Preparation method of adsorbent containing SnO2/Sb2O5, product and application of adsorbent

An adsorbent, H2O2 technology, applied in chemical instruments and methods, other chemical processes, nuclear engineering and other directions, can solve the problems of large-scale preparation of unfavorable materials, difficult to obtain, etc., and achieve the effect of good adsorption selectivity and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

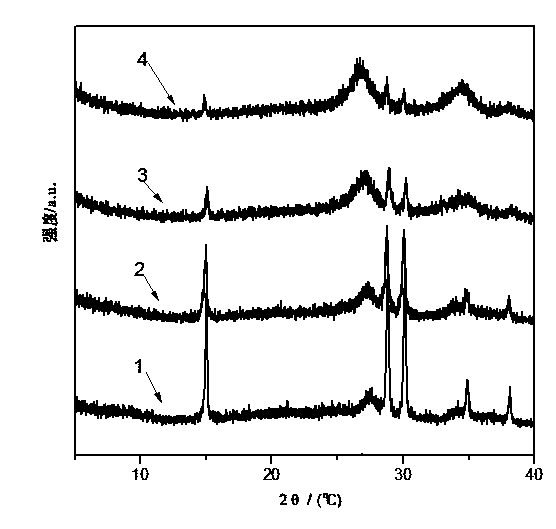

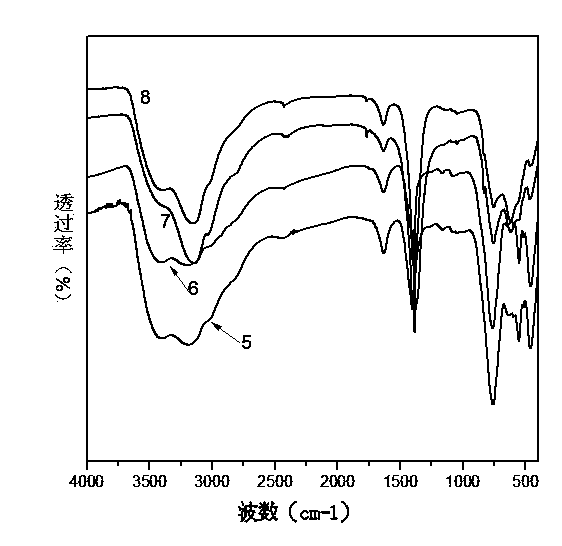

[0038] Step 1: 4.56g of anhydrous SbCl 3 and 1.4g of SnCl 4 ·5H 2 O was dissolved in 20mL of anhydrous ethylene glycol, and then added to a 250mL three-necked flask equipped with electromagnetic stirring, oil bath heating, and a water-cooled condensing reflux tube. Heat in an oil bath to make the solution reach the set reaction temperature of 60°C. The molar ratio of Sn / Sb in the reaction system is 0.2.

[0039] Step 2: Keeping the temperature at 60°C, slowly add 20mL of 30wt% H 2 o 2 solution and 8 mL of concentrated hydrochloric acid with a concentration of 37%. A slight bumping phenomenon occurred at the beginning of the dropwise addition, but disappeared as the dropwise addition progressed. During the dropwise addition of the mixed solution, the system generates a colorless transparent colloidal solution.

[0040] Step 3: After the dropwise addition, set the reaction temperature to 80°C, turn on the ultraviolet lamp (254nm) placed outside the flask, and turn off the...

Embodiment 2

[0044] With reference to Example 1 in this embodiment, the SnCl in step 1 4 ·5H 2 The addition amount of O was adjusted to 5.6g, and the molar ratio of Sn / Sb in the reaction system was 0.8. Other operations are the same as in Comparative Example 1, and the material preparation is carried out.

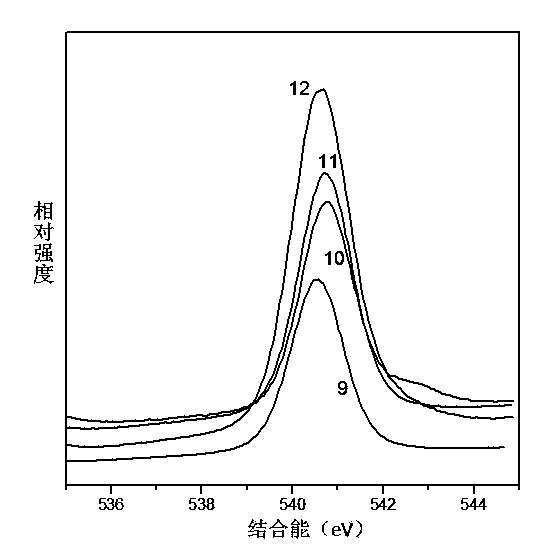

[0045]The experimental results show that the obtained samples are detected by XPS, and the oxidation rates of Sb(III)→Sb(V) are all 100%. The Co ion adsorption performance of the material is measured. When the initial concentration of Co is 10mg / L, the distribution coefficient K of the material to Co is d-Co It is 1354362mg / L.

Embodiment 3

[0047] With reference to Example 1 in this embodiment, the SnCl in step 1 4 ·5H 2 The amount of O added was adjusted to 14.2 g, the molar ratio of Sn / Sb in the reaction system was 2.0, and the other operations were the same as in Comparative Example 1 for material preparation.

[0048] The experimental results show that the obtained samples are detected by XPS, and the oxidation rates of Sb(III)→Sb(V) are all 100%. The Co ion adsorption performance of the material is measured. When the initial concentration of Co is 10mg / L, the distribution coefficient K of the material to Co is d-Co It is 2766503mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| partition coefficient | aaaaa | aaaaa |

| partition coefficient | aaaaa | aaaaa |

| partition coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com