Preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch

A technology of hydroxyethyl starch and molecular weight, applied in the field of medicine and chemical industry, can solve the problems of wide molecular weight distribution of hydroxyethyl starch, rapid change of starch weight-average molecular weight, difficult process control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

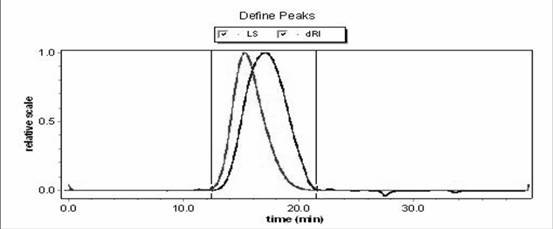

Image

Examples

Embodiment 1

[0021] Example 1 Weight average molecular weight 100 000 ~ Preparation of 150 000 narrow distribution hydroxyethyl starches.

[0022] Hydrolysis: Take 300kg of waxy cornstarch, put it into 1 400L of purified water, add 6L of 36% hydrochloric acid (W / V), stir and suspend it fully, then raise the temperature from room temperature to 90°C at a rate of 2°C / min, and keep it warm for 90 minutes. Cool down to 80°C at a rate of 1°C / min and keep warm for 20 minutes. Then cool down to 70°C at a rate of 1°C / min and keep warm. Sampling every 10 minutes, using Ping's viscometer to control the kinematic viscosity: 20.5mm 2 / s. Cool to below 60°C.

[0023] Hydroxyethylation: Cool down the hydrolyzate to 22°C, add 1000mol of 4mol / L sodium hydroxide, and mix thoroughly. Into the container, pass into nitrogen replacement 3 times, pass into ethylene oxide 78kg. Mix well, and keep stirring at 30°C for 4 hours.

[0024] Decarburization and filtration: Add 36% hydrochloric acid (W / V) to t...

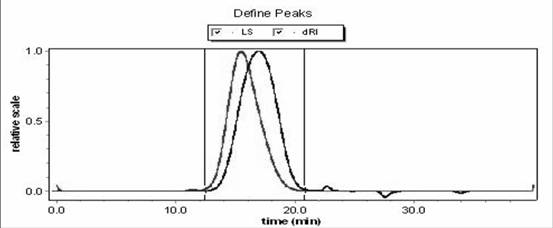

Embodiment 2

[0029] Example 2 Weight average molecular weight 100 000 ~ Preparation of 150 000 narrow distribution hydroxyethyl starches.

[0030] Hydrolysis: Take 500kg of waxy cornstarch, put it into 1400L of purified water, add 7L of 36% hydrochloric acid (W / V), stir and suspend it fully, raise the temperature from room temperature to 90℃ at a rate of 1℃ / min, and keep it warm for 80 minutes. Cool down to 80°C at a rate of 0.5°C / min and keep warm for 30 minutes. Then cool down to 70°C at a rate of 0.5°C / min and keep warm. Take samples every 10 minutes, and use Ping's viscometer to control the kinematic viscosity: 19.3mm 2 / s. Cool to below 60°C.

[0031] Hydroxyethylation: Cool down the hydrolyzate to 23°C, add 1000mol of 4mol / L sodium hydroxide, and mix well. Into the container, pass into nitrogen replacement 3 times, pass into ethylene oxide 77kg. Mix well, and keep stirring at 30°C for 4 hours.

[0032] Decarburization and filtration: Add 36% hydrochloric acid (W / V) to the h...

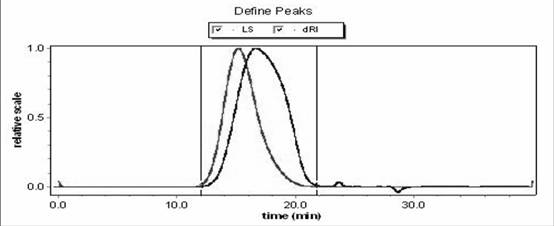

Embodiment 3

[0037] Example 3 Weight average molecular weight 150 000 ~ 300 000 Preparation of narrow distribution hydroxyethyl starch.

[0038] Hydrolysis: Take 300kg of waxy cornstarch, put it into 1400L of purified water, add 4L of 36% hydrochloric acid (W / V), stir well and suspend it, raise the temperature from room temperature to 90℃ at a rate of 1℃ / min, and keep it warm for 60 minutes. Cool down to 80°C at a rate of 1°C / min and keep warm for 30 minutes. Then cool down to 70°C at a rate of 1°C / min and keep warm. Sampling every 10 minutes, using Ping's viscometer to control the kinematic viscosity: 27.3mm 2 / s. After passing, cool to below 60°C.

[0039]Hydroxyethylation: Cool down the hydrolyzate to 24°C, add 1 000 mol of 4mol / L sodium hydroxide, and mix well. In the container, feed nitrogen replacement 3 times, and feed 83 kg of ethylene oxide. Mix well, and keep stirring at 30°C for 4 hours.

[0040] Decarburization and filtration: Add 36% hydrochloric acid (W / V) to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com