Sludge squeezing dehydration device

A dehydration device and sludge pressing technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of wasting resources, increasing the treatment cost of sewage treatment plants, environmental pollution, etc., and achieves low energy consumption and no environmental pollution , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

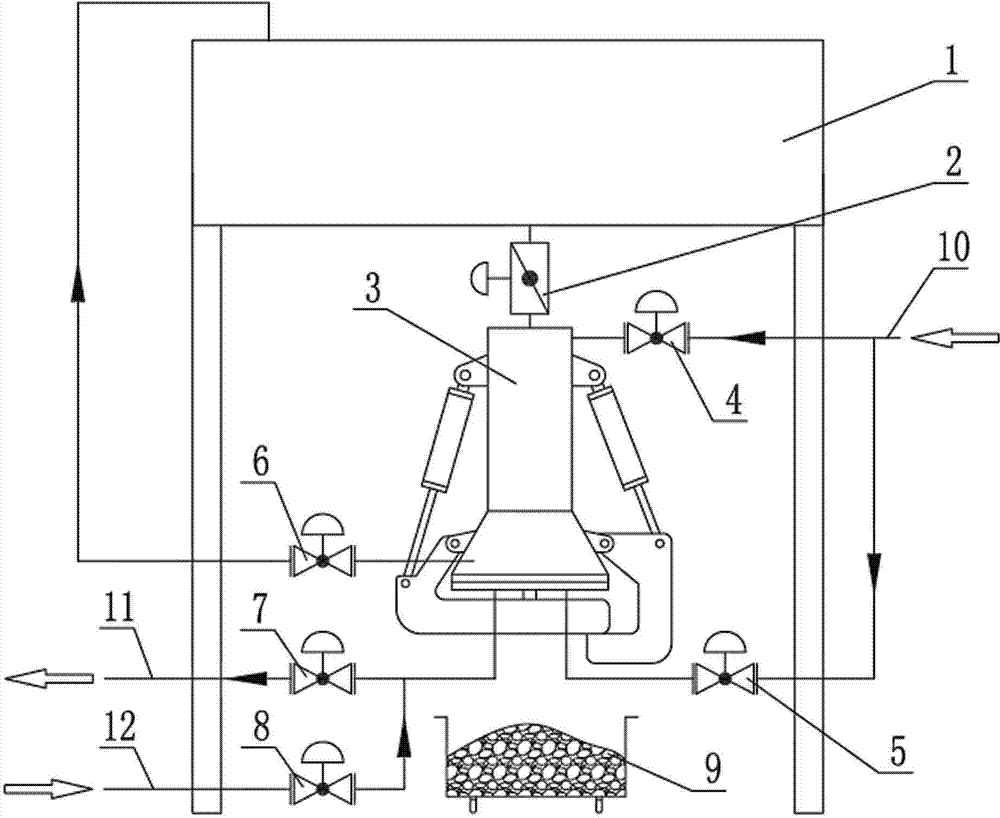

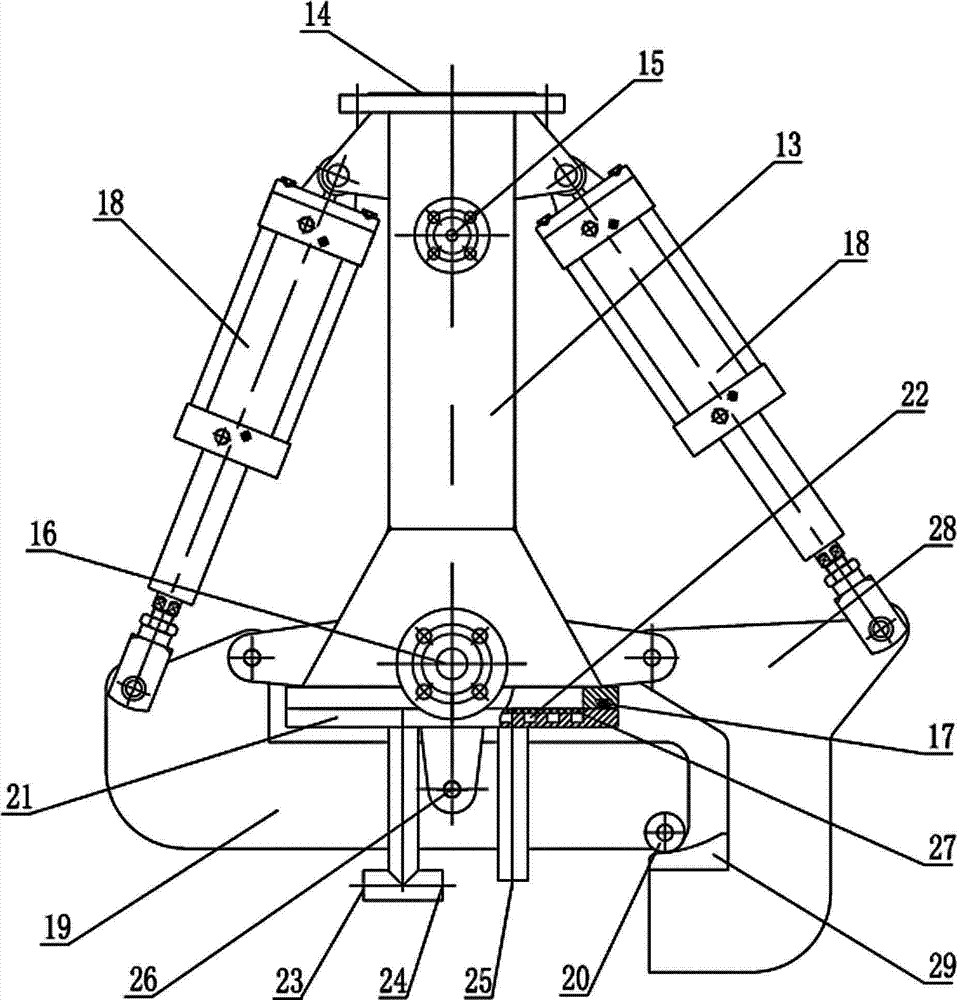

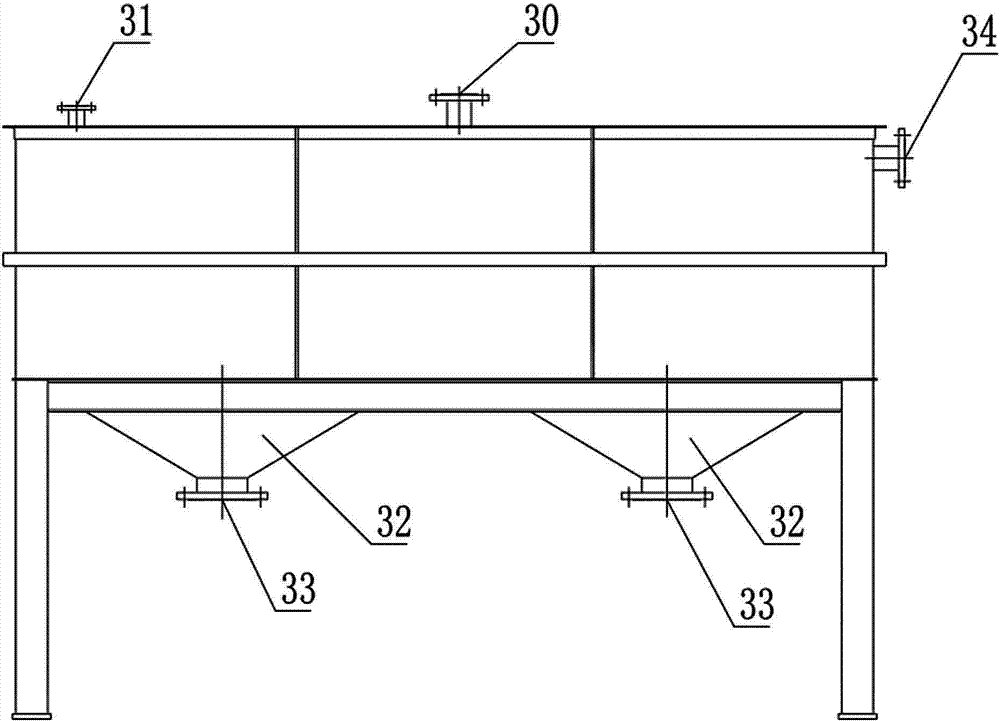

[0014] A sludge press dewatering device, such as Figure 1 to Figure 3 As shown, it is composed of sludge sedimentation, sludge pressing, back blowing slag unloading, and filter plate cleaning, including the following equipment: waste liquid storage tank 1, slag discharge valve 2, squeezer 3, air intake valve 4, back blowing Valve 5, drain valve 6, liquid outlet valve 7, backwash valve 8, slag truck 9, compressed air input pipe 10, clean liquid pipe 11, water inlet pipe 12. The squeezer 3 is the main equipment of this device, which includes a squeeze cylinder 13, a top discharge port 14, an upper air inlet 15, a pressure relief, a drain port 16, an O-ring 17, an air cylinder or a hydraulic cylinder 18, and a connecting plate 19. Roller 20, press bottom plate 21, drainage groove 22, lower liquid outlet 23, backwash port 24, back blow port 25, bottom center pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com