Sulfonated carbonaceous solid acid catalyst as well as preparation method and application thereof

A solid acid catalyst and sulfonated carbonaceous technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, applications, etc., can solve the problems of reduced selectivity and yield reduction of reducing sugars such as glucose, and avoid waste gas The effect of generating acidic waste liquid, optimizing acidity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0051] Glucose and p-toluenesulfonic acid with a mass ratio of 4:1 were thoroughly mixed in a 100mL polytetrafluoroethylene-lined self-pressurized stainless steel hydrothermal kettle, and then the hydrothermal kettle was sealed and placed in an oven at 180°C Hydrothermal carbonization for 24h. The obtained black blocky solid was placed in a beaker and continued to be heat-treated in an oven at 180° C. for 24 h to remove small molecular polymers attached to the surface of the catalyst. After cooling, grind the obtained black blocky solid, wash it with absolute ethanol and deionized water higher than 80°C until the washing liquid is neutral, collect the black powder and dry it in an oven at 120°C for 6 hours to prepare sulfonated carbon quality solid acid. The densities of sulfonic acid groups and oxygen-containing groups on the surface of the catalyst were 0.15 and 2.78 mmol / g, respectively.

preparation Embodiment 2

[0053] Mix glucose and p-toluenesulfonic acid with a mass ratio of 4:2 in a 100mL polytetrafluoroethylene-lined self-pressurized stainless steel hydrothermal kettle, then seal the hydrothermal kettle and place it in an oven at 180°C Hydrothermal carbonization for 24h. The obtained black blocky solid was placed in a beaker and continued to be heat-treated in an oven at 180° C. for 24 h to remove small molecular polymers attached to the surface of the catalyst. After cooling, grind the obtained black blocky solid, wash it with absolute ethanol and deionized water higher than 80°C until the washing liquid is neutral, collect the black powder and dry it in an oven at 120°C for 6 hours to prepare sulfonated carbon quality solid acid. The densities of sulfonic acid groups and oxygen-containing groups on the surface of the catalyst were 0.40 and 1.93 mmol / g, respectively.

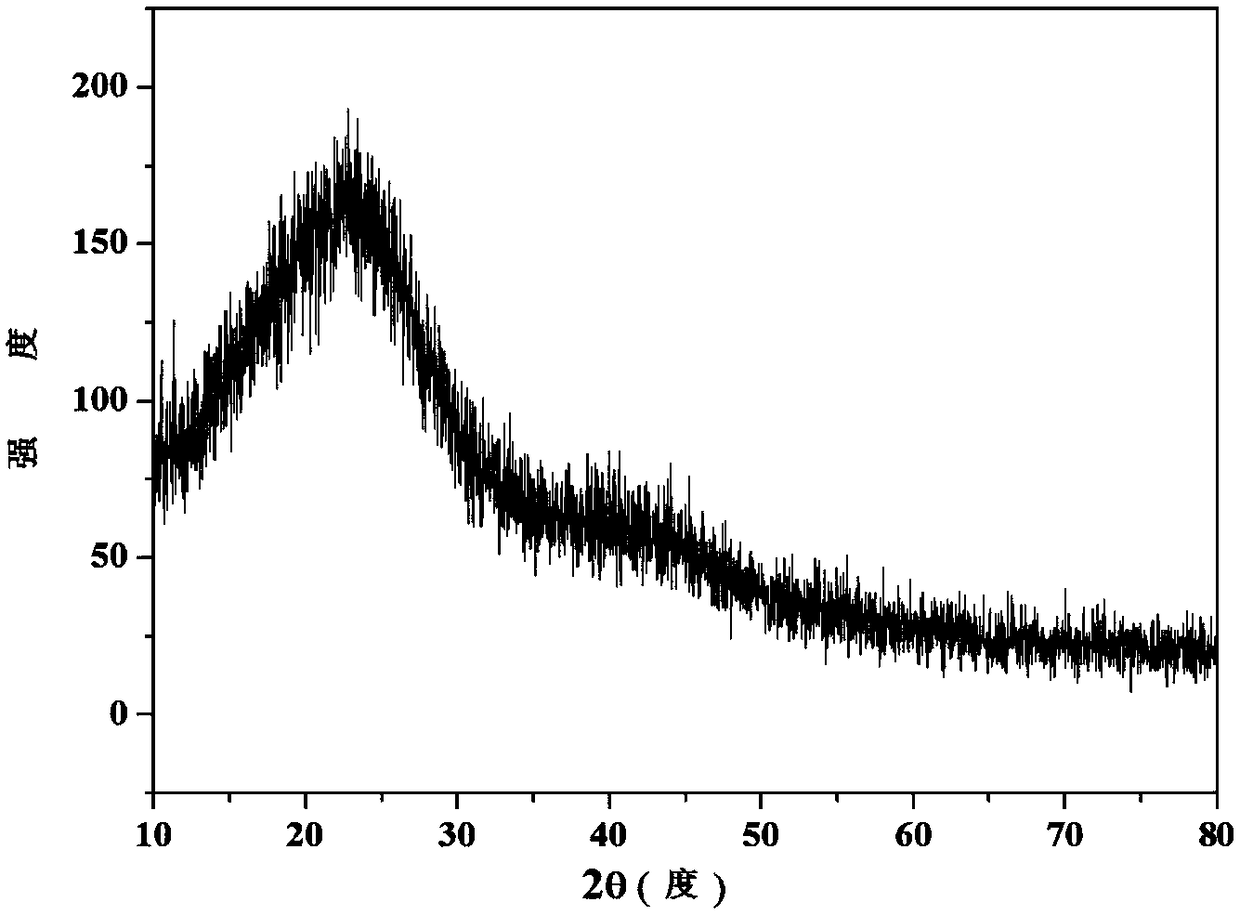

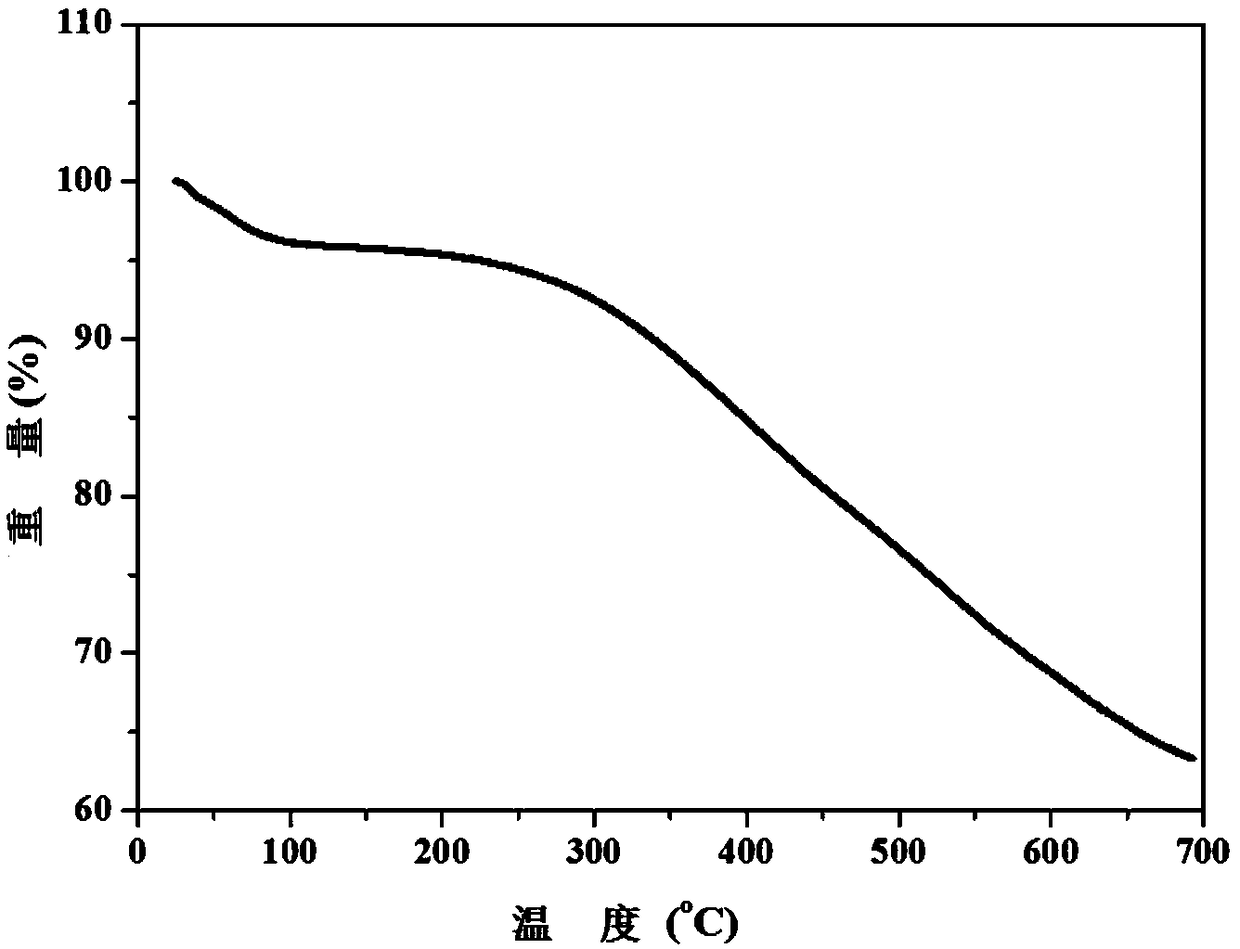

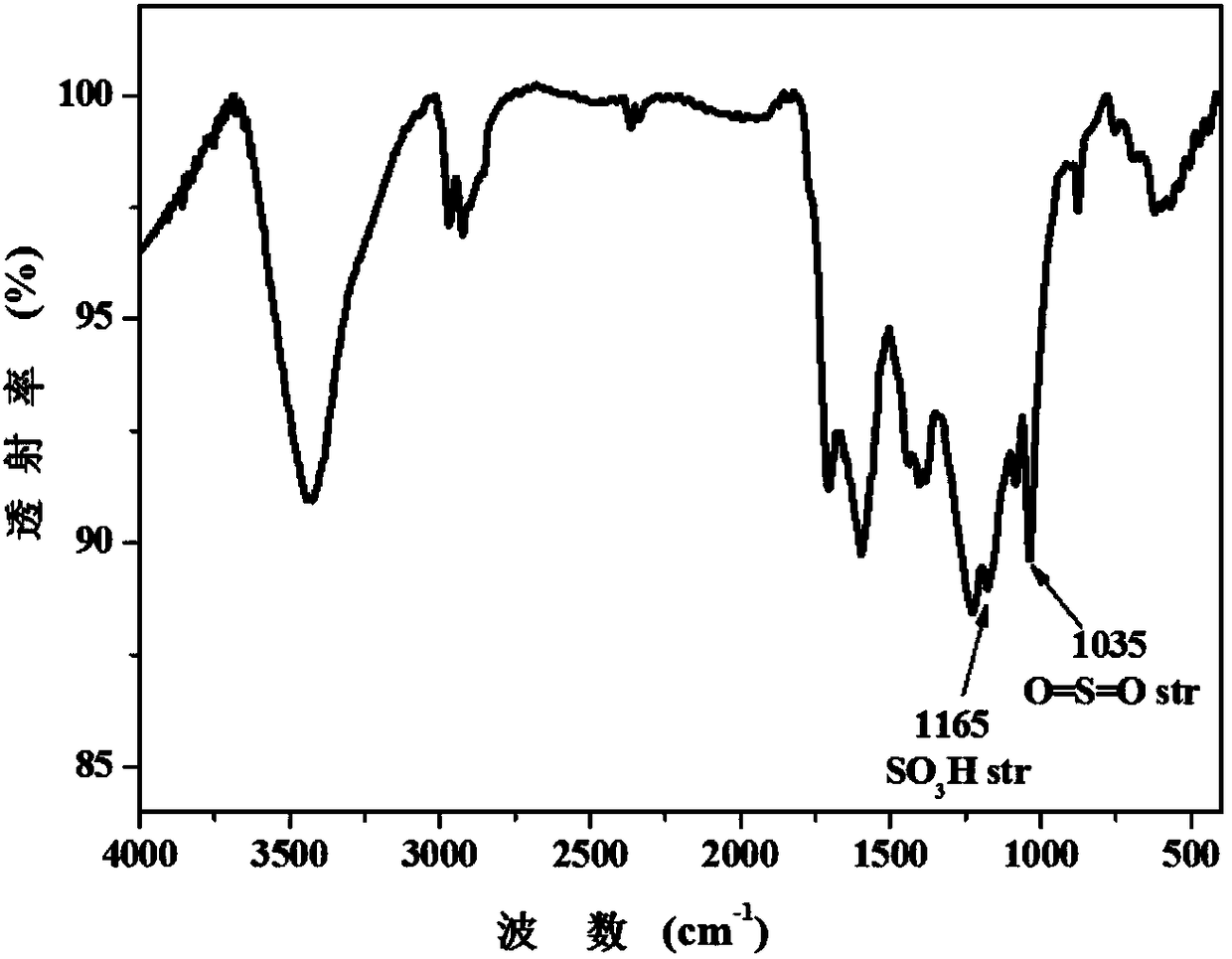

[0054] figure 1 For the XRD spectrogram of the obtained sulfonated carbonaceous solid acid catalyst; figur...

preparation Embodiment 3

[0056] Glucose, p-toluenesulfonic acid and benzyl chloride with a mass ratio of 4:4 were fully mixed in a 100mL Teflon-lined self-pressurized stainless steel hydrothermal kettle, and then the hydrothermal kettle was sealed and placed in Hydrothermal carbonization in an oven at 180°C for 24h. The obtained black blocky solid was placed in a beaker and continued to be heat-treated in an oven at 180° C. for 24 h to remove small molecular polymers attached to the surface of the catalyst. After cooling, grind the obtained black blocky solid, wash it with absolute ethanol and deionized water higher than 80°C until the washing liquid is neutral, collect the black powder and dry it in an oven at 120°C for 6 hours to prepare sulfonated carbon quality solid acid. The densities of sulfonic acid groups and oxygen-containing groups on the catalyst surface were 0.56 and 1.42 mmol / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com