Method for producing piperine

A production method and a technology for piperine, which are applied in the field of deep processing of agricultural products, can solve problems such as no extraction of piperine, and achieve the effects of improving separation efficiency and purity, low energy consumption, and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

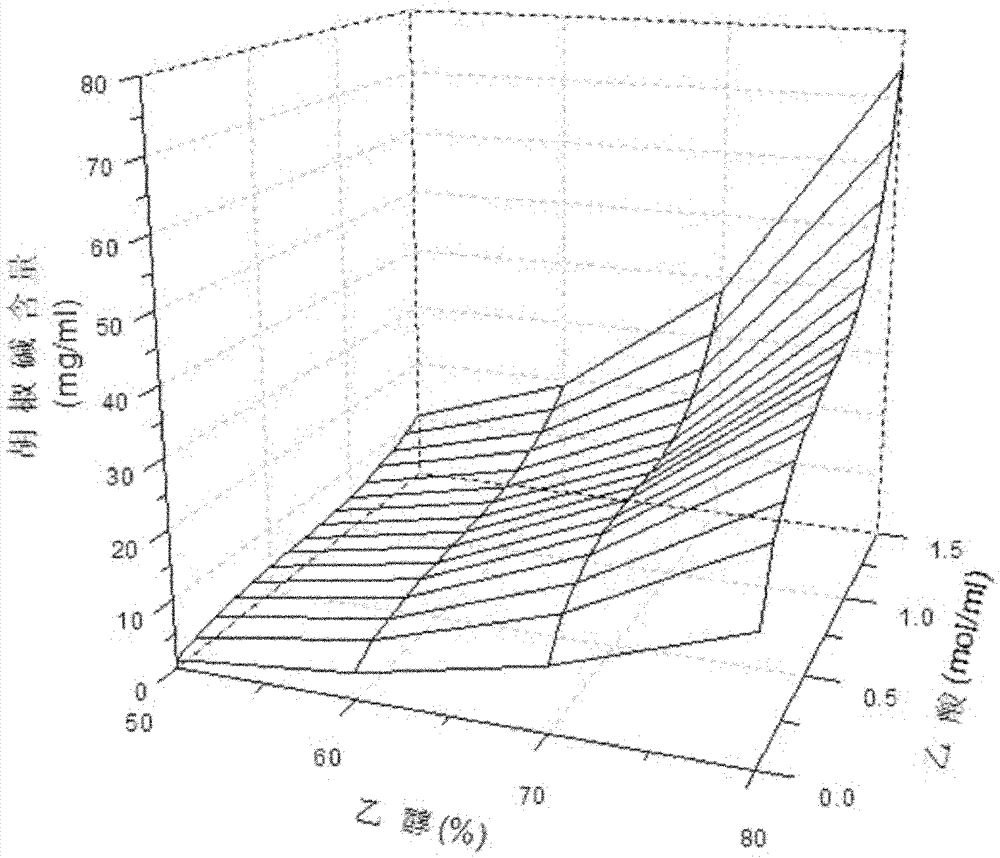

Image

Examples

Embodiment 1

[0030] Embodiment 1 carries out according to the following steps:

[0031] Get 100 kg of dry white pepper and crush it into pepper powder, then use 80 liters of mixed solvent (20 parts of 95% edible alcohol, 10 parts of 1 mol / liter of acetic acid, V / V) to moisten the pepper powder overnight, and use it every 1 hour Spiral stirring was stirred for 5 minutes, and then 200 liters of the above-mentioned mixed solvent was added for static soaking. After 12 hours, the solid phase and the liquid phase in the mixture were separated. Repeat the immersion and separation process 3 times. Combine all extracts and filter by centrifugation or plate and frame filter. Put the filtrate on the D101 macroporous resin column, and put it on the column until piperine just flows out in the effluent. Then wash 3 column volumes with clear water, and then wash 3-4 column volumes with a mixed solvent (80:20, V / V) of ethanol solution composed of 95% edible alcohol and 1 mol / L acetic acid. The collecte...

Embodiment 2

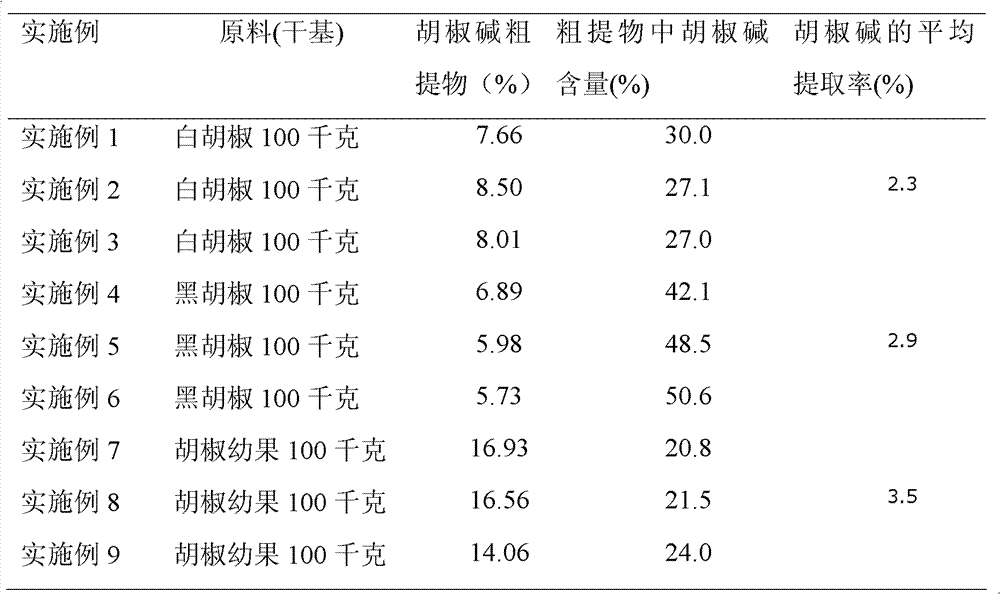

[0033] With the raw material that contains piperine in Table 1 as experimental raw material, extraction solvent is 20 parts of methanol, 10 parts (V / V) of the hydrochloric acid of 1 mol / liter, and all the other steps are with embodiment 1, and experimental result is shown in Table 1.

[0034] Table 1

[0035]

Embodiment 10

[0036] Embodiment 10 carries out according to the following steps:

[0037] Get 300 kilograms of immature pepper young fruits, break into pulp, then use 120 liters of mixed solvent (20 parts per liter of 1 mole hydrochloric acid, 80 parts of 95% edible alcohol) to wet pepper powder overnight, and use mechanical continuous Stir, then add 150 liters of the above mixed solvent for soaking, and separate the solid and liquid phases in the mixture after 12 hours. Repeat the soaking and separating process 3-4 times. Combine all extracts and filter by centrifugation or plate and frame filter. Put the filtrate on the H103 macroporous resin column, and put it on the column until piperine just flows out in the effluent. Then wash 3 column volumes with clear water, and then wash 3-4 column volumes with an ethanol solution (85:15, V / V) composed of 95% edible alcohol and 1 mole of hydrochloric acid per liter. The collected effluent was concentrated in vacuo, and after recovering the alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com