Processing method of collagen

A collagen and processing method technology, applied in multi-step food processing, protein food ingredients, fish protein ingredients, etc., can solve the problems of low collagen hydrolysis rate and high production cost, and achieve improved hydrolysis rate, low cost, Easy to absorb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

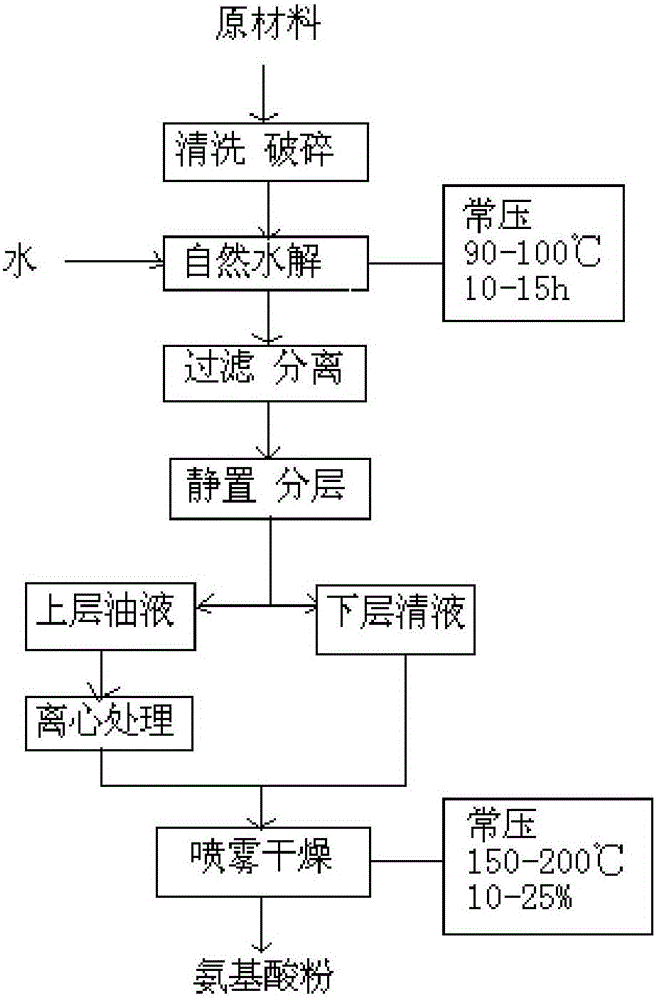

Method used

Image

Examples

Embodiment 1

[0037] 1. Wash 1500kg of beef tendon with clean water and crush it with a meat grinder with a 2.5mm orifice plate. The particle size of the broken beef tendon is 1.2cm;

[0038] 2. Mix the broken beef tendons obtained in step 1 with 2.5 tons of water and put them into a hydrolysis tank. Under normal pressure, heat up to 80°C within 35 minutes, then heat up to 95°C in 15 minutes, and then carry out natural hydrolysis treatment for 10 hours to obtain hydrolyzed broth;

[0039] 3. Filter and separate the hydrolyzed soup liquid obtained in step 2 with a 60-mesh vibrating sieve, and the filtrate is the original soup;

[0040] 4. Keep the original soup obtained in step 3 at a temperature of 80°C, let it stand for 2 hours, and then separate into layers. Centrifuge the upper oil liquid 3 times with a centrifuge to remove fat, and obtain a clear liquid, which is mixed with the lower clear liquid to obtain the original soup clear liquid ;

[0041] 5. Spray-dry the broth clear liquid o...

Embodiment 2

[0044]1. Wash 1500kg of grass carp with clean water and crush it with a meat grinder with a 3mm orifice plate. The particle size of the broken ribs is 1.5cm;

[0045] 2. Mix the broken plate obtained in step 1 with 2.0 tons of water and add it to the hydrolysis tank. Under normal pressure, heat up to 80°C within 40 minutes, then heat up to 90°C in 20 minutes, and then perform natural hydrolysis treatment for 15 hours to obtain hydrolysis Soup;

[0046] 3. Filter and separate the hydrolyzed soup liquid obtained in step 2 with a 100-mesh vibrating sieve, and the filtrate is the original soup;

[0047] 4. Keep the original soup obtained in step 3 at a temperature of 85°C, let it stand for 2 hours, and then separate into layers. Centrifuge the upper oil liquid 5 times with a centrifuge to remove fat, and obtain a clear liquid, which is mixed with the lower clear liquid to obtain the original soup clear liquid ;

[0048] 5. Spray-dry the broth clear liquid obtained in step 4 unde...

Embodiment 3

[0051] 1. Wash 1500kg of pigskin with clean water and crush it with a meat grinder with a 2mm orifice plate. The particle size of the broken beef tendons is 1.0cm;

[0052] 2. Mix the broken beef tendons obtained in step 1 with 2.5 tons of water and add them into a hydrolysis tank. Under normal pressure, heat up to 80°C within 35 minutes, then heat up to 100°C in 15 minutes, and then carry out natural hydrolysis treatment for 12 hours to obtain hydrolyzed broth;

[0053] 3. Filter and separate the hydrolyzed soup liquid obtained in step 2 with an 80-mesh vibrating sieve, and the filtrate is the original soup;

[0054] 4. Keep the original soup obtained in step 3 at a temperature of 83°C, let it stand for 2 hours, and then separate into layers. Centrifuge the upper oil liquid 3 times with a centrifuge to remove fat, and obtain a clear liquid, which is mixed with the lower clear liquid to obtain the original soup clear liquid ;

[0055] 5. Spray-dry the broth clear liquid obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com