Concrete curing film production technology and production equipment thereof

A production process and production equipment technology, applied in the field of curing film production process and production equipment, can solve the problems of low automation, low output and production quality, and achieve high automation, low production cost and low energy consumption of production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

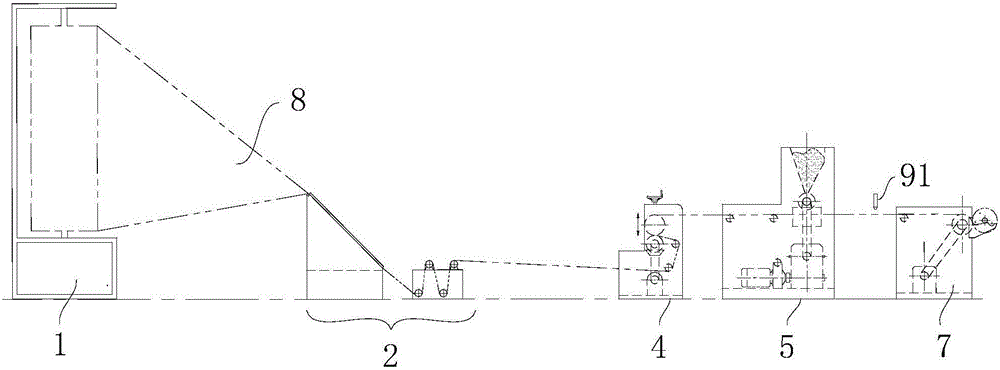

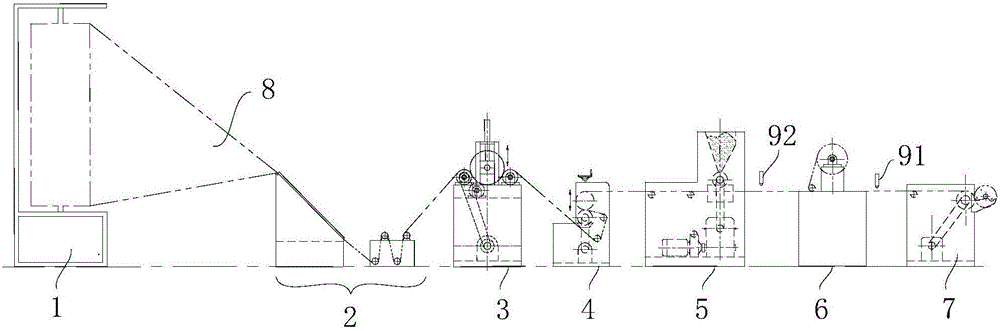

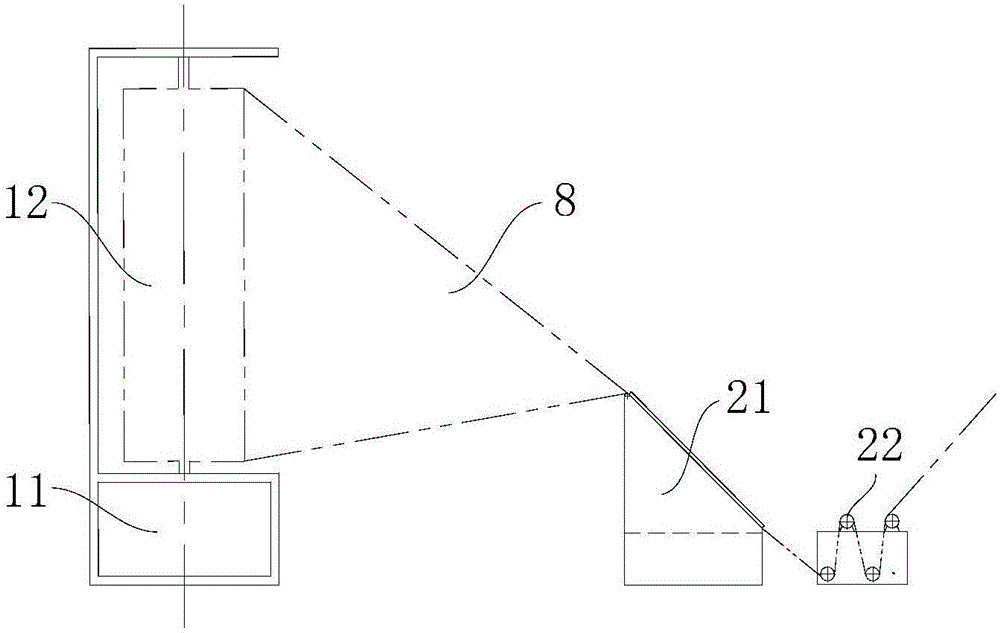

Method used

Image

Examples

Embodiment 1

[0075] Take a high-pressure polyethylene film with a thickness of 0.08mm and a width of 1m, unfold it by a film spreading device, and coat the surface with a water-soluble adhesive polyacrylic acid, and then evenly coat the super absorbent polymer powder on the surface of the treated film, and sprinkle it. The powder amount is 3 g / m2. After applying the buckle glue, it is rolled up to obtain a single-layer product with a water-absorbing and water-retaining concrete water-saving and moisturizing curing film. It is used for the maintenance of the lean concrete at the base of the highway concrete pavement without continuous watering during the maintenance cycle.

Embodiment 2

[0077] Take a high-pressure polyethylene film with a thickness of 0.08mm and a width of 2m, unfold it through a film spreading device, and coat the surface with a water-soluble adhesive polyvinyl formal, and then evenly coat the super absorbent polymer powder on the surface of the treated film On the top, the dusting amount is 6 g / m2. After the buckle glue is applied, it is rolled to obtain a single-layer product of concrete water-saving and moisturizing curing film with water-absorbing and water-retaining effects. It is used for the maintenance of the lean concrete of the highway concrete pavement. Watering.

[0078] The double-layer concrete water-saving and moisturizing curing film is based on the single-layer curing film, compounded with a perforated plastic film, which can further lock the covering layer in the curing film and improve the water-saving and moisturizing performance of the curing film. . The specific production process steps are:

[0079] 1. Unfold the plastic ...

Embodiment 3

[0089] Take a high-pressure polyethylene film with a thickness of 0.08mm and a width of 2m, unfold it through a film spreading device, perforate, and coat the surface with the water-soluble adhesive polyvinyl formal, and then evenly coat the super absorbent polymer powder on the treated On the surface of the film, the amount of dusting is 6 g / ㎡, and the adhesive glue is applied, and then the unperforated plastic film is evenly combined with the perforated plastic film with super absorbent polymer materials distributed on the surface. Finally, The double-layer concrete water-saving and moisturizing curing film is obtained by applying the buckle glue and rewinding, which is used for the maintenance of highway concrete pavement, without continuous watering during the maintenance cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com