Method for preparing biomass retarder from agricultural wastes, and application of biomass retarder

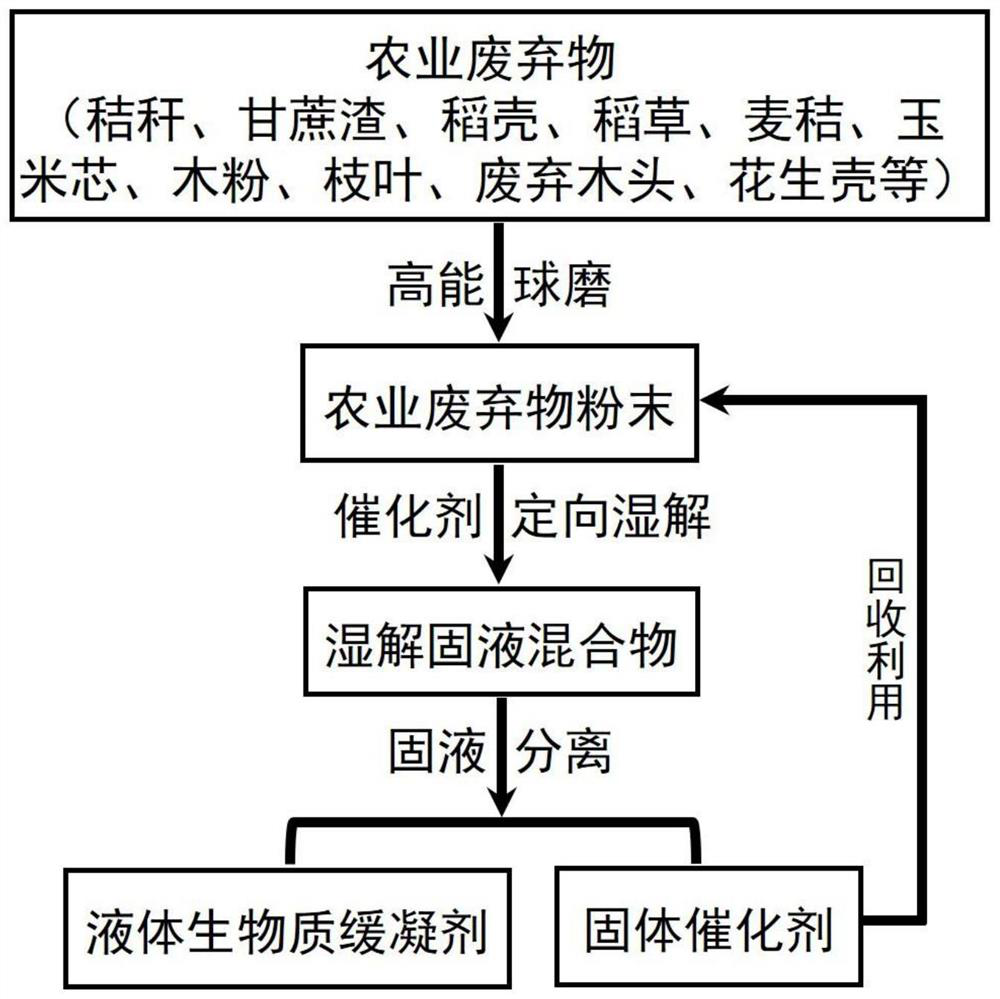

A technology for agricultural waste and biomass, which is applied in the field of high-value conversion of agricultural waste and its utilization, can solve the problems of high price of aminotrimethylidene phosphate, insoluble cellulose derivatives, and restrictions on large-scale use, and achieves water solubility. Good performance, simple and easy solid-liquid separation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

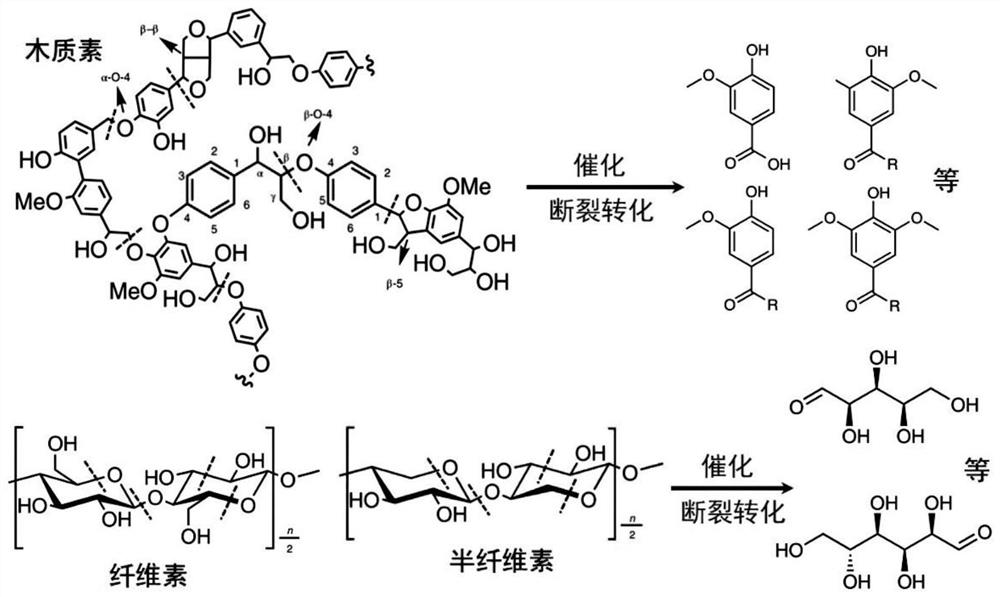

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 50g of agricultural straw and transfer it to a 500mL stainless steel ball mill container, control the mass ratio of stainless steel beads to agricultural straw to 50:1, and then keep forward rotation and reverse rotation at a speed of 600r / min for 1h, The forward and reverse cycles were switched 6 times, and the ball milling time was set at 12 hours. After stopping, cool to room temperature, separate the straw and steel balls, and obtain straw powder.

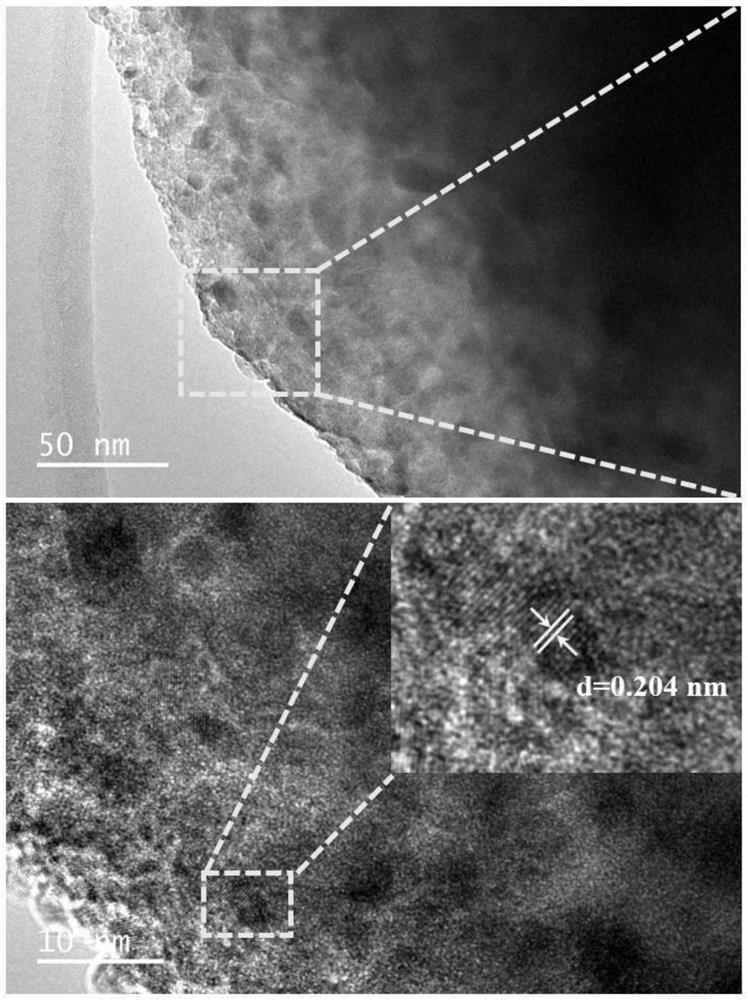

[0036] (2) Transfer the 50g straw powder after the ball milling to a 500mL stainless steel reactor, add 100mL water and 2.5g FAU molecular sieve-supported nickel catalyst (transmission electron microscope photo as shown in image 3 shown), keep the mass ratio of catalyst, straw and water at 0.05:1:2, and stop the reaction at 170°C for 2 hours.

[0037] (3) After the above-mentioned wet hydrolysis product is cooled to room temperature, it is suction-filtered under normal temperature and pressure conditions, and t...

Embodiment 2

[0041] (1) Take 50g of agricultural straw and transfer it to a 500mL stainless steel ball mill container, control the mass ratio of stainless steel beads to agricultural straw to 50:1, and then keep forward rotation and reverse rotation at a speed of 600r / min for 1h, The forward and reverse cycles were switched 6 times, and the ball milling time was set at 12 hours. After stopping, cool to room temperature, separate the straw and steel balls, and obtain straw powder.

[0042](2) Transfer 50g of straw powder after ball milling to a 500mL stainless steel reactor, add 100mL of water and 2.5g of nickel catalyst supported by FAU molecular sieves, keep the mass ratio of catalyst, straw, and water at 0.05:1:2. The reaction was stopped after 2 h at the temperature of ℃.

[0043] (3) After the above-mentioned wet hydrolysis product is cooled to room temperature, it is suction-filtered under normal temperature and pressure conditions, and the liquid and solid catalyst are separated to o...

Embodiment 3

[0047] (1) Take 50g of agricultural straw and transfer it to a 500mL stainless steel ball mill container, control the mass ratio of stainless steel beads to agricultural straw to 50:1, and then keep forward rotation and reverse rotation at a speed of 600r / min for 1h, The forward and reverse cycles were switched 6 times, and the ball milling time was set at 12 hours. After stopping, cool to room temperature, separate the straw and steel balls, and obtain straw powder.

[0048] (2) Transfer 50g of straw powder after ball milling to a 500mL stainless steel reactor, add 100mL of water and 2.5g of nickel catalyst supported by FAU molecular sieves, keep the mass ratio of catalyst, straw, and water at 0.05:1:2, at 200 The reaction was stopped after 2 h at the temperature of ℃.

[0049] (3) After the above-mentioned wet hydrolysis product is cooled to room temperature, it is suction-filtered under normal temperature and pressure conditions, and the liquid and solid catalyst are separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com