Method and system for producing sponge iron through COREX device and direct reduction vertical furnace

A technology of sponge iron and shaft furnace, which is applied in the field of metallurgical chemistry, can solve the problems of low utilization rate of reducing gas in shaft furnace and low reduction degree of DRI, etc., and achieve the effects of making up for insufficient gas production, improving reduction capacity, and promoting reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

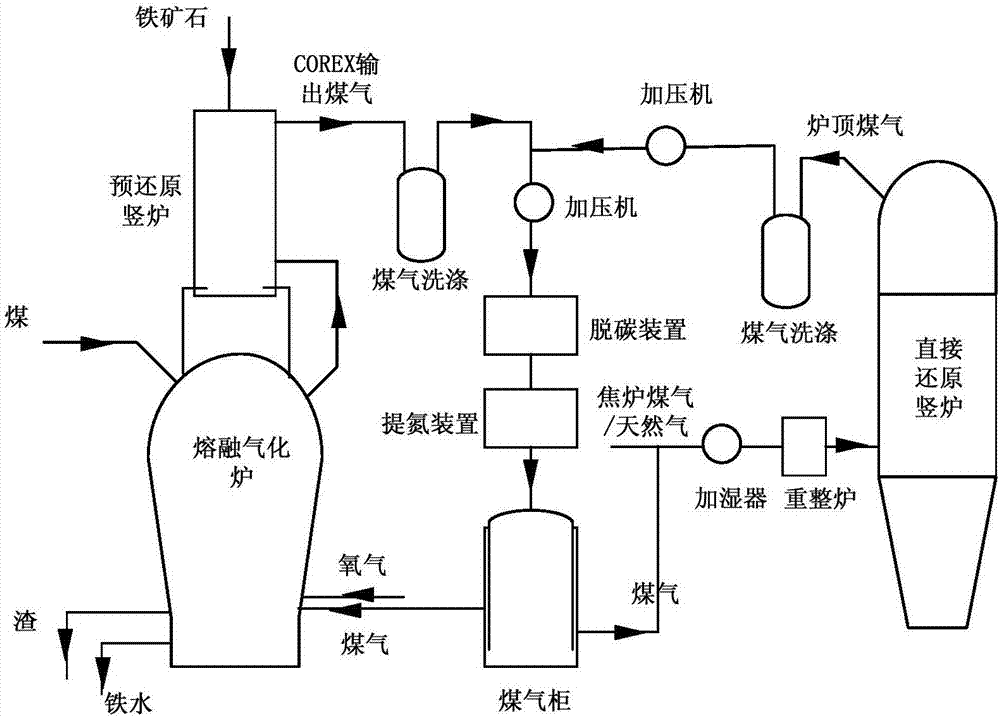

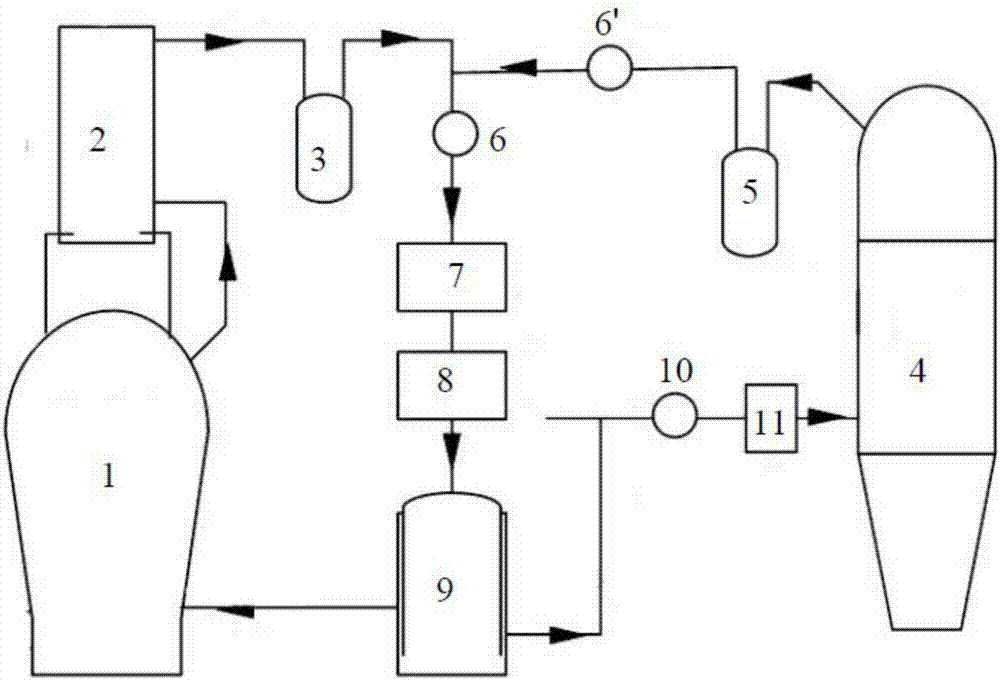

[0054] refer to Figure 1-2 , coal is pyrolyzed in the melter-gasifier 1 to produce pyrolysis gas, and at the same time, the coal coke produced by pyrolysis is reacted with oxygen at high temperature to generate coal gas in the gasifier 1, and the generated coal gas is transported to the In the pre-reduction shaft furnace 2, the iron ore in the pre-reduction shaft furnace 2 is reduced to obtain the COREX output gas, wherein the composition and volume of the COREX output gas are: H 2 13.82 parts by volume, CO 45.25 parts by volume, CH 4 0.63 parts by volume, N 2 9.62 parts by volume, CO 2 30.68 parts by volume; reducing gas reduces iron ore in the direct reduction shaft furnace 4, and generates top gas at the top section of the direct reduction shaft furnace 4, wherein the composition and volume of the top gas are H 2 29.6 parts by volume, CO 21.2 parts by volume, CH 4 2.6 parts by volume, CO 2 18.7 parts by volume, N 2 9.3 parts by volume, H 2 O 18.6 parts by vo...

Embodiment 2

[0057] refer to Figure 1-2 , coal is pyrolyzed in the melter-gasifier 1 to produce pyrolysis gas, and at the same time, the coal coke produced by pyrolysis is reacted with oxygen at high temperature to generate coal gas in the gasifier 1, and the generated coal gas is transported to the In the pre-reduction shaft furnace 2, the iron ore in the pre-reduction shaft furnace 2 is reduced to obtain the COREX output gas, wherein the composition and volume of the COREX output gas are: H 2 10 parts by volume, CO 40 parts by volume, CH 4 0.5 parts by volume, N 2 8 parts by volume, CO 2 35 parts by volume; reducing gas reduces iron ore in the direct reduction shaft furnace 4, and generates top gas at the top of the direct reduction shaft furnace 4, wherein the composition and volume of the top gas are H 2 25 parts by volume, CO 15 parts by volume, CH 4 1 part by volume, CO 2 15 parts by volume, N 2 10 parts by volume, H 2 O 20 parts by volume; the obtained COREX output g...

Embodiment 3

[0060] refer to Figure 1-2 , coal is pyrolyzed in the melter-gasifier 1 to produce pyrolysis gas, and at the same time, the coal coke produced by pyrolysis is reacted with oxygen at high temperature to generate coal gas in the gasifier 1, and the generated coal gas is transported to the In the pre-reduction shaft furnace 2, the iron ore in the pre-reduction shaft furnace 2 is reduced to obtain the COREX output gas, wherein the composition and volume of the COREX output gas are: H 2 15 parts by volume, CO 50 parts by volume, CH 4 1 part by volume, N 2 10 parts by volume, CO 2 25 parts by volume; reducing gas reduces iron ore in the direct reduction shaft furnace 4, and generates top gas at the top of the direct reduction shaft furnace 4, wherein the composition and volume of the top gas are H 2 35 parts by volume, CO 25 parts by volume, CH 4 4 parts by volume, CO 2 20 parts by volume, N 2 8 parts by volume, H 2 O 15 parts by volume; the obtained COREX output gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com