Organic fertilizer preparation formula and preparation and application methods thereof

An organic fertilizer and formula technology, applied in the field of organic fertilizer preparation formula and its preparation, can solve the problems of soil compaction, incomplete fermentation, expensive unit price, etc., and achieve the effects of ensuring interaction rate, shortening fermentation cycle, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

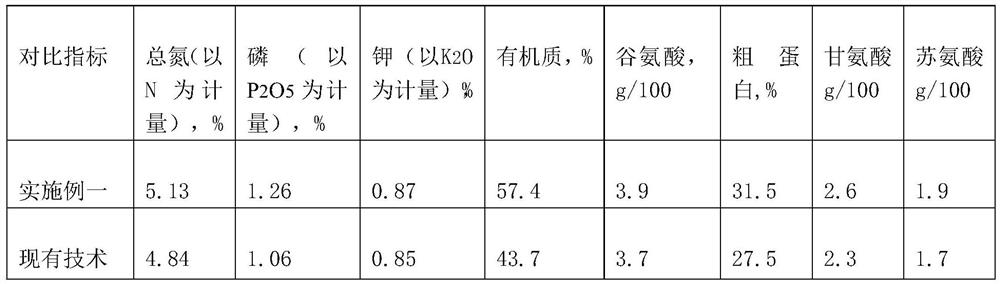

Embodiment 1

[0018] Embodiment 1: Prepare the mass percentage except water: 58% of rabbit manure, 11.7% of fine bran, 0.46% of phosphorus-dissolving microbial agent, silicate microbial agent, 0.31% of rapeseed oil residue, 16.3% of carbonized rice husk and 13% , root nodules and nitrogen-fixing bacteria agent 0.23% raw materials, the nitrogen, phosphorus and potassium content of raw materials should be tested before use. Then, choose a storage yard with a length, width, and height of 4.2m, 4.6m, and 1.8m respectively, shallowly turn over 20cm of the surface soil in the storage yard, and place the pile aside to be used as mixed materials. The fermentation site uses straw piles to prepare piles. Field foundation, used to pad the bottom of the yard to increase air permeability. Then, pile the rabbit manure in the range of the yard, pile it into a circle, add 5cm thick carbonized rice husks and 10cm fine bran to the height of each pile of 40cm, until the top of the yard, and finally cover it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com