Preparation method and device of semi-solid slurry

A technology of semi-solid slurry and preparation device, which is applied in the field of new semi-solid slurry preparation and semi-solid slurry preparation of light alloys, and can solve the problems of difficult control and operation, inclusion of air in the melt, and easy contamination. , to achieve the effect of short pulping process, simple equipment and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

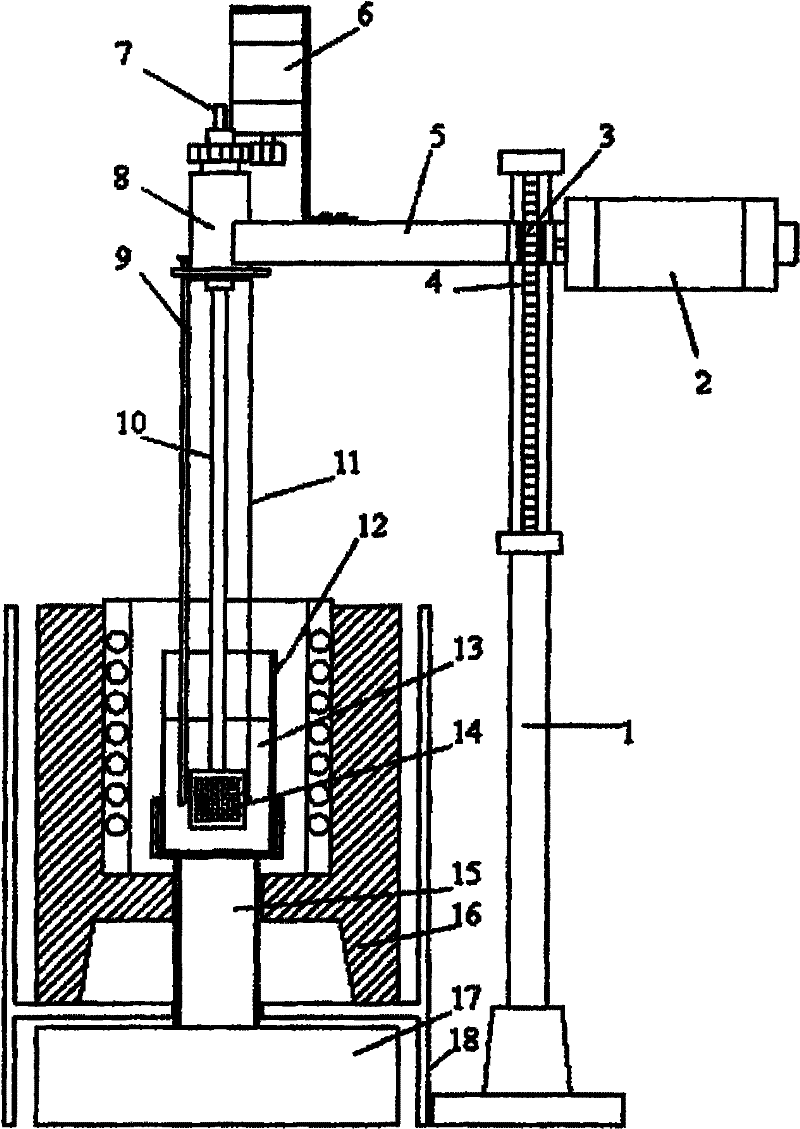

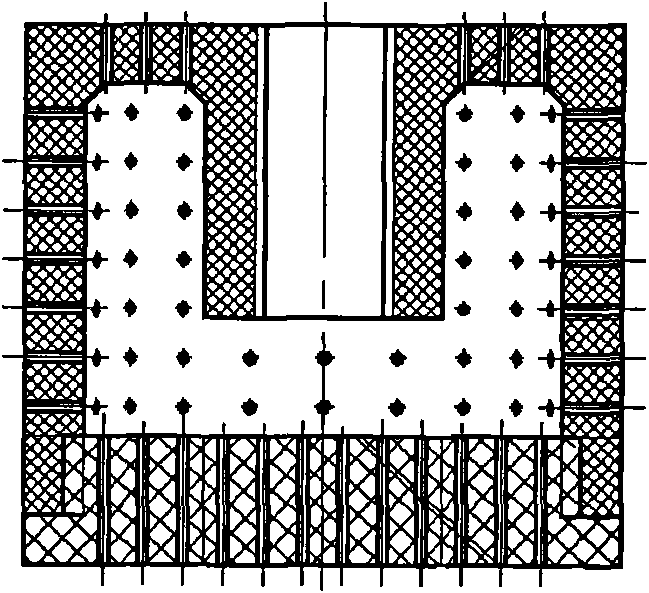

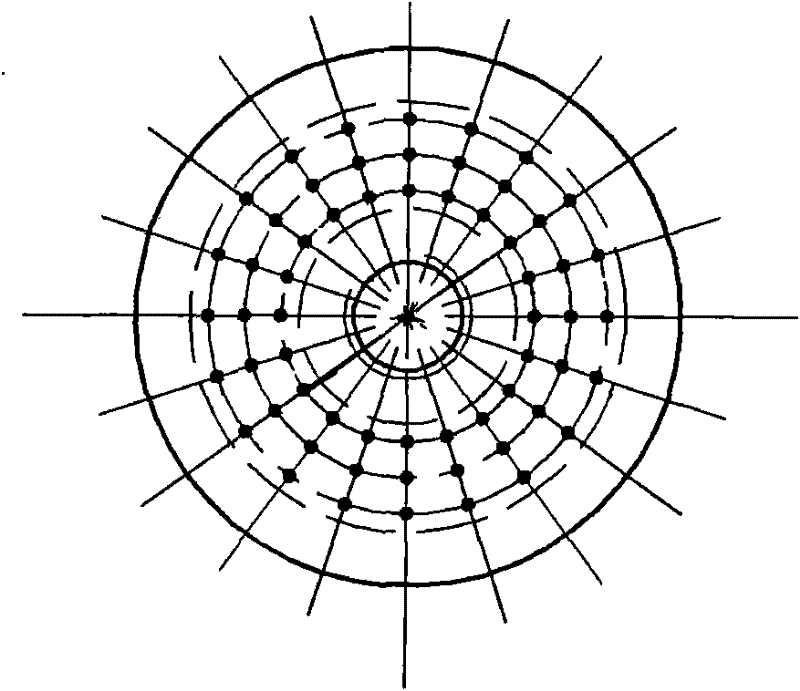

[0032] Clean the smelting tools and dry the paint, the composition of the paint used is 70% CaCO 3 +20% ZnO+10ml water glass+water. Put the ZL101 aluminum alloy into the steel crucible 12 in the resistance furnace 16 for melting. Superheat the molten metal to 700°C, and wait for the temperature to drop to the predetermined temperature range after refining and removing slag. Set the test parameters such as stirring speed, gas flow rate, vibration frequency and amplitude, and the amount of foreign material added.

[0033] When the temperature of the molten metal drops to 650°C, start the lifting motor 2 to lower the crossbeam 5, so that the graphite head 14 and the powder feeding pipe 9 are preheated above the surface of the high-temperature molten metal. When the temperature of the molten metal drops to 620°C, lower the beam 5 to penetrate the preheated graphite head 14, powder feeding pipe 9 and thermocouple 11 into the molten metal, turn on the argon gas and start the rotat...

example 2

[0035] Clean the smelting tools and dry the paint, the composition of the paint used is 70% CaCO 3 +20% ZnO+10ml water glass+water. The AZ91D magnesium alloy is put into the steel crucible 12 in the electric resistance furnace 16 for smelting, and uses shielding gas (CO 2 : SF 6 =100:1) to protect the molten magnesium alloy. Superheat the molten metal to 670°C, and wait for the temperature to drop to the predetermined temperature range after refining and removing slag. Set the test parameters such as stirring speed, gas flow rate, vibration frequency and amplitude.

[0036] When the temperature of the molten metal drops to 630°C, the lifting motor 2 is started to lower the beam 5, so that the graphite head 14 and the powder feeding pipe 9 are preheated above the surface of the high-temperature molten metal. When the temperature of the molten metal drops to 600°C, lower the beam 5 to penetrate the preheated graphite head 14, powder feeding pipe 9 and thermocouple 11 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com