Method for improving gas barrier property of film substrate, film and application

A gas barrier and film technology, applied in transportation and packaging, flexible coverings, packaging, etc., can solve problems such as poor interface interaction, shedding, and limitations in practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

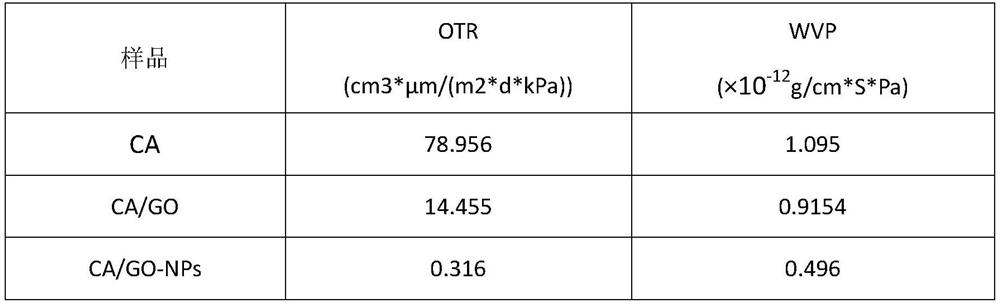

Examples

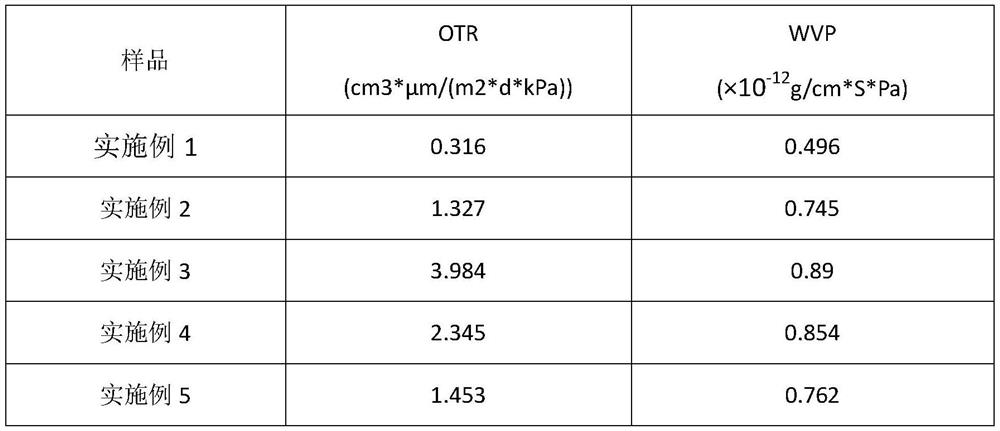

Embodiment 1

[0024] 1) Accurately weigh 12 g of cellulose acetate and 5 mL of glycerol and dissolve them in 95 mL of acetic acid solution, and stir thoroughly until they are completely dissolved. The cellulose acetate film was obtained by the casting method, and was naturally dried at room temperature to obtain a CA film with a film thickness of 100 μm.

[0025] 2) Soak 5 g of cellulose acetate film in 20 mL of a chitosan aqueous solution with a concentration of 3 wt.%, and keep it at 60° C. for 24 hours.

[0026] The film was taken out and rinsed with deionized water to remove unreacted molecular glue; then immersed in 20 mL of GO (1-2 nm thick) aqueous solution with a concentration of 1 mg / ml, and incubated at 60 °C for 24 h. The film was taken out, rinsed with deionized water to remove unfixed GO, and dried at room temperature to obtain the CA / GO film.

[0027] 3) Accurately weigh 0.18 g of cobalt acetate tetrahydrate and dissolve it in 10 mL of ethylene glycol, and slowly add 100 mg o...

Embodiment 2

[0030] 1) Accurately weigh 15 g of cellulose acetate and 5 mL of glycerol and dissolve in 95 mL of acetic acid solution, and stir well until all dissolved. The cellulose acetate film was obtained by the casting method, and was naturally dried at room temperature to obtain a CA film with a film thickness of 100 μm.

[0031] 2) Soak 4 g of cellulose acetate film in 20 mL of a polyvinyl alcohol aqueous solution with a concentration of 2 wt. %, and keep it at 90° C. for 12 hours. The film was taken out, rinsed with deionized water to remove unreacted molecular glue, and then immersed in 20 mL of an aqueous solution with a concentration of 2 mg / ml GO (1-2 nm in thickness), and incubated at 60 °C for 10 h. The film was taken out, rinsed with deionized water to remove unfixed GO, and dried at room temperature to obtain the CA / GO film.

[0032] 3) Accurately weigh 0.18g of nickel acetate tetrahydrate and dissolve it in 10mL of ethylene glycol, and slowly add 150mg of sodium borohydri...

Embodiment 3

[0035]1) Accurately weigh 6 g of cellulose acetate and 10 mL of glycerol and dissolve in 90 mL of acetic acid solution, and stir well until all dissolved. The cellulose acetate film was obtained by a casting method, and was naturally dried at room temperature to obtain a CA film with a film thickness of 90 μm.

[0036] 2) Soak 5 g of cellulose acetate film in 20 mL of a polyethyleneimine aqueous solution with a concentration of 2 wt.%, and keep it at 40° C. for 5 hours. The film was taken out, rinsed with deionized water to remove unreacted molecular glue, and then immersed in 20 mL of an aqueous solution with a concentration of 2 mg / ml GO (1-2 nm in thickness), and incubated at 50 °C for 6 h. The film was taken out, rinsed with deionized water to remove unfixed GO, and dried at room temperature to obtain the CA / GO film.

[0037] 3) Accurately weigh 0.18g of ferric acetate tetrahydrate and dissolve it in 10mL of ethylene glycol, and slowly add 300mg of sodium borohydride unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com