Attraction type anti-ultraviolet finishing method capable of achieving magnetic lifting of bonding liquid for fabric

An anti-ultraviolet, adsorption-type technology, applied in the textile field, can solve the problems of concentration drop, fluctuation of anti-ultraviolet finishing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

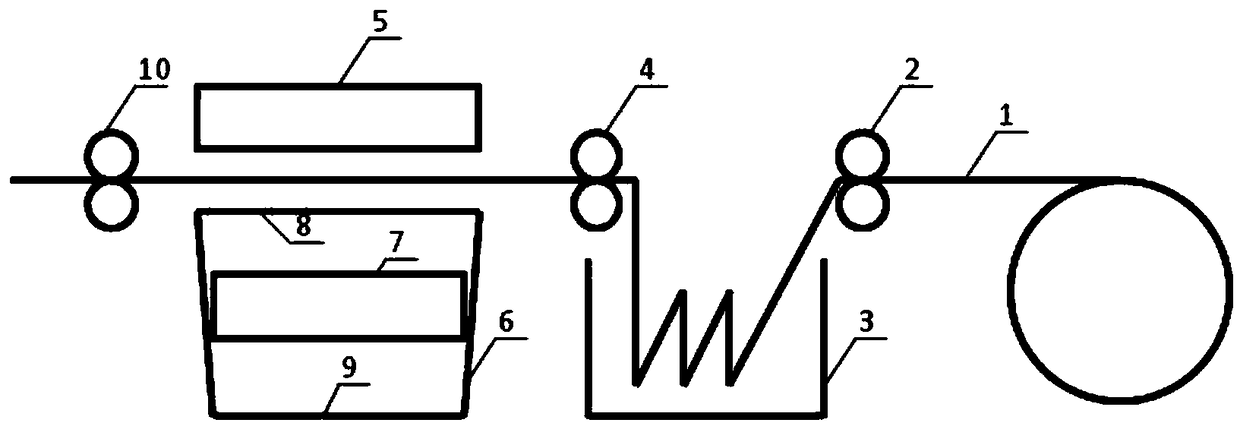

Method used

Image

Examples

Embodiment 1

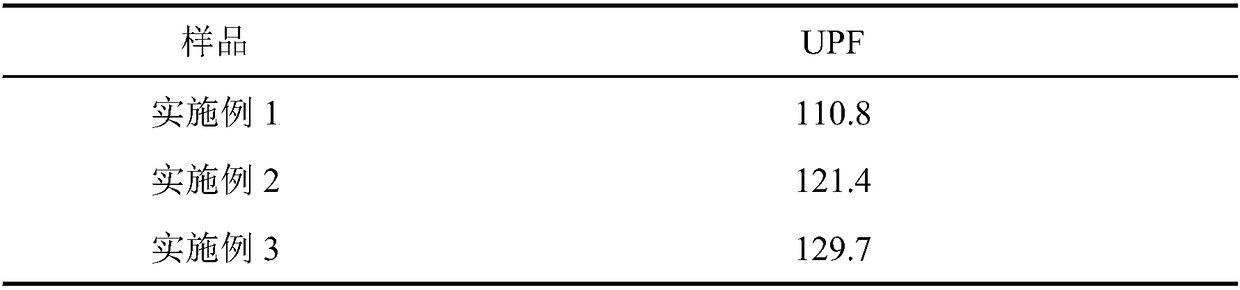

[0014] The pure cotton fabric is pulled to the cloth storage trough at 5 m / min, and then pulled to the bottom of the electromagnet by the active traction guide roller group in the anti-ultraviolet finishing process. , the magnetic force of the electromagnet is 784N, the weight of the dipping plate is 60kg, and the depth of the finishing liquid tank is 0.4 meters. The generated magnetic force lifts the iron dipping plate and holds the fabric between the electromagnet and the dipping plate. The clamping time is 0.5 seconds, the anti-ultraviolet finishing agent is nano TiO 2 -SiO 2 Composite particles, the finishing liquid is a dispersion liquid with a solid content of 0.4%, the electromagnet is powered off, stops working, the active traction guide roller in the anti-ultraviolet finishing process is powered on and starts to work, and the fabric runs for the next stage of fabric finishing. The anti-ultraviolet effect of the fabric is shown in Table 1.

Embodiment 2

[0016] The pure cotton fabric is pulled to the cloth storage trough at 25 m / min, and then pulled to the bottom of the electromagnet by the active traction guide roller group in the anti-ultraviolet finishing process. , the magnetic force of the electromagnet is 882N, the weight of the dipping plate is 65kg, and the depth of the finishing liquid tank is 0.5 meters. The generated magnetic force will lift the iron dipping plate and hold the fabric between the electromagnet and the dipping plate. The clamping time is 0.75 seconds, the anti-ultraviolet finishing agent is nano-TiO 2 -SiO 2 Composite particles, the finishing liquid is a dispersion liquid with a solid content of 0.4%, the electromagnet is powered off, stops working, the active traction guide roller in the anti-ultraviolet finishing process is powered on and starts to work, and the fabric runs for the next stage of fabric finishing. The anti-ultraviolet effect of the fabric is shown in Table 1.

Embodiment 3

[0018] The pure cotton fabric is pulled to the cloth storage trough at 45 m / min, and then pulled to the bottom of the electromagnet by the active traction guide roller group in the anti-ultraviolet finishing process. , the magnetic force of the electromagnet is 980N, the weight of the dipping plate is 70kg, and the depth of the finishing liquid tank is 0.6 meters. The generated magnetic force will lift the iron dipping plate, and hold the fabric between the electromagnet and the dipping plate. The clamping time is 1 second, the anti-ultraviolet finishing agent is nano TiO 2 -SiO 2 Composite particles, the finishing liquid is a dispersion liquid with a solid content of 0.4%, the electromagnet is powered off, stops working, the active traction guide roller in the anti-ultraviolet finishing process is powered on and starts to work, and the fabric runs for the next stage of fabric finishing. The anti-ultraviolet effect of the fabric is shown in Table 1.

[0019] Table 1 fabric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com