Process for producing a combustible product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The feedstock materials contain a large amount of organic material which can be converted into a useful combustible product. The process of the present invention is concerned with a process of converting the feedstock, such as sewage sludge and wood, into a combustible product. The combustible product is typically in the form of a coal-like material and it may optionally be further processed to provide a combustible product in liquid form.

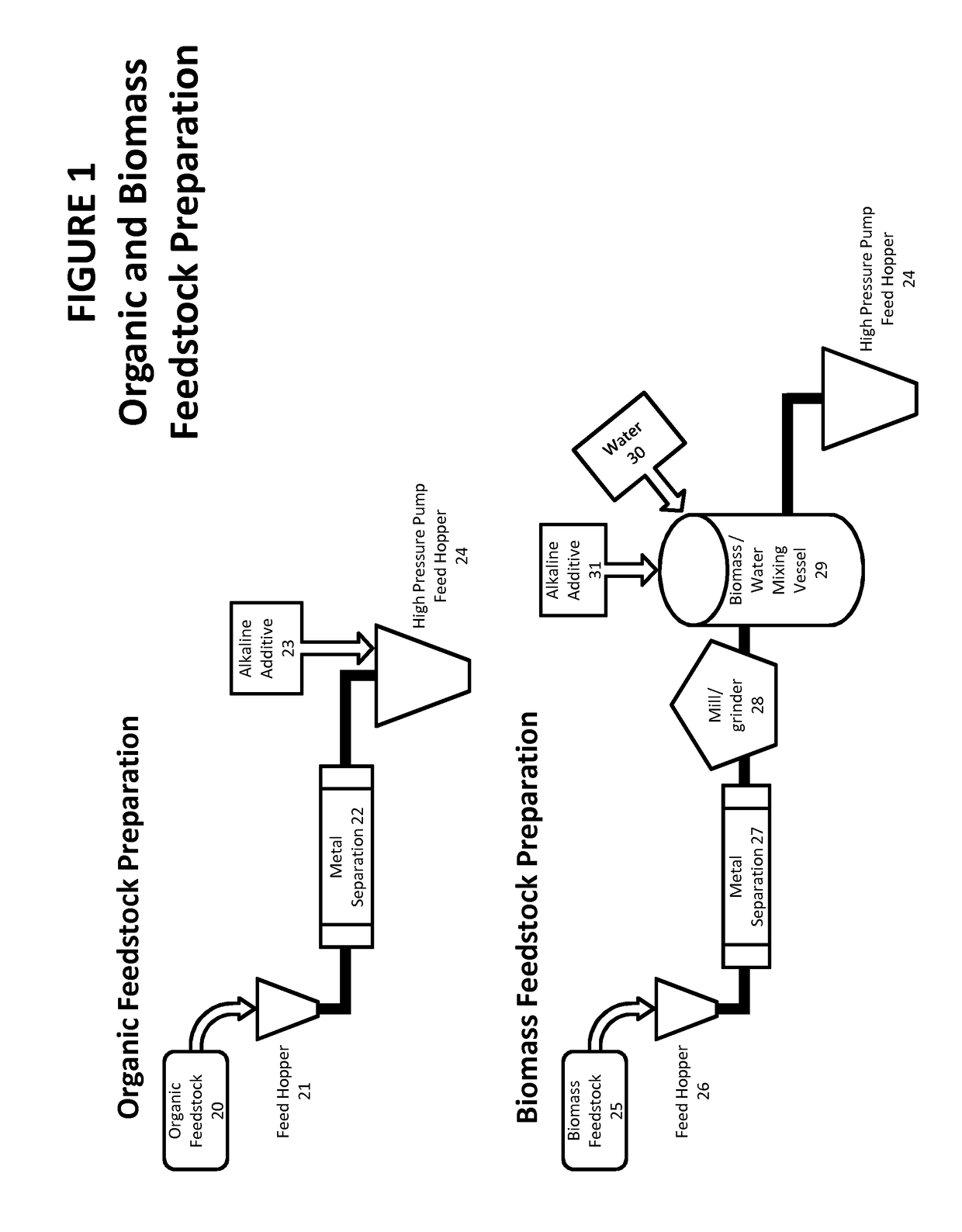

[0029]Due to the difference in moisture content of organic and biomass feedstock the process prepares the materials in different methods to achieve the optimal feedstock conditions required.

[0030]FIG. 1 shows flow charts of the processes 20 for the preparation of feedstock.

[0031]Organic feedstock 20 is fed into the feed hopper 21 via mechanical loading machine and onto a conveyor belt. It passes a metal separation stage 22 to remove any unwanted metallic objects via an over conveyor magnet and or drum magnet. The material is then deposited in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com