Imitated natural stone and production process thereof

A technology imitating natural stone and production process, applied in the direction of architecture, building structure, covering/lining, etc., can solve the problems of low energy consumption and low cost of production process, and achieve low energy consumption, low cost and good toughness of production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

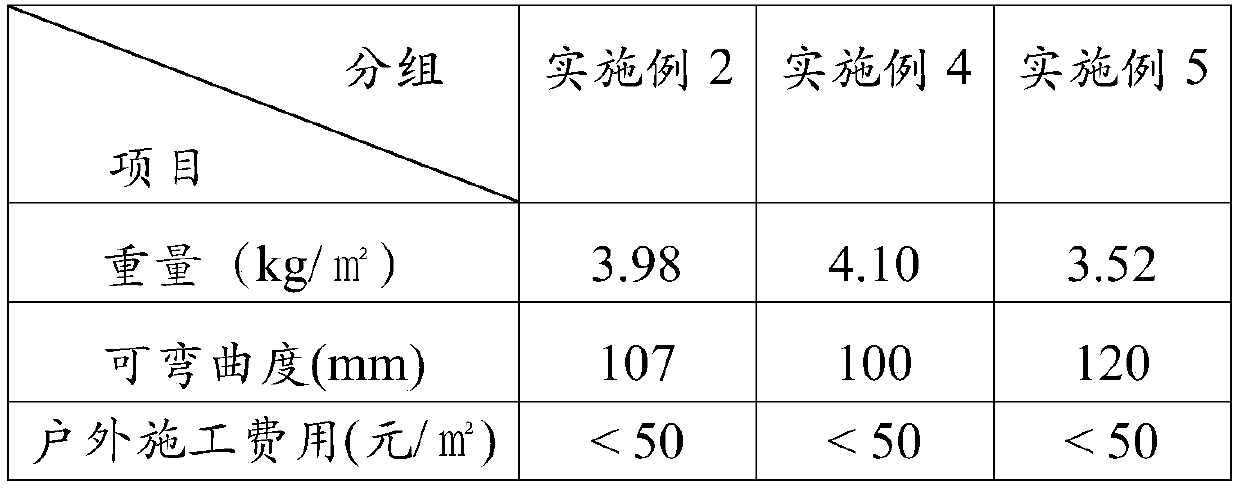

Examples

Embodiment 1

[0065] A kind of imitation natural stone material comprises surface layer bonding layer material: 50 parts of resin, 5 parts of curing agent and 10 parts of aluminum hydroxide; Surface layer crystal layer material: 30 parts of 80 mesh glass sand, 10 parts of 50 mesh glass sand and 5 parts of 10-mesh glass sand; middle layer bonding layer material: 50 parts of resin, 1 part of curing agent, 1 part of cement and 5 parts of aluminum hydroxide; middle layer thickening layer material: 50 parts of 70-mesh quartz sand, 10 parts of 100-mesh ore Powder, 1 part cement and 1 part polyester fiber; and 2mm mesh fiber.

[0066] The production process of imitating natural stone includes the following steps:

[0067] S1, laying a release film in the template;

[0068] S2, mix the surface layer adhesive layer material evenly, evenly spray or shower on the release film to form the surface layer adhesive layer;

[0069] S3, stirring the surface layer crystal layer material evenly, evenly spray...

Embodiment 2

[0078] A kind of imitation natural stone material comprises surface layer bonding layer material: 60 parts of resin, 6 parts of curing agent and 25 parts of aluminum hydroxide; Surface layer crystal layer material: 60 parts of 90 mesh glass sand, 30 parts of 60 mesh glass sand and 20 parts of 20-mesh glass sand; middle layer bonding layer material: 65 parts of resin, 1.5 parts of curing agent, 5 parts of cement and 20 parts of aluminum hydroxide; middle layer thickening layer material: 65 parts of 80-mesh quartz sand, 20 parts of 200-mesh ore Powder, 10 parts of cement and 2 parts of polyester fiber; and 3mm mesh fiber.

[0079] The production process of imitating natural stone includes the following steps:

[0080] S1, laying a release film in the template;

[0081] S2, mix the surface layer adhesive layer material evenly, evenly spray or shower on the release film to form the surface layer adhesive layer;

[0082] S3, stirring the surface layer crystal layer material evenl...

Embodiment 3

[0091] A kind of imitation natural stone material comprises surface layer bonding layer material: 80 parts of resin, 8 parts of curing agent and 40 parts of aluminum hydroxide; Surface layer crystal layer material: 80 parts of 100 mesh glass sand, 50 parts of 70 mesh glass sand and 30 parts of 30-mesh glass sand; middle layer bonding layer material: 80 parts of resin, 1.5 parts of curing agent, 10 parts of cement and 40 parts of aluminum hydroxide; middle layer thickening layer material: 80 parts of 90-mesh quartz sand, 30 parts of 250-mesh ore Powder, 20 parts of cement and 3 parts of polyester fiber; and 5mm of mesh fiber.

[0092] The production process of imitating natural stone includes the following steps:

[0093] S1, laying a release film in the template;

[0094] S2, mix the surface layer adhesive layer material evenly, evenly spray or shower on the release film to form the surface layer adhesive layer;

[0095] S3, stirring the surface layer crystal layer material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com