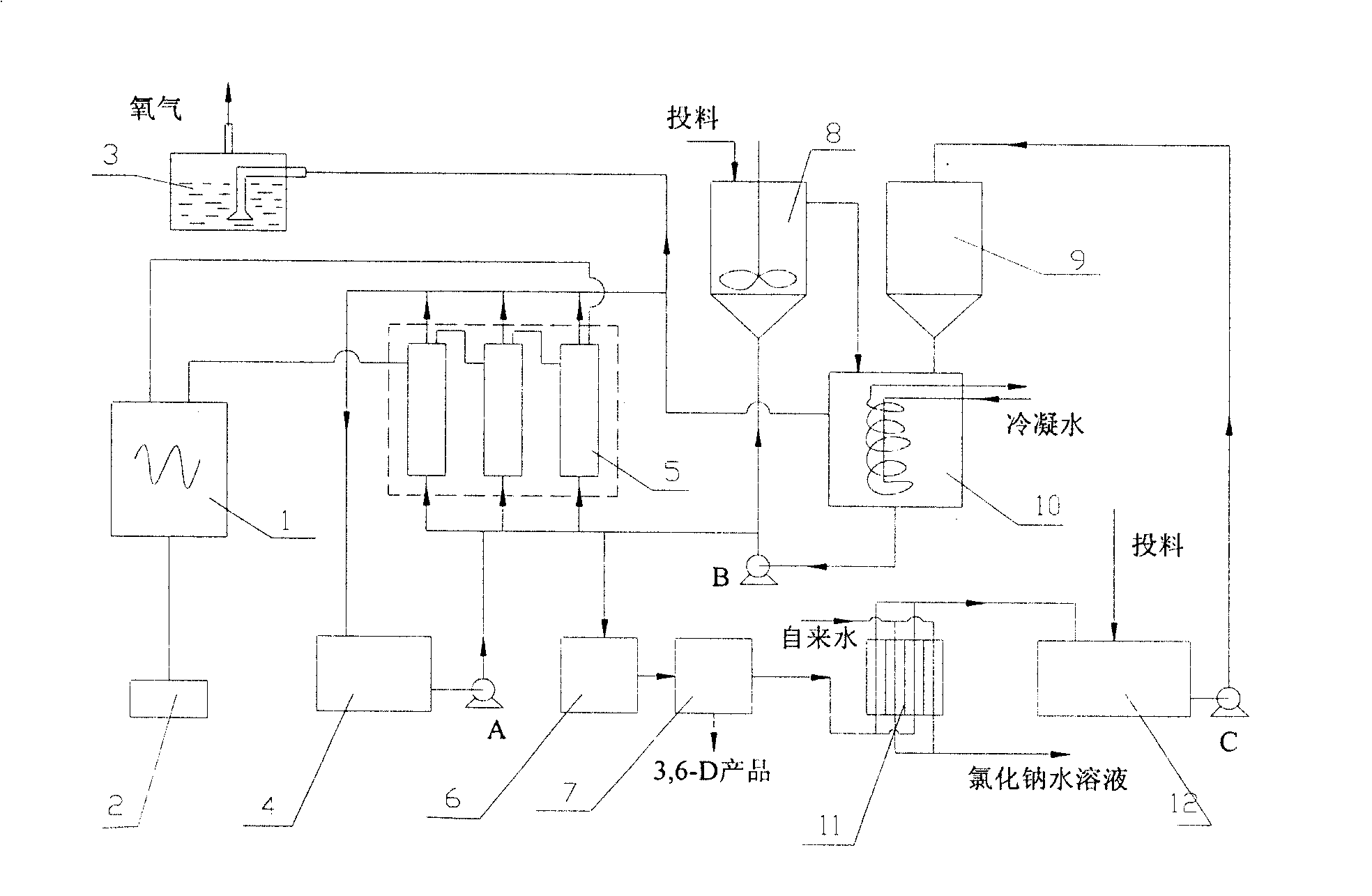

Method and apparatus for electrolytic synthesis of 3,6-dichloropyridine-carboxylic acid

InactiveCN1807691ALow energy consumption in the production processLess side effectsOrganic chemistryElectrolysis componentsElectrolysisSynthesis methods

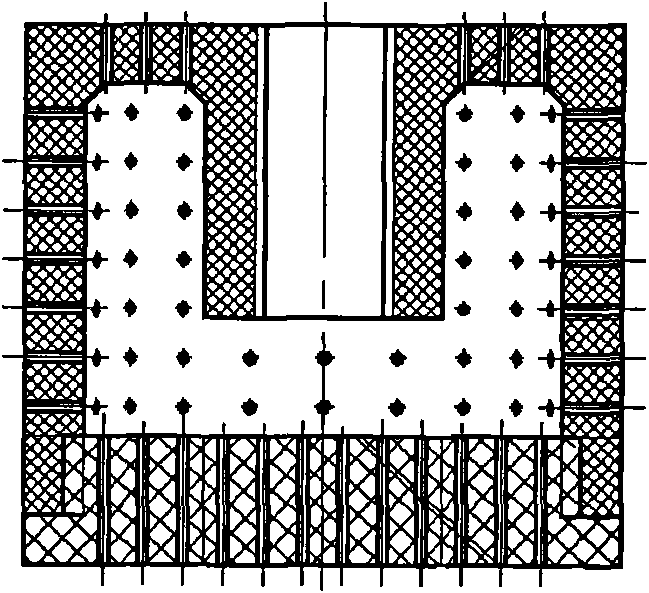

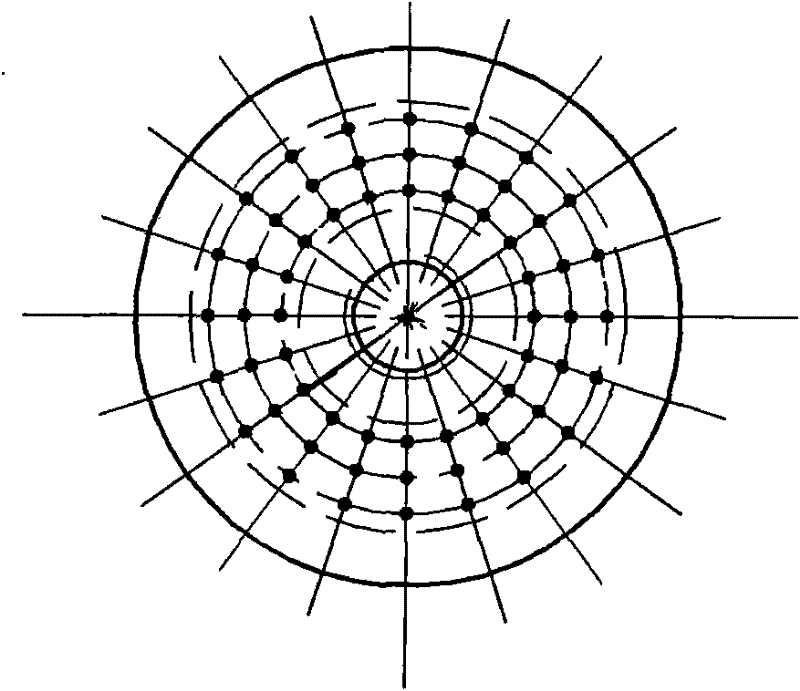

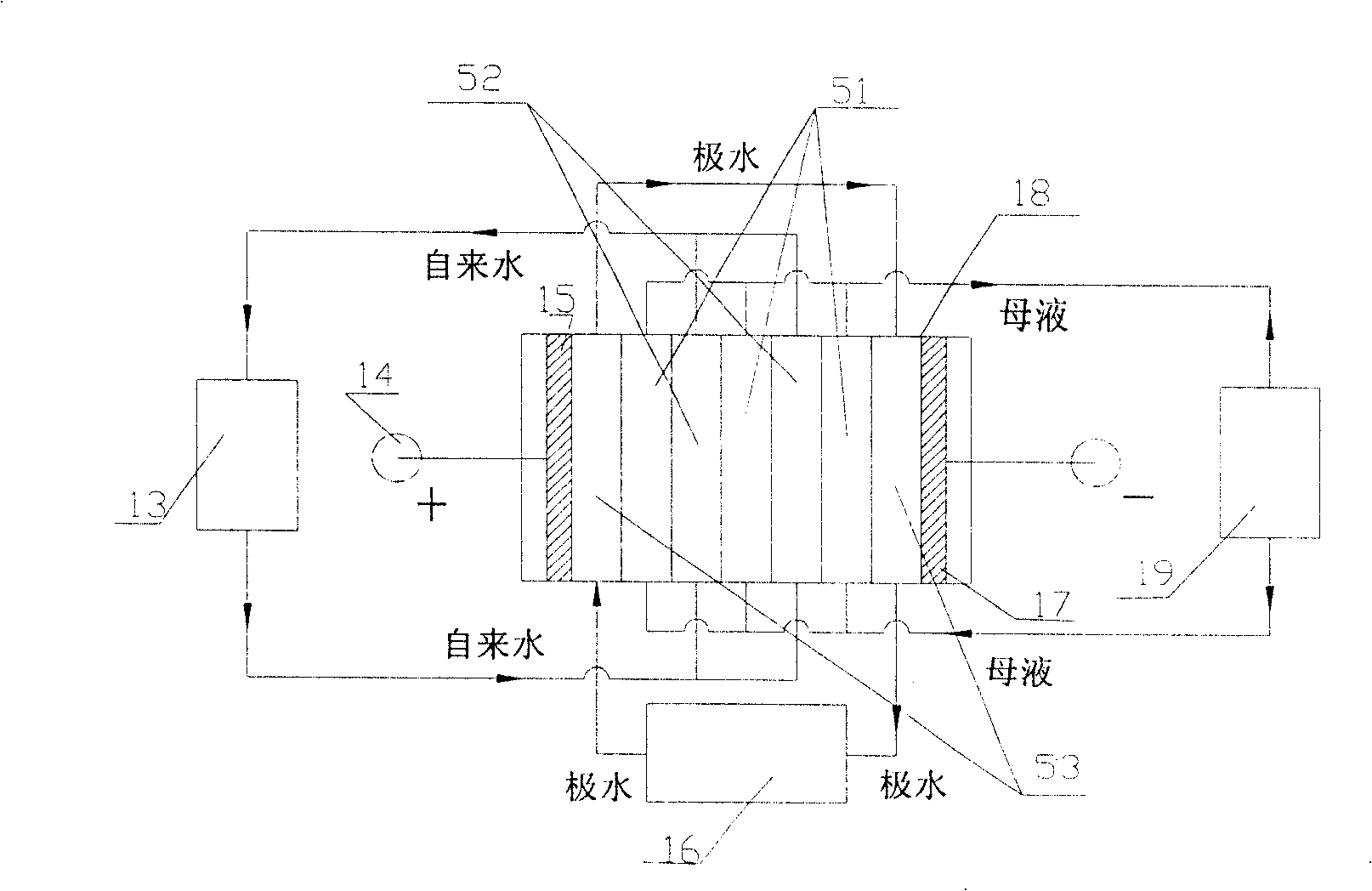

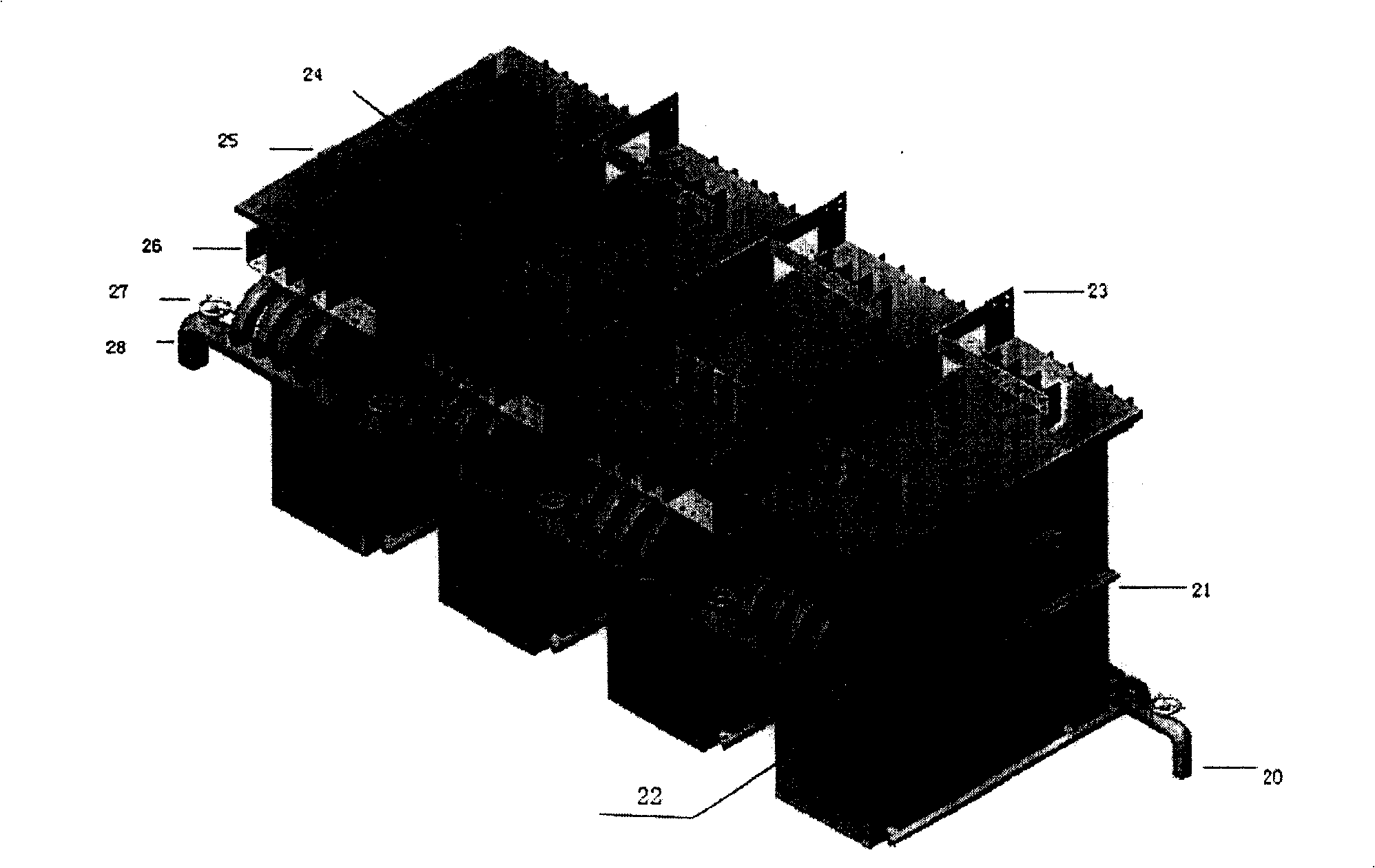

The invention discloses a 3, 6- dichloro pyridine methanamine electrolytic synthesis method and device, which comprises the following steps: using 3, 4, 5, 6-tetrachloro pyridine aminic acid for main electrolysis material; placing electrolytic solution in electrolysis bath to electrolyze; getting 3, 6- dichloro pyridine methanamine by neutralizing, cooling, crystallizing, filtering and drying; carrying on toughening treatment for cathode of electrolysis bath by periodic reversible power of thyristors. The device is composed of power, dosage bunker, electrolysis bath, wherein the power is stabilized voltage and permanent flow, which can control the cycle reverse power; the power connects to current commutator; program control unit is installed for current commutator; the anode of power is connected to anode of electrolysis bath; the minus pole of power connects to cathode of electrolysis bath.

Owner:ZHEJIANG UNIV OF TECH

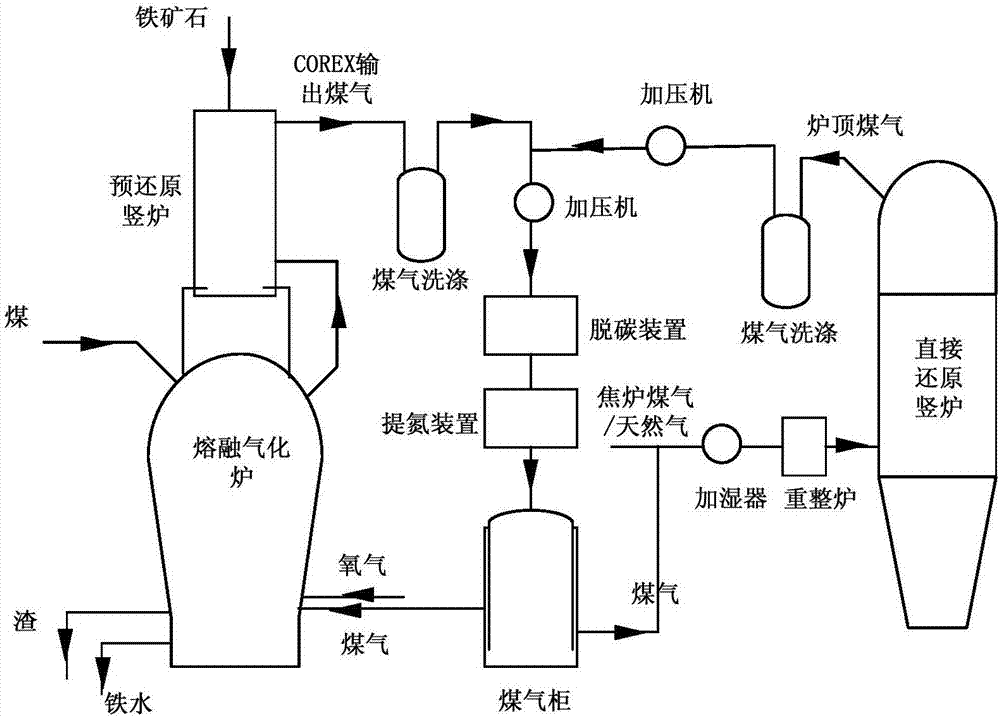

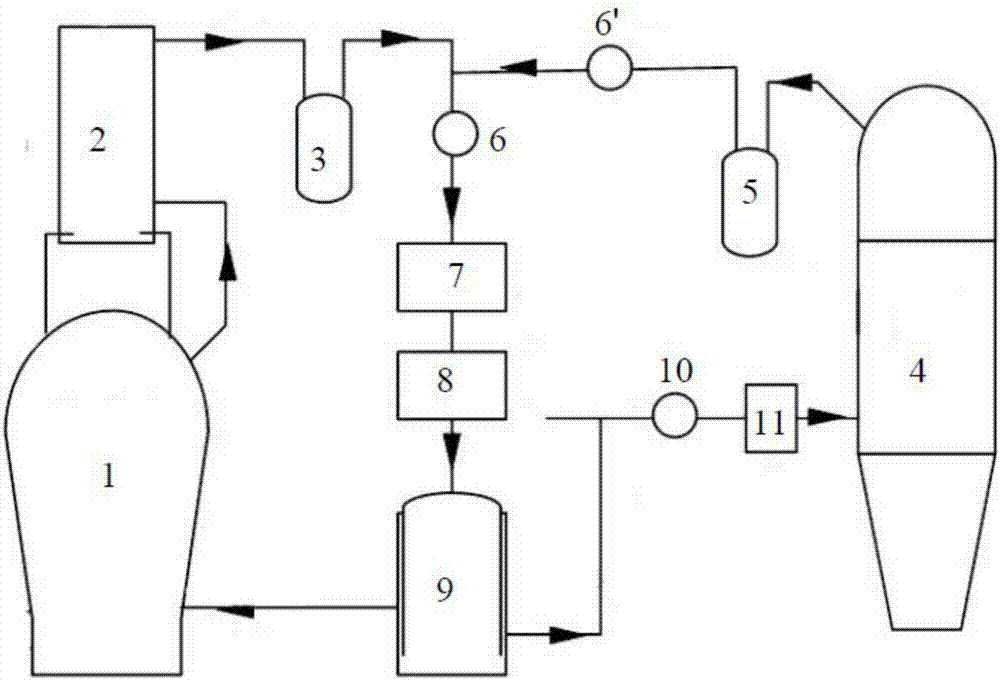

Method and system for producing sponge iron through COREX device and direct reduction vertical furnace

PendingCN106957937AExpand production scaleIncrease H2 ratioShaft furnaceGas emission reductionCorexNatural gas

The invention relates to a method for producing sponge iron through a COREX device and a direct reduction vertical furnace. The method comprises the steps that coal is pyrolyzed in a melting gasifier to produce pyrolysis gas, meanwhile, coal char and oxygen react to produce coal gas, and the coal gas is conveyed into a pre-reduction vertical furnace through a pipeline to reduce iron ore, so that COREX output coal gas is obtained; iron ore is reduced in the direct reduction vertical furnace through reduction gas, and furnace top coal gas is generated; after being cooled and dedusted through a coal gas washing device, the obtained two kinds of coal gas are mixed and enter a pressurizing machine to be pressurized, and then the mixed coal gas enters a decarbonization device and a nitrogen extraction device to be processed and is conveyed to a coal gas cabinet to be stored; one part of the stored coal gas is sprayed into the melting gasifier, and the rest of the stored coal gas and coke furnace coal gas or natural gas are mixed and enter a humidifier to be supplemented with water vapor; the mixed gas supplemented with the water vapor enters a reforming furnace to be prepared into reduction gas; and the reduction gas is conveyed into the direct reduction vertical furnace to reduce the iron ore, so that the sponge iron is prepared. According to the method for producing the sponge iron through the COREX device and the direct reduction vertical furnace, the reduction capacity of the reduction coal gas can be improved, and the utilization ratio of the reduction coal gas can be increased.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Rice bran oil refining production method

InactiveCN103981022AImprove oil yieldGood decolorization effectFatty-oils/fats refiningFatty-oils/fats productionRice Bran ExtractSolvent

The invention discloses a rice bran oil refining production method. The method comprises the following steps: (1) freshness preservation of rice bran, namely adding isopropanol taken as a leaching solvent into fresh rice bran so as to leach a crude mixed rice bran oil; (2) preprocessing of the crude mixed rice bran oil, namely controlling the content of impurities in the crude rice bran oil to be below 0.2%; (3) degumming and dewaxing; (4) decoloring; (5) deacidification; and (6) deodorization, thereby obtaining rice bran oil. The method disclosed by the invention overcomes the defects in the prior art, and is low in energy consumption in a production process, high in oil yield and good in rice bran oil decoloring effect; the impurity treatment is carried out in the production process of the rice bran oil, so that the content of the impurities in the rice bran oil is further decreased. Thus, the quality of the rice bran oil is improved.

Owner:安徽渡民粮油有限公司

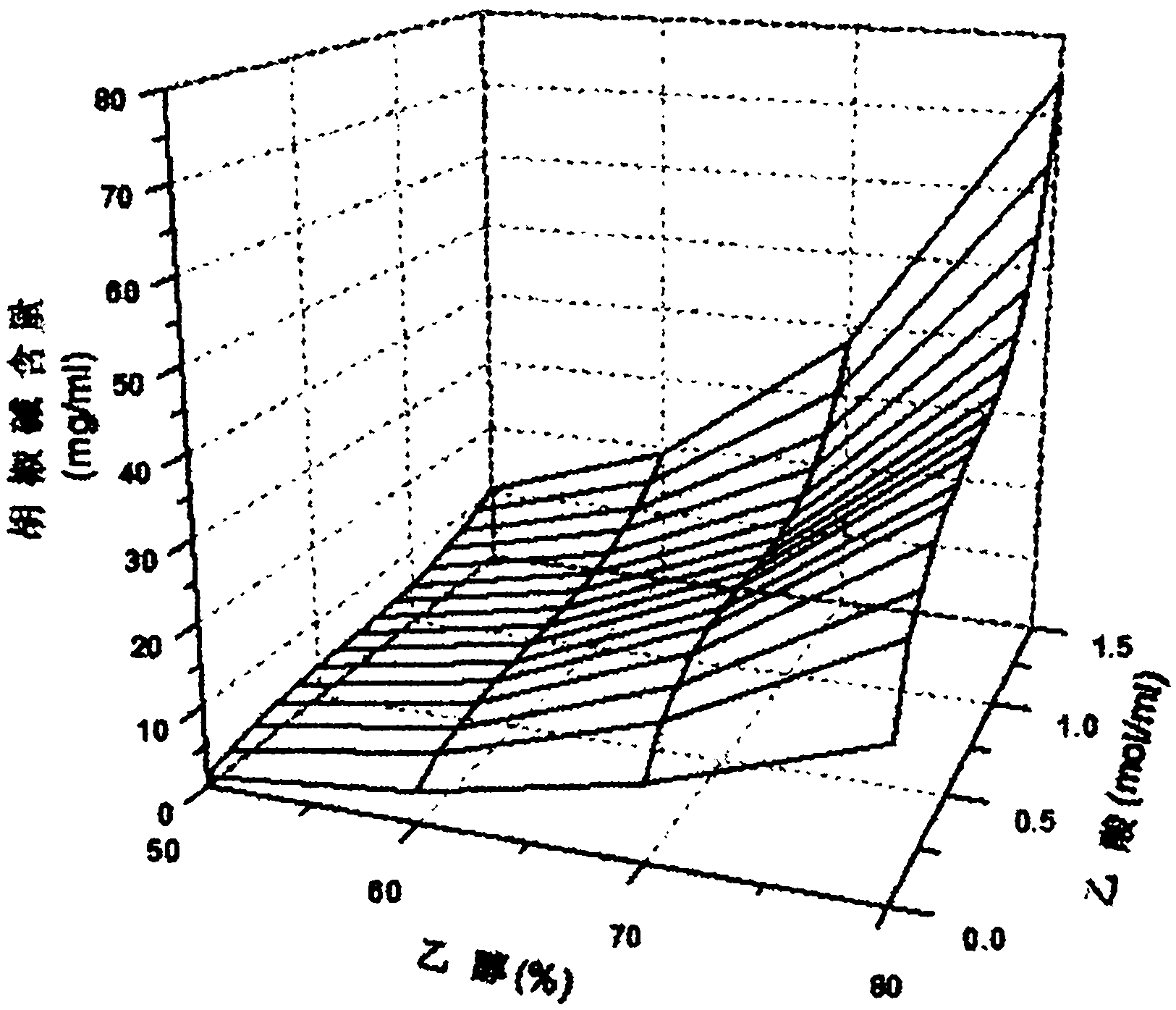

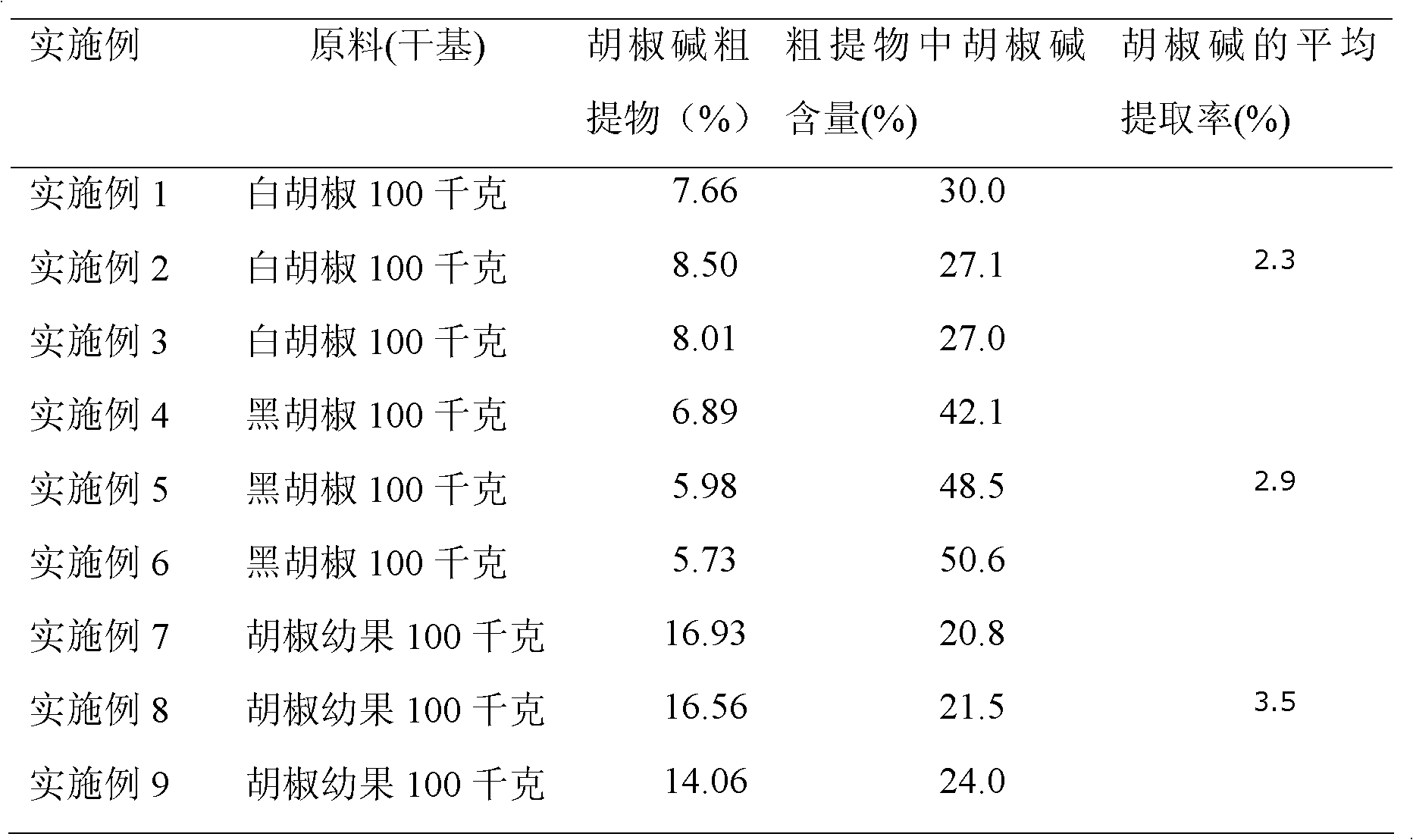

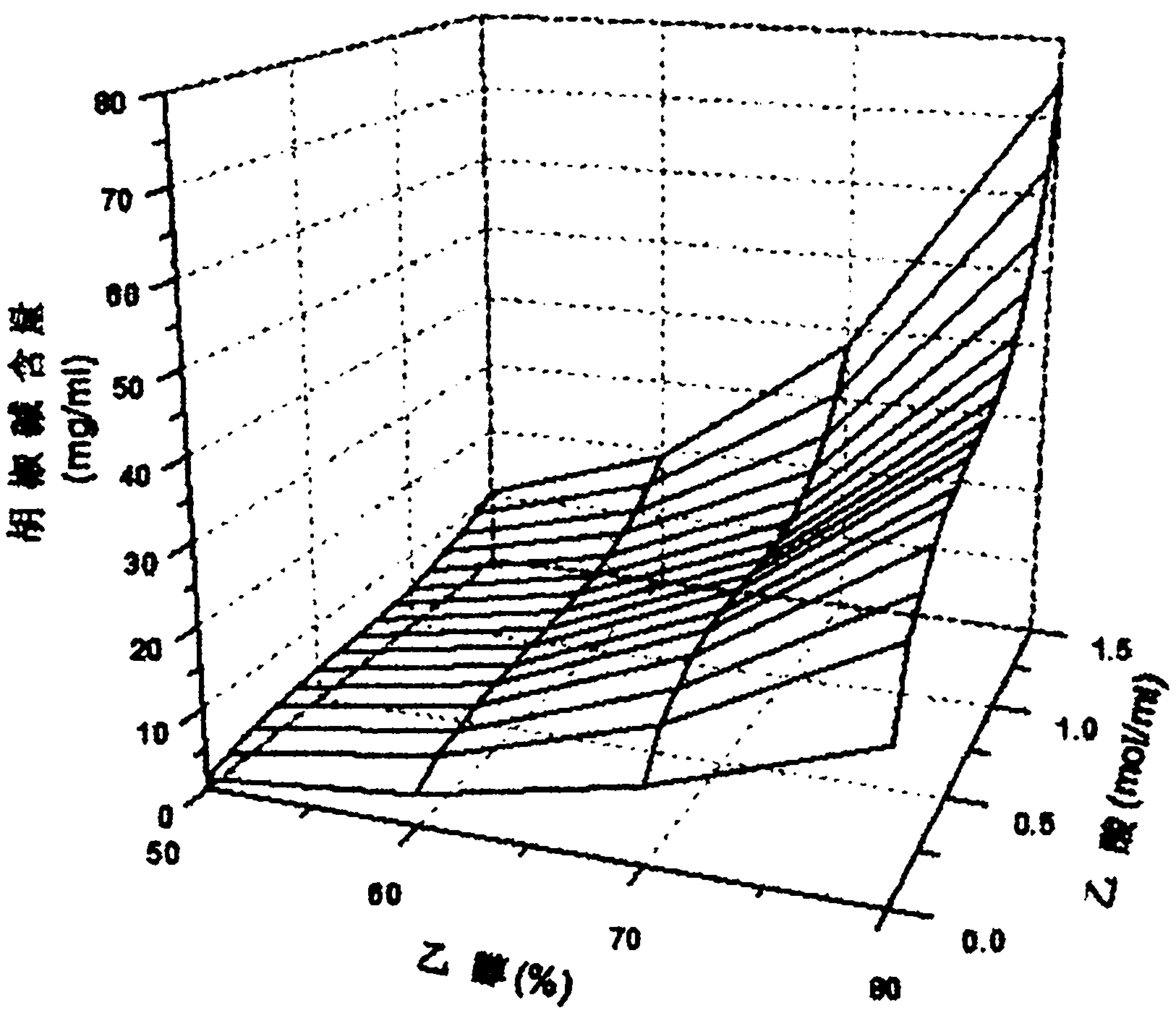

Method for producing piperine

InactiveCN101985440AImprove solubilityImprove extraction efficiencyOrganic chemistryOrganic solventSolvent

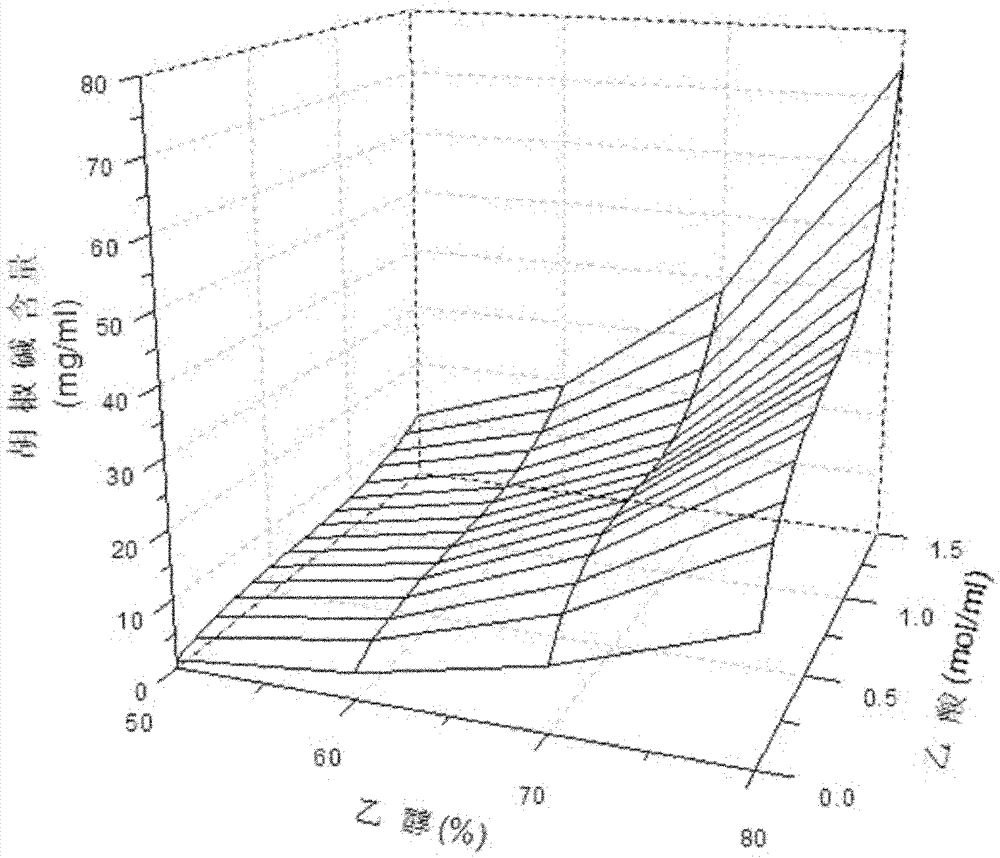

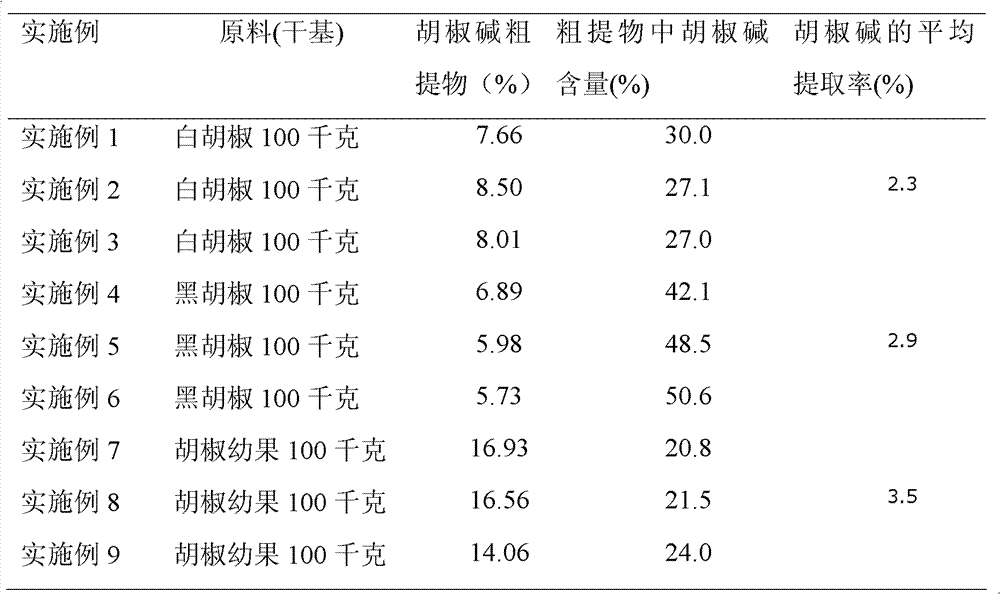

The invention discloses a method for producing piperine, which comprises the following steps of: uniformly mixing an acid solvent and a piperine-containing raw material, allowing leach liquor to flow through an adsorption resin chromatographic column, stopping adding the leach liquor until the piperine is adsorbed to flow out, and eluting the adsorbed piperine by using an eluting solvent; concentrating the piperine eluent in vacuum and recovering an organic solvent to obtain piperine concentrate; dissolving the piperine concentrate, and adding seed crystals for crystallization; and recrystallizing to obtain piperine crystals with the purity of over 98 percent. According to the alkaloid properties of the piperine, the acid organic solvent is used, the dissolubility of the piperine is greatly improved, and the extraction efficiency is improved; the chromatography is used, so the separation efficiency and purity of the piperine are improved, the whole production process is low in energy consumption, and the prepared piperine has high yield and purity; besides, the immature pepper fruits which are always wasted and discarded conventionally are used for extracting the piperine, and sources of raw materials for producing the piperine are increased.

Owner:JINAN UNIVERSITY

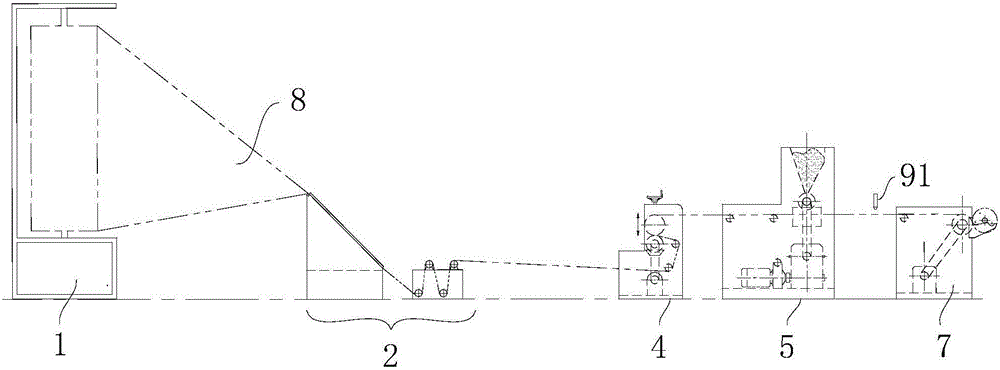

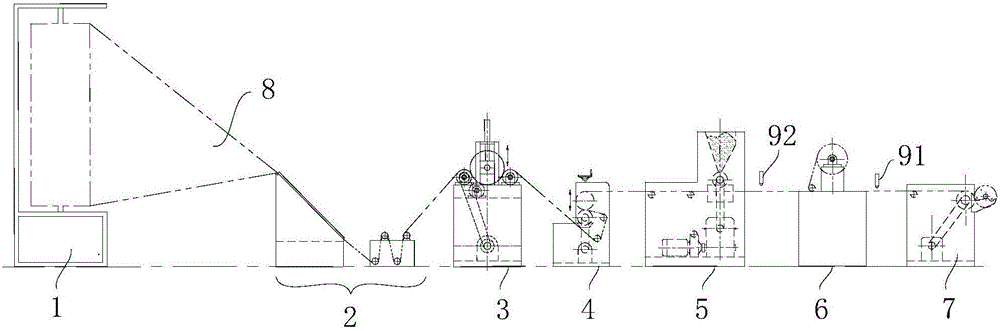

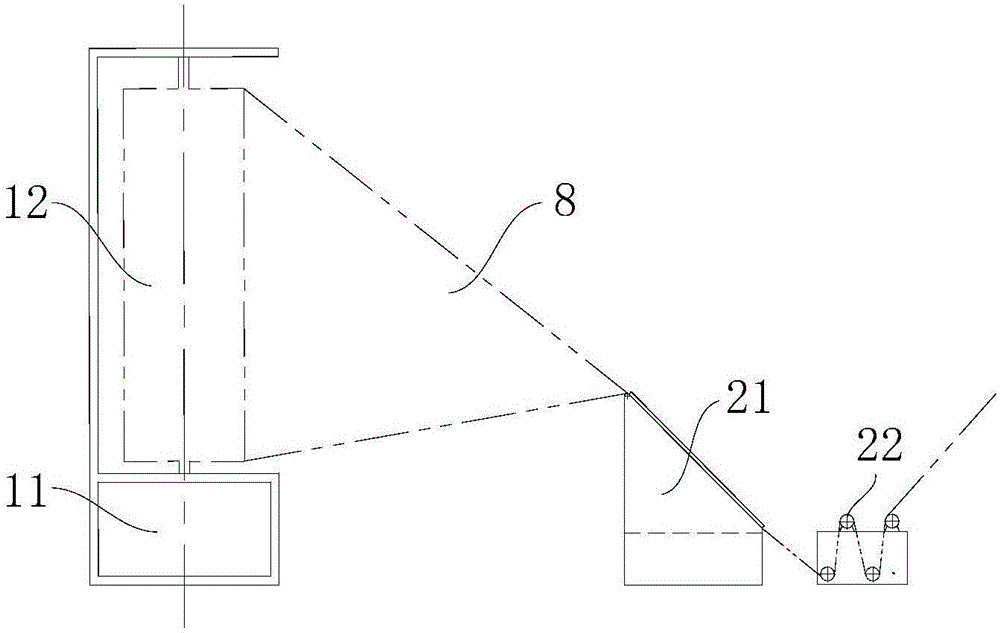

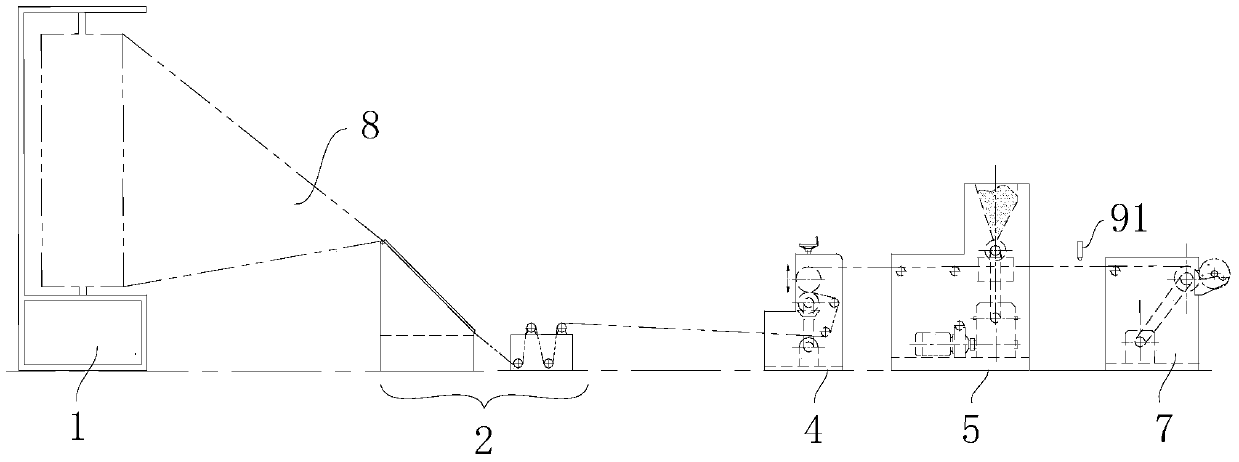

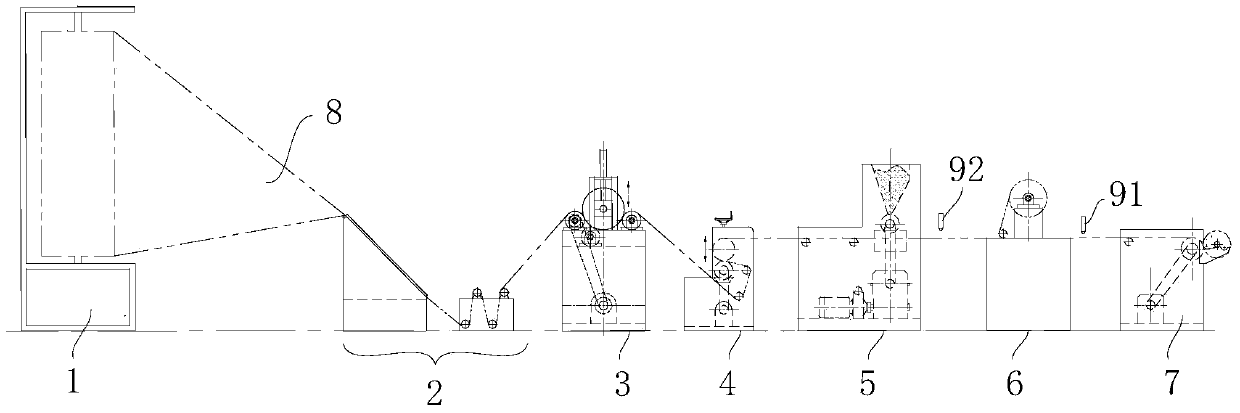

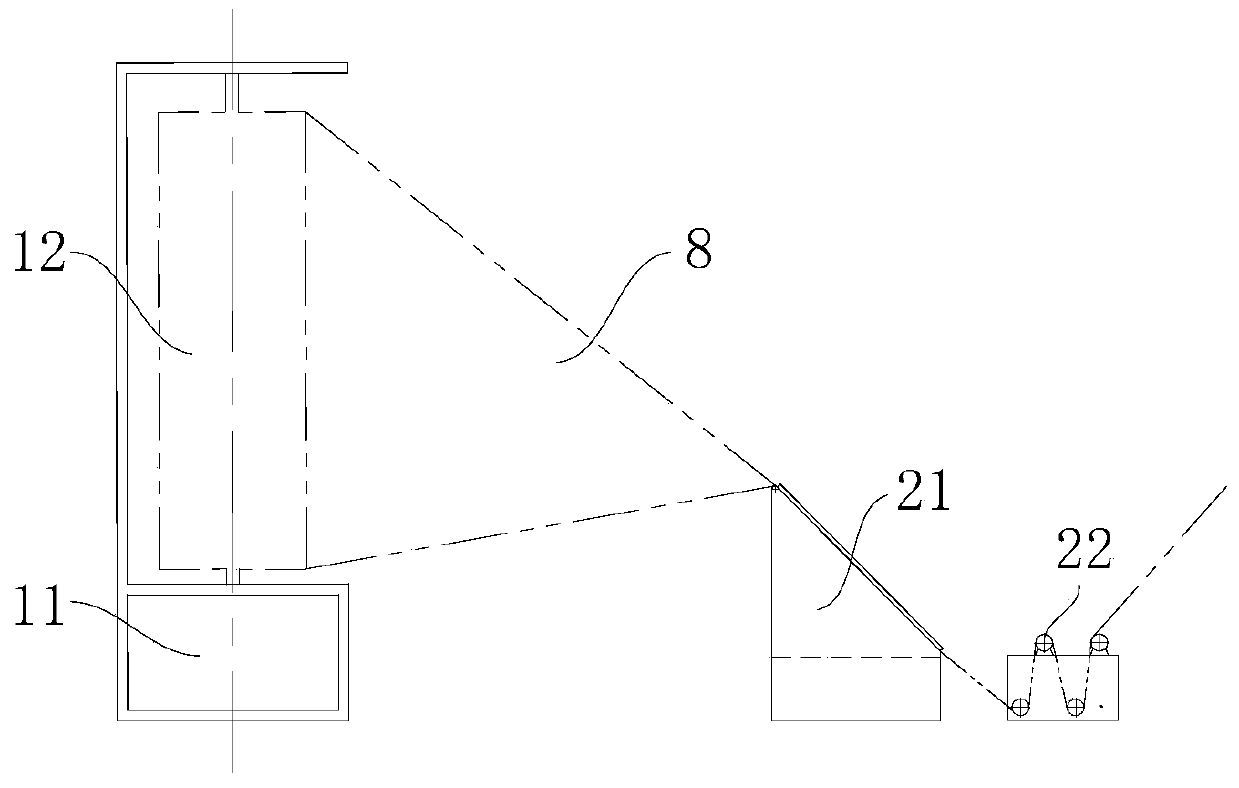

Concrete curing film production technology and production equipment thereof

ActiveCN105965679ALow energy consumption in the production processSimple structure of production equipmentCeramic shaping apparatusRoads maintainenceManufacturing linePlastic film

The invention discloses a concrete curing film production technology and production equipment thereof. A plastic film is coated with a covering layer with super-strong water absorbing and retaining performance. The covering layer comprises a super-strong macromolecule water absorbing material and a bonding agent. The invention further discloses the concrete curing film production equipment. The concrete curing film production equipment comprises an unreeling device, a film expanding device, a punching device, a gluing device, a powder scattering device, a composite device and a reeling device. The plastic film is expanded into a single layer from a folded interlayer through the unreeling device, and the plastic film is tidied and conducted by the film expanding device to enter the subsequent procedure. The whole production line is in continuous variable transmission, and linkage is achieved. The concrete curing film produced through the technology is an update product of a traditional concrete curing material, the production technology of the concrete curing film is low in energy consumption, the production equipment is simple in structure, and construction is convenient. The equipment is high in automation degree and suitable for meeting the industrial requirement. A concrete water-saving moisturizing curing film of a single-layer structure can be produced, and a concrete water-saving moisturizing curing film of a double-layer structure can be produced as well.

Owner:湖南圣华节水科技股份有限公司

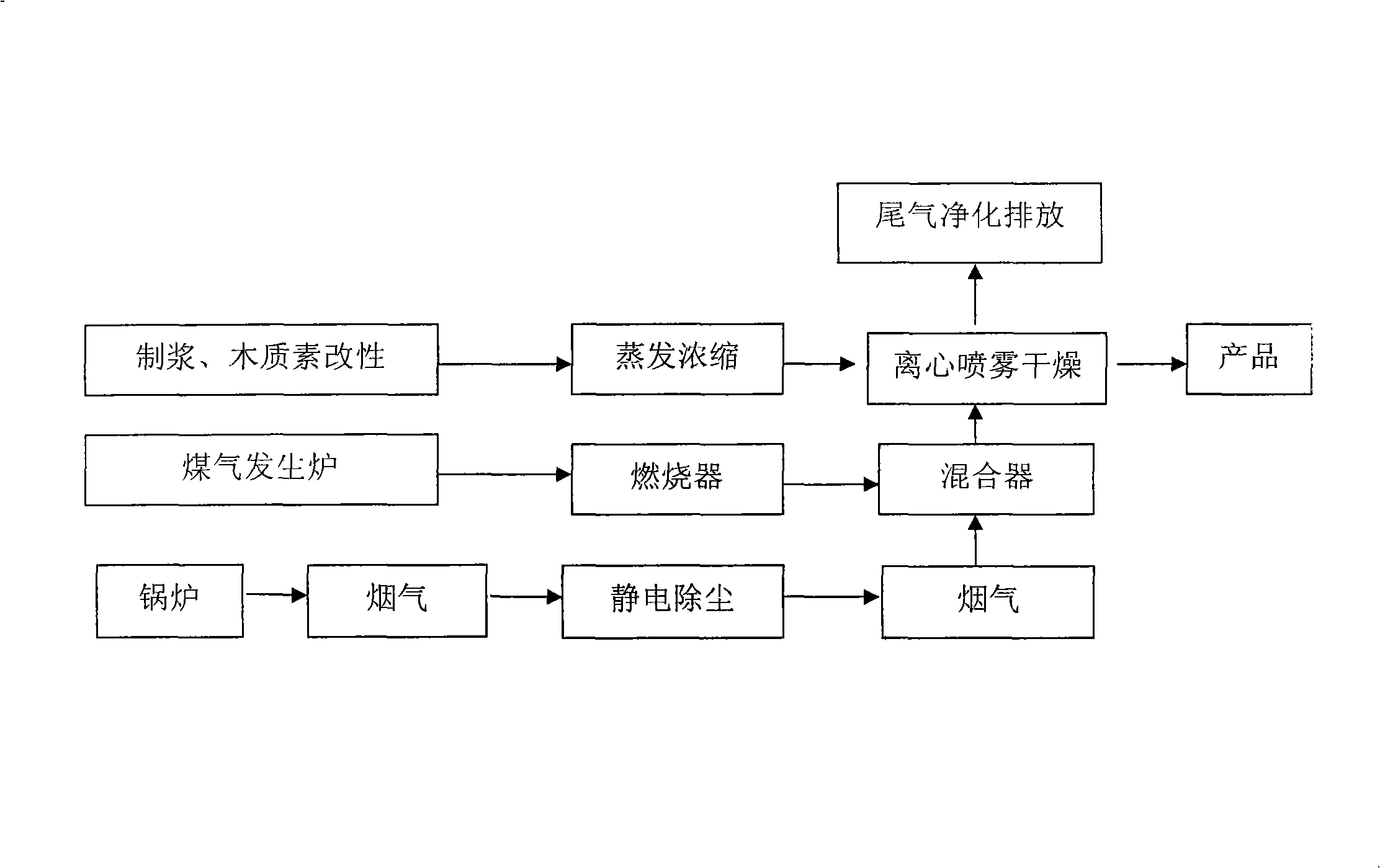

Boiler flue gas recycling method

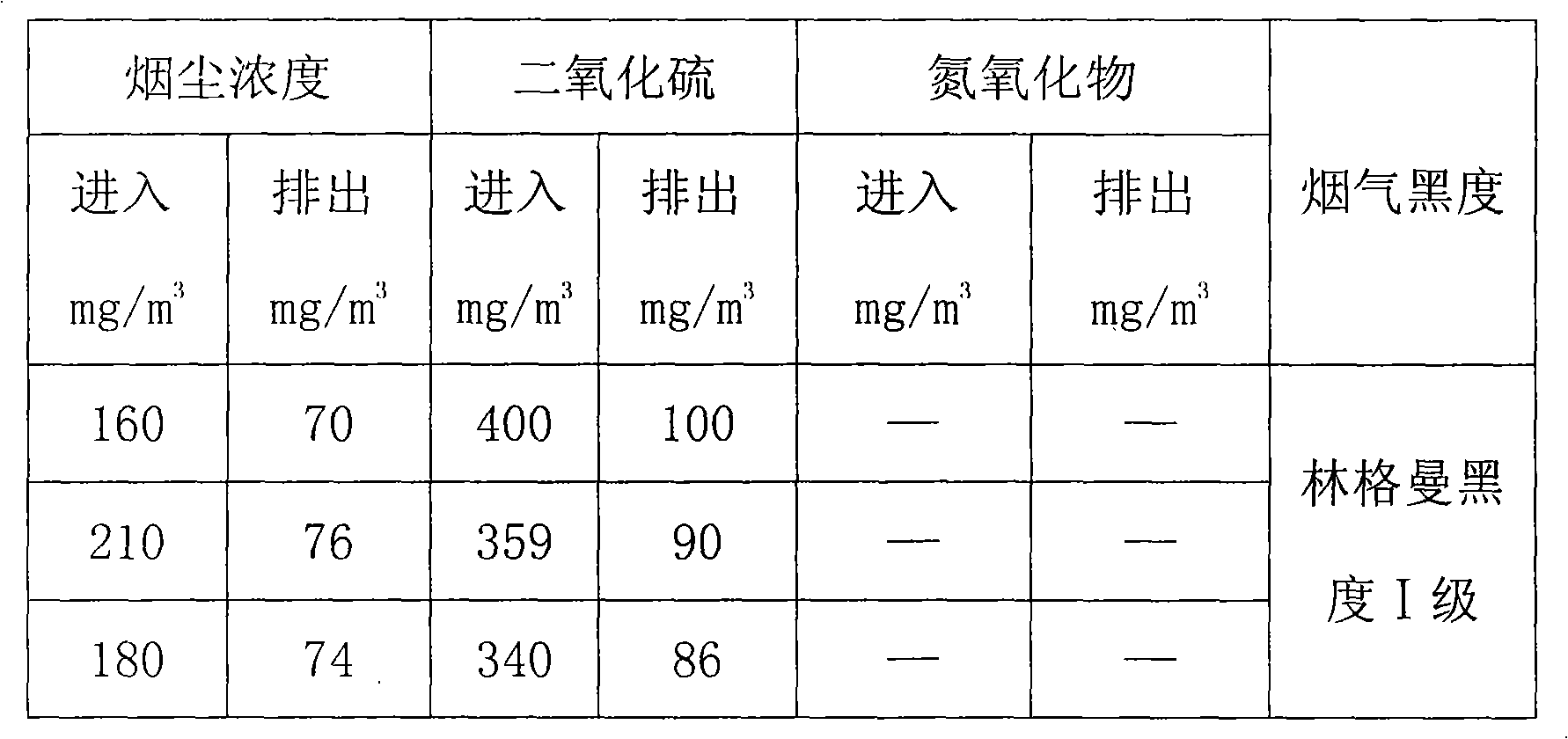

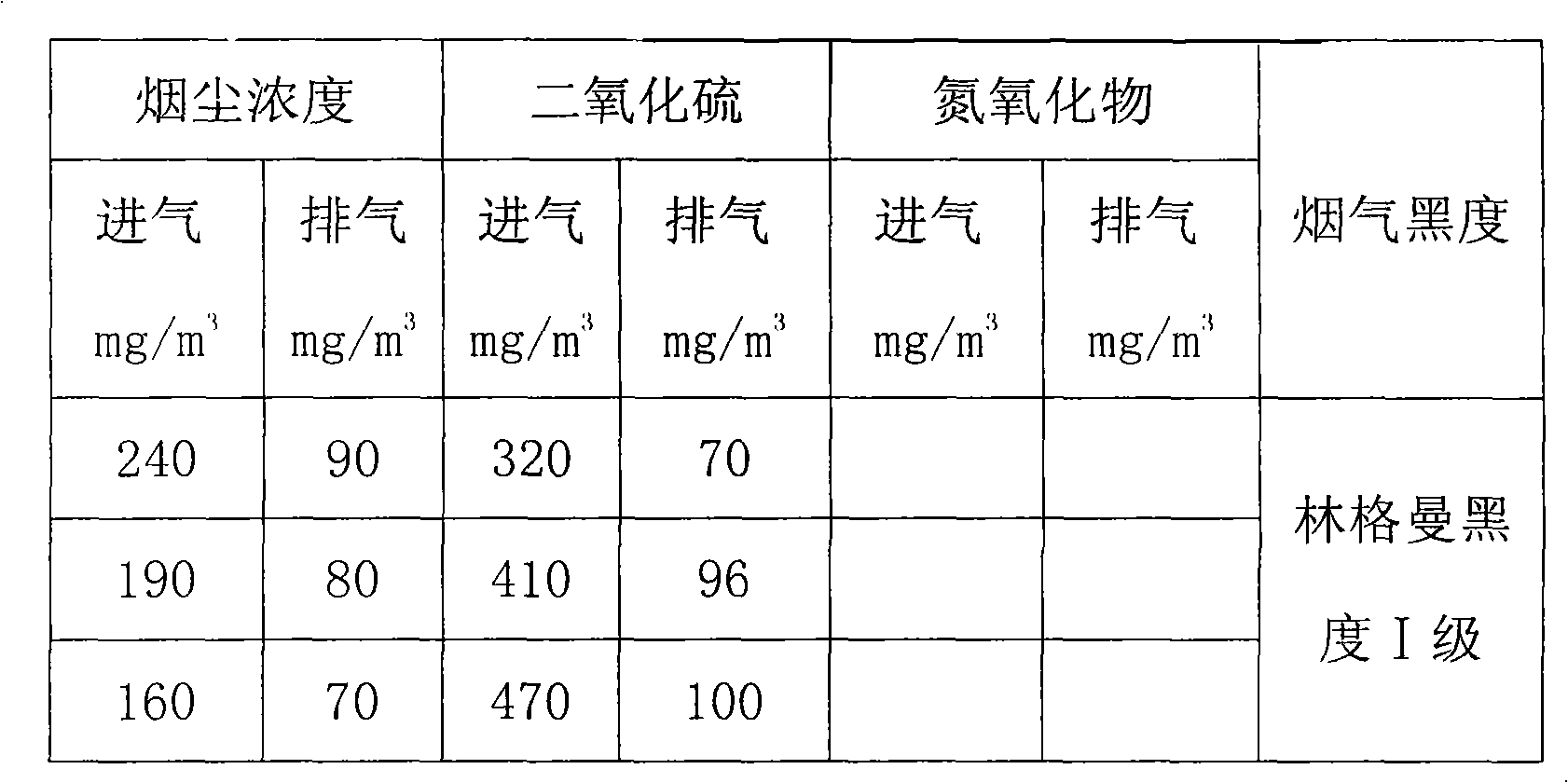

InactiveCN101298916AImprove qualityQuality improvementDrying solid materials with heatDrying gas arrangementsElectricityFlue gas

The invention belongs to the energy source circulating reuse field and discloses a boiler flue gas reuse method, which integrates the boiler flue gas use and the clean pulping production improved wood, namely using the fume of the boiler and the cogeneration boiler, through the electro dedust to remove the dust in the fume, as one of the hot wind source of the centrifugal spray drying means to produce the improved wood, realizes the utilization of the fume remaining heat. Meanwhile in the spray drying process, the sulfur dioxide, the nitric oxides in the fume are adsorbed and used in the spray drying means of the improved wood, which advances the quality of the improved wood, purifies the boiler off gas, to make the boiler fume standard discharge develop waste cyclic utilization means, and reduce the pulping paper making and the off gas contamination.

Owner:舞钢市海明科技有限公司 +2

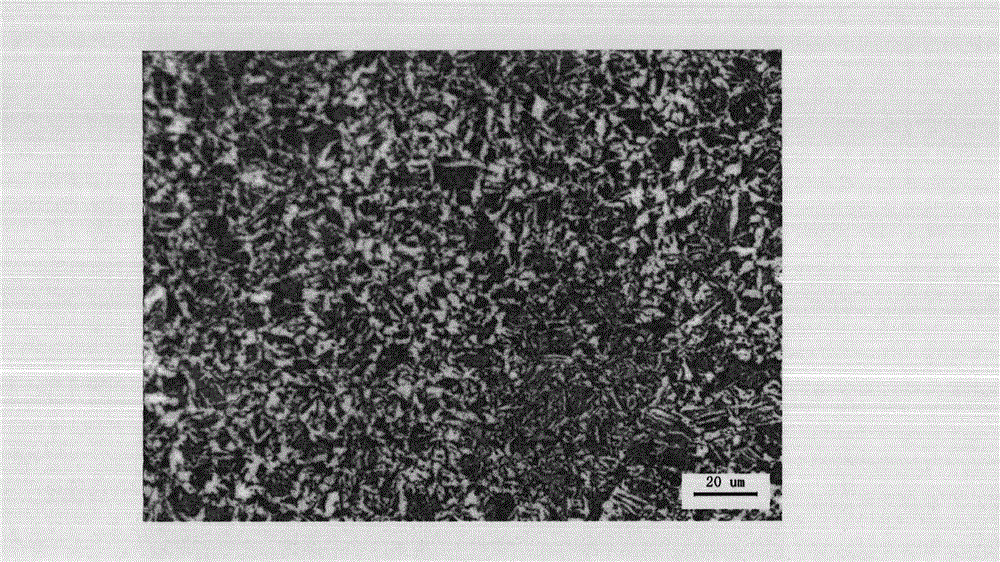

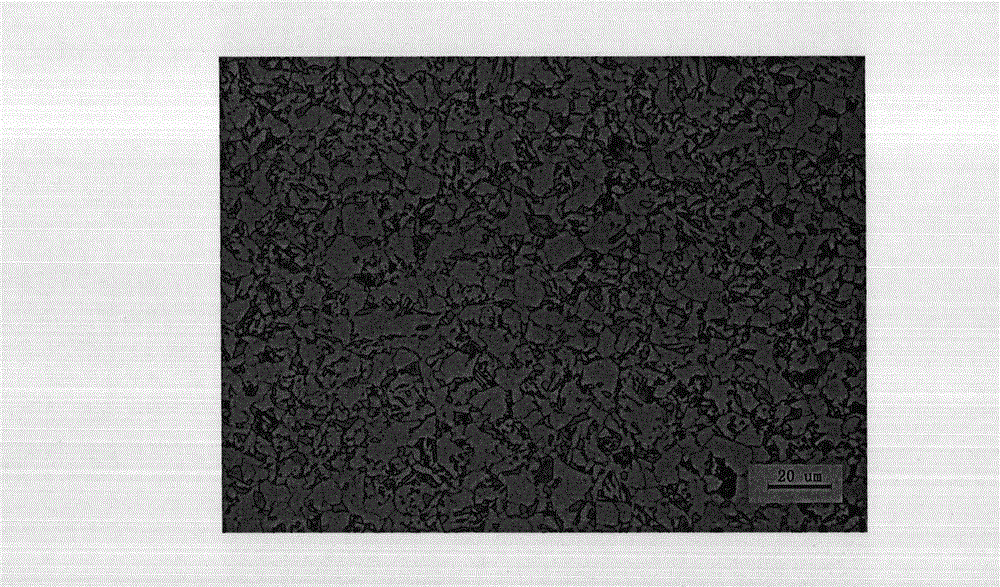

Low-yield ratio and high-strength stirrup provided with bainite structure and used for buildings and production process

The invention discloses a low-yield ratio and high-strength stirrup which is provided with a bainite structure and is used for buildings and a production process. The stirrup can improve the earthquake resistant performance of the buildings obviously, so that the collapse time of the buildings can be delayed under the condition of high-intensity earthquake levels or the buildings are not collapsed to provide escape opportunity for life. According to the production process, a ferrite and a hot-rolled steel bar with a pearlitic structure are used as raw materials, and the stirrup comprises the following chemical ingredients in percentage by weight: 0.15 to 0.30 percent of C, less than or equal to 1.5 percent of Si, 0.5 to 1.5 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S and the balance of Fe and impurities, wherein one of V and B is added appropriately according to requirements. According to the process, the raw materials are subjected to isothermal treatment to prepare the finished product; and during isothermal treatment, the processed steel bar is heated to above 850 DEG C, and then is water-cooled to 350 to 400 DEG C to obtain dual-phase steel with the ferrite and the bainite structure, wherein the isothermal treatment is completed within one minute. The strength level of the stirrup serving as the finished product is 800 to 1,100 MPa, the yield ratio is about 0.8 to 0.85, A is more than or equal to 12 percent, Agt is more than or equal to 3.5 percent, cracks at the bending position after the stirrup is bent 180 degrees are avoided, and the diameter of the finished product is 5 to 12 millimeters.

Owner:ANYANG LONGTENG SPECIAL STEEL MFG +3

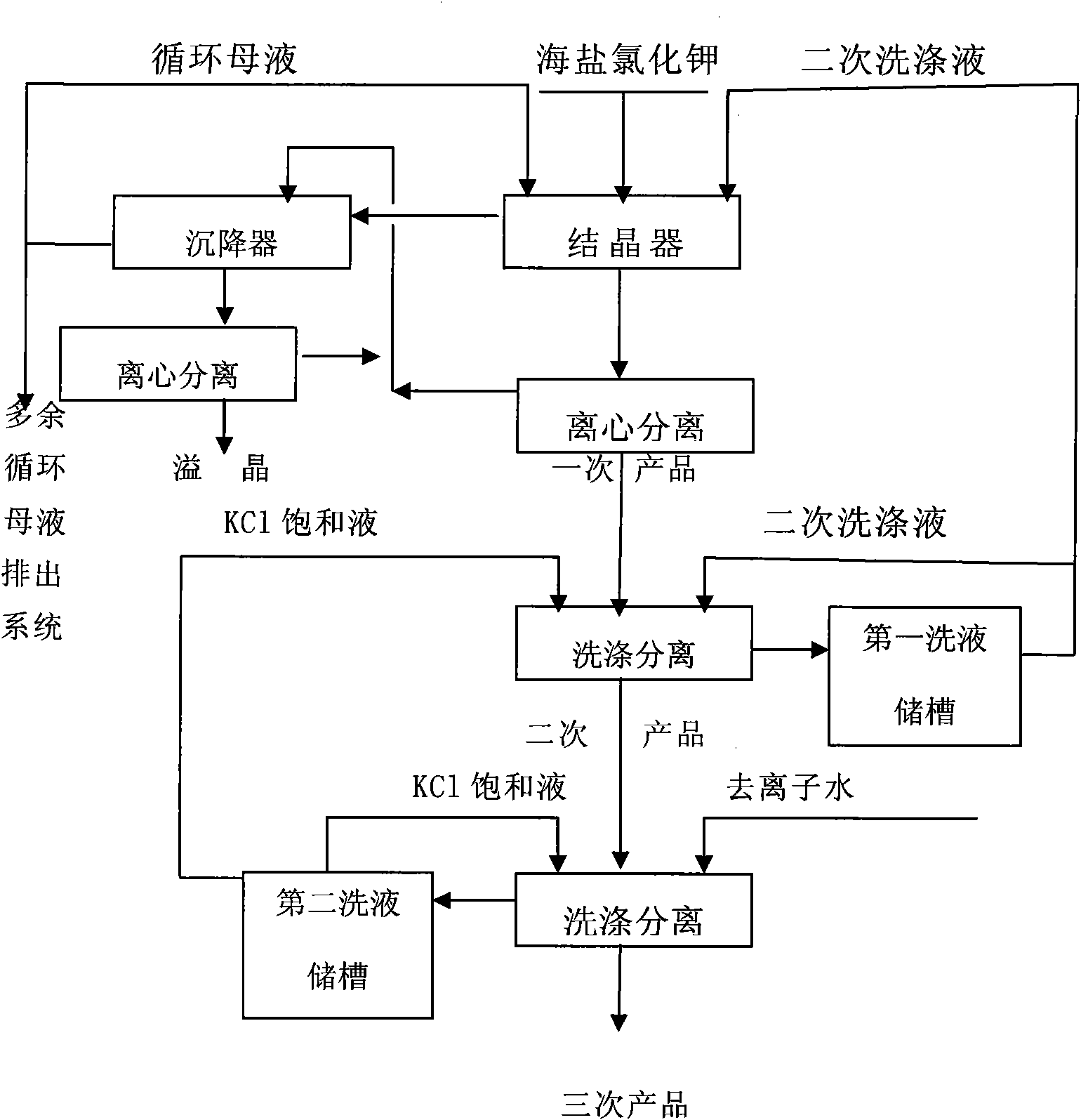

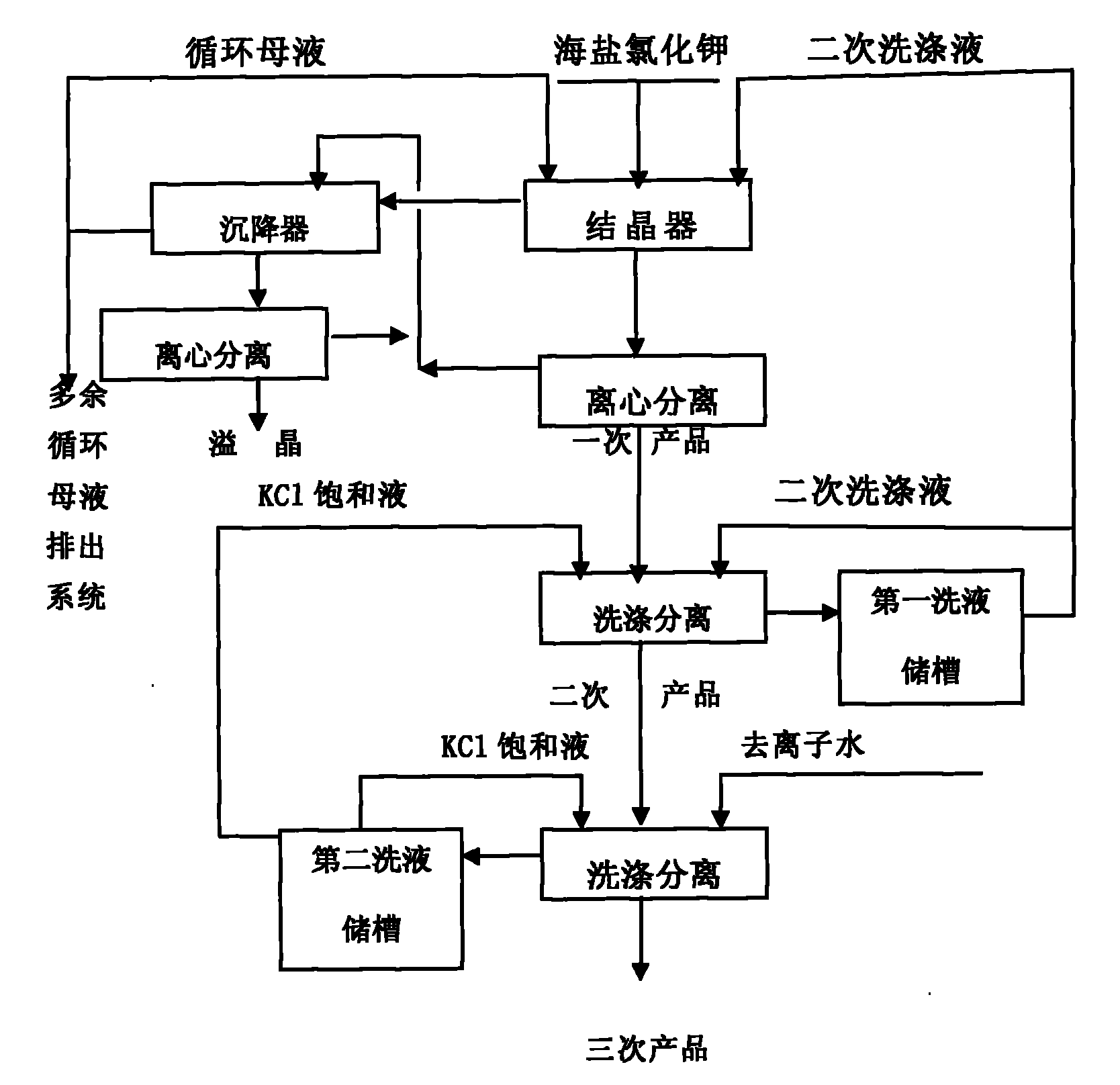

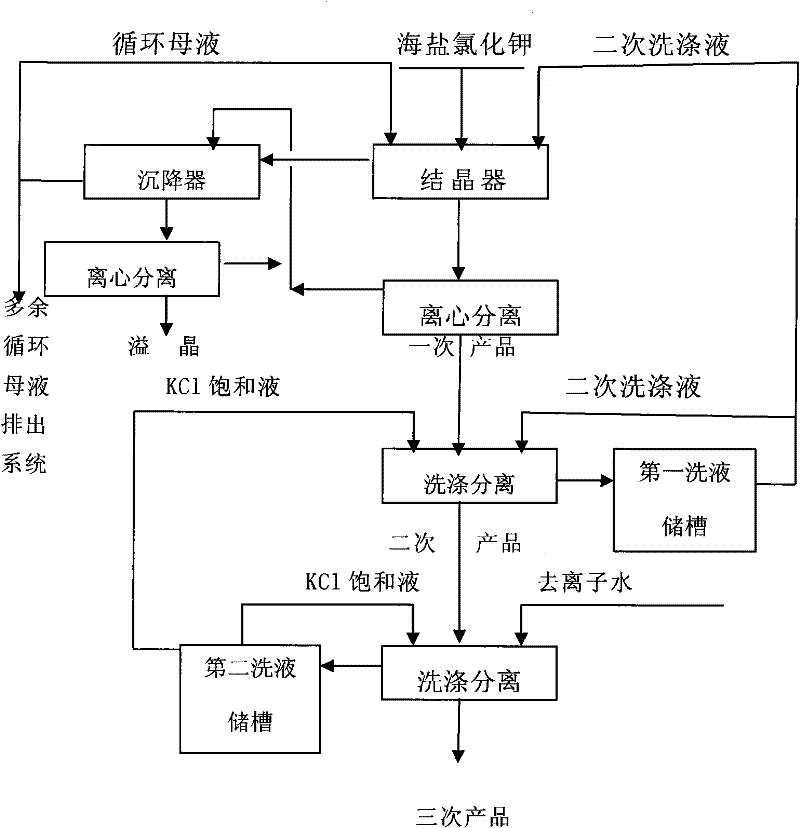

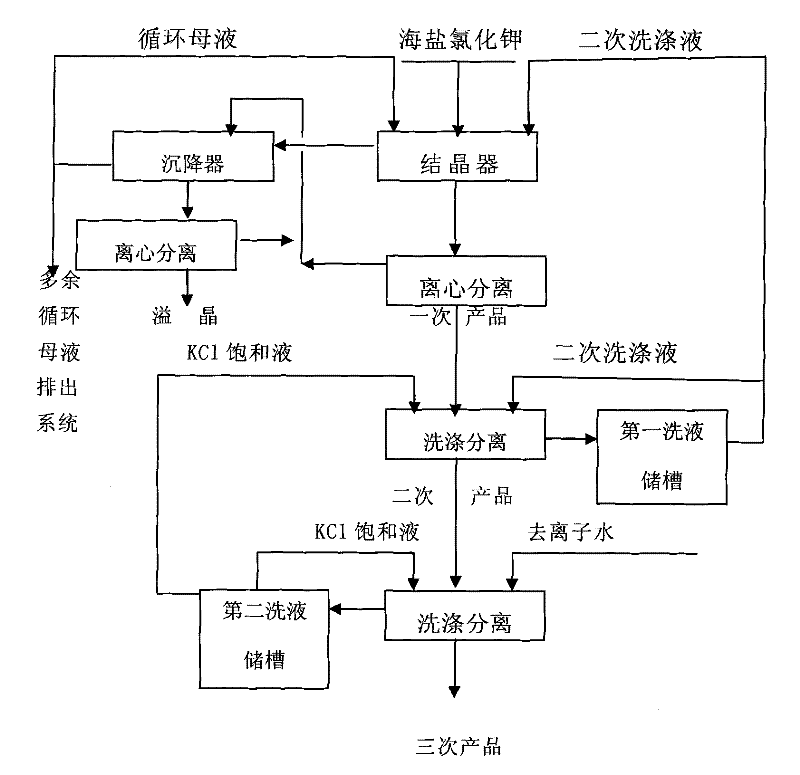

Method for preparing pharmaceutical grade potassium chloride with sea salt potassium chloride

ActiveCN101823734AEasy to operateReduce manufacturing costAlkali metal halide purificationPotassiumSystem stability

The invention relates to a method for preparing pharmaceutical grade potassium chloride with sea salt potassium chloride, which is characterized in that the sea salt potassium chloride is crushed to be loose and added into a crystallizer by a certain ratio together with circulating mother liquor and secondary washing liquid, so that materials in a crystallizer reaction area interflow; crystallizer underflow is discharged under the premise of ensuring system stability; the crystallizer underflow is centrifuged and separated to obtain a primary product and primary filtrate; and then the primary product, saturated potassium chloride solution and secondary washing liquid are added into a stirring tank by a certain ratio to be size-mixed and washed, centrifuged and separated to obtain a secondary product and secondary washing liquid; and the secondary product, the saturated potassium chloride solution and deionized water are added into the stirring tank by a certain ratio to be size mixed and washed, centrifuged and separated so as to obtain pharmaceutical grade potassium chloride and saturated potassium chloride solution.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Production process of soft wheat malt

The invention discloses a production process of soft wheat malt, which screens, classifies, removes impurities, soaks wheat, germinates, dries, removes root leaf bud, removes ash, and packages to obtain high-quality soft wheat malt. as the wheat malt extract rate is high, the extract content is high, the saccharifying enzyme pow is far higher than that of barley, and the prepared wheat beer has soft taste, fine foam and rich foam; the content of polyphenols and anthocyanins is low, which can prolong the shelf lifting e of beer and reduce the astringency of beer. The invention has the advantages of simple process, lower energy consumption in the production process flow and high yield of the finished product, provides high-quality raw materials for the production of wheat beer, and the wheatbeer prepared from soft wheat malt has mellow taste, good quality and unique flavor, and is liked by consumers.

Owner:甘肃祥永啤酒原料有限责任公司

Method of improving hardness of granular sodium nitrate

ActiveCN104591230AContinuous productionLow energy consumption in the production processAlkali metal nitrate shape formationNitrate fertilisersWater contentScrew conveyor

The invention relates to a method of improving the hardness of granular sodium nitrate. According to the method, a waste salt is added by using a hopper and a screw conveyer in the process of conveying the wet sodium nitrate which is obtained by crystallizing through evaporation to a melting tank, wherein the waste salt contains 60-90% by weight of sodium chloride or 10-40% by weight of sodium sulfate. Due to the addition of 0.01-2.5% of the waste salt which contains sodium chloride or sodium sulfate, the hardness of the granular sodium nitrate can be up to 2-4kgf, and the granular sodium nitrate with a size of 2-4mm accounts for more than 96%. Due to the added waste salt which is rich in sodium chloride, the hardness of the granular sodium nitrate can be improved. By adopting the method provided by the invention, the granular sodium nitrate which has a lower content of water, higher roundness and more uniform size than the existing granules can be obtained. In addition, the method can realize continuous production, consumes less energy, is high in efficiency and low in cost and can be particularly applied to the field of tower-based chemical granulation.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

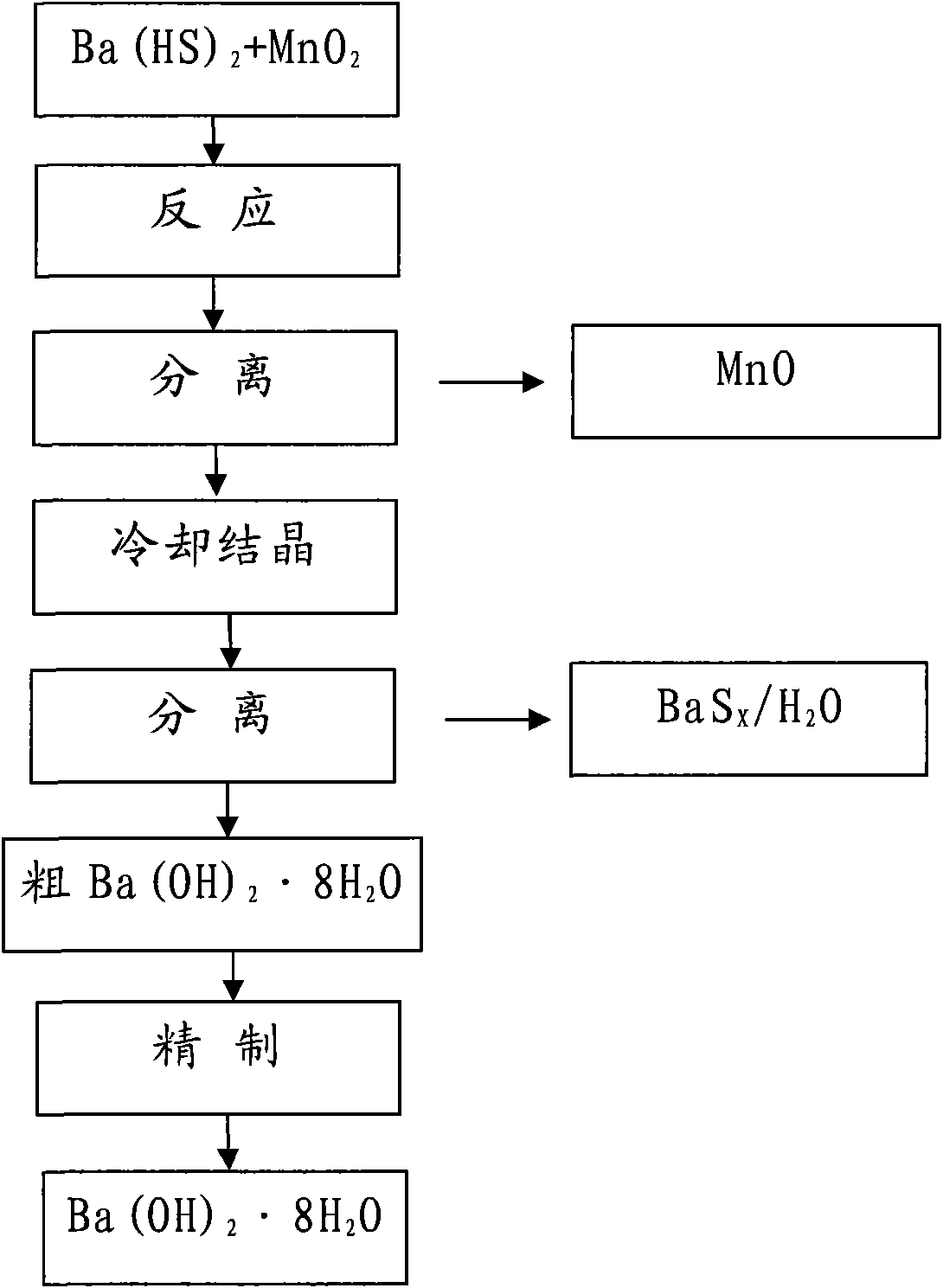

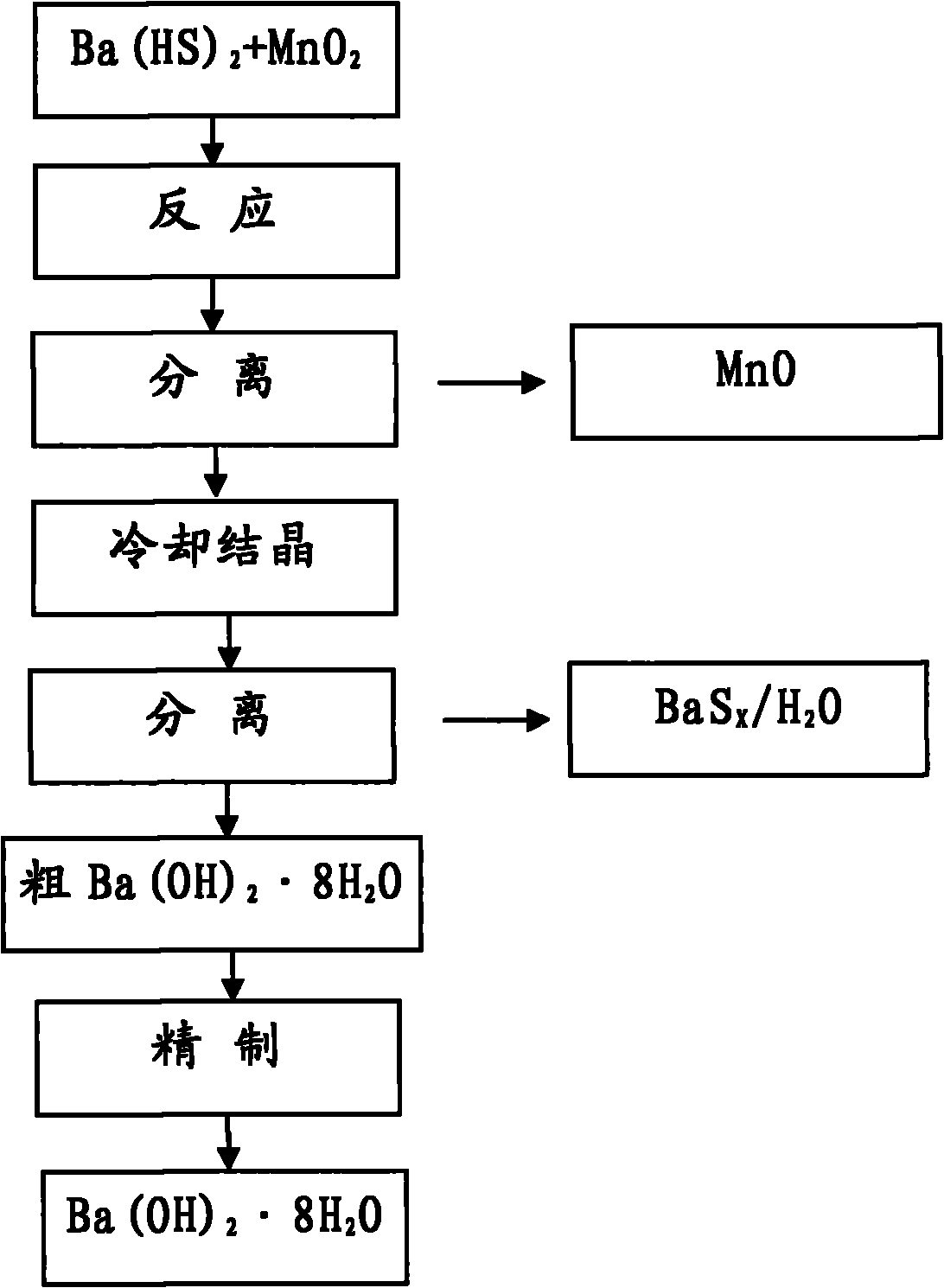

Method for preparing Ba(OH)2.8H2O

InactiveCN101774619ALow energy consumption in the production processLow costCalcium/strontium/barium oxides/hydroxidesReaction systemCrystallization

The invention relates to a method for preparing Ba(OH)2.8H2O, comprising the following steps: reacting Ba(HS)2 solution with [Ba2+] of 0.70-1.5mol / L with manganese oxide mineral powder, controlling the temperature of the reaction system between 60 DEG C and 90 DEG C and the reaction time between 1h and 2.5h and ensuring solid-liquid separation after reaction; hermetically cooling the obtained liquid phase to 30-40 DEG C to carry out solid-liquid separation to obtain the solid phase; dissolving the solid phase, namely coarse Ba(OH)2.8H2O, with deionized water according to an accessory with [Ba2+] of 1.5-3.0mol / L, proportionally adding H2O2 according to 3-8ml / L, heating to boil the mixture and ensuring solid-liquid separation after keeping slight boiling for 15-30min to obtain the filtrate; carrying out cooling crystallization on the filtrate to 35-45 DEG C and then carrying out separation, and drying the solid phase to obtain the Ba(OH)2.8H2O product. Compared with the existing pyrolysis technology, the production technology of the invention is low in energy consumption and low in cost.

Owner:GUIZHOU REDSTAR DEVING +1

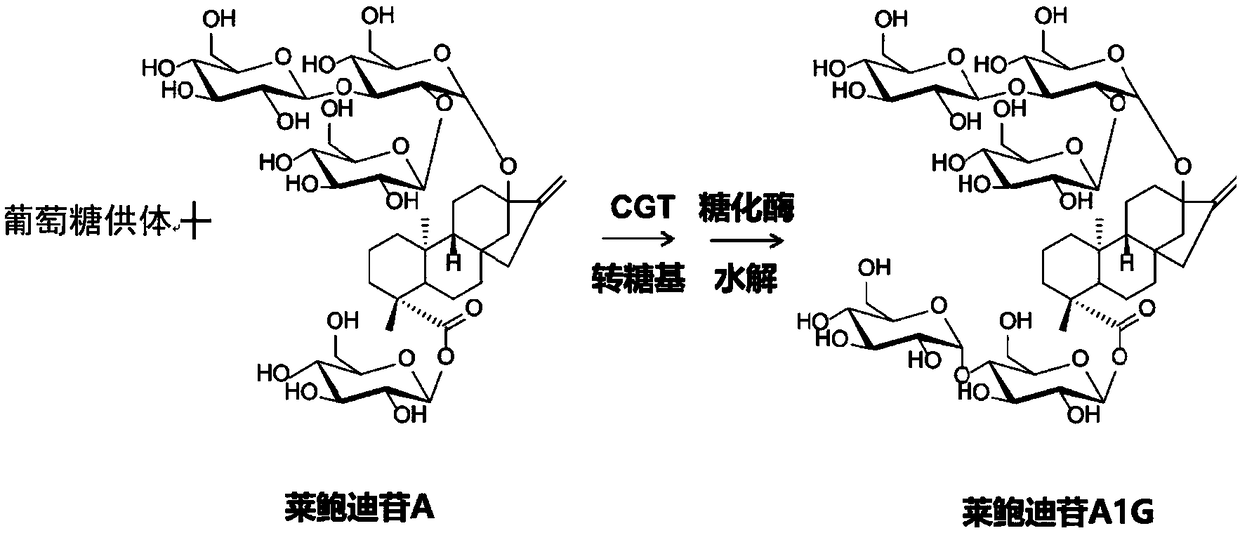

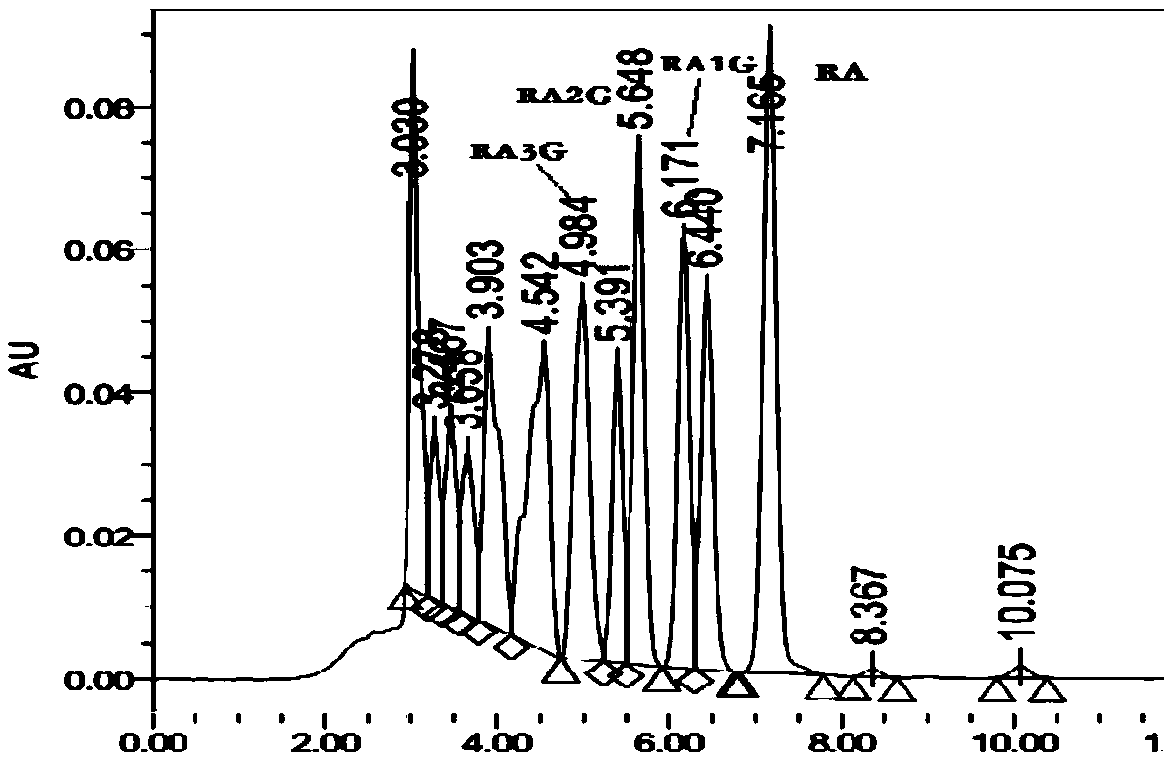

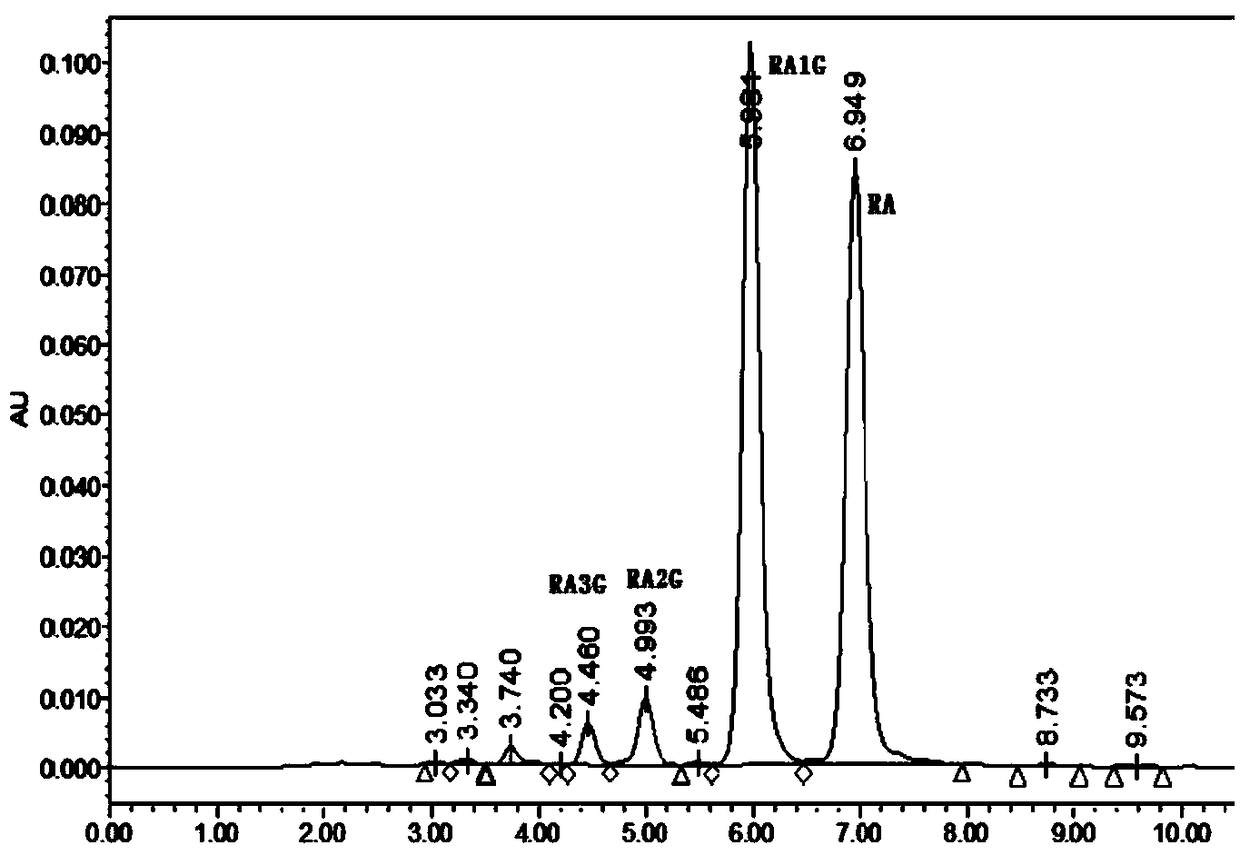

Crystallization method capable of increasing rebaudioside A1G content as well as product and application thereof

PendingCN108727443AGreat tasteImprove qualityCosmetic preparationsSugar derivativesCrystallizationLiquid phase

The invention relates to a crystallization method capable of increasing rebaudioside A1G content as well as a product and application thereof. Stevioside rebaudioside A(RA) derivative product RA1G ispurified by a multi-time crystallization method (such as twice and three times), and high-purity RA1G with improved taste is obtained. Furthermore, crystallization liquid phase can be recycled into further production, so that the production cost is saved. The method is simple to operate, green and environmentally friendly in production process, low in cost, short in cycle and high in conversion efficiency; and the obtained product has good taste and has important application value in the industries of food, beverage and the like.

Owner:DONGTAI HIRYE BIOTECH CO LTD

Preparation method and device of semi-solid slurry

Owner:HUAZHONG UNIV OF SCI & TECH

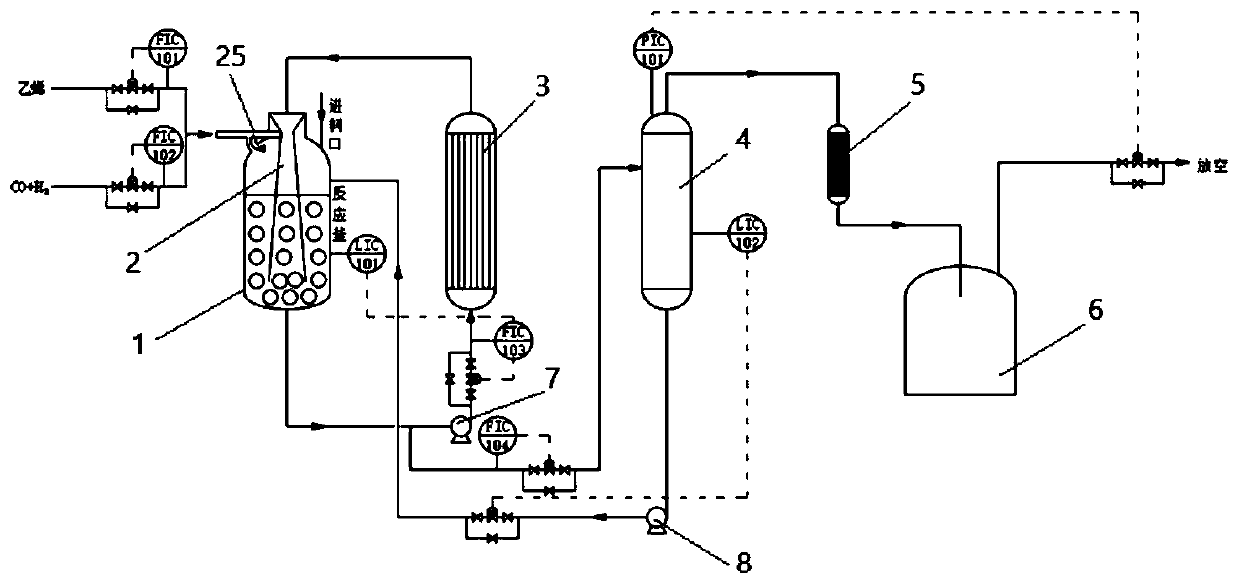

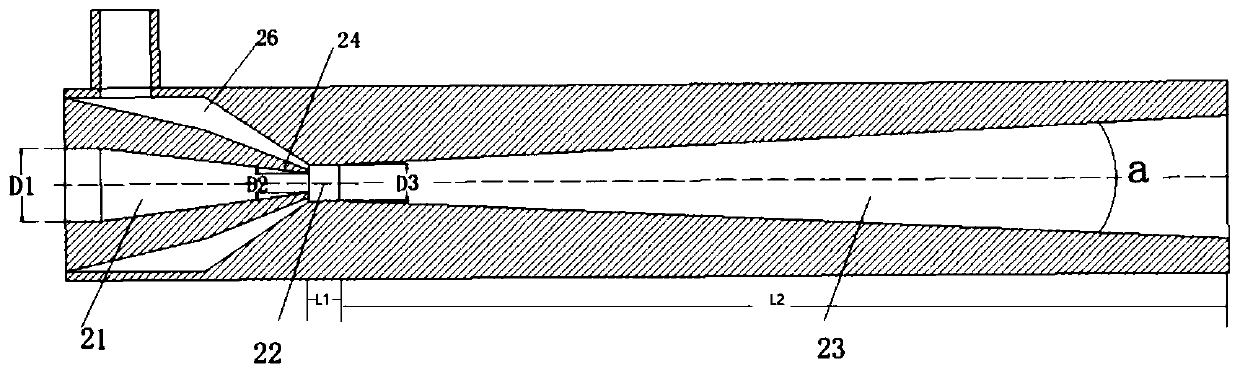

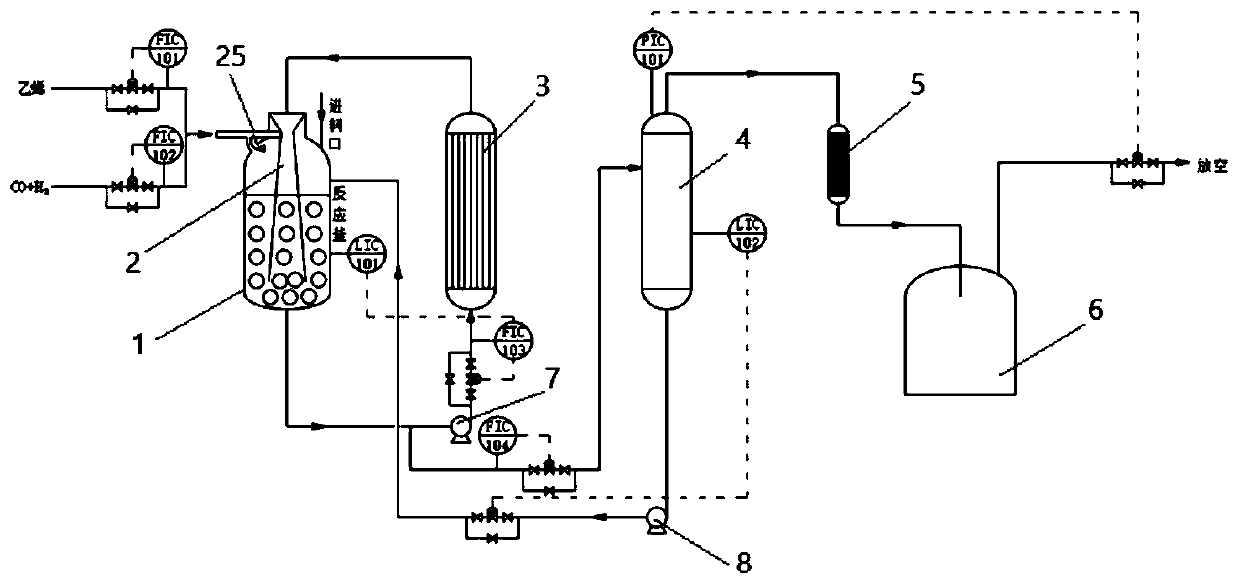

Continuous propionaldehyde production method and reaction system

PendingCN111151205ANo change in concentrationStable and continuousProcess control/regulationLiquid-gas reaction as foam/aerosol/bubblesPtru catalystProcess engineering

The invention discloses a continuous production method of propionaldehyde, wherein the continuous production method of propionaldehyde takes ethylene as a reaction raw material and triphenylphosphinecarbonyl rhodium as a catalyst for carbonyl synthesis to prepare propionaldehyde. According to the continuous production method of propionaldehyde, a loop reactor is adopted; in the reaction process,a solution in the loop reactor is continuously pumped out and divided into two paths, one path of the solution returns to the loop reactor through a heat exchanger, the other path of the solution enters an evaporation separator, propionaldehyde separated from the upper portion of the evaporation separator is stored after being cooled, and part of the undistilled solution in the evaporation separator returns to the loop reactor again. By utilizing the loop reactor, industrial continuous preparation of propionaldehyde can be effectively realized.

Owner:JIANGSU NUOMENG CHEM

Method for continuously synthesizing sodium dichloro isocyanurate dihydrate by wet process

ActiveCN102206192AIncrease productivityReduce energy consumptionOrganic chemistrySodium carbonateChemistry

The invention belongs to the technical field of disinfecting and sterilizing agent and discloses a method for continuously synthesizing sodium dichloro isocyanurate dihydrate by using cyanuric acid, caustic soda liquid and chlorine. The production method comprises the following steps: synthesizing disodium cyanurate, filtering, purifying, performing two stages of chlorination, cooling, crystallizing, centrifuging, mixing with sodium carbonate with a wet process, drying, granulating and the like to obtain the sodium dichloro isocyanurate dehydrate. The method is characterized in that: the adoption of a continuous chlorination synthesis process improves the utilization rate of equipment; and the process avoids dissolution, alkali addition and chlorine addition processes, so the production cost is reduced.

Owner:河北冀衡化学股份有限公司

Processing process of rice bran oil

InactiveCN103981023AGood decolorization effectLow energy consumption in the production processFatty-oils/fats productionEdible oils/fatsSalting outProcess engineering

The invention discloses a processing process of rice bran oil. The processing process comprises the following steps of sequentially feeding rice bran to a feeding auger, a 1# lifter and a bran and tip separating sieve, and then entering into a 2# lifter; then, entering the rice bran processed by the above steps into a softening pot for being softened, passing through an expanding machine by a 3# lifter, conveying to a drying box for being dried by a belt conveyor, entering into a horizontal scrapper by a 1# buried scraper lifter and then entering into a material storage box, and then feeding to a rotocel extractor by a 2# buried scraper lifter; and finally, passing the rice bran through a desolvation dryer by a 3# buried scraper lifter, entering into a rice dreg outlet horizontal scraper by a 4# buried scraper lifter and then entering into the material storage box, wherein the material enters the rotocel extractor which is further connected with a mixed oil filter tank, a mixed oil temporary storage tank and a salting-out tank, and the rice bran is finally processed into crude bran oil by a 1# evaporator, a 2# evaporator, and a laminated stripping tower. The processing process disclosed by the invention overcomes defects in the prior art, is low in production process energy consumption and high in oil extraction rate; moreover, the processing method of the rice bran oil is good in discoloring effect.

Owner:安徽渡民粮油有限公司

Concrete curing film production process and its production equipment

ActiveCN105965679BSimple structureEasy constructionCeramic shaping apparatusRoads maintainenceWater savingProduction line

The invention discloses a concrete curing film production technology and production equipment thereof. A plastic film is coated with a covering layer with super-strong water absorbing and retaining performance. The covering layer comprises a super-strong macromolecule water absorbing material and a bonding agent. The invention further discloses the concrete curing film production equipment. The concrete curing film production equipment comprises an unreeling device, a film expanding device, a punching device, a gluing device, a powder scattering device, a composite device and a reeling device. The plastic film is expanded into a single layer from a folded interlayer through the unreeling device, and the plastic film is tidied and conducted by the film expanding device to enter the subsequent procedure. The whole production line is in continuous variable transmission, and linkage is achieved. The concrete curing film produced through the technology is an update product of a traditional concrete curing material, the production technology of the concrete curing film is low in energy consumption, the production equipment is simple in structure, and construction is convenient. The equipment is high in automation degree and suitable for meeting the industrial requirement. A concrete water-saving moisturizing curing film of a single-layer structure can be produced, and a concrete water-saving moisturizing curing film of a double-layer structure can be produced as well.

Owner:湖南圣华节水科技股份有限公司

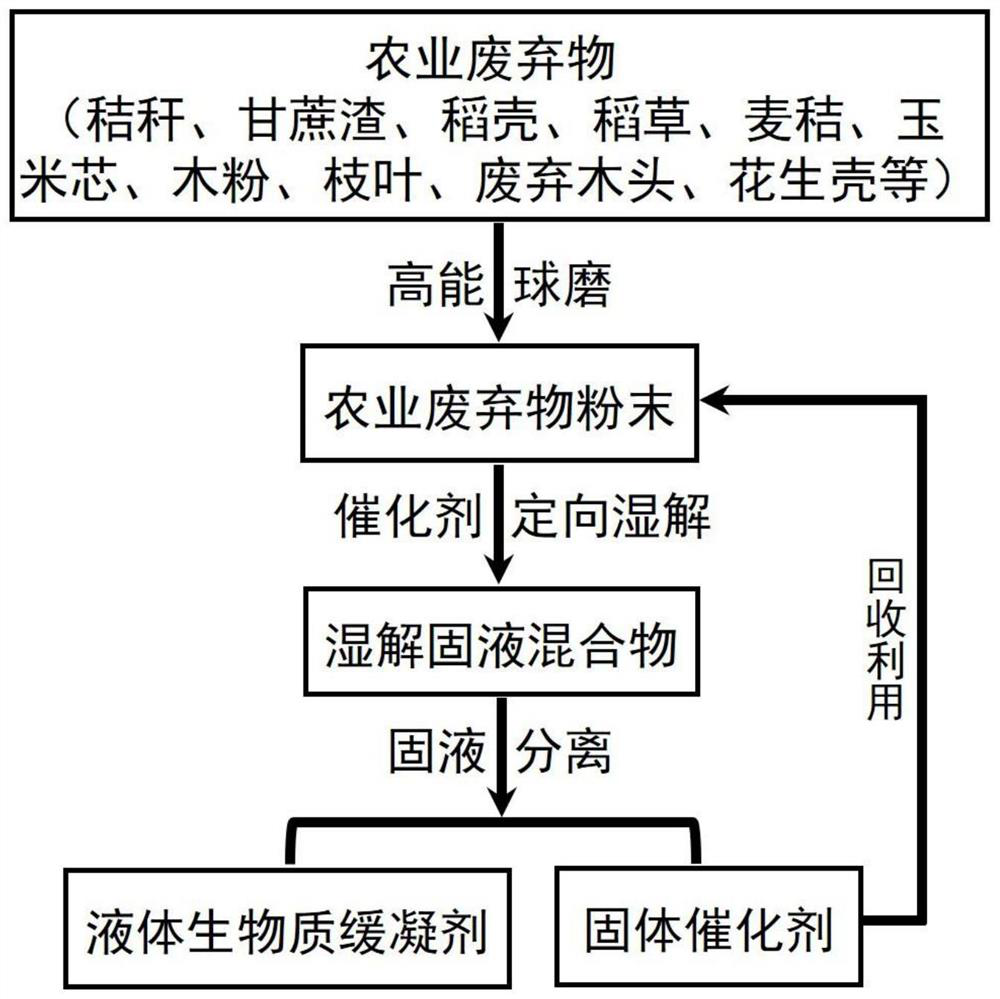

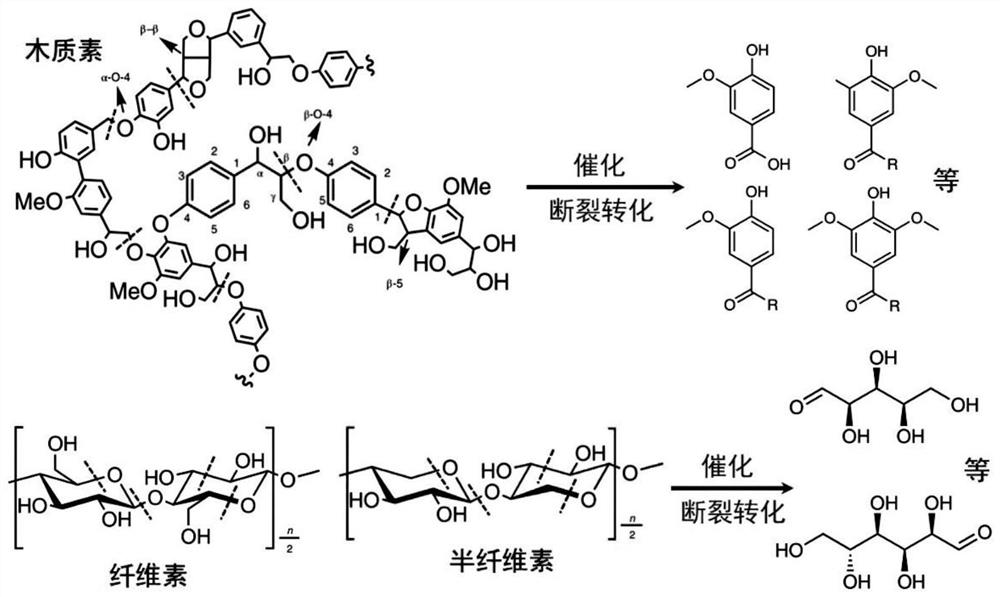

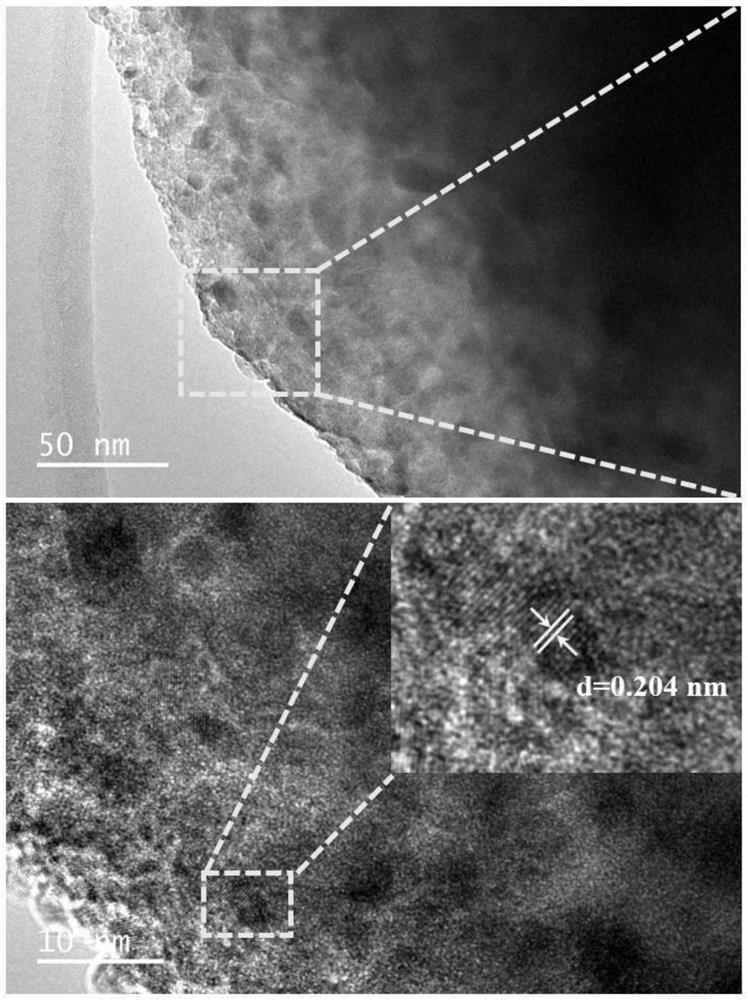

Method for preparing biomass retarder from agricultural wastes, and application of biomass retarder

The invention provides a method for preparing a biomass retarder from agricultural wastes, and application of the biomass retarder. The method comprises the following steps: 1) performing high-energy ball milling on the agricultural wastes to obtain agricultural waste powder; 2) carrying out directional wet degradation on the agricultural wastes obtained in the step 1) through a metal-loaded solid acid catalyst; and 3) carrying out solid-liquid separation on the wet decomposition product to obtain the liquid biomass retarder, and recovering the catalyst at the same time. The biomass retarder prepared by the invention is good in water solubility, green, degradable, excellent in performance and low in cost, the whole production process is low in energy consumption and small in pollution, and the biomass retarder can be used as a cement retarder in cement admixtures. The invention provides a feasible technical path for high-value utilization of agricultural wastes and application of the agricultural wastes in the field of construction industry.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Production process of N06600 iron-nickel base alloy hot continuous rolling plate coil

InactiveCN114737132AReduce pollutionAvoid disadvantagesTemperature control deviceWork cleaning devicesFernicoHeating furnace

Owner:山东盛阳金属科技股份有限公司

Amino acid-rich distilled spirit with sweet potatoes as raw materials and preparation method thereof

InactiveCN103571694AHigh nutritional valueReduce consumptionAlcoholic beverage preparationBiotechnologyReverse osmosis

The invention discloses an amino acid-rich distilled spirit with sweet potatoes as raw materials and a preparation method thereof, which belong to the field of distilled spirit production. The preparation method comprises the following steps of: drying peeled dried sweet potatoes, then crushing, sifting and baking; cooking the baked peeled dried sweet potatoes together with unbaked peeled dried sweet potatoes; adding water and a fermentation seed solution into the cooked dried sweet potatoes for fermentation; filtering a fermented mash, centrifuging and collecting a supernate; and condensing the supernate through a reverse osmosis membrane to obtain the amino acid-rich distilled spirit. By using a reverse osmosis technology, a lot of energy consumption is avoided, nutrient substances produced in a fermentation process can be kept to the largest extent; the prepared distilled spirit has mellow mouth feel and health-care effects, an alcoholic content of 37% (v / v), an amino acid content of 0.3 g / L and good social popularization value.

Owner:HUBEI UNIV OF TECH

Corrosion-resistant metal material and production process thereof

InactiveCN107034419AHigh strengthImprove toughnessFurnace typesHeat treatment furnacesRare-earth elementManganese

The invention discloses a corrosion-resistant metal material and a production process thereof. The corrosion-resistant metal material comprises the following components in percentage by weight: 1-5% of carbon, 0.01-0.08% of silicon, 0.02-0.08% of manganese, 1.2-3% of nickel, 0.06-0.12% of zirconium, 0.02-0.23% of antimony, 0.12-0.18% of tin, and the balance of iron and inevitable impurities; the production process of the metal material comprises the following steps: melting in an electric furnace: fully and uniformly mixing the metal element components, refining in a converter, performing casting molding, carrying out heat treatment and tempering. According to the corrosion-resistant metal material and the production process thereof, the various metal elements and rare earth elements are added, the electrical conductivity and thermal conductivity are improved, the hardening capacity is reduced, the mechanical property is excellent, and therefore the corrosion-resistant metal material is suitable for kitchen or operating room knives.

Owner:合肥博创机械制造有限公司

Method and apparatus for electrolytic synthesis of 3,6-dichloropyridine-carboxylic acid

InactiveCN100436648CLow energy consumption in the production processLess side effectsOrganic chemistryElectrolysis componentsElectrolysisSynthesis methods

The invention provides an electrolytic synthesis method and equipment of 3,6-dichloropicolinic acid with high electrolytic efficiency. The electrolytic synthesis method includes: taking 3,4,5,6-tetrachloropicolinic acid as the main electrolytic raw material, placing the electrolytic solution in an electrolytic cell for electrolysis, neutralizing after the reaction, cooling and crystallizing, filtering, and drying to obtain 3 , 6-dichloropicolinic acid, in which the cathode of the electrolytic cell is automatically roughened by the voltage-stabilized and current-controlled silicon-controlled periodic commutation power supply. The electrolytic synthesis equipment includes a power supply, a batching tank, and an electrolytic tank. The power supply is a voltage-stabilizing thyristor periodic commutation power supply. The power supply is connected to a current commutator, and the current commutator is provided with a program control unit ; The positive pole of the power supply is connected to the anode of the electrolyzer, and the negative pole of the power supply is connected to the cathode of the electrolyzer. The electrolytic synthesis equipment solves many defects in the current 3,6-D electrolytic synthesis process, and has great practical value and social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

Fiber-reinforced resin composite hollow sphere and preparation method thereof

The invention discloses a fiber reinforced resin composite hollow ball and a preparation method thereof, wherein the fiber reinforced resin composite hollow ball has the diameter of 5-15mm, the wall thickness of 0.3-2.0mm, the density of 0.18-0.40g / cm<3>, and the breaking strength of 2-10MPa, a shell material is fiber reinforced resin, fiber is one or two or three of carbon fiber, glass fiber and aramid fiber, resin is epoxy resin, and an expanded polystyrene sphere is used as a core material template. The fiber reinforced resin composite hollow ball has the characteristics of high breaking strength, and low density, can be used as a density regulating media for deep-sea solid buoyancy materials, lightweight composite materials and heat insulation materials, is low in production process energy consumption, and can meet the needs of the deep-sea solid buoyancy materials.

Owner:北京大敖海洋科技有限公司

A kind of calcium-doped cobalt aluminate blue nano pigment and preparation method thereof

ActiveCN106976915BIncrease brightnessGood chromaNanotechnologyCobalt compoundsCobalt blueRoom temperature

The present invention relates to a novel calcium-doped cobalt aluminate blue nanometer pigment and a preparation method thereof, wherein the novel calcium-doped cobalt aluminate blue nanometer pigment has a chemical general formula: Co1-xCaxAl2O4 (x is more than 0 and is less than 0.9). The preparation method comprises: respectively weighing cobalt nitrate, aluminum nitrate and calcium nitrate according to a molar ratio of Co to Al to Ca of (1-X):2:X (X is more than 0 and is less than 0.9), preparing into a mixed solution, respectively adding acrylamide adopted as a polymerization agent and a N,N'-methylenebisacrylamide monomer adopted as a polymerization agent to the mixed solution, stirring, respectively adding ammonium persulfate and N,N,N',N'-tetramethylethylenediamine to the mixed solution, initiating a polymerization reaction to form a gel, drying the obtained gel, crushing, calcining, and cooling to a room temperature to obtain the novel calcium-doped cobalt aluminate blue nanometer pigment.

Owner:NANJING TECH UNIV

Method for producing piperine

InactiveCN101985440BImprove solubilityImprove extraction efficiencyOrganic chemistryOrganic solventSolvent

The invention discloses a method for producing piperine, which comprises the following steps of: uniformly mixing an acid solvent and a piperine-containing raw material, allowing leach liquor to flow through an adsorption resin chromatographic column, stopping adding the leach liquor until the piperine is adsorbed to flow out, and eluting the adsorbed piperine by using an eluting solvent; concentrating the piperine eluent in vacuum and recovering an organic solvent to obtain piperine concentrate; dissolving the piperine concentrate, and adding seed crystals for crystallization; and recrystallizing to obtain piperine crystals with the purity of over 98 percent. According to the alkaloid properties of the piperine, the acid organic solvent is used, the dissolubility of the piperine is greatly improved, and the extraction efficiency is improved; the chromatography is used, so the separation efficiency and purity of the piperine are improved, the whole production process is low in energy consumption, and the prepared piperine has high yield and purity; besides, the immature pepper fruits which are always wasted and discarded conventionally are used for extracting the piperine, and sources of raw materials for producing the piperine are increased.

Owner:JINAN UNIVERSITY

A kind of white wine rich in amino acid with rice as raw material and preparation method thereof

InactiveCN103571696BReduce energy consumptionIncrease health functionAlcoholic beverage preparationAlcohol contentCentrifugation

The invention discloses amino acid-rich white spirit prepared from rice and a preparation method thereof, and belongs to the field of white spirit production. The preparation method comprises the following steps of stewing parched rice and un-parched rice together, adding water, amylase and a fermentation culture liquid into the stewed rice, carrying out fermentation, filtering the fermentation mash, carrying out centrifugation, collecting a supernatant, and carrying out supernatant reverse osmosis concentration to obtain the amino acid-rich white spirit. The preparation method utilizes a reverse osmosis technology so that a large amount of energy consumption is avoided and nutrients produced in fermentation are retained. The amino acid-rich white spirit obtained by the preparation method has a mellow taste, alcohol content of 41% (v / v) and amino acid content of 0.2g / L and has a high social popularization value.

Owner:HUBEI UNIV OF TECH

Method for preparing pharmaceutical grade potassium chloride with sea salt potassium chloride

ActiveCN101823734BEasy to operateReduce manufacturing costAlkali metal halide purificationPotassiumChloride

The invention relates to a method for preparing pharmaceutical grade potassium chloride with sea salt potassium chloride, which is characterized in that the sea salt potassium chloride is crushed to be loose and added into a crystallizer by a certain ratio together with circulating mother liquor and secondary washing liquid, so that materials in a crystallizer reaction area interflow; crystallizer underflow is discharged under the premise of ensuring system stability; the crystallizer underflow is centrifuged and separated to obtain a primary product and primary filtrate; and then the primaryproduct, saturated potassium chloride solution and secondary washing liquid are added into a stirring tank by a certain ratio to be size-mixed and washed, centrifuged and separated to obtain a secondary product and secondary washing liquid; and the secondary product, the saturated potassium chloride solution and deionized water are added into the stirring tank by a certain ratio to be size mixed and washed, centrifuged and separated so as to obtain pharmaceutical grade potassium chloride and saturated potassium chloride solution.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

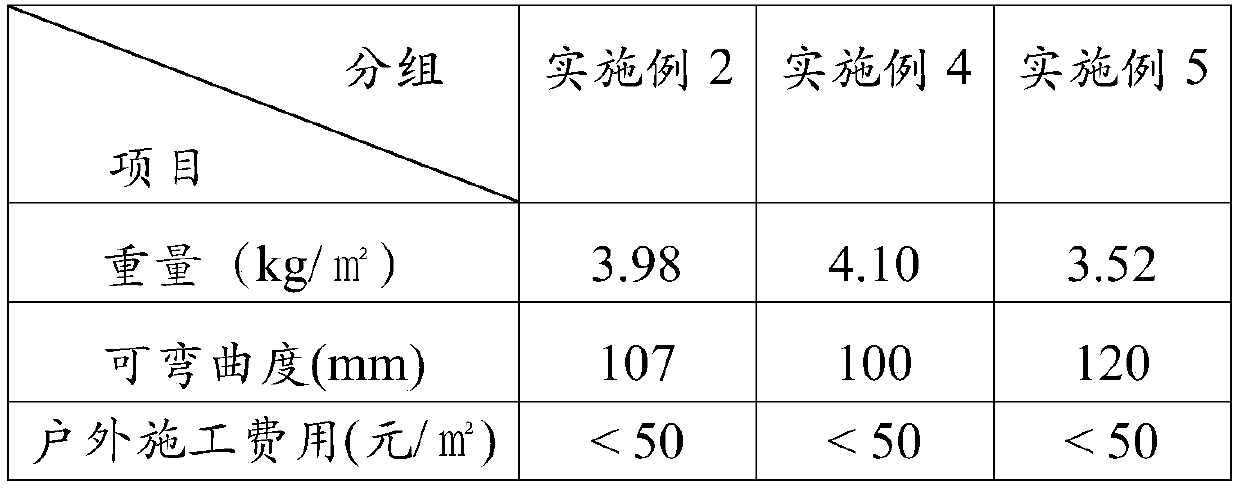

Imitated natural stone and production process thereof

InactiveCN111138128AExtended service lifeReduce transportationCovering/liningsFiberMechanical engineering

The invention discloses imitated natural stone, which is provided with a surface layer bonding layer material, a surface layer crystal layer material, a middle layer bonding layer material, a middle layer thickening layer material and grid fibers, has the same texture, layering, permeability and stone crystal feeling as natural stone, and can ensure long service life no matter used indoors or outdoors. According to the invention, the product is light and thin, the thickness of the product can be thinned to 1-5 mm, and the weight of the product is only 2-10 kg / m<2>, so that the transportation and construction energy consumption is greatly reduced, wet pasting mode can be adopted in construction due to light weight so as to greatly reduce construction cost and accelerate the construction progress, and the stone selectivity is provided for furniture and decoration materials; the toughness is good, and the bonding layer and the grid fibers are used for enhancing the toughness of the imitated natural stone structure, so that the imitated natural stone structure can be flexibly bent so as to conveniently and rapidly apply and construct on arc-shaped surface and cylinder structures; and the production process disclosed by the invention is low in energy consumption and low in cost, and has high safety and environmental friendliness.

Owner:惠州市创鑫隆实业有限公司

Method for improving the hardness of granular sodium nitrate

ActiveCN104591230BHigh hardnessReduce moisture contentAlkali metal nitrate shape formationNitrate fertilisersMelting tankEvaporation

The invention relates to a method of improving the hardness of granular sodium nitrate. According to the method, a waste salt is added by using a hopper and a screw conveyer in the process of conveying the wet sodium nitrate which is obtained by crystallizing through evaporation to a melting tank, wherein the waste salt contains 60-90% by weight of sodium chloride or 10-40% by weight of sodium sulfate. Due to the addition of 0.01-2.5% of the waste salt which contains sodium chloride or sodium sulfate, the hardness of the granular sodium nitrate can be up to 2-4kgf, and the granular sodium nitrate with a size of 2-4mm accounts for more than 96%. Due to the added waste salt which is rich in sodium chloride, the hardness of the granular sodium nitrate can be improved. By adopting the method provided by the invention, the granular sodium nitrate which has a lower content of water, higher roundness and more uniform size than the existing granules can be obtained. In addition, the method can realize continuous production, consumes less energy, is high in efficiency and low in cost and can be particularly applied to the field of tower-based chemical granulation.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

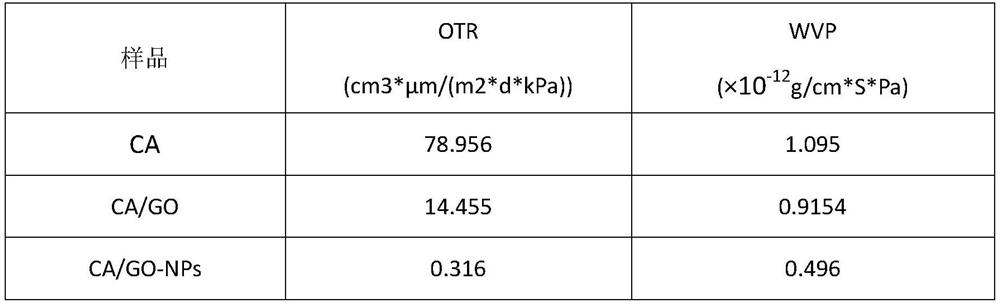

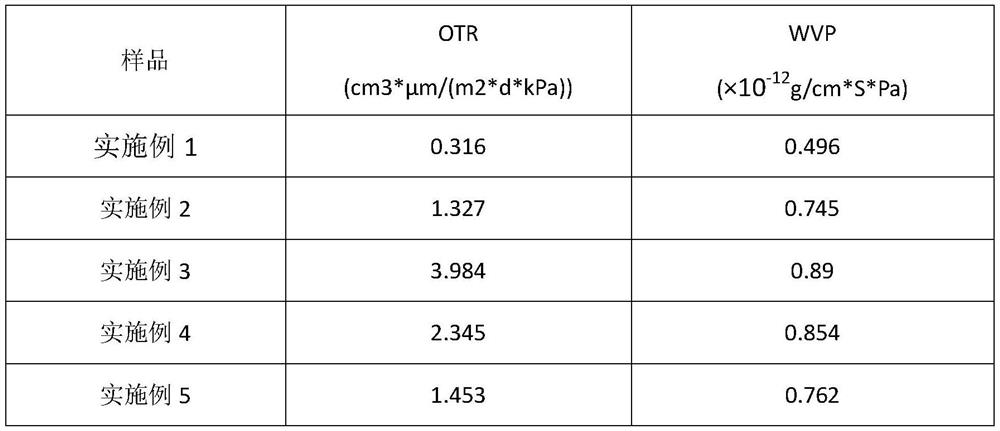

Method for improving gas barrier property of film substrate, film and application

ActiveCN114805900AStable structureHigh barrier propertiesFlexible coversWrappersComposite filmGraphite oxide

The invention discloses a method for improving the gas barrier property of a matrix, and belongs to the technical field of bioplastic packaging. According to the technical scheme, a certain mass fraction of cellulose acetate (CA) and a glycerol solution are prepared into a cellulose acetate film through a tape casting method, and the cellulose acetate film is combined with graphene oxide (GO) nanosheets under the action of molecular glue to form a compact composite film material (CA / GO); and then riveting transition metal oxide nanoparticles (NPs) prepared by adopting a room-temperature rapid reduction method on the surface of the CA / GO film under the action of hydrogen bonds to realize precise repair of GO defect sites and block a gas transmission channel, thereby obtaining the high-gas-barrier CA / GO-NPs nano composite film. The method is low in energy consumption, simple in technological process and easy for batch and large-area production, effectively reduces the permeability of oxygen and water vapor molecules, and is expected to be widely applied to the bioplastic-based packaging fields of food preservation, medicine packaging, electronic product packaging, agricultural packaging and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com