Bean puffed food and preparation method thereof

A technology of puffed food and beans, which is applied in food freezing, food ingredients, food forming, etc., can solve the problems of soybean waste environment, pollution, and insufficient crispness, so as to improve crispness and nutritional value, avoid waste, and ensure taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

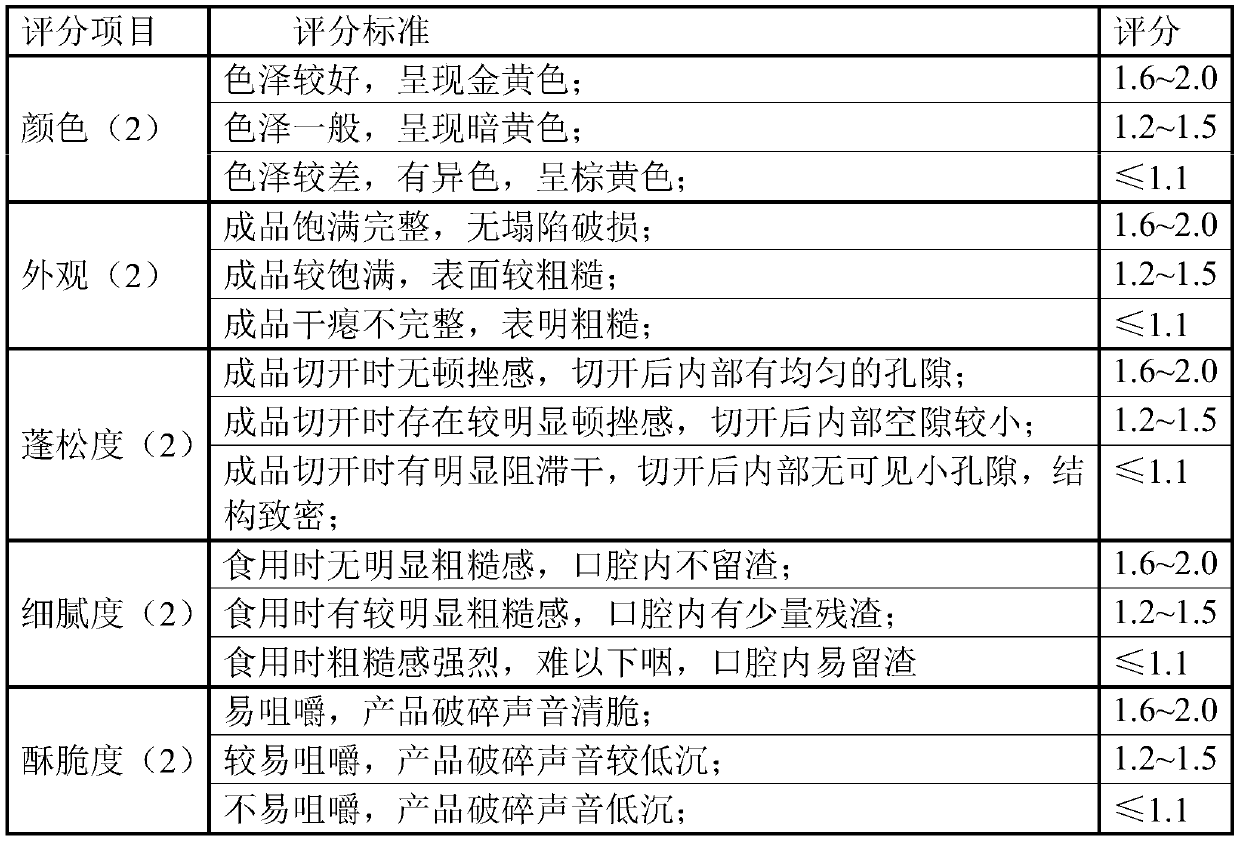

Examples

preparation example Construction

[0023] The preparation method of puffed beans food according to an embodiment of the present invention includes the following steps S1 to S3:

[0024] S1. Soak the dried beans in water for 5-15 hours, then use a grinding wheel to grind to obtain the first soy milk, and then use a colloid mill to grind to obtain the second soy milk. It can be understood that the dried beans may be one or more of beans such as soybeans, black beans, and green beans, which can be selected according to needs.

[0025] S2. The second soybean milk is matured, and then a coagulant is added to prepare soybean brains.

[0026] S3. The soybean brain is mechanically pressed, then frozen to a core temperature of below -18°C, and then fried to obtain puffed beans. It can be understood that in the field of food processing, due to the large volume of food, the temperature inside and outside may be different. The core temperature refers to the middle temperature of the processed food, and a food thermometer is gene...

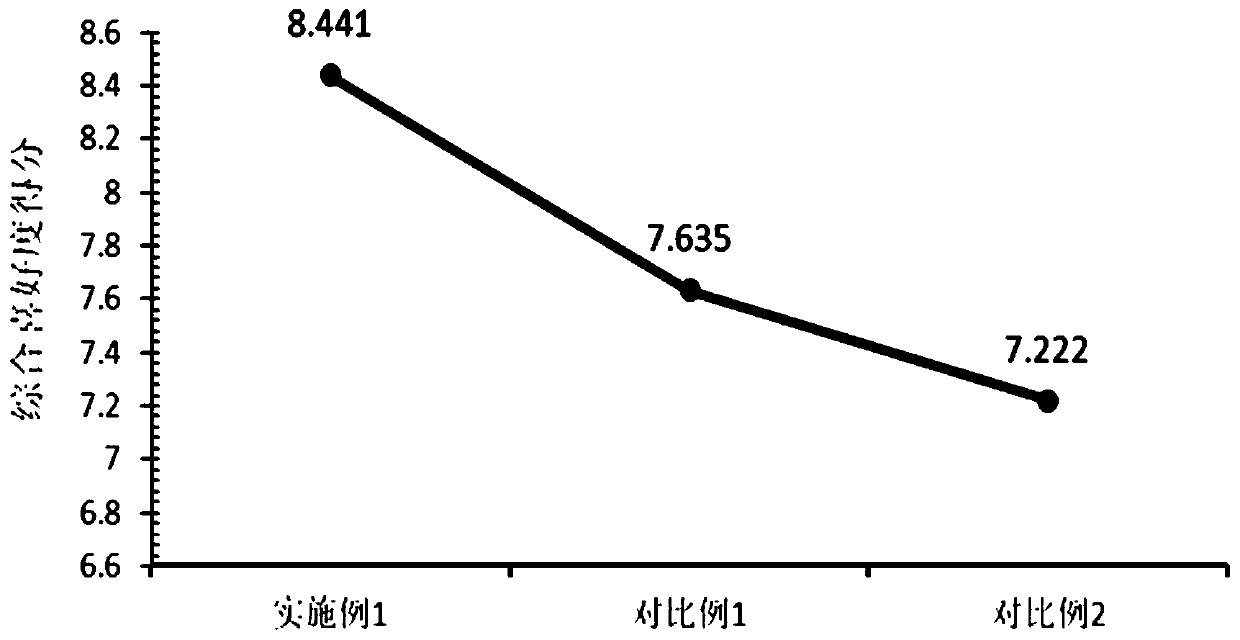

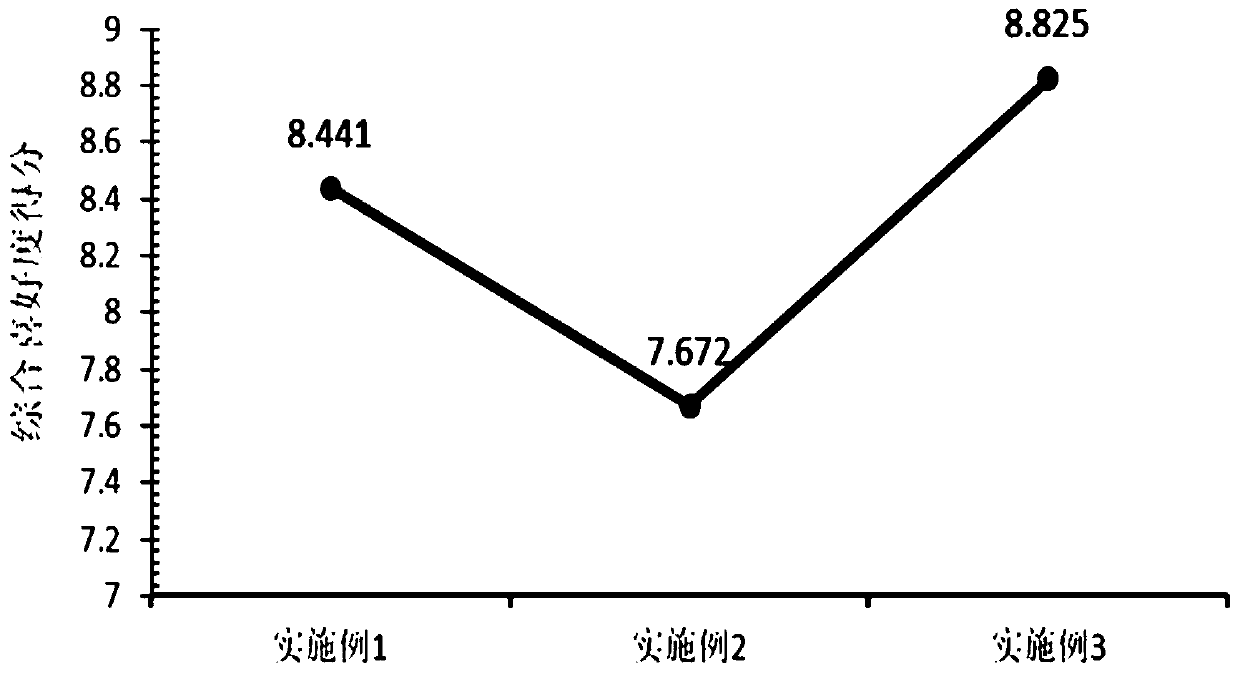

Embodiment 1

[0042] (1) Soak the soybeans for 10 hours, let the soybeans fully absorb water and expand, and the soaking mass ratio of dry beans to water is 1:3.

[0043] (2) Use a grinding wheel mill to grind the soaked soybeans with water for 30 seconds to form a slurry. The gap is set to 0.6mm, the detection particle size reaches 100 meshes, and the concentration of soy milk is 8°-11° (measured by refractometer) without removing the bean dregs;

[0044] (3) Add modified corn starch to the soybean milk in step (2), and the mass ratio of soybean milk to modified corn starch is 100:4.

[0045] (4) On the basis of step (3), a colloid mill is used for further grinding for 10 seconds, the gap is set to 0.4mm, and the detected particle size reaches 120-140 mesh.

[0046] (5) Use steam to heat the soybean milk to above 95°C, with a steam pressure of 0.7Mpa, and maintain the temperature for 10 minutes.

[0047] (6) Add a magnesium chloride solution (refractive index of 9°-10°) to the matured soybean milk, ...

Embodiment 2

[0078] (1) Soak the soybeans for 10 hours, let the soybeans fully absorb water and expand, and the soaking mass ratio of dry beans to water is 1:3.

[0079] (2) Use a grinding wheel mill to grind the soaked soybeans with water for 30 seconds to form a slurry. The gap is set to 0.6mm, the detection particle size reaches 100 meshes, and the concentration of soybean milk is 8-11° (measured by a refractometer) without removing the bean dregs;

[0080] (3) On the basis of step (2), a colloid mill is used for further grinding for 10 seconds, the gap is set to 0.4mm, and the detected particle size reaches 120-140 mesh.

[0081] (4) Use steam to heat the soybean milk to above 95°C, with a steam pressure of 0.7Mpa, and maintain the temperature for 10 minutes.

[0082] (5) Add magnesium chloride solution (refractive index of 9°-10°) to the matured soybean milk, the mass ratio of soybean milk to magnesium chloride is 100:0.2, stir evenly and let stand for 25 minutes to prepare soybean brain.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com