Crystallization method capable of increasing rebaudioside A1G content as well as product and application thereof

A technology for rebaudioside and crystallization products, which is applied in the field of crystallization to increase the content of rebaudioside A1G in rebaudioside A enzyme-modified products, and can solve the problems of difficult separation and purification by conventional methods, uneven taste, and product composition complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

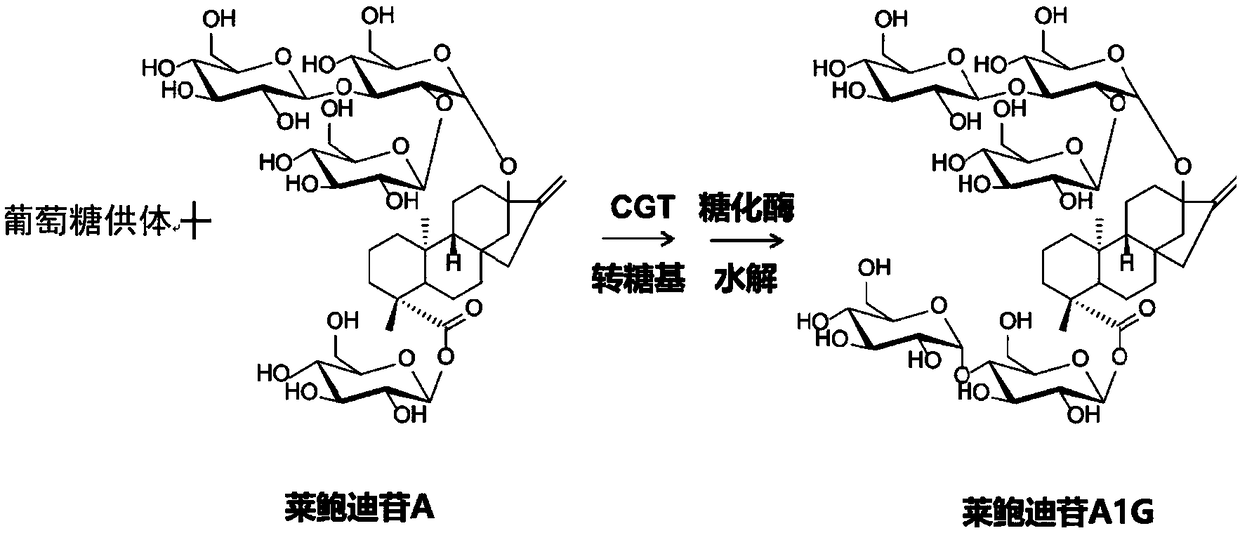

[0184] Example 1: Preparation and Identification of Rebaudioside A1G, a Rebaudioside A Double Enzyme Modified Product

[0185] according to figure 1 In the brief process shown, the modified product of rebaudioside A is prepared by a double-enzyme method. in particular:

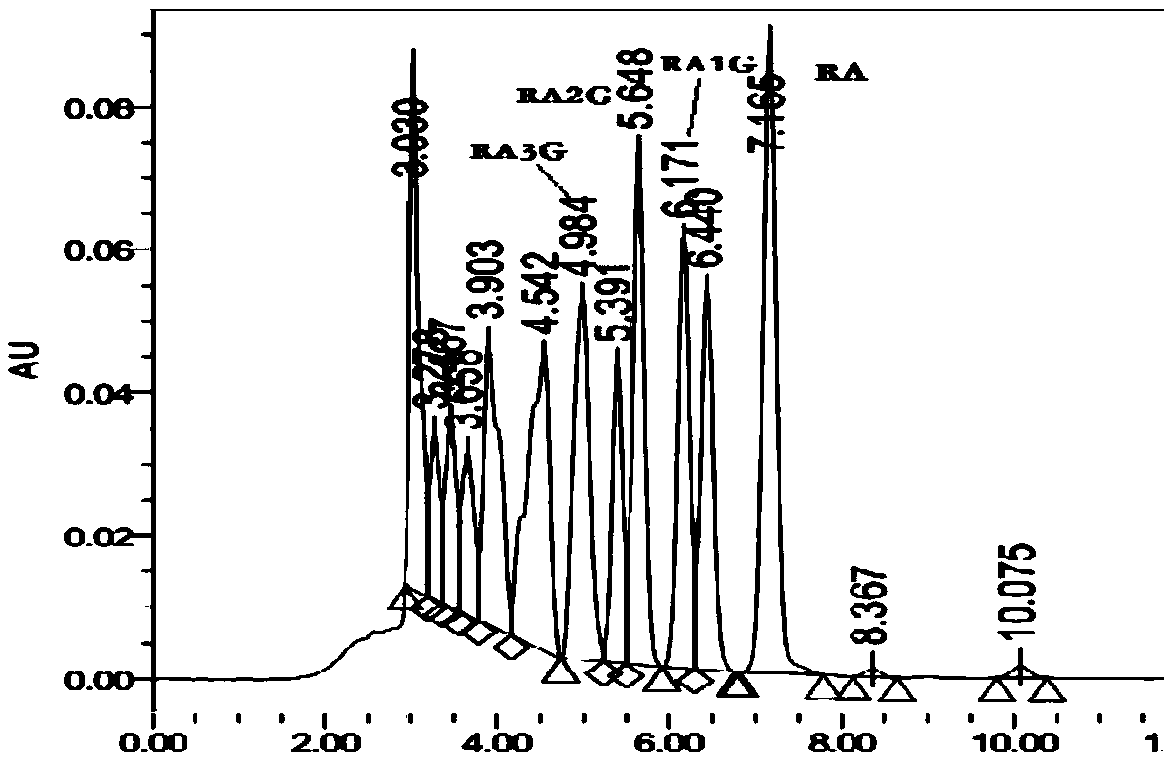

[0186] Add 100L of purified water to the reaction kettle (Wuxi Hongqi Pressure Vessel Manufacturing Co., Ltd., 500KG emulsification pot, equipment code 21701098220170001). Weigh 6Kg rebaudioside A (Haotian Pharmaceutical Co., Ltd., RA97) and 6Kg β-cyclodextrin (Qufu Tianli Pharmaceutical Excipients Co., Ltd., 170805), put them into the reaction kettle, and heat to dissolve. Cyclodextrin glycosyltransferase (purchased from Novozymes (China) Biotechnology Co., Ltd., Toruzyme 3.0L, ACN00216, 3kNU / mL) 600kNU required for the first step of enzyme modification was added. The feed liquid temperature was maintained at 60°C, the stirring speed was 30 rpm / min, and the reaction was carried out for 24 hours. Boil at...

Embodiment 2

[0194] Example 2. The first crystallization of rebaudioside A enzyme modified product

[0195] Take 100 L of the rebaudioside A enzyme-modified product (i.e. the reaction system after boiling to terminate the reaction in Example 1), and separate it with a precision filter plate with a pore size of 5-10 μm (Shenyang Great Wall Filter Paperboard Co., Ltd., product number 1001), Pass through 100L of macroporous resin (Lanxiao Technology New Material Co., Ltd., LX-28; the new resin needs to be pretreated as follows: wash with 200L 85% ethanol solution, and then wash with purified water until the effluent has no alcohol smell, flow rate 100L / h) Adsorbed for 2 hours. The resin adsorbed with the sample was first washed with 300L of pure water to remove small molecules such as glucose mixed in the product, and then eluted with 200L of 60% (v / v) ethanol, and the eluate was collected, -0.07MPa, 75°C concentrate. Concentrate to a solid content of 50%, and then dry it in a spray dryer...

Embodiment 3

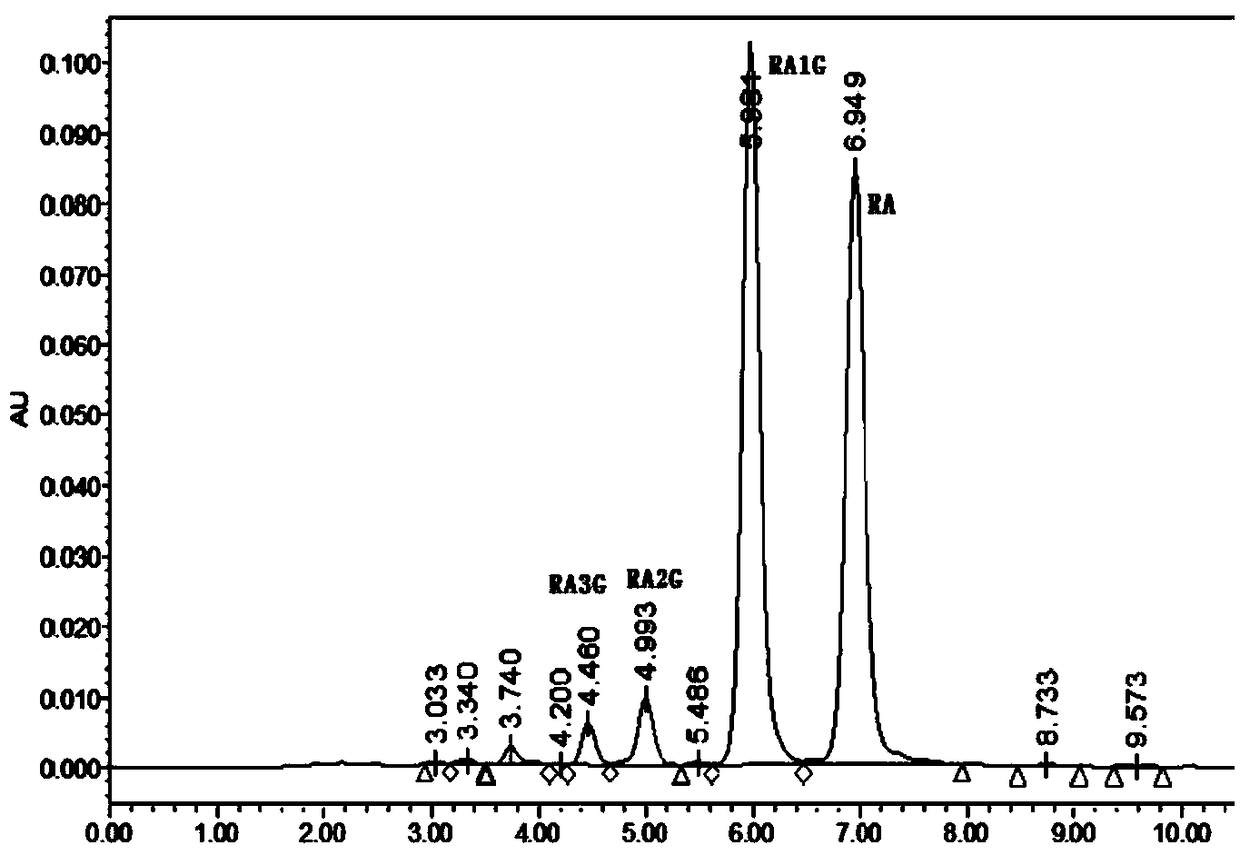

[0199] Example 3. The second crystallization of the rebaudioside A enzyme modified product

[0200] Take 7 Kg of the wet product of the first crystallization (ie the undried solid phase obtained in Example 2) and dissolve it by heating in 15 L, 65% (V / V) methanol aqueous solution. The temperature of the solution water bath was controlled at 20° C., the stirring speed was 15 rpm, and the crystallization time was 15 hours. The crystallization mixture was suction filtered with a Buchner funnel to obtain the second crystallization solid phase and liquid phase.

[0201] Gained solid phase adds ultrapure water after dissolving, detects with HPLC liquid phase (detection condition is as described in Example 1) (spectrum is as follows Figure 6 shown), the measured content of the new product rebaudioside A1G is 72.55%, and the wet weight is 5Kg (Table 3).

[0202] Add 2.5 L of purified water to the wet product of the second crystallization solid phase, dissolve it, and spray dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com