Method for preparing pharmaceutical grade potassium chloride with sea salt potassium chloride

A potassium chloride, pharmaceutical-grade technology, applied in the field of purification of alkali metal halides, can solve the problems of high requirements for equipment corrosion resistance, large medical expenses, large equipment investment, etc., and achieves reduction of production process energy consumption and shortening of production processes. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

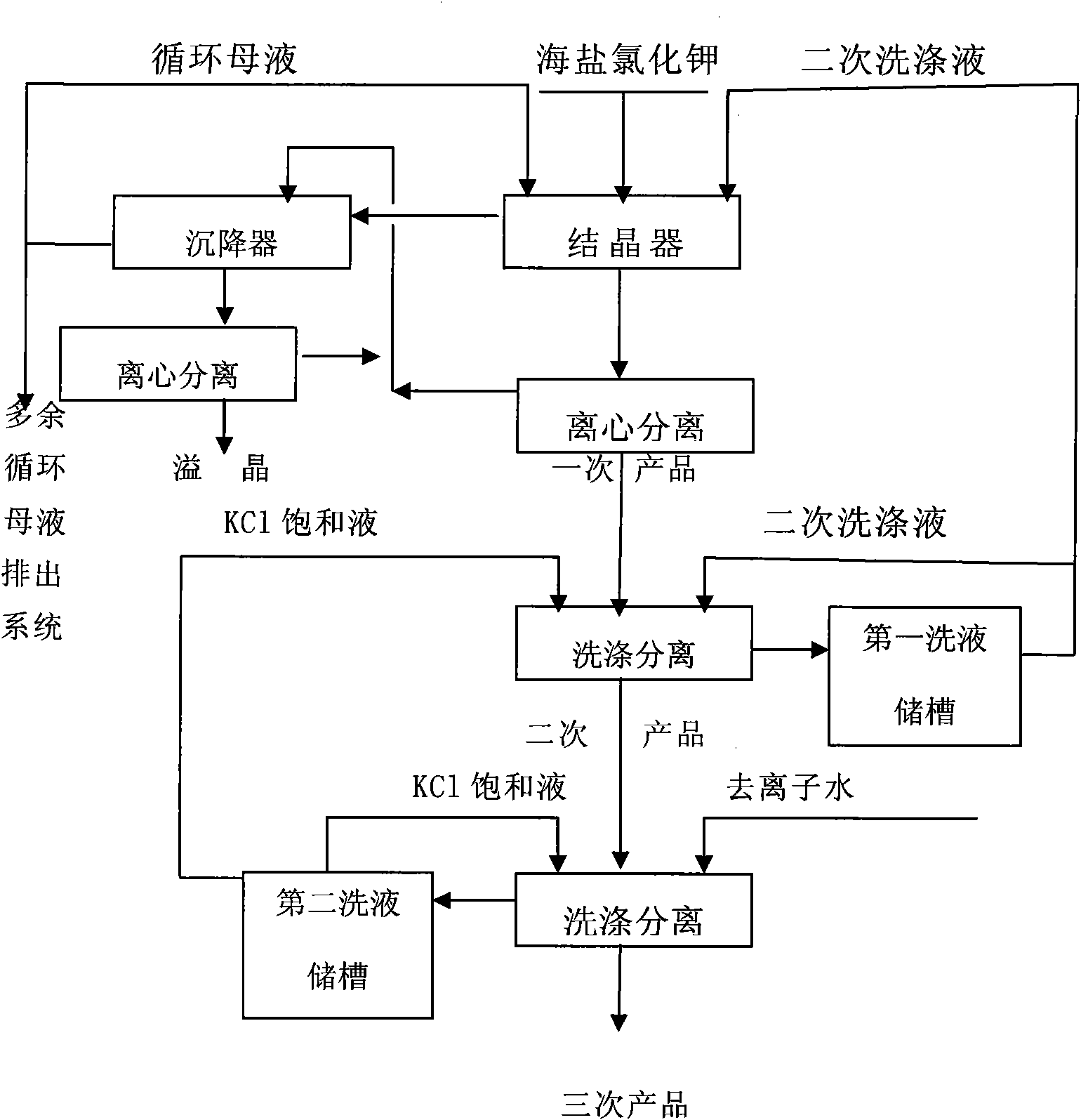

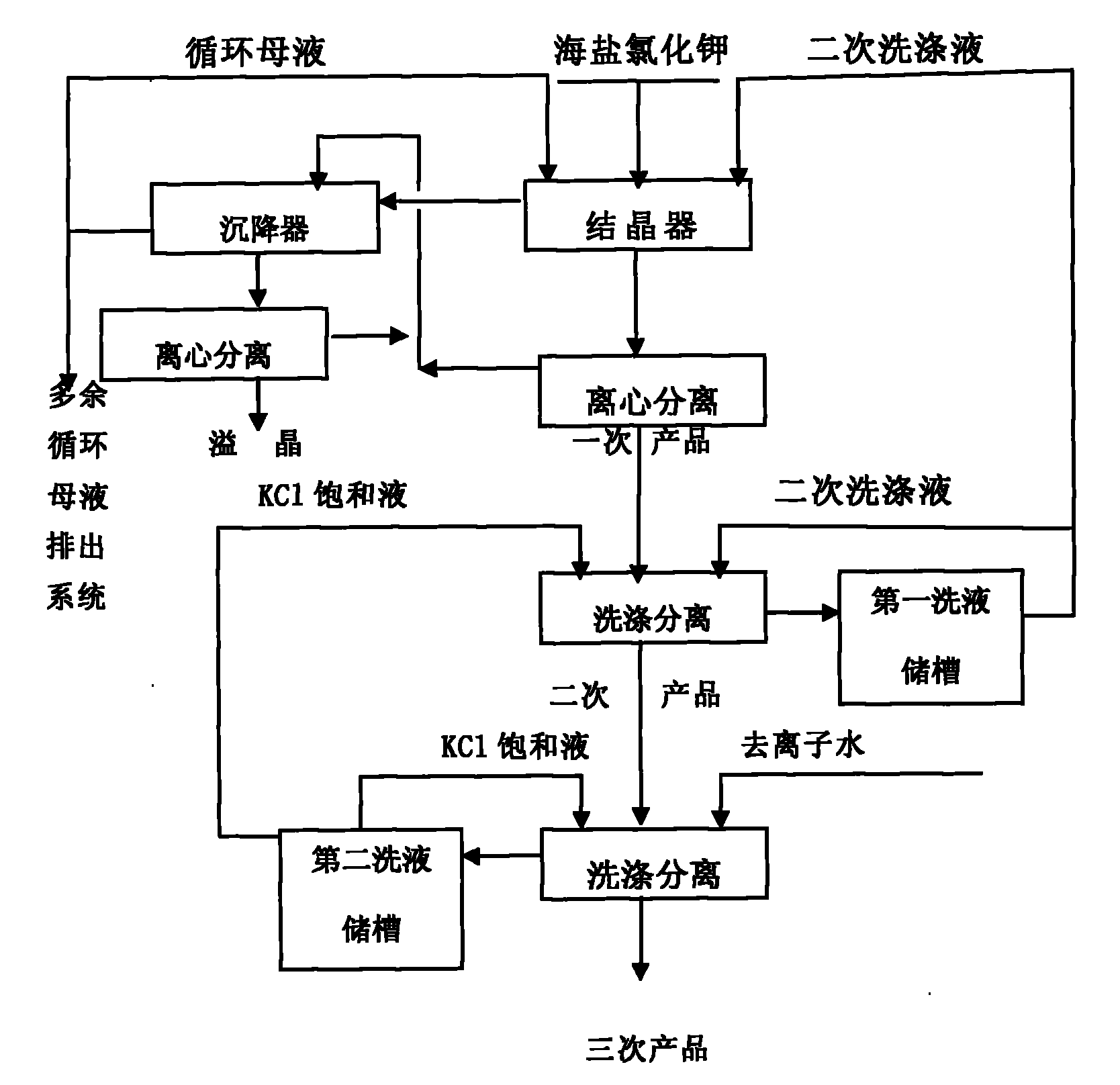

[0021] Example 1. refer to figure 1 . A method for producing pharmaceutical grade potassium chloride with sea salt potassium chloride, the steps are as follows:

[0022] (1) After the sea salt potassium chloride is crushed until loose, it is continuously and stably added to the crystallizer in proportion to the circulating mother liquor and the secondary washing liquid, and the stirring speed of the crystallizer is controlled so that the materials in the reaction zone of the crystallizer are in a fully mixed flow state; The residence time of the reaction materials in the crystallizer is 0.1 hour; the weight ratio of sea salt potassium chloride, circulating mother liquor and secondary washing liquid is 1:2:0.2;

[0023] (2) under the premise of ensuring system stability, the crystallizer underflow of continuous or intermittent, stable discharge; the weight concentration of the crystallizer underflow is 5%; the crystallizer underflow obtains a product and a filtrate through ce...

Embodiment 2

[0026] Example 2. refer to figure 1 . A method for producing pharmaceutical grade potassium chloride with sea salt potassium chloride, the steps are as follows:

[0027] (1) After the sea salt potassium chloride is crushed until loose, it is continuously and stably added to the crystallizer in proportion to the circulating mother liquor and the secondary washing liquid, and the stirring speed of the crystallizer is controlled so that the materials in the reaction zone of the crystallizer are in a fully mixed flow state; The residence time of the reaction materials in the crystallizer is 10 hours; the weight ratio of sea salt potassium chloride, circulating mother liquor and secondary washing liquid is 1:20:2;

[0028] (2) under the premise of ensuring system stability, the crystallizer underflow of continuous or intermittent, stable discharge; the weight concentration of the crystallizer underflow is 35%; the crystallizer underflow obtains a product and a filtrate through ce...

Embodiment 3

[0031] Example 3. refer to figure 1 . A method for producing pharmaceutical grade potassium chloride with sea salt potassium chloride, the steps are as follows:

[0032] (1) After the sea salt potassium chloride is crushed until loose, it is continuously and stably fed into the crystallizer in proportion to the circulating mother liquor and the secondary washing liquid, and the stirring speed of the crystallizer is controlled so that the materials in the reaction zone of the crystallizer are in a fully mixed flow state; The residence time of the reaction materials in the crystallizer is 1 hour; the weight ratio of sea salt potassium chloride, circulating mother liquor and secondary washing liquid is 1:5:1;

[0033] (2) under the premise of ensuring system stability, the crystallizer underflow of continuous or intermittent, stable discharge; the weight concentration of the crystallizer underflow is 20%; the crystallizer underflow obtains a product and a filtrate through centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com