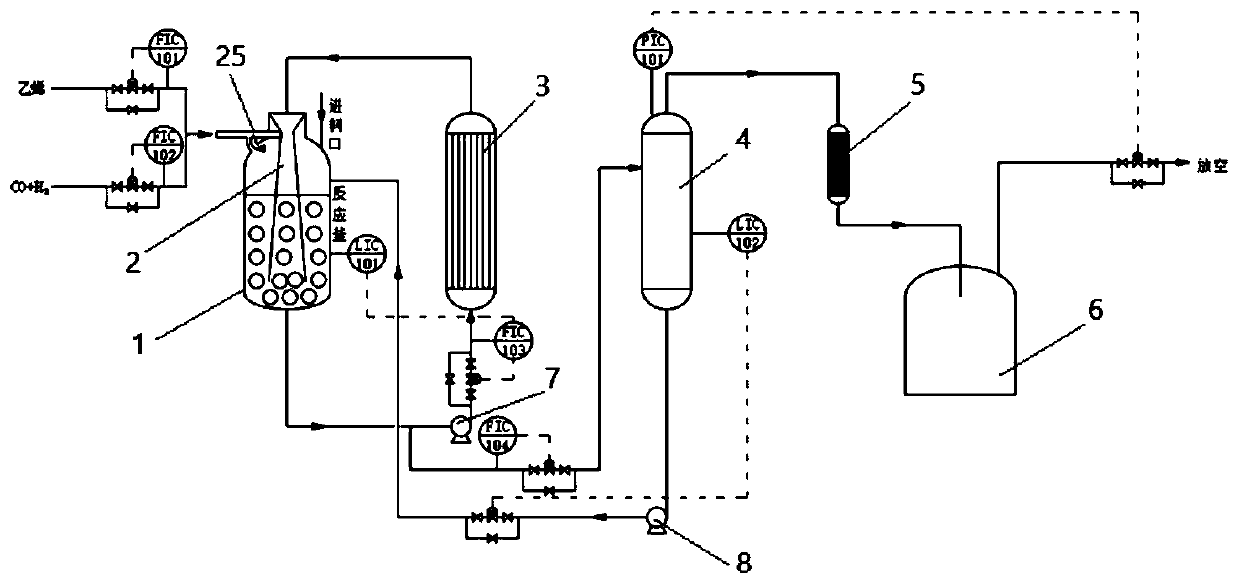

Continuous propionaldehyde production method and reaction system

A production method and chemical reaction technology, applied in the field of chemical synthesis, can solve problems such as slowing down the reaction speed, and achieve the effects of stable output, saving energy consumption of production processes, and optimizing structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

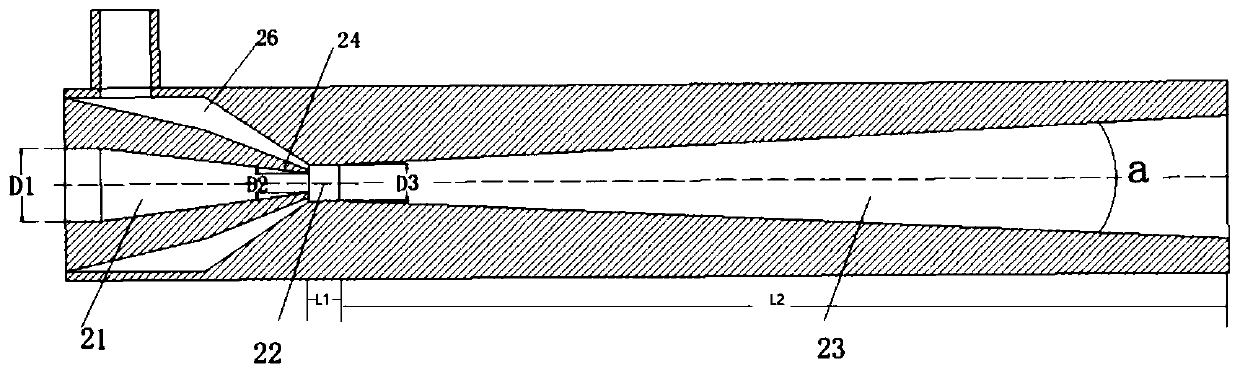

Method used

Image

Examples

Embodiment 1

[0037] In the loop reactor of 30L (reactor volume 30L), add Rh(acac)(CO) 2 and the propionaldehyde solution of TPP to the height of 50% of the liquid level of the reactor, the Rh metal content in the initial solution is 45ppm, and the molar ratio of TPP to Rh is 300. After sealing, feed ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide 1:1.05:1) into the reactor to a system pressure of 1.0 MPa, turn on the circulation pump, and replace the air in the reactor six times. Regulate the reactor pressure to 0.4MPa by injecting ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide: 1:1.05:1), raise the temperature to the reaction temperature of 85°C (heating time is about 1h), and immediately fill the mixed gas to the reaction pressure of 0.9MPa , which is recorded as the reaction start time. During the reaction process, the pressure of the reaction system is constant at 0.9MPa, and the volume ratio of ethylene, hydrogen ...

Embodiment 2

[0041] In the loop reactor of 30L (reactor volume 30L), add Rh(acac)(CO) 2 and the propionaldehyde solution of TPP to the height of 50% of the liquid level of the reactor, the Rh metal content in the initial solution is 45ppm, and the molar ratio of TPP to Rh is 300. After sealing, feed ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide 1:1.05:1) into the reactor to a system pressure of 1.0 MPa, turn on the circulation pump, and replace the air in the reactor six times. Regulate the reactor pressure to 0.4MPa by injecting ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide: 1:1.05:1), raise the temperature to the reaction temperature of 85°C (heating time is about 1h), and immediately fill the mixed gas to the reaction pressure of 0.9MPa , which is recorded as the reaction start time. During the reaction process, the pressure of the reaction system is constant at 0.9MPa, and the volume ratio of ethylene, hydrogen ...

Embodiment 3

[0045] In the loop reactor of 30L (reactor volume 30L), add Rh(acac)(CO) 2 and the propionaldehyde solution of TPP to the height of 50% of the liquid level of the reactor, the Rh metal content in the initial solution is 45ppm, and the molar ratio of TPP to Rh is 300. After sealing, feed ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide 1:1.05:1) into the reactor to a system pressure of 1.0 MPa, turn on the circulation pump, and replace the air in the reactor six times. Regulate the reactor pressure to 0.4MPa by injecting ethylene and synthesis gas (volume ratio of ethylene, hydrogen and carbon monoxide: 1:1.05:1), raise the temperature to the reaction temperature of 85°C (heating time is about 1h), and immediately fill the mixed gas to the reaction pressure of 0.9MPa , which is recorded as the reaction start time. During the reaction process, the pressure of the reaction system is constant at 0.9MPa, and the volume ratio of ethylene, hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com